Abstract

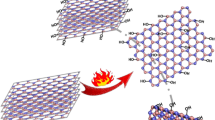

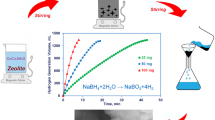

Boron carbide (B4C) and its in situ composites were synthesized via a simple bottom-up process using low-cost boric acid and a sucrose-based precursor solution with silicon (Si), titanium (Ti), or zirconium (Zr) species. The precursor solution was first dried at 250 °C and then heat-treated at 1650 °C for 90 min under argon and hydrogen gas flow. Free boron oxide phases appeared in the boric acid-rich precursor compositions, whereas free carbon appeared in the sucrose-rich compositions. The B4C particles exhibited a coarser and elongated morphology with boron-rich stoichiometric compositions (B/C:4/1), whereas the particles had a finer equiaxed morphology in carbon-rich compositions (B/C:2/1). As the carbon concentration increased in the precursor solution, the hexagonal lattice parameters of B4C and its corresponding lattice volume decreased. On the other hand, the addition of Si, Ti, or Zr species into the precursor solution resulted in the formation of a silicon carbide (SiC), a titanium diboride (TiB2), or a zirconium diboride (ZrB2) phase along with the B4C phase and was associated with an overall reduction in the average particle size and a more uniform size distribution. Moreover, the addition of these species increased the B4C lattice parameter with a corresponding increase in the lattice volume; this was most likely due to an elemental substitution into the B4C lattice. In addition, the data provide evidence that the formation of an ideal B4C lattice is possible when synthesized from carbon-rich precursors using this method, despite the potential presence of free carbon.

Highlights

-

Synthesis of pure B4C and in-situ composites of B4C–SiC, B4C–TiB2, and B4C–ZrB2 from organic–inorganic hybrid precursor.

-

Effects of C content and addition of Si, Ti, and Zr species on the morphology of different kinds of ceramic particles.

-

Obtainment of standard B4C structure (JCPDS #35-0798) in C-rich precursor.

-

The changes in lattice parameters of B4C depending on B/C ratio and Si, Ti, and Zr contents in precursor solution.

Similar content being viewed by others

References

Andrievski RA (2012) Micro- and nanosized boron carbide: synthesis, structure and properties. Russ Chem Rev 81:549–559

Suri AK, Subramanian C, Sonber JK, Murthy TSRC (2010) Synthesis and consolidation of boron carbide: a review. Int Mater Rev 55:4–40

Thévenot F (1990) Boron carbide—a comprehensive review. J Eur Ceram Soc 6:205–225

Natan B, Netzer DW (1996) Boron carbide combustion in solid-fuel ramjets using bypass air. Part I: Experimental investigation. Propellants Explos Pyrotech 21:289–294

Wood C (1988) Materials for thermoelectric energy conversion. Rep Prog Phys 51:459

Iwagami T, Ishikawa Y, Koshizaki N, Yamamoto N, Tanaka H, Masunaga S, Sakurai Y, Kato I, Iwai S, Suzuki M, Yura Y (2014) Boron carbide particle as a boron compound for boron neutron capture therapy. J Nucl Med Radiat Ther 5:2

Singh P, Singh B, Kumar M, Kumar A (2014) One step reduction of boric acid to boron carbide nanoparticles. Ceram Int 40:15331–15334

Matsumoto A, Goto T, Kawakami A (2004) Slip casting and pressureless sintering of boron carbide and its application to the nuclear field. J Ceram Soc Jpn Supplement 112:S399–S402

Bose DK, Nair KU, Gupta CK (1986) Production of high purity boron carbide. High Temp Mater Process 7:133–140

Goller G, Toy C, Tekin A, Gupta CK (1996) The production of boron carbide by carbothermic reduction. High Temp Mater Process 15:117–122

Alizadeh A, Taheri-Nassaj E, Ehsani N, Baharvandi HR (2013) Production of boron carbide powder by carbothermic reduction from boron oxide and petroleum coke or carbon active. Adv Appl Ceram 105:291–296

