Abstract

Reduction of friction and wear by lubrication is necessary to improve the efficiency and prolong the lifespan of industrial machinery. However, several aspects regarding the lubrication effects in additive-combined oil are still unresolved. This study focuses on the effects of combining zinc dialkyldithiophosphate (ZnDTP), molybdenum dithiocarbamate (MoDTC), and Ca sulfonate on the frictional behavior of poly-α-olefin 4 (PAO4) lubricant oils. Ball-on-disk friction tests demonstrated that the exclusive addition of high-base Ca sulfonate solution reduced friction and wear of the lubricating oil. When combined with ZnDTP and MoDTC, the friction coefficients of PAO with high-base and low-base Ca sulfonate are affected by competitive reactions on the sliding surface. Quartz crystal microbalance with dissipation monitoring measurements suggests that high-base Ca sulfonate forms a stronger adsorption film than low-base Ca sulfonate. Atomic force microscope observations confirmed that the addition of low-base Ca sulfonate reduced friction and wear, whereas high-base Ca sulfonate induced competitive reactions with ZnDTP and MoDTC. This study provides valuable insights into the effects of the combination of additives on the lubricity of PAO and their impact on friction and wear characteristics, which are valuable for the design of suitable lubricants for industrial machinery.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Lubricating oils are mixed with different types of additives to optimize their properties and improve the tribological performance of industrial machinery. Zinc dialkyldithiophosphate (ZnDTP) and molybdenum dithiocarbamate (MoDTC) are commonly used as additives to enhance friction and wear resistance [1,2,3,4,5,6]. In combination with ZnDTP, MoDTC efficiently forms MoS2 tribofilms, particularly through synergistic effects, resulting in excellent low-friction properties. [7,8,9,10,11,12]. For example, Muraki et al. have demonstrated that the synergistic effects of MoDTC and ZnDTP promote MoS2 formation and provide low friction under rolling–sliding conditions [8]. ZnDTP serves as a source of sulfur and suppresses the formation of high-friction sulfate and sulfide [9]. Lubricating oils also contain rust inhibitors that physically adsorb onto metal surfaces and prevent them from rusting. Furthermore, sulfonate-based rust inhibitors form micellar structures in the oil, which help in adsorbing polar substances (such as sludge) and dispersing them in the oil. Rust inhibitors are likely to induce competitive reactions with other additives on the metal surfaces and can reduce the lubricating effects of ZnDTP and MoDTC [13,14,15]. For example, an overbased rust inhibitor decreases the extreme pressure and antiwear performance of ZnDTP owing to the competitive adsorption between the rust inhibitor and ZnDTP [13]. In this way, additive-combined oil may occasionally exhibit unexpected lubrication effects. Such unexpected lubrication effects can significantly impact the performance and lifespan of products in industrial machinery. The chemical interaction between lubricant additives causes wear; however, the mechanism is not completely understood in detail. Furthermore, while numerous studies on additives have been conducted, the formation process of tribofilm has not been elucidated especially in the case of additive-combined oil. Therefore, the lubrication effects of additive-combined oil should be understood to develop appropriate lubricants for different applications.

In this study, we investigated the effects of rust inhibitors on ZnDTP and MoDTC by adding calcium sulfonate with high and low total basic numbers (TBNs). The friction and antiwear characteristics of the additives were investigated using a reciprocating-type tribotester, and the elemental mapping of the wear track was obtained using an electron probe microanalyzer (EPMA). To elucidate the formation process of the tribofilm, the properties of the additives were characterized using atomic force microscopy (AFM) and quartz crystal microbalance with dissipation monitoring (QCM-D).

2 Methods

2.1 Materials

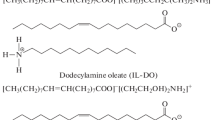

Poly-α-olefin 4 (PAO4) with a kinematic viscosity of 19.0 mm2/s at 100 °C was used as the base oil. The chemical structures of the additives used in this study are illustrated in Fig. 1. The concentrations of ZnDTP (with an alkyl structure of secondary C3/C6 mixed) and MoDTC (with an alkyl structure of C8/C13 mixed) were 0.75 mass% (2.5 mmol/kg) and 0.46 mass% (10 mmol/kg), respectively. Additionally, calcium sulfonate with TBN values of 303 mg KOH/g (high-base calcium sulfonate, HBCS) and 44.2 mg KOH/g (low-base calcium sulfonate, LBCS) were added at a concentration of 0.50 mass%.

