Abstract

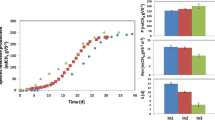

In olive-oil-producing countries, large amounts of waste material are generated as by-product for which there is no ready use and in some cases may have a negative value because of the cost of disposal. Most of these countries depend on fossil fuels for their energy uses, and olive mill wastes can be used to supplement such energy sources using thermochemical conversion processes such as pyrolysis. However, efficient operation of thermochemical conversion systems requires a thorough understanding of the influence of the composition and thermal properties of these by-products on their behaviour during the conversion process. In this study, the thermal behaviour of two olive mill wastes samples (olive mill solid waste: OMSW, and concentrated olive mill wastewater: COMWW) was examined at different heating rates ranging from 5 to 50 °C min−1 in inert atmosphere using the technique of thermogravimetric analysis. As the increment of heating rates, the variations of characteristic parameters from the TG-DTG curves were determined. The initial temperature of degradation is higher in OMSW, which present a high amount of cellulose in comparison with COMWW. Three methods were used for the determination of kinetic reaction parameters: Friedman, Ozawa–Flynn–Wall and Vyazovkin methods. The results showed that apparent activation energy obtained for the decomposition of hemicelluloses and cellulose derived from OMSW was given as 150–176 and 210.5–235.7 kJ mol−1, while for COMWW, the values were 133–145 and 255–275 kJ mol−1, respectively.

Similar content being viewed by others

References

Aktas ES, Imre S, Ersoy L. Characterization and lime treatment of olive mill wastewater. Water Res. 2001;35(9):2336–40.

Miranda T, Esteban A, Rojas S, Montero I, Ruiz A. Combustion analysis of different olive residues. Int J Mol Sci. 2008;9(4):512–25.

Achak M, Hafidi A, Ouazzani N, Sayadi S, Mandi L. Low cost biosorbent “banana peel” for the removal of phenolic compounds from olive mill wastewater: kinetic and equilibrium studies. J Hazard Mater. 2009;166(1):117–25.

Caputo AC, Scacchia F, Pelagagge PM. Disposal of by-products in olive oil industry: waste-to-energy solutions. Appl Therm Eng. 2003;23(2):197–214.

Pütün AE, Uzun BB, Apaydin E, Pütün E. Bio-oil from olive oil industry wastes: pyrolysis of olive residue under different conditions. Fuel Process Technol. 2005;87(1):25–32.

Şensöz S, Demiral İ, Gerçel HF. Olive bagasse (Olea europea L.) pyrolysis. Bioresour Technol. 2006;97(3):429–36.

André RN, Pinto F, Franco C, Dias M, Gulyurtlu I, Matos M, et al. Fluidised bed co-gasification of coal and olive oil industry wastes. Fuel. 2005;84(12):1635–44.

Jauhiainen J, Martin-Gullon I, Conesa JA, Font R. Emissions from pyrolysis and combustion of olive oil solid waste. J Anal Appl Pyrolysis. 2005;74(1):512–7.

Jauhiainen J, Conesa JA, Font R, Martın-Gullón I. Kinetics of the pyrolysis and combustion of olive oil solid waste. J Anal Appl Pyrolysis. 2004;72(1):9–15.

Uzun BB, Pütün AE, Pütün E. Composition of products obtained via fast pyrolysis of olive-oil residue: effect of pyrolysis temperature. J Anal Appl Pyrolysis. 2007;79(1):147–53.

Encinar J, Gonzalez J, Martínez G, Roman S. Catalytic pyrolysis of exhausted olive oil waste. J Anal Appl Pyrolysis. 2009;85(1):197–203.

Taralas G, Kontominas MG. Pyrolysis of solid residues commencing from the olive oil food industry for potential hydrogen production. J Anal Appl Pyrolysis. 2006;76(1):109–16.

Aboulkas A, Makayssi T, Bilali L, El harfi K, Nadifiyine M, Benchanaa M. Co-pyrolysis of oil shale and plastics: Influence of pyrolysis parameters on the product yields. Fuel Process Technol. 2012;96:209–13.