Yaghoubi M, Torabi O (2014) Effect of the magnesium content on the mechanochemical behavior in ternary system Mg–B2O3–C. Int J Refract Met Hard Mater 43:132–140

Berchmans LJ, Mani V, Amalajyothi K (2009) Synthesis of boron carbide by calciothermic reduction process. Int J Self-Propag High-Temp Synth 18:60–63

Deng F, Xie HY, Wang L (2006) Synthesis of submicron B4C by mechanochemical method. Mater Lett 60:1771–1773

Sinha A, Mahata T, Sharma BP (2002) Carbothermal route for preparation of boron carbide powder from boric acid–citric acid gel precursor. J Nucl Mater 301:165–169

Yamada K (1996) Boron carbide particles formed from an amorphous boron/graphite powder mixture using a shock-wave technique. J Am Ceram Soc 79:1113–1116

MacKinnon IM, Reuben BG (1975) The synthesis of boron carbide in an RF plasma. J Electrochem Soc 122:806–811

Knudsen AK (1997) Laser processes. In: Weimer AW (ed.) Carbide, nitride and boride materials synthesis and processing. Chapman & Hall, London

Shi L, Gu Y, Chen L, Qian Y, Yang Z, Ma J (2003) A low temperature synthesis of crystalline B4C ultrafine powders. Solid State Commun 128:5–7

Ronning C, Schwen D, Eyhusen S, Vetter U, Hofsass H (2002) Ion beam synthesis of boron carbide thin films. Surf Coat Technol 158-159:382–387

Ozcelik B, Ergun C (2016) Synthesis of boron carbide nanoparticles via spray pyrolysis. J Mater Res 31:2789–2803

Maqbool M, Zahid GH, Ahmad E, Asghar Z, Subhani T, Shahzad M, Kaleem I (2015) Effect of saccharides as carbon source on the synthesis and morphology of B4C fine particles from carbothermal synthesis precursors. Mater Express 5:390–400

Ahmed YMZ, El-Sheikh SM, Ewais EMM, Abd-Allah AA, Sayed SA (2017) Controlling the morphology and oxidation resistance of boron carbide synthesized via carbothermic reduction reaction. J Mater Eng Perform 26:1444–1454

Rafiuddin, Zahid GH, Ahmad E, Maqbool M, Subhani T, Syed WA, Hussain SZ (2015) Effect of cellulose-derived structural homogeneity of precursor on the synthesis and morphology of boron carbide. J Inorg Organomet Polym Mater 25:995–999

Weimer AW, Moore WG, Roach RP, Hitt JE, Dixit RS, Pratsinis SE (1992) Kinetics of carbothermal reduction synthesis of boron carbide. J Am Ceram Soc 75:2509–2514

Pilladi TR, Ananthasivan K, Anthonysamy S, Ganesan V (2012) Synthesis of nanocrystalline boron carbide from boric acid–sucrose gel precursor. J Mater Sci 47:1710–1718

Kakiage M, Tominaga Y, Yanase I, Kobayashi H (2012) Synthesis of boron carbide powder in relation to composition and structural homogeneity of precursor using condensed boric acid–polyol product. Powder Technol 221:257–263

Tahara N, Kakiage M, Yanase I, Kobayashi H (2013) Effect of addition of tartaric acid on synthesis of boron carbide powder from condensed boric acid–glycerin product. J Alloy Compd 573:58–64

Mondal S, Banthia AK (2005) Low-temperature synthetic route for boron carbide. J Eur Ceram Soc 25:287–291

Najafi A, Golestani-Fard F, Rezaie HR, Ehsani N (2011) Effect of APC addition on precursors properties during synthesis of B4C nano powder by a sol–gel process. J Alloy Compd 509:9164–9170

Cihangir S, Ergun C, Yılmaz S, Sahin FC (2009) Synthesis of B4C/SiC composite from sugar based precursor. Defect Diffus Forum 283–286:268–272