2.2 Friction Tests

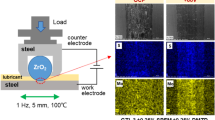

The friction coefficients were measured using a reciprocating-type ball-on-disk tribotester (SRV5, Optimol, DE), as illustrated in Fig. 2. The friction test conditions are listed in Table 1. A 10-mm-diameter ball specimen and a 24-mm-diameter disk specimen (thickness: 7.9 mm) were used for the friction tests. The ball and disk specimens had an arithmetic average roughness (Ra) of 0.02 µm.

2.3 Analysis

Following the friction tests, the disks were rinsed with an acetone/petroleum benzine solution. The wear volume of the disk specimen was determined by confocal laser scanning microscopy (VK-X150, KEYENCE, JP) and electron probe microanalysis (EPMA-8050G, Shimadzu, JP) at an accelerating voltage of 15.0 kV and a beam current of 0.20 μA. The elemental mapping of the wear track was performed over an area of 1.9 mm × 2.6 mm.

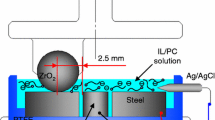

The adsorption properties of the additives were evaluated using QCM-D (Biolin Scientific, Q-Sense E4, Sweden) with a quartz sensor coated with iron oxide (Fe3O4). All the QCM-D measurements were conducted in a flow cell at 50 °C, consistent with the friction test conditions. As shown in Fig. 3, the QCM-D experiments were performed in three stages: (A) flowing of the base oil to stabilize the set temperature and ensure the stability of signals (frequency change: ΔF and dissipation: ΔD); (B) change of liquid from the base oil to the additive solution containing ZnDTP, MoDTC, and Ca sulfonate (PAO + ZnDTP + MoDTC + Ca sulfonate); (C) replacement of the additive solution with ZnDTP and MoDTC solution excluding Ca sulfonate (PAO + ZnDTP + MoDTC). The adsorbed mass per unit area (Δm) was calculated based on the frequency change using Sauerbrey’s equation, where C is related to the properties of the quartz crystal (Eq. 1) [16].

Figure 4 shows the schematic of the in-situ AFM setup used to observe the growth of the tribofilm; the measurement conditions are listed in Table 2. The in-situ AFM studies were carried out using a commercial AFM system (Nano Navi, Hitachi High-Tech, JP) with a silicon tip (SI-DF40, Hitachi High-Tech, JP) immersed in the base oil and additive solution. While observing the formation of tribofilms in high-temperature environments, the impact of thermal drift needs to be minimized. Therefore, the oil temperature was increased to 80 °C and maintained for more than 12 h to suppress the thermal drift. For the in-situ AFM observations of the sliding surfaces, a substrate made of bearing steel (AISI 52100) with an Ra of 0.02 µm was used. To generate the tribofilm, the AFM was operated in the contact mode for 8000 cycles at a normal force of 2000 nN, sliding frequency of 40.0 Hz (sliding velocity: 40 μm/s), oil temperature of 80 °C, and an image range of 1.0 µm × 1.0 µm (64 pixels × 64 pixels) by acquiring the lateral force signal at an operating angle of 90°. Subsequently, we acquired a height image in the range of 2.0 µm × 2.0 µm (128 pixels × 128 pixels) to confirm the tribofilm growth on the sliding area. The images were acquired at a normal force of 800 nN and a sliding frequency of 4.0 Hz (sliding velocity: 4 μm/s).

