Abstract

The sintering process of compacts of nanostructured gadolinia-doped ceria was investigated by dilatometry and by construction of the master sintering curve. Corrections for the thermal expansion of the experimental setup and mass loss were proposed. The aim of this work was to investigate the sintering evolution of compacts constituted by a powder material with very high specific surface area and to verify the effectiveness of the proposed corrections for generating reliable density data. Validation of the obtained results was accomplished by comparison of corrected data with density values obtained for conventionally sintered compacts. Dilatometry experiments were carried out for 3, 6, 10 and 12 °C min−1 heating rates. Good convergence of relative density curves calculated from corrected shrinkage data was obtained. The determined value of the activation energy for sintering of nanostructured gadolinia-doped ceria compacts is 576 kJ mol−1.

Similar content being viewed by others

References

German RM. Sintering: from empirical observations to scientific principles. Oxford: Elsevier; 2014.

Kang SL. Densification, grain growth, and microstructure. Oxford: Elsevier; 2005.

Fang ZZ. Sintering of advanced materials. Cambridge: Woodhead; 2010.

He Z, Yuan H, Glasscock JA, Chatzichristodoulou C, Phair JW, Kaiser A, Ramousse S. Densification and grain growth during early-stage sintering of Ce0.9Gd0.1O1.95-δ in a reducing atmosphere. Acta Mater. 2010;58:3860–6.

Pouchly V, Maca K, Shen Z. Two-stage master sintering curve applied to two-step sintering of oxide ceramics. J Eur Ceram Soc. 2013;33:2275–83.

Muccillo R, Muccillo ENS. An experimental setup for shrinkage evaluation during electric field-assisted flash sintering: application to yttria-stabilized zirconia. J Eur Ceram Soc. 2013;33:515–20.

Su H, Johnson DL. Master sintering curve: a practical approach to sintering. J Am Ceram Soc. 1996;79:3211–7.

American Society for Testing Materials, ASTM E228-11. Standard test method for linear thermal expansion of solid materials with a push-rod dilatometer. West Conshohocken: ASTM; 2011.

Mazaheri M, Simchi A, Dourandish M, Golestani-Fard F. Master sintering curves of a nanoscale 3Y-TZP powder compacts. Ceram Int. 2009;35:547–54.

Maca K, Pouchly V, Boccaccini AR. Sintering densification curve—a practical approach for its construction from dilatometric shrinkage data. Sci Sinter. 2008;40:117–22.

Panigrahi BB. Evaluation of dimensional changes from as received dilatometric sintering plot. J Mater Sci Technol. 2007;23:103–7.

Blaine DC, Park S, German RM. Linearization of master sintering curve. J Am Ceram Soc. 2009;92:1403–7.

Mohapatra G, Sommer F, Mittmeijer EJ. A temperature correction procedure for temperature in homogeneity in dilatometer specimens. Termochim Acta. 2007;453:57–66.

Jud E, Huwiler CB, Gauckler LJ. Sintering analysis of undoped and cobalt oxide doped ceria solid solutions. J Am Ceram Soc. 2005;88:3013–9.

De Florio DZ, Esposito V, Traversa E, Muccillo R, Fonseca FC. Master sintering curve for Gd-doped CeO2 solid electrolytes. J Therm Anal Calorim. 2009;97:143–7.

Guan L, Le S, He S, Zhu X, Liu T, Sun K. Densification behavior and space charge blocking effect of Bi2O3 and Gd2O3 co-doped CeO2 as electrolyte for solid oxide fuel cells. Electrochim Acta. 2015;161:129–36.

Ravat B, Oudot B, Perron A, Lalire F, Delaunay F. Phase transformations in PuGa 1 at% alloy: study of whole reversion process following martensitic transformation. J Alloys Compd. 2013;580:298–309.

Hillman SH, German RM. Constant heating rate analysis of simultaneous sintering mechanisms in alumina. J Mater Sci. 1992;27:2641–8.

Valentich J. Calibration of tube type dilatometers. J Therm Anal Calorim. 1977;11:387–403.

Larson AC, von Deele RB. General structure analysis system (GSAS). Los Alamos National Laboratory Report LAUR 86-748; 1994.

Ewsuk KG, Ellerby DT, DiAntonio CB. Analysis of nanocrystalline and microcrystalline ZnO sintering using master sintering curves. J Am Ceram Soc. 2006;89:2003–9.

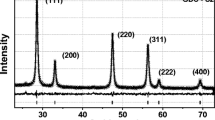

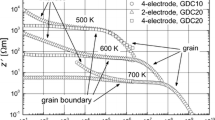

Reis SL, Souza ECC, Muccillo ENS. Solid solution formation, densification and ionic conductivity of Gd- and Sm-doped ceria. Solid State Ionics. 2011;192:172–5.

Acknowledgements

The authors gratefully acknowledge FAPESP (Proc. nº. 2013/07296-2), CNPq (Proc. no. 304073/2014-8) and CNEN for financial supports, and to S. G. M. Carvalho and R. L. Grosso for mass spectrometry analyses. One of the authors (R.M.B.) acknowledges CAPES for the scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Batista, R.M., Muccillo, E.N.S. Dilatometry analysis of the sintering process of nanostructured gadolinia-doped ceria. J Therm Anal Calorim 126, 1007–1013 (2016). https://doi.org/10.1007/s10973-016-5674-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5674-5