C. Ergun, S. Yilmaz (2009) Boron carbide production method. WO 2009/070131 A2

Cakir E, Ergun C, Sahin FC, Erden I (2010) In situ synthesis of B4C/TiB2 composites from low cost sugar based precursor. Defect Diffus Forum 297–301:52–56

Ji W, Rehman SS, Wang W, Wang H, Wang Y, Zhang J, Zhang F, Fu Z (2015) Sintering boron carbide ceramics without grain growth by plastic deformation as the dominant densification mechanism. Sci Rep 5(15827):1–8

Kuzenkova M, Kislyi P, Grabchuk BL, Bodnaruk NI (1979) The structure and properties of sintered boron carbide. J Less Common Met 67:217–223

Dole SL, Prochazka S, Doremus RH (1989) Microstructural coarsening during sintering of boron carbide. J Am Ceram Soc 72:958–966

Fanchini G, McCauley JW, Chhowalla M (2006) Behavior of disordered boron carbide under stress. Phys Rev Lett 97:035502

Domnich V, Reynaud S, Haber RA, Chhowalla M (2011) Boron carbide: structure, properties, and stability under stress. J Am Ceram Soc 94:3605–3628

Subhash G, Awasthi AP, Kunka C, Jannotti P, DeVries M (2016) In search of amorphization-resistant boron carbide. Scr Mater 123:158–162

Speyer RF, Lee H (2004) Advances in pressureless densification of boron carbide. J Mater Sci 39:6017–6021

Cho N, Silver KG, Berta Y, Speyer RF, Vanier N, Hung CH (2011) Densification of carbon-rich boron carbide nanopowder compacts. J Mater Res 22:1354–1359

Lee H, Speyer RF (2003) Pressureless sintering of boron carbide. J Am Ceram Soc 86:1468–1473

Zorzi JE, Perottoni CA, da Jornada JAH (2005) Hardness and wear resistance of B4C ceramics prepared with several additives. Mater Lett 59:2932–2935

Levin L, Frage N, Dariel MP (1999) The effect of Ti and TiO2 additions on the pressureless sintering of B4C. Met Mater Trans A 30:3201–3210

Skorokhod V, Vlajic MD, Krstic VD (1996) Mechanical properties of pressureless sintered boron carbide containing TiB2 phase. J Mater Sci Lett 15:1337–1339

Baharvandi HR, Hadian AM (2007) Pressureless sintering of TiB2-B4C ceramic matrix composite. J Mater Eng Perform 17:838–841

Oh JH, Orr KK, Lee CK, Kim DK, Lee JK, Kim CH (1985) A study for the sintering of boron carbide J Korean Ceram Soc 22:60–66

Subramanian C, Roy TK, Murthy TSRC, Sengupta P, Kale GB, Krishnaiah MV, Suri AK (2008) Effect of zirconia addition on pressureless sintering of boron carbide. Ceram Int 34:1543–1549

Baharvandi HR, Hadian AM, Abdizade H, Ehsani N (2006) Investigation on addition of talc on sintering behavior and mechanical properties of B4C. J Mater Eng Perform 15:280–283

Goldstein A, Yeshurun Y, Goldenberg A (2007) B4C/metal boride composites derived from B4C/metal oxide mixtures. J Eur Ceram Soc 27:695–700

Lee CH, Kim CH (1992) Pressureless sintering and related reaction phenomena of Al2O3-doped B4C. J Mater Sci 27:6335–6340

Sigl LS (1998) Processing and mechanical properties of boron carbide sintered with TiC. J Eur Ceram Soc 18:1521–1529

Prochazka S (1977) Dense sintered boron carbide containing beryllium carbide, U.S. Patent 4,005,235

Weaver GQ (1982) Sintered high density boron carbide, U.S. Patent 4,320,204

Yamada S, Hirao K, Yamauchi Y, Kanzaki S (2002) Sintering behavior of B4C–CrB2 ceramics. J Mater Sci Lett 21:1445–1447

Zakhariev Z, Radev D (1988) Properties of polycrystalline boron carbide sintered in the presence of W2B5 without pressing. J Mater Sci Lett 7:695–696