3 Results

3.1 Friction and Wear

Figure 5 illustrates the frictional behaviors of the different lubricants as a function of sliding time. In the case of Ca sulfonate-added oil, PAO + HBCS and PAO + LBCS exhibit similar friction coefficients of 0.15–0.20 up to 1500 s. Thereafter, the friction coefficient of PAO + HBCS decreases and stabilizes at approximately 0.15. Similar results have been reported in previous studies. Kubo et al. demonstrated that over-based Ca sulfonates exhibit lower frictional properties than neutral Ca sulfonate. The deposition of calcium oxide plays a crucial role in reducing friction and wear [17]. In the presence of ZnDTP and MoDTC additives, the friction coefficient of the lubricant oil is lower than that of the Ca sulfonate-added oil. The friction coefficients of PAO + ZnDTP + MoDTC + LBCS and PAO + ZnDTP + MoDTC + HBCS are approximately 0.08 and 0.13, respectively. These results indicate a reversal in the effects of HBCS and LBCS on the friction coefficient of the ZnDTP + MoDTC combined oil.

Figure 6 illustrates the wear volumes calculated from the wear tracks on the disk specimens. The wear properties of each lubricant exhibit the same trend as those of the frictional properties, and a reversal in wear volume between LBCS and HBCS is observed in Ca sulfonate-added PAO and ZnDTP + MoDTC combined oils.

3.2 Composition of Wear Track

The results of the electron probe microanalysis of the disk specimens after the friction tests (Fig. 7) show the presence of P, S, Ca, Zn, and Mo. Phosphorus and zinc originate from ZnDTP; sulfur from ZnDTP, MoDTC, and Ca sulfonate; and Mo from MoDTC. As evident from Fig. 7a, b, PAO + ZnDTP + MoDTC + HBCS has a higher amount of Ca than PAO + ZnDTP + MoDTC + LBCS, suggesting the presence of calcium-based compounds on the sliding surfaces. Contrarily, the amounts of P and Mo are higher in PAO + ZnDTP + MoDTC + LBCS, indicating that tribofilms derived from ZnDTP and MoDTC are more abundantly formed than calcium-based compounds. These results are consistent with the frictional behavior of the lubricants described in Sect. 3.1. Thus, the low-friction is attributed to the formation of tribofilms of calcium-based compounds derived from HBCS [17].

3.3 Adsorption Characteristics

Figure 8 shows the results of QCM-D measurements, where changes in Δf values were fitted to Sauerbrey’s equation (Eq. 1) and converted to adsorbed mass per cm2. When PAO (region A) is replaced with PAO + ZnDTP + MoDTC + Ca sulfonate (Fig. 8 (region B)), the adsorbed mass of the lubricant oil with HBCS is relatively higher than that of the oil with LBCS. The adsorbed mass of PAO + ZnDTP + MoDTC + LBCS remains approximately constant at 400 ng/cm2. In contrast, the adsorbed mass of PAO + ZnDTP + MoDTC + HBCS continuously increases from 700 to 1000 ng/cm2. Additionally, the adsorbed mass decreases when Ca sulfonate is excluded (Fig. 8 (region C)). However, while the adsorbed mass of the lubricant with LBCS decreases to nearly zero, the lubricant with HBCS retains an adsorbed mass of approximately 500 ng/cm2. These results suggest that HBCS is more likely to be adsorbed and retained on the iron oxide surface than LBCS.

3.4 In-situ AFM Studies

Figures 9–10 illustrate the results of in-situ AFM observations of PAO + ZnDTP + MoDTC, PAO + ZnDTP + MoDTC + HBCS, and PAO + ZnDTP + MoDTC + LBCS, respectively. A tribofilm is formed on the substrates in all the cases. Figure 11 shows the temporal evolution of the average tribofilm thickness. In the cases of PAO + ZnDTP + MoDTC and PAO + ZnDTP + MoDTC + LBCS, the tribofilm thickness increases with an increase in the number of sliding cycles, reaching 100 and 120 nm, respectively after 8000 cycles (Fig. 11a, c). In the case of PAO + ZnDTP + MoDTC + HBCS, the tribofilm with a thickness of approximately 110 nm after 4000 cycles is partially scraped off and detached (Fig. 11b). However, the tribofilm is regenerated at 5500–8000 cycles. These results indicate that the growth behavior of tribofilms depends on the basicity of Ca sulfonate. The tribofilms formed from PAO + ZnDTP + MoDTC and ZnDTP + MoDTC + LBCS continue to grow, while the tribofilm formed from ZnDTP + MoDTC + HBCS undergoes repeated cycles of generation and detachment.

