Abstract

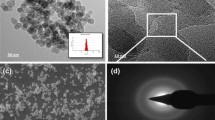

Recently, there has been increasing interest in developing artificial superhydrophobic surfaces, especially in the field of self-cleaning application. However, the poor robustness and high-cost preparation of these surfaces have always been some issues for their industrial development. Herein, we describe an environmentally friendly way to prepare stable, robust, and transparent superhydrophobic coatings through the deposition of a rough substructure of TiO2 film followed by chemical modification using octadecyltrichlorosilane (OTS), a fluorine-free organic silane. The as-prepared coatings exhibited a great superhydrophobic property and ultralow adhesion (with a static water contact angle of 158 ± 2° and sliding angle of 4 ± 1°). It was found that the superhydrophobic coatings can still maintain good performance after UV irradiation, chemical immersion, and physical abrasion. More importantly, the coated surfaces showed an excellent self-cleaning ability against dirt particles after rinsed with water droplets.

Highlights

-

Environmentally friendly and low-cost method to prepare superhydrophobic coatings using TiO2 thin film and monolayer octadecyltrichlorosilane (OTS).

-

High transparency of the as-prepared superhydrophobic coatings.

-

The superhydrophobic coatings exhibited good chemical and mechanical stability.

-

The surface of superhydrophobic glass showed an excellent self-cleaning property.

Similar content being viewed by others

References

Schlaich C, Yu L, Cuellar Camacho L et al. (2016) Fluorine-free superwetting systems: construction of environmentally friendly superhydrophilic, superhydrophobic, and slippery surfaces on various substrates. Polym Chem 7:7446–7454. https://doi.org/10.1039/c6py01596d

Foorginezhad S, Zerafat MM (2019) Fabrication of stable fluorine-free superhydrophobic fabrics for anti-adhesion and self-cleaning properties. Appl Surf Sci 464:458–471. https://doi.org/10.1016/j.apsusc.2018.09.058

Das A, Deka J, Raidongia K, Manna U (2017) Robust and self-healable bulk-superhydrophobic polymeric coating. Chem Mater 29:8720–8728. https://doi.org/10.1021/acs.chemmater.7b02880

Corti G, Schmiesing NC, Barrington GT et al. (2019) Characterization of methyl-functionalized silica nanosprings for superhydrophobic and defrosting coatings. ACS Appl Mater Interfaces 11:4607–4615. https://doi.org/10.1021/acsami.8b18873

Chen C, Weng D, Chen S et al. (2019) Development of durable, fluorine-free, and transparent superhydrophobic surfaces for oil/water separation. ACS Omega 4:6947–6954. https://doi.org/10.1021/acsomega.9b00518

Zu G, Kanamori K, Nakanishi K, Huang J (2019) Superhydrophobic ultraflexible triple-network graphene/polyorganosiloxane aerogels for a high-performance multifunctional temperature/strain/pressure sensing array. Chem Mater 31:6276–6285. https://doi.org/10.1021/acs.chemmater.9b02437

Zu G, Kanamori K, Wang X et al. (2020) Superelastic triple-network polyorganosiloxane-based aerogels as transparent thermal superinsulators and efficient separators. Chem Mater 32:1595–1604. https://doi.org/10.1021/acs.chemmater.9b04877

Wang F, Pi J, Song F et al. (2020) A superhydrophobic coating to create multi-functional materials with mechanical/chemical/physical robustness. Chem Eng J 381:122539. https://doi.org/10.1016/j.cej.2019.122539

Guo X-J, Xue C-H, Sathasivam S et al. (2019) Fabrication of robust superhydrophobic surfaces via aerosol-assisted CVD and thermo-triggered healing of superhydrophobicity by recovery of roughness structures. J Mater Chem A 7:17604–17612. https://doi.org/10.1039/C9TA03264A

Pozzato A, Zilio SD, Fois G et al. (2006) Superhydrophobic surfaces fabricated by nanoimprint lithography. Microelectron Eng 83:884–888. https://doi.org/10.1016/j.mee.2006.01.012

Kim KS, Kim JH, Lee HJ, Lee SR (2010) Tribology issues in nanoimprint lithography. J Mech Sci Technol 24:5–12. https://doi.org/10.1007/s12206-009-1216-4

