Abstract

This review discusses various sol–gel coatings for the corrosion protection of Cu. It is used in various industries, including automotive, electronics, oil/gas, and thermal–power plants, owing to its electrical/thermal conductivity, and mechanical ductility. However, Cu undergoes severe corrosion in aggressive chloride environments, causing considerable industrial losses. Sol–gel coatings for Cu metal protection are a preferred to other types of metallic coatings, because they are cost effectiveness, simple preparation methodology and eco-friendly. Sol–gel coatings compromise a produce an adhesive and compact layer that adheres to the metal surface and acts as a barrier, preventing the diffusion of aggressive Cl ions into the Cu metal and impeding corrosion. The synthesis, morphological studies, and corrosion protection methods of some advanced sol–gel based hybrid protective coatings are discussed in this review. Furthermore, the corrosion protection ability of these sol–gel coatings and their future development prospects are addressed.

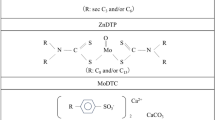

Graphical abstract

Highlights

-

Sol–gel coatings is a very effective method for Cu protection especially in aggressive corrosive media.

-

Sol–gel coatings generate an adhesive layer and acted as a barrier between the Cu and corrosive species.

-

Sol–gel coatings possess several mode of synthesis accordingly with the metal specimen and its surroundings.

-

Sol–gel coatings exhibit an exceptional corrosion inhibitive potential that has been well proven via standard corrosion measurement techniques.

Similar content being viewed by others

Abbreviations

- GPTMS:

-

glycidoxypropyltrimethoxysilane;

- BTMSE:

-

bis (trimethoxysilyl)ethane;

- MPTMS:

-

(3-mercaptopropyl)trimethoxysilane;

- TAVS:

-

triacetoxyvinylsilane;

- HMDS:

-

hexamethyldisilozane;

- MTES:

-

methyltriethoxysilane;

- PTMS:

-

phenyltrimethoxysilane;

- BTA:

-

benzotriazole;

- MPES:

-

3-mercaptopropyltriethoxysilane;

- TEOS:

-

tetraethylorthosilicate;

- TSC:

-

thiosemicarbazide;

- TPS:

-

3-tri-methoxysilyl-1-propanethiol;

- APTES:

-

3-aminopropyltriethoxysilane (APTES);

- LA:

-

lauric acid;

- AMTa:

-

3-amino-5-mercapto-1,2,4-triazole;

- TAT:

-

1H-1,2,4-triazole-3-thiol;

- ATP:

-

4-aminothiophenol;

- GPTMS:

-

3-glycidoxypropyltrimethoxysilane;

- (Al(OsBu)3):

-

aluminum-tri-sec-butoxide;

- GF70:

-

(3-mercaptopropyl) trimethoxysilane;

- Si69:

-

bis -[3-(triethoxysilyl)-propyl]tetrasulfide;

- FAS:

-

fluoroalkylsilane;

- EAcAc:

-

ethyl acetoacetate;

- FAS:

-

fluoroalkylsilane;

- TBT:

-

tetra-n-butyl titanate;

- TU:

-

thiourea;

- SU:

-

sucrose;

- f-GNs:

-

functional graphene nanoplates;

- DCC:

-

dicyclohexylcarbodiimide;

- DMAP:

-

4-dimethylaminopyridine;

- MATMS:

-

3-mercapto propyltrimethoxysilane;

- GO:

-

graphene oxide;

- SEM:

-

scanning electron microscopy,

- TEM:

-

transmission electron microscopy;

- AFM:

-

atomic force microscopy;

- EIS:

-

electrochemical impedance spectroscopy;

- PDS:

-

potentiodynamic polarization.

References

Hammond (2004) The elements, In: Handbook of Chemistry and Physics. CRC Press, Boca Raton.

Harb SV, Trentin A, Uvida MC et al. (2020) A comparative study on PMMA-TiO2 and PMMA-ZrO2 protective coatings. Prog Org Coat 140:105477. https://doi.org/10.1016/j.porgcoat.2019.105477

Davis (2001) Copper and copper metals. ASM International, United States of America.

Hashemi T, Hogarth CA (1988) The mechanism of corrosion inhibition of copper in NaCl solution by benzotriazole studied by electron spectroscopy. Electrochim Acta 33:1123–1127. https://doi.org/10.1016/0013-4686(88)80203-2

Brusic V, Frisch MA, Eldridge BN et al. (1991) Copper COrrosion with and without inhibitors. J Electrochem Soc 138:2253–2259. https://doi.org/10.1149/1.2085957

Autoridad Nacional del Servicio Civil (2021) 済無No title no title no title. Angew Chem Int Ed 6(11):951–952. 144:2013–2015

Wang D, Bierwagen GP (2009) Sol–gel coatings on metals for corrosion protection. Prog Org Coat 64:327–338. https://doi.org/10.1016/j.porgcoat.2008.08.010

Mittal (2020) Silanes and other coupling agents. CRC Press, Boston.