4 Discussion

4.1 Friction and Wear Characteristics of PAO with Additives

According to Fig. 5, the friction and wear characteristics of PAO with HBCS are lower than those of PAO with LBCS solution. In the presence of ZnDTP + MoDTC, PAO with LBCS exhibits lower friction and wear characteristics than PAO with HBCS. Thus, the HBCS solution tends to reduce friction and wear when added exclusively. However, in the presence of ZnDTP and MoDTC, the HBCS solution causes competitive reactions on the sliding surface, inhibiting the friction-reducing effects of ZnDTP and MoDTC. In previous studies, Kubo et al. have reported that overbased calcium sulfonate demonstrates lower friction effects compared to neutral calcium sulfonate [17], and Yamada et al. reported that overbased detergent decreases the effect of extreme pressure and anti-wear of ZnDTP owing to competitive reactions [13]. Therefore, the competitive reactivity of HBCS obtained in this study can be considered reasonable.

4.2 Effect of Total Basic Number of Ca Sulfonate on Lubrication Properties

The results of the surface analysis after the friction tests, as illustrated in Fig. 7, indicate the presence of a higher amount of Ca in the wear track of PAO + ZnDTP + MoDTC + HBCS. However, the amounts of P and Mo are lower than those in the wear track of PAO + ZnDTP + MoDTC + LBCS. These results suggest competitive tribochemical reactions between Ca-based compounds in PAO + ZnDTP + MoDTC + HBCS and the tribofilms derived from ZnDTP and MoDTC on the sliding surface. However, the formation of tribofilms of ZnDTP and MoDTC is not inhibited in PAO + ZnDTP + MoDTC + LBCS, resulting in low friction and wear.

The adsorption characteristics of the additives investigated using the QCM-D method (Fig. 8) indicate that the adsorbed mass in PAO + ZnDTP + MoDTC + HBCS is higher than that in PAO + ZnDTP + MoDTC + LBCS. Furthermore, the adsorbed mass of PAO + ZnDTP + MoDTC + HBCS continues to increase over time. This suggests not only the adsorption of additive molecules on the iron oxide (Fe3O4) substrate but also the adsorption between Ca sulfonate molecules. After replacing PAO + ZnDTP + MoDTC + HBCS with PAO + ZnDTP + MoDTC, the adsorbed mass does not decrease significantly, retaining approximately 500 ng/cm2. These results indicate that the high-Ca sulfonate solution forms a relatively robust adsorption film that is retained on the iron oxide (Fe3O4) substrate.

4.3 In-situ AFM Studies of Tribofilm Formation

Using in-situ AFM, the processes of tribofilm formation in PAO + ZnDTP + MoDTC and PAO + ZnDTP + MoDTC + LBCS were observed (Figs. 9, 10). In the case of PAO + ZnDTP + MoDTC + HBCS (Fig. 12), the tribofilm was detached and regenerated. These results indicate that the tribofilm of PAO + ZnDTP + MoDTC + LBCS, which is retained even after repeated sliding, contributes to the observed reduction in friction and wear in the macro-friction tests. The generation and detachment of the tribofilm in PAO + ZnDTP + MoDTC + HBCS are attributed to competitive tribochemical reactions between the Ca-based compounds and ZnDTP + MoDTC. Gosvami et al. studied the process of tribofilm formation in a ZnDTP-containing solution (single additive) using in-situ AFM [18, 19]. However, in the case of additive-combined oil involving ZnDTP, MoDTC, and Ca sulfonate (present study), the thickness of the tribofilm increases with an increase in the number of sliding cycles. Furthermore, the tribofilm growth depends on the additive combination. In the ZnDTP-added solution, the tribofilm has a pad-like structure. Contrarily, in the additive-combined oil, the tribofilm exhibits fewer irregularities and grows uniformly across the sliding area. Therefore, the reaction products determine the structure of the tribofilm in lubricant oil with additives.

