Abstract

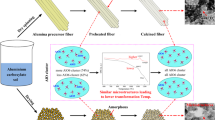

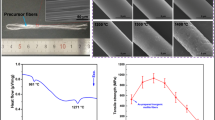

The preparation of precursor sol is the first and crucial step in fabricating oxide fibers by the sol–gel method. In this study, different aluminum-silica sols were prepared by adjusting the alumina and silica source mixing procedure using aluminum carboxylate sol and tetraethoxysilane (TEOS) as the aluminum source and silicon source, respectively. Continuous alumina-mullite precursor fibers were obtained by dry spinning and the effects of alumina and silica source mixing procedure on the phase transition and microstructure evolution of alumina-mullite composite fibers were investigated. The results showed that the mullite formation temperature in the fibers obtained by adding TEOS during the preparation of aluminum carboxylate sol was about 1300 °C, while it was 800 °C in the fibers obtained by mixing aluminum carboxylate sol and TEOS. In addition, the grain size of the fibers obtained by adding TEOS during the preparation of aluminum carboxylate sol was significantly smaller than that obtained by mixing aluminum carboxylate sol and TEOS. The mechanism of this difference was that the aluminum-silica sol obtained by adding TEOS during the preparation of aluminum carboxylate sol was a diphasic sol, while the aluminum-silica sol obtained by adding TEOS in the prepared aluminum carboxylate sol was a monophasic sol.

Graphical Abstract

Highlights

-

Different alumina-mullite fibers precursor sols were prepared by adjusting the alumina and silica source mixing procedures.

-

The phase transformation and microstructural evolution of alumina-mullite composite fibers obtained by different alumina and silica source mixing procedures were investigated systematically.

-

The grain size of the fibers obtained by adding TEOS during the preparation of aluminum carboxylate sol was significantly smaller than that obtained by mixing aluminum carboxylate sol and TEOS.

Similar content being viewed by others

References

Wang W, Zhang L, Dong X, Wu J, Zhou Q, Li S, Shen C, Liu W, Wang G, He R (2022) Additive manufacturing of fiber reinforced ceramic matrix composites: advances, challenges, and prospects. Ceram Int 48(14):19542–19556

Belmonte M (2006) Advanced ceramic materials for high temperature applications. Adv Eng Mater 8(8):693–703

Schawaller D, Clauß B, Buchmeiser MR (2012) Ceramic filament fibers - a review. Macromol Mater Eng 297(6):502–522

Li L, Chen M, Dong Y, Dong X, Cerneaux S, Hampshire S, Cao J, Zhu L, Zhu Z, Liu J (2016) A low-cost alumina-mullite composite hollow fiber ceramic membrane fabricated via phase-inversion and sintering method. J Eur Ceram Soc 36(8):2057–2066

Wilson DM, Visser LR (2001) High performance oxide fibers for metal and ceramic composites. Compos Part A 32(8):0–1153

Li J, Wu W, Yang H, Wang X, Wang X, Sun C, Hu Z (2019) Rigid silica xerogel/alumina fiber composites and their thermal insulation properties. J Porous Mater 26(4):1177–1184

Krenkel W (2008) Ceramic matrix composites: fiber reinforced ceramics and their applications. John Wiley & Sons, pp. 165–186

Li X, Su X, Xiao H, Chen L, Li S, Tang M (2020) Continuous α-Al2O3 fibers grown by seeding with in-situ suspension. Ceram Int 46(10, Part A):15638–15645

Zamani SMM, Behdinan K (2018) Multiscale modeling of the mechanical properties of Nextel 720 composite fibers. Compo Struct 204:578–586

Song X, Ma Y, Wang J, Liu B, Yao S, Cai Q, Liu W (2018) Homogeneous and flexible mullite nanofibers fabricated by electrospinning through diphasic mullite sol-gel route. J Mater Sci 53(20):14871–14883

Li X, Xu H, Wang Q, Li S, Xiao H, Zhang L, Tang M, Chen L (2019) Control of continuous α-Al2O3 fibers by self-seeding and SiO2-Sol doping. Ceram Int 45(9):12053–12059

Taktak Ş, Artır R, Yılmaz S, Bindal C (2004) Fracture toughness of alumina-mullite composites produced by infiltration process. Key Eng Mater 264:981–984