Aboulkas A, Makayssi T, Bilali L, Elharfi K, Nadifiyine M, Benchanaa M. Co-pyrolysis of oil shale and high density polyethylene: Structural characterization of the oil. Fuel Process Technol. 2012;96:203–8.

Yaman S. Pyrolysis of biomass to produce fuels and chemical feedstocks. Energy Convers Manag. 2004;45(5):651–71.

Aguilar MJ. Olive oil mill wastewater for soil nitrogen and carbon conservation. J Environ Manage. 2009;90(8):2845–8.

Galiatsatou P, Metaxas M, Kasselouri-Rigopoulou V. Adsorption of zinc by activated carbons prepared from solvent extracted olive pulp. J Hazard Mater. 2002;91(1):187–203.

Ounas A, Aboulkas A, Bacaoui A, Yaacoubi A. Pyrolysis of olive residue and sugar cane bagasse: non-isothermal thermogravimetric kinetic analysis. Bioresour Technol. 2011;102(24):11234–8.

Barneto AG, Carmona JA, Alfonso JEM, Blanco JD. Kinetic models based in biomass components for the combustion and pyrolysis of sewage sludge and its compost. J Anal Appl Pyrolysis. 2009;86(1):108–14.

Font R, Conesa J, Moltó J, Munoz M. Kinetics of pyrolysis and combustion of pine needles and cones. J Anal Appl Pyrolysis. 2009;85(1):276–86.

Jeguirim M, Trouvé G. Pyrolysis characteristics and kinetics of Arundo donax using thermogravimetric analysis. Bioresour Technol. 2009;100(17):4026–31.

Aboulkas A, El Harfi K. Effects of acid treatments on Moroccan Tarfaya oil shale and pyrolysis of oil shale and their kerogen. J Fuel Chem Technol. 2009;37(6):659–67.

Aboulkas A. Kinetic and mechanism of Tarfaya (Morocco) oil shale and LDPE mixture pyrolysis. J Mater Process Technol. 2008;206(1):16–24.

Aboulkas A, El harfi K, El bouadili A, Ben Chanda M, Mokhlisse A. Pyrolysis kinetics of polypropylene: Morocco oil shale and their mixture. J Therm Anal Calorim. 2007;89(1):203–9.

Aboulkas A, El Harfi K. Co-pyrolysis of olive residue with poly (vinyl chloride) using thermogravimetric analysis. J Therm Anal Calorim. 2009;95(3):1007–13.

Kök M, Iscan AG. Oil shale kinetics by differential methods. J Therm Anal Calorim. 2007;88(3):657–61.

Kök M, Pamir M. Non-isothermal pyrolysis and kinetics of oil shales. J Therm Anal Calorim. 1999;56(2):953–8.

Ozgur E, Miller SF, Miller BG, Kok MV. Thermal analysis of co-firing of oil shale and biomass fuels. Oil Shale. 2012;29(2):190–201.

Kok MV, Özgür E. Thermal analysis and kinetics of biomass samples. Fuel Process Technol. 2013;106:739–43.

Janković B. On-line pyrolysis kinetics of swine manure solid samples collected from rearing farm. J Therm Anal Calorim. 2015;. doi:10.1007/s10973-015-4717-7.

Zhu X, Chen Z, Xiao B, Hu Z, Hu M, Liu C, Zhang Q. Co-pyrolysis behaviors and kinetics of sewage sludge and pine sawdust blends under non-isothermal conditions. J Therm Anal Calorim. 2014;119(3):2269–79.

Garcıa-Perez M, Chaala A, Yang J, Roy C. Co-pyrolysis of sugarcane bagasse with petroleum residue, Part I: thermogravimetric analysis. Fuel. 2001;80(9):1245–58.

Aboulkas A, El BA. Thermal degradation behaviors of polyethylene and polypropylene. Part I: pyrolysis kinetics and mechanisms. Energy Convers Manag. 2010;51(7):1363–9.

Mu L, Chen J, Yin H, Song X, Li A, Chi X. Pyrolysis behaviors and kinetics of refining and chemicals wastewater, lignite and their blends through TGA. Bioresour Technol. 2015.