5 Conclusions

To investigate the effects of Ca sulfonate on ZnDTP and MoDTC, we conducted friction tests, in-situ AFM studies, and QCM-D tests of additive-combined PAO. The main conclusions are as follows:

-

(1)

When Ca sulfonate is added exclusively, PAO with LBCS exhibited a higher friction coefficient and wear volume than PAO with HBCS. However, in combination with ZnDTP and MoDTC, PAO + ZnDTP + MoDTC + HBCS exhibited higher friction coefficients and wear volumes than PAO + ZnDTP + MoDTC + LBCS. Therefore, HBCS is more likely to inhibit the lubricating effects of ZnDTP and MoDTC than LBCS.

-

(2)

Surface analysis after friction tests revealed the presence of higher amount of calcium in PAO + ZnDTP + MoDTC + HBCS than that in PAO + ZnDTP + MoDTC + LBCS, whereas the detection rates of P and Mo were lower. Furthermore, the results of QCM-D indicated that HBCS-added oil has a higher adsorbed mass than LBCS-added oil. These results suggest competitive tribochemical reactions between the chemical species derived from calcium in PAO + ZnDTP + MoDTC + HBCS and ZnDTP + MoDTC on the sliding surface.

-

(3)

In-situ AFM observations of PAO + ZnDTP + MoDTC and PAO + ZnDTP + MoDTC + LBCS showed that the thickness of the tribofilm increased with an increase in the number of sliding cycles. However, the tribofilms originating from PAO + ZnDTP + MoDTC + HBCS were detached during the sliding motion. This is attributed to the inherent property of HBCS to induce competitive tribochemical reactions with ZnDTP and MoDTC on the sliding surface.

In the future work, we plan to investigate the chemical state of the tribofilm obtained from in-situ AFM observations. Additionally, we will focus on activation energies and reaction rates, exploring the differences in the generation processes based on the types of additives.

Availability of Data and Materials

No datasets were generated or analysed during the current study.

References

Sakurai, T., Okabe, H., Isoyama, H.: The synthesis of di-µ-thio-dithio-bis(dialkyldithiocarbamates) dimolybdenum (V) and their effects on boundary lubrication. Bull. Japan Petrol Inst. 13(2), 243–249 (1971). https://doi.org/10.1627/jpi1959.13.243

Isoyama, H., Sakurai, T.: The lubricating mechanism of di-u-thio-dithio-bis-(diethyl dithiocarbamate) dimolybdenum during extreme pressure lubrication. Tribol. Int. 7(4), 151–160 (1974). https://doi.org/10.1016/0041-2678(74)90022-0

Yamamoto, Y., Gondo, S.: Friction and wear characteristics of molybdenum dithiocarbamate and molybdenum dithiophosphates. Tribol. Trans. 32(2), 251–257 (1989). https://doi.org/10.1080/10402008908981886

Spikes, H.A.: The history and mechanisms of ZDDP. Tribol. Lett. 17, 469–489 (2004). https://doi.org/10.1023/B:TRIL.0000044495.26882.b5

Gellman AJ, Spencer ND 2002 Surface chemistry in tribology. Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol. 216(6), 443–461. https://doi.org/10.1243/135065002762355352

Barnes, A.M., Keith, D.B.: A review of zinc dialkyldithiophosphates (ZDDPS): Characterisation and role in the lubricating oil. Tribol. Int. 34(6), 389–395 (2001). https://doi.org/10.1016/S0301-679X(01)00028-7

Yamamoto, Y., Gondo, S., Kamakura, T., Tanaka, N.: Frictional characteristics of molybdenum dithiophosphates. Wear 112, 79–87 (1986). https://doi.org/10.1016/0043-1648(86)90202-4

