Abstract

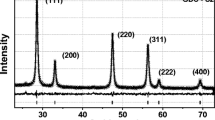

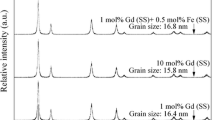

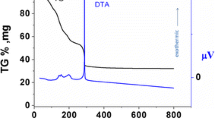

The sintering behavior of gadolinia-doped ceria powders was studied by the master sintering curve (MSC). Dilatometric analyses of powders produced by a soft chemical method were performed to provide the experimental data set for the construction of the MSC. The assumed model provided good fittings of the MSC and the activation energy for the sintering of Ce1−x Gd x O3−δ, with x = 0, 0.05, 0.1, and 0.2 were found to be in the 218–325 KJ/mol range, depending on the dopant content. The results supported that both the nanometric size of the particles and the difference in ionic radii between Gd3+ and Ce4+ affects the sintering of Gd-doped CeO2.

Similar content being viewed by others

References

Singhal SC, Kendall K. High temperature solid oxide fuel cells—fundamentals, design and applications. New York: Elsevier; 2004. p. 1.

Pérez-Coll D, Núñez P, Frade JR. Improved conductivity of Ce1−x Sm x O2-ceramics with submicrometer grain sizes. J Electrochem Soc. 2006;153:A478–83.

Esposito V, Traversa E. Design of electroceramics for solid oxides fuel cell applications: playing with ceria. J Am Ceram Soc. 2008;91:1037–51.

Su H, Johnson DL. Master sintering curve: a practical approach to sintering. J Am Ceram Soc. 1996;79:3211–7.

Kutty TRG, Khan KB, Hegde PV, Banerjee J, Sengupta AK, Majumdar S, et al. Development of a master sintering curve for ThO2. J Nucl Mater. 2004;327:211–9.

Kinemuchi Y, Watari K. Dilatometer analysis of sintering behavior of nano CeO2 particles. J Eur Ceram Soc. 2008;28:2019–24.

Gil V, Moure C, Durán P, Tartaj J. Low-temperature densification and grain growth of Bi2O3-doped-ceria gadolinia ceramics. Solid State Ionics. 2007;178:359–65.

Li J-G, Ikegami T, Mori T. Low-temperature processing of dense samarium-doped CeO2 ceramics: sintering and grain growth behaviors. Acta Mater. 2004;52:2221–8.

Yan R, Chu F, Ma Q, Liu X, Meng G. Sintering kinetics of samarium doped ceria with addition of cobalt oxide. Mater Lett. 2006;60:3605–9.

Acknowledgements

Authors are thankful to CNPq, FAPESP, and MIUR for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Florio, D.Z., Esposito, V., Traversa, E. et al. Master sintering curve for Gd-doped CeO2 solid electrolytes. J Therm Anal Calorim 97, 143–147 (2009). https://doi.org/10.1007/s10973-009-0238-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0238-6