Mittal (2000) Silanes and other coupling agents. VSP, Boca Raton.

Mittal KL (2004) Silanes and Other Coupling Agents, Volume 3. CRC Press

Mehrotra RC (1992) Structure and bonding; chemistry, spectroscopy and applications of sol-gel glasses. Springer International Publishing

Benzbiria N, Echihi S, Belghiti ME et al. (2021) Novel synthetized benzodiazepine as efficient corrosion inhibitor for copper in 3.5% NaCl solution. Mater Today Proc 37:3932–3939. https://doi.org/10.1016/j.matpr.2020.09.030

Hasanin MS, Al Kiey SA (2020) Environmentally benign corrosion inhibitors based on cellulose niacin nano-composite for corrosion of copper in sodium chloride solutions. Int J Biol Macromol 161:345–354. https://doi.org/10.1016/j.ijbiomac.2020.06.040

Liu H, Fan B, Fan G et al. (2021) Long-term protective mechanism of poly(N-methylaniline)/phosphate one-step electropolymerized coatings for copper in 3.5% NaCl solution. J Alloy Compd 872:159752. https://doi.org/10.1016/j.jallcom.2021.159752

Brou YS, Coulibaly NH, Diki N’GYS, Creus J, Trokourey A (2020) Chitosan biopolymer effect on copper corrosion in 3.5 wt.% NaCl solution: Electrochemical and quantum chemical studies. Int J Corros Scale Inhib 9. https://doi.org/10.17675/2305-6894-2020-9-1-11

Vinothkumar K, Rajkumar G, Sethuraman MG (2021) Enhancement of protection of copper through electropolymerised poly-2-amino-1,3,4-thiadiazole and its composite films. Mater Chem Phys 259:123987. https://doi.org/10.1016/j.matchemphys.2020.123987

Vinothkumar K, Sethuraman MG (2021) Protection of copper from corrosion through electrodeposited poly-2,5-dimercapto-1,3,4-thiadiazole–TiO2 composite film. Polym Bull 78:15–34. https://doi.org/10.1007/s00289-019-03090-6

Vinothkumar K, Sethuraman MG (2018) Corrosion inhibition ability of electropolymerised composite film of 2-amino-5-mercapto-1,3,4-thiadiazole/TiO2 deposited over the copper electrode in neutral medium. Mater Today Commun 14:27–39. https://doi.org/10.1016/j.mtcomm.2017.12.007

Vinothkumar K, Sethuraman MG (2020) A robust method of enhancement of corrosion inhibitive ability of electrodeposited poly-3-amino-5-mercapto-1,2,4-triazole films over copper surface using graphene oxide. J Adhes Sci Technol 34:651–669. https://doi.org/10.1080/01694243.2019.1674599

Rajkumar G, Sethuraman MG (2013) Electrosynthesis of a novel poly(3-amino-1,2,4-triazole) + TiO2 hybrid composite on copper and its corrosion protection. Ind Eng Chem Res 52:15057–15065. https://doi.org/10.1021/ie401444b

Rajkumar G, Sethuraman MG (2014) Synthesis, characterization and corrosion protection of poly-4-methyl-3-mercapto-1,2,4-triazole/TiO2 composite on copper. Polym Bull 71:3249–3260. https://doi.org/10.1007/s00289-014-1248-5

Rajkumar G, Sethuraman MG (2016) A novel hybrid composite coating of poly-3-amino-5-mercapto-1,2,4-triazole/TiO2 on copper for corrosion protection. Iran Polym J 25:119–128. https://doi.org/10.1007/s13726-015-0406-4

Rajkumar G, Sethuraman MG (2015) Electrochemical synthesis of poly-3-amino-5-mercapto-1,2,4-triazole on copper and its protective effect in 3.5% NaCl medium. Res Chem Intermed 41:8041–8055. https://doi.org/10.1007/s11164-014-1876-2

Rajkumar G, Sethuraman MG (2014) Corrosion protection ability of self-assembled monolayer of 3-amino-5-mercapto-1,2,4-triazole on copper electrode. Thin Solid Films 562:32–36. https://doi.org/10.1016/j.tsf.2014.03.074

Rajkumar G, Sethuraman MG (2016) A study of copper corrosion inhibition by self-assembled films of 3-mercapto-1H-1,2,4-triazole. Res Chem Intermed 42:1809–1821. https://doi.org/10.1007/s11164-015-2119-x