Taktak S, Baspinar M (2005) Wear and friction behaviour of alumina/mullite composite by sol-gel infiltration technique. Mater Des 26(5):459–464

Scholz H, Vetter J, Herborn R, Ruedinger A (2020) Oxide ceramic fibers via dry spinning process—from lab to fab. Int J Appl Ceram Technol 17(4):1636–1645

Yin L, Zhang Z-F, Halloran J, Laine RM (1998) Yttrium aluminum garnet fibers from metalloorganic precursors. J Am Ceram Soc 81(3):629–645

Schneider H, Okada K, Pask JA (1994) Mullite and Mullite Ceramic. Wiley, New York, pp. 213–240

Mendonca A, Ferreira J, Salvado IM (1998) Mullite-alumina composites prepared by sol-gel. J Sol Gel Sci Technol 13:201–205

Chakraborty AK (2005) Aluminosilicate formation in various mixtures of tetra ethyl orthosilicate (TEOS) and aluminum nitrate (ANN). Thermochim Acta 427(1):109–116

Sedaghat A, Taheri-Nassaj E, Soraru G, Ebadzadeh T (2011) A comparative study of microstructural development in the sol-gel derived alumina-mullite nanocomposites using colloidal silica and tetraethyl orthosilicate. J Sol Gel Sci Technol 58:689–697

Dong X, Liu J, Li X, Zhang X, Xue Y, Liu J, Guo A (2017) Electrospun mullite nanofibers derived from diphasic mullite sol. J Am Ceram Soc 100(8):3425–3433

Wu J, Lin H, Li JB, Zhan XB, Li JF (2009) Fabrication and characterization of electrospun mullite nanofibers. Mater Lett 63(27):2309–2312

Jiang W, Lin H, Li J, Zhan X, Li J (2010) Synthesis and characterization of electrospun mullite nanofibers. Adv Eng Mater 12(1-2):71–74

Nýblová D, Senna M, Düvel A, Heitjans P, Billik P, Filo J, Šepelák V (2019) NMR study on reaction processes from aluminum chloride hydroxides to alpha alumina powders. J Am Ceram Soc 102(5):2871–2881

Jaymes I, Douy A (1996) New aqueous mullite precursor synthesis. Structural study by 27Al and 29Si NMR spectroscopy. J Eur Ceram Soc 16(2):155–160

Liu Q, Wu C, Zhan L, Liu W, Yao S, Wang J, Ma Y (2023) Effect of residual carbon on the phase transformation and microstructure evolution of alumina-mullite fibers prepared by sol-gel method. J Eur Ceram Soc 43(3):1039–1050

Cividanes LS, Campos T, Rodrigues LA, Brunelli DD, Thim GP (2010) Review of mullite synthesis routes by sol-gel method. J Sol Gel Sci Technol 55(1):111–125

Wei WC, Halloran JW (1988) Transformation kinetics of diphasic aluminosilicate gels. J Am Ceram Soc 71(7):581–587

Li C, Liu W, Luo T, Cheng M, Liu Q, Wang J, Yao S, Ma Y (2021) Effect of formic-acid-to-acetic-acid ratio on the structure and spinnability of aqueous aluminium sol of alumina fibre. Ceram Int 47(18):26034–26041

Brinker CJ, Scherer GW (2013) Sol-gel science: the physics and chemistry of sol-gel processing. Academic press, pp. 45–69

Chen X, Gu L (2009) Sol-gel dry spinning of mullite fibers from AN/TEOS/AIP system. Mater Res Bull 44(4):865–873

Harris MT, Brunson RR, Byers CH (1990) The base-catalyzed hydrolysis and condensation reactions of dilute and concentrated TEOS solutions. J Non Cryst Solids 121(1-3):397–403

Rubio F, Rubio J, Oteo J (1998) A FT-IR study of the hydrolysis of tetraethylorthosilicate (TEOS). Spectrosc Lett 31(1):199–219

Acknowledgements

The authors gratefully acknowledge the financial support from the National Nature Science Foundation of China (Project No. U20A20240).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Q., Zhan, L., Wu, C. et al. Effect of the alumina and silica source mixing procedure on the microstructural evolution of alumina-mullite composite fibers prepared by sol–gel method. J Sol-Gel Sci Technol 108, 609–620 (2023). https://doi.org/10.1007/s10971-023-06227-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06227-2