Zuo Z, Gao J, Liao R et al. (2019) A novel and facile way to fabricate transparent superhydrophobic film on glass with self-cleaning and stability. Mater Lett 239:48–51. https://doi.org/10.1016/j.matlet.2018.12.059

Yoon H, Kim H, Latthe SS et al. (2015) A highly transparent self-cleaning superhydrophobic surface by organosilane-coated alumina particles deposited via electrospraying. J Mater Chem A Mater Energy Sustain 3:11403–11410. https://doi.org/10.1039/C5TA02226F

Xue C-H, Jia S-T, Zhang J, Ma J-Z (2010) Large-area fabrication of superhydrophobic surfaces for practical applications: an overview. Sci Technol Adv Mater 11:33002. https://doi.org/10.1088/1468-6996/11/3/033002

Simpson JT, Hunter SR, Aytug T (2015) Superhydrophobic materials and coatings: a review. Rep Prog Phys 78:086501. https://doi.org/10.1088/0034-4885/78/8/086501

Nguyen-Tri P, Tran HN, Plamondon CO et al. (2019) Recent progress in the preparation, properties and applications of superhydrophobic nano-based coatings and surfaces: a review. Prog Org Coat 132:235–256. https://doi.org/10.1016/j.porgcoat.2019.03.042

Meena MK, Sinhamahapatra A, Kumar A (2019) Superhydrophobic polymer composite coating on glass via spin coating technique. Colloid Polym Sci 297:1499–1505. https://doi.org/10.1007/s00396-019-04560-z

Kong X, Hu Y, Wang X, Pan W (2016) Effect of surface morphology on wettability conversion. J Adv Ceram 5:284–290. https://doi.org/10.1007/s40145-016-0201-5

Zhang Y, Dong B, Wang E et al. (2017) Mechanically robust, thermally stable, highly transparent superhydrophobic coating with low-temperature sol–gel process. RSC Adv 7:47357–47365. https://doi.org/10.1039/C7RA08578H

Xu L, He J (2012) Fabrication of highly transparent superhydrophobic coatings from hollow silica nanoparticles. Langmuir 28:7512–7518. https://doi.org/10.1021/la301420p

Kong X, Hu Y, Wang X, Pan W (2016) Effect of surface morphology on wettability conversion. J Adv Ceram 5:284–290. https://doi.org/10.1007/s40145-016-0201-5

Zhang C, Kalulu M, Sun S et al. (2019) Environmentally safe, durable and transparent superhydrophobic coating prepared by one-step spraying. Colloids Surf A Physicochem Eng Asp 570:147–155. https://doi.org/10.1016/j.colsurfa.2019.03.015

Pozzato A, Zilio SD, Fois G et al. (2006) Superhydrophobic surfaces fabricated by nanoimprint lithography. Microelectron Eng 83:884–888. https://doi.org/10.1016/j.mee.2006.01.012

Pratiwi N, Zulhadjri, Arief S, Wellia DV (2020) A facile preparation of transparent ultrahydrophobic glass via TiO2/octadecyltrichlorosilane (ODTS) coatings for self-cleaning material. ChemistrySelect 5:1450–1454. https://doi.org/10.1002/slct.201904153

Xu QC, Wellia DV, Amal R et al. (2010) Superhydrophilicity-assisted preparation of transparent and visible light activated N-doped titania film. Nanoscale 2:1122–1127. https://doi.org/10.1039/c005273f

Liu J, Zhu X, Zhang H et al. (2018) Superhydrophobic coating on quartz sand filter media for oily wastewater filtration. Colloids Surf A Physicochem Eng Asp 553:509–514. https://doi.org/10.1016/j.colsurfa.2018.06.007

Xu B, Cai Z (2008) Fabrication of a superhydrophobic ZnO nanorod array film on cotton fabrics via a wet chemical route and hydrophobic modification. Appl Surf Sci 254:5899–5904. https://doi.org/10.1016/j.apsusc.2008.03.160

Latthe SS, Demirel AL (2013) Polystyrene/octadecyltrichlorosilane superhydrophobic coatings with hierarchical morphology. Polym Chem 4:246–249. https://doi.org/10.1039/c2py20731a

Huang J-Y, Lai Y-K (2015) TiO2-based surfaces with special wettability—from nature to biomimetic application. In: Aliofkhazraei Y-KLE-M (ed) Wetting and wettability. IntechOpen, Rijeka, Ch. 3.