Rajkumar G, Sagunthala R, Sethuraman MG (2015) Investigation of inhibiting properties of self-assembled films of 4-aminothiophenol on copper in 3.5% NaCl. J Adhes Sci Technol 29:1107–1117. https://doi.org/10.1080/01694243.2015.1019391

Dislich H (1971) New routes to multicomponent oxide glasses. Angew Chem Int Ed Engl 10:363–370. https://doi.org/10.1002/anie.197103631

Matijevic E (1986) Monodispersed colloids: art and science. Langmuir 2:12–20. https://doi.org/10.1021/la00067a002

Brinker SPM CJ (1981) Conversion of monolithic gels to glasses in a multicomponent silicate glass system. J Mater Sci 16:1980

Sakka S, Kamiya K (1980) Glasses from metal alcoholates. J Non Cryst Solids 42:403–421. https://doi.org/10.1016/0022-3093(80)90040-X

Peng S, Zhao W, Li H et al. (2013) The enhancement of benzotriazole on epoxy functionalized silica sol–gel coating for copper protection. Appl Surf Sci 276:284–290. https://doi.org/10.1016/j.apsusc.2013.03.083

Perumal V, Mohamed NM, Mohamed Saheed MS, Mohamed Saheed MS (2019) Microtechnology and nanotechnology advancements toward bio-molecular targeting. In: Nanobiosensors for biomolecular targeting. Elsevier, Netherlands, pp 225–251.

Tan ALK, Soutar AM (2008) Hybrid sol-gel coatings for corrosion protection of copper. Thin Solid Films 516:5706–5709. https://doi.org/10.1016/j.tsf.2007.07.066

Boysen W, Frattini A, Pellegri N, de Sanctis O (1999) Protective coatings on copper prepared by sol–gel for industrial applications. Surf Coat Technol 122:14–17. https://doi.org/10.1016/S0257-8972(99)00402-8

Eric Bescher JDM (2003) No title. J Sol-Gel Sci Technol 26:1223

Li Y-S, Lu W, Wang Y, Tran T (2009) Studies of (3-mercaptopropyl)trimethoxylsilane and bis(trimethoxysilyl)ethane sol–gel coating on copper and aluminum. Spectrochim Acta Part A Mol Biomol Spectrosc 73:922–928. https://doi.org/10.1016/j.saa.2009.04.016

Li Y-S, Ba A, Mahmood MS (2008) An environmentally friendly coating for corrosion protection of aluminum and copper in sodium chloride solutions. Electrochim Acta 53:7859–7862. https://doi.org/10.1016/j.electacta.2008.05.062

Kiele E, Senvaitiene J, Griguceviciene A et al. (2016) Application of sol–gel method for the conservation of copper alloys. Microchem J 124:623–628. https://doi.org/10.1016/j.microc.2015.10.003

Fan Y, Li C, Chen Z, Chen H (2012) Study on fabrication of the superhydrophobic sol–gel films based on copper wafer and its anti-corrosive properties. Appl Surf Sci 258:6531–6536. https://doi.org/10.1016/j.apsusc.2012.03.072

Peng S, Zeng Z, Zhao W et al. (2014) Novel functional hybrid silica sol–gel coating for copper protection via in situ thiol–ene click reaction. RSC Adv 4:15776–15781. https://doi.org/10.1039/C4RA00142G

Rao AV, Latthe SS, Mahadik SA, Kappenstein C (2011) Mechanically stable and corrosion resistant superhydrophobic sol–gel coatings on copper substrate. Appl Surf Sci 257:5772–5776. https://doi.org/10.1016/j.apsusc.2011.01.099

Seifzadeh D, Golmoghani-Ebrahimi E (2012) Formation of novel and crack free nanocomposites based on sol gel process for corrosion protection of copper. Surf Coat Technol 210:103–112. https://doi.org/10.1016/j.surfcoat.2012.08.073

Peng S, Zeng Z, Zhao W et al. (2014) Performance evaluation of mercapto functional hybrid silica sol–gel coating on copper surface. Surf Coat Technol 251:135–142. https://doi.org/10.1016/j.surfcoat.2014.04.017

Karthik N, Sethuraman MG (2015) Improved copper corrosion resistance of epoxy-functionalized hybrid sol–gel monolayers by thiosemicarbazide. Ion 21:1477–1488. https://doi.org/10.1007/s11581-014-1274-1

Peng S, Han J, Zhao W et al. (2015) The protection and degradation behaviors of mercapto functional sol-gel coating on copper surface. J Electrochem Soc 162:C128–C134. https://doi.org/10.1149/2.0091504jes