Muraki, M., Yanagi, Y., Sakaguchi, K.: Synergistic effect on frictional characteristics under rolling-sliding conditions due to a combination of molybdenum dialkyldithiocarbamate and zinc dialkyldithiophosphate. Tribol. Int. 30(1), 69–75 (1997). https://doi.org/10.1016/0301-679X(96)00025-4

Kasrai, M., Cutler, J.N., Gore, K., Canning, G., Bancroft, G.M., Tan, K.H.: The chemistry of antiwear films generated by the combination of ZDDP and MoDTC examined by X-ray absorption spectroscopy. Tribol. Trans. 41, 69–77 (1998). https://doi.org/10.1080/10402009808983723

Martin, J.M., Grossiord, C., Varlot, K., Vacher, B., Igarashi, J.: Synergistic effects in binary systems of lubricant additives: a chemical hardness approach. Tribol. Lett. 8, 193–201 (2000). https://doi.org/10.1023/A:1019147520893

Graham, J., Jensen, R., Spikes, H.A.: The friction-reducing properties of molybdenum dialkyldithiocarbamate additives. Part 2. Durability of friction reducing capability. Tribol. Trans. 44, 637–646 (2001). https://doi.org/10.1080/10402000108982505

Morina, A., Neville, A.: Understanding the composition and low friction tribofilm formation/removal in boundary lubrication. Tribol. Int. 40, 1696–1704 (2007). https://doi.org/10.1016/j.triboint.2007.02.001

Yamada, Y., Igarashi, J., Inoue, K.: Effects of metallic detergents on the antioxidant and antiwear properties of zinc alkyldothiophosphates. Lubr. Eng. 48(6), 511–518 (1992)

Wan, Y., Fuller, M.L.S., Kasrai, M., Bancroft, G.M., Fyfe, K., Torkelson, J.R., Hu, Y.F., Tan, K.H.: Effects of detergents on the chemistry of tribofilms from ZDDP: Studied by X-ray adsorption spectroscopy and XPS. Tribol. Series. 40, 155–166 (2002). https://doi.org/10.1016/S0167-8922(02)80017-7

Costello, M.T., Urrego, R.A.: Study of surface films of the ZDDP and the MoDTC with crystalline and amorphous overbased calcium sulfonates by XPS. Tribol. Trans.Trans. 50(2), 217–226 (2007). https://doi.org/10.1080/10402000701271051

Sauerbrey, G.: Verwendung von schwingquarzen zur wägung dünner schichten und zur mikrowägung. Z. Phys. 155, 206–222 (1959). https://doi.org/10.1007/BF01337937

Kubo, T., Fujiwara, S., Nanao, H., Minami, I., Mori, S.: TOF-SIMS analysis of boundary films derived from calcium sulfonates. Tribol. Lett. 23(2), 171–176 (2006). https://doi.org/10.1007/s11249-006-9093-9

Gosvami, N.N., Bares, J.A., Mangolini, F., Konicek, A.R., Yablon, D.G., Carpick, R.W.: Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts. Science 348(6230), 102–106 (2015). https://doi.org/10.1126/science.1258788

Gosvami, N.N., Ma, J., Carpick, R.W.: An in situ method for simultaneous friction measurements and imaging of interfacial tribochemical film growth in lubricated contacts. Tribol. Lett. 66, 154 (2018). https://doi.org/10.1007/s11249-018-1112-0

Acknowledgements

The authors thank ADEKA CORPORATION (MoDTC), The Lubrizol Corporation (ZnDTP), and the Shima Trading Company (HBCS and LBCS) for supplying the respective materials for this work.

Funding

Open Access funding provided by Tokyo University of Science. The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

Yumi Hayashi: Investigation, Formal analysis, Data curation, Writing–original draft.; Kaisei Sato: Methodology, Formal analysis, Review.; Shinya Sasaki: Supervision, Resources, Funding acquisition, Review & Editing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hayashi, Y., Sato, K. & Sasaki, S. The Effect of Lubricity of Calcium Sulfonate on ZnDTP and MoDTC. Tribol Lett 72, 62 (2024). https://doi.org/10.1007/s11249-024-01860-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-024-01860-6