Wang R, Hashimoto K, Fujishima A et al. (1997) Light-induced amphiphilic surfaces. Nature 388:431–432. https://doi.org/10.1038/41233

Liu J, Zhu X, Zhang H et al. (2018) Superhydrophobic coating on quartz sand filter media for oily wastewater filtration. Colloids Surf A Physicochem Eng Asp 553:509–514. https://doi.org/10.1016/j.colsurfa.2018.06.007

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546–551. https://doi.org/10.1039/TF9444000546

Duta L, Popescu AC, Zgura I, et al. (2015) Wettability of nanostructured surfaces. In: Popescu AC (ed) Wetting and wettability. IntechOpen, Rijeka, Ch. 8.

Gao Z, Ma M, Zhai X et al. (2015) Improvement of chemical stability and durability of superhydrophobic wood surface via a film of TiO2 coated CaCO3 micro-/nano-composite particles. RSC Adv 5:63978–63984. https://doi.org/10.1039/C5RA04000K

Soleymani Eil Bakhtiyari S, Karbasi S, Monshi A (2015) Evaluation of the effects of nano-TiO2 on physical and mechanical properties of nano-bioglass 45S5 scaffold for bone tissue engineering. Sci Iran 22:1337–1345

Garai M, Sasmal N, Molla AR et al. (2014) Effects of nucleating agents on crystallization and microstructure of fluorophlogopite mica-containing glass-ceramics. J Mater Sci 49:1612–1623. https://doi.org/10.1007/s10853-013-7844-1

Lihitkar NB, Abyaneh MK, Samuel V et al. (2007) Titania nanoparticles synthesis in mesoporous molecular sieve MCM-41. J Colloid Interface Sci 314:310–316. https://doi.org/10.1016/j.jcis.2007.05.069

Li J, Zheng H, Sun Q et al. (2015) Fabrication of superhydrophobic bamboo timber based on an anatase TiO2 film for acid rain protection and flame retardancy. RSC Adv 5:62265–62272. https://doi.org/10.1039/C5RA09643J

Wellia DV, Mustaqimah A, Wulandari W et al. (2018) Fabrication of hydrophobic indonesia bamboo modified by octa fluoro 1-pentanol (OFP) based on TiO2 thin film for self-cleaning application. J Pure Appl Chem Res 7:149–159. https://doi.org/10.21776/ub.jpacr.2018.007.02.396

Li J, Lu Y, Wu Z et al. (2016) Durable, self-cleaning and superhydrophobic bamboo timber surfaces based on TiO2 films combined with fluoroalkylsilane. Ceram Int 42:9621–9629. https://doi.org/10.1016/j.ceramint.2016.03.047

Yao C, Yu J, Wang Y et al. (2018) Acidic pH weakens the bonding effectiveness of silane contained in universal adhesives. Dent Mater 34:809–818. https://doi.org/10.1016/j.dental.2018.02.004

Li Y, Li B, Zhao X et al. (2018) Totally waterborne, nonfluorinated, mechanically robust, and self-healing superhydrophobic coatings for actual anti-icing. ACS Appl Mater Interfaces 10:39391–39399. https://doi.org/10.1021/acsami.8b15061

Quan Y-Y, Zhang L-Z, Qi R-H, Cai R-R (2016) Self-cleaning of surfaces: the role of surface wettability and dust types. Sci Rep 6:38239. https://doi.org/10.1038/srep38239

Acknowledgements

Authors gratefully acknowledge Universitas Andalas for financial support (contract number: T/58/UN.16.17/PP.IS.KRP2GB/LPPM/2019).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pratiwi, N., Zulhadjri, Arief, S. et al. Self-cleaning material based on superhydrophobic coatings through an environmentally friendly sol–gel method. J Sol-Gel Sci Technol 96, 669–678 (2020). https://doi.org/10.1007/s10971-020-05389-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05389-7