Adhami S, Atapour M, Allafchian AR (2015) Corrosion protection of copper by silane sol–gel coatings. J Sol-Gel Sci Technol 74:800–809. https://doi.org/10.1007/s10971-015-3665-9

Karthik N, Sethuraman MG (2015) Assessment of the corrosion protection ability of cysteamine and hybrid sol–gel twin layers on copper in 1% NaCl. RSC Adv 5:8693–8705. https://doi.org/10.1039/C4RA12138D

Balaji J, Sethuraman MG (2016) Improved corrosion resistance by forming multilayers over a copper surface by electrodeposition followed by a novel sol–gel coating method. RSC Adv 6:95396–95404. https://doi.org/10.1039/C6RA19173H

Balaji J, Sethuraman MG (2016) Corrosion protection of copper with 3-glycidoxypropyltrimethoxysilane-based sol–gel coating through 3-amino-5-mercapto-1,2,4-triazole doping. Res Chem Intermed 42:1315–1328. https://doi.org/10.1007/s11164-015-2087-1

Sui W, Zhao W, Zhang X et al. (2016) Comparative anti-corrosion properties of alkylthiols SAMs and mercapto functional silica sol–gel coatings on copper surface in sodium chloride solution. J Sol–Gel Sci Technol 80:567–578. https://doi.org/10.1007/s10971-016-4108-y

Balaji J, Sethuraman MG (2016) Corrosion protection of copper with hybrid sol-gel containing 1H-1, 2, 4-triazole-3-thiol. Iran J Chem Chem Eng 35:61. https://doi.org/10.30492/IJCCE.2016.23557

Karthik N, Asha S, Sethuraman MG (2016) Influence of pH-sensitive 4-aminothiophenol on the copper corrosion inhibition of hybrid sol–gel monolayers. J Sol-Gel Sci Technol 78:248–257. https://doi.org/10.1007/s10971-015-3944-5

Kesmez Ö, Akarsu E (2017) Corrosion-resistant hybrid coatings for copper surfaces substrates by sol-gel chemistry. J Turkish Chem Soc Sect A Chem 1. https://doi.org/10.18596/jotcsa.324873

Raimondo M, Veronesi F, Boveri G et al. (2017) Superhydrophobic properties induced by sol-gel routes on copper surfaces. Appl Surf Sci 422:1022–1029. https://doi.org/10.1016/j.apsusc.2017.05.257

Karthik N, Lee YR, Sethuraman MG (2017) Hybrid sol-gel/thiourea binary coating for the mitigation of copper corrosion in neutral medium. Prog Org Coat 102:259–267. https://doi.org/10.1016/j.porgcoat.2016.10.024

Razavi F, Shabani-Nooshabadi M, Behpour M (2018) Sol-gel synthesis, characterization and electrochemical corrosion behavior of S-N-C-doped TiO2 nano coating on copper. J Mol Liq 266:99–105. https://doi.org/10.1016/j.molliq.2018.06.056

Tian S, Liu Z, Shen L et al. (2018) Performance evaluation of mercapto functional hybrid silica sol–gel coating and its synergistic effect with f-GNs for corrosion protection of copper surface. RSC Adv 8:7438–7449. https://doi.org/10.1039/C7RA11435D

Qin F (2020) Effect of deposition potential on preparation and corrosion resistance of SiO2 film on copper. Int J Electrochem Sci: 6478–6487. https://doi.org/10.20964/2020.07.49

Balaji J, Roh S-H, Edison TNJI et al. (2020) Sol-gel based hybrid silane coatings for enhanced corrosion protection of copper in aqueous sodium chloride. J Mol Liq 302:112551. https://doi.org/10.1016/j.molliq.2020.112551

Balaji J, Oh TH, Sethuraman MG (2021) Effects of pH on inhibitor-doped hybrid protective sol–gel coatings on the copper electrode surface. J Taiwan Inst Chem Eng 119:259–268. https://doi.org/10.1016/j.jtice.2021.02.006

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2022R1A2C1004283) and the authors thank the Core Research Support Center for Natural Products and Medical Materials (CRCNM) in Yeungnam University.

Author contribution

JB: Conceptualization, methodology, data curation, writing- original draft, preparation, software, validation. PBR: Visualization, editing. THO: Reviewing, supervision. MGS: Supervision.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Balaji, J., Raja, P.B., Sethuraman, M.G. et al. Recent studies on sol–gel based corrosion protection of Cu—A review. J Sol-Gel Sci Technol 103, 12–38 (2022). https://doi.org/10.1007/s10971-022-05818-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-022-05818-9