Vyazovkin S. Model-free kinetics. J Therm Anal Calorim. 2006;83(1):45–51.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. Journal of Polymer Science Part C: Polymer Symposia; Wiley Online Library; 1964.

Flynn JH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci, Part C: Polym Lett. 1966;4(5):323–8.

Flynn JH, Wall LA. General treatment of the thermogravimetry of polymers. J Res Nat Bur Stand. 1966;70(6):487–523.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38(11):1881–6.

Ozawa T. Kinetic analysis of derivative curves in thermal analysis. J Therm Anal Calorim. 1970;2(3):301–24.

Doyle C. Kinetic analysis of thermogravimetric data. J Appl Polym Sci. 1961;5(15):285–92.

Vyazovkin S, Lesnikovick A. Transformation of “degree of conversion against temperature” into “degree of conversion against time” kinetic data. Russ J Phys Chem. 1988;62(1525):e7.

Vyazovkin S, Sbirrazzuoli N. Confidence intervals for the activation energy estimated by few experiments. Anal Chim Acta. 1997;355(2):175–80.

Vitolo S, Petarca L, Bresci B. Treatment of olive oil industry wastes. Bioresour Technol. 1999;67(2):129–37.

Wang S, Wang K, Liu Q, Gu Y, Luo Z, Cen K, et al. Comparison of the pyrolysis behavior of lignins from different tree species. Biotechnol Adv. 2009;27(5):562–7.

Chouchene A, Jeguirim M, Favre-Reguillon A, Trouvé G, Le Buzit G, Khiari B, et al. Energetic valorisation of olive mill wastewater impregnated on low cost absorbent: sawdust versus olive solid waste. Energy. 2012;39(1):74–81.

Reed TB. Biomass gasification: principles and technology. Monograph. (1981).

Nassar MM. Kinetic studies on thermal degradation of nonwood plants. Wood Fiber Sci. 1985;17(2):266–73.

Gai C, Dong Y, Zhang T. The kinetic analysis of the pyrolysis of agricultural residue under non-isothermal conditions. Bioresour Technol. 2013;127:298–305.

Huang M, Li X. Thermal degradation of cellulose and cellulose esters. J Appl Polym Sci. 1998;68(2):293–304.

Maddi B, Viamajala S, Varanasi S. Comparative study of pyrolysis of algal biomass from natural lake blooms with lignocellulosic biomass. Bioresour Technol. 2011;102(23):11018–26.

Niaounakis M, Halvadakis CP. Olive processing waste management: literature review and patent survey. 2nd ed. Amsterdam: Elsevier; 2006.

Paredes C, Cegarra J, Roig A, Sánchez-Monedero M, Bernal M. Characterization of olive mill wastewater (alpechin) and its sludge for agricultural purposes. Bioresour Technol. 1999;67(2):111–5.

Haykiri-Acma H, Yaman S, Kucukbayrak S. Effect of heating rate on the pyrolysis yields of rapeseed. Renew Energy. 2006;31(6):803–10.

Di Blasi C. Modeling chemical and physical processes of wood and biomass pyrolysis. Prog Energy Combust Sci. 2008;34(1):47–90.

Milosavljevic I, Suuberg EM. Cellulose thermal decomposition kinetics: global mass loss kinetics. Ind Eng Chem Res. 1995;34(4):1081–91.

Gundogar AS, Kok MV. Thermal characterization, combustion and kinetics of different origin crude oils. Fuel. 2014;123(1):59–65.

Kok MV. Characterization of medium and heavy crude oils using thermal analysis techniques. Fuel Process Technol. 2011;92(5):1026–31.

Kök MV, GUL, Kiymet G. Combustion characteristics and kinetic analysis of Turkish crude oils and their SARA fractions by DSC. J Therm Anal Calorim. 2013;114(1)269–275.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Guida, M.Y., Bouaik, H., Tabal, A. et al. Thermochemical treatment of olive mill solid waste and olive mill wastewater. J Therm Anal Calorim 123, 1657–1666 (2016). https://doi.org/10.1007/s10973-015-5061-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-5061-7