Kanno Y, Kawase K, Nakano K (1987) Additive effect on sintering of boron carbide. J Ceram Assoc, Jpn 95:1137–1140

Li X, Jiang D, Zhang J, Lin Q, Chen Z, Huang Z (2014) Pressureless sintering of boron carbide with Cr3C2 as sintering additive. J Eur Ceram Soc 34:1073–1081

Yamada S, Hirao K, Yamauchi Y, Kanzaki S (2002) Densification behaviour and mechanical properties of pressureless-sintered B4C–CrB2 ceramics. J Mater Sci 37:5007–5012

Zhang C, Ru H, Wang W, Yue X, Zhao J, Bordia R (2014) The role of infiltration temperature in the reaction bonding of boron carbide by silicon infiltration J Am Ceram Soc 97:3286–3293

Neuman EW, Hilmas GE, Fahrenholtz WG, Cinibulk M (2016) Ultra-high temperature mechanical properties of a zirconium diboride-zirconium carbide ceramic. J Am Ceram Soc 99:597–603

Mashhadi M, Taheri-Nassaj E, Sglavo VM (2010) Pressureless sintering of boron carbide. Ceram Int 36:151–159

Du X, Zhang Z, Wang Y, Wang J, Wang W, Wang H, Fu Z, Jayaram V (2015) Hot-pressing kinetics and densification mechanisms of boron carbide. J Am Ceram Soc 98:1400–1406

Wang D, Ran S, Shen L, Sun H, Huang Q (2015) Fast synthesis of B4C–TiB2 composite powders by pulsed electric current heating TiC–B mixture. J Eur Ceram Soc 35:1107–1112

Sonber JK, Murthy TSRC, Subramanian C, Kumar S, Fotedar RK, Suri AK (2011) Investigations on synthesis of ZrB2 and development of new composites with HfB2 and TiSi2. Int J Refract Met Hard Mater 29:21–30

Cao YN, Du S, Wang JK, Zhang H, Li FL, Lu LL, Zhang SW, Deng XG (2014) Preparation of zirconium diboride ultrafine hollow spheres by a combined sol–gel and boro/carbothermal reduction technique. J Sol-Gel Sci Technol 72:130–136

Guo S (2016) Reactive hot-pressed hybrid ceramic composites comprising SiC(SCS-6)/Ti composite and ZrB2-ZrC Ceramic. J Am Ceram Soc 99:3241–3250

Singh M (1996) Thermodynamic analysis for the combustion synthesis of SiC-B4C composites. Scr Mater 34:923–927

Yao S, Gao Q, Widom M (2017) Phase diagram of boron carbide with variable carbon composition. Phys Rev B: Condens Matter 95(0541001):1–6

Goswami R, Qadri SB, Wollmershauser J, Kolel-Veetil MK, Feygelson B (2017) Pressure- and additive-mediated sintering of B4C at relatively low temperatures. Met Mater Trans A 48:1230–1235

An Q, Goddard WA (2014) Microalloying boron carbide with silicon to achieve dramatically improved ductility. J Phys Chem Lett 5:4169–4174

Kolel-Veetil MK, Gamache RM, Bernstein N, Goswami R, Qadri SB, Fears KP, Miller JB, Glaser ER, Keller TM (2015) Substitution of silicon within the rhombohedral boron carbide (B4C) crystal lattice through high-energy ball-milling. J Mater Chem C Mater 3:11705–11716

Kobayashi T, Yoshida K, Yano T (2013) Effects of heat-treatment temperature and starting composition on morphology of boron carbide particles synthesized by carbothermal reduction. Ceram Int 39:597–603

Radev D, Avramova I, Kovacheva D, Gautam D, Radev I (2016) Synthesis of boron carbide by reactive-pulsed electric current sintering in the presence of tungsten boride. Int J Appl Ceram Tec 13:997–1007

Cheng C, Reddy KM, Hirata A, Fujita T, Chen M (2017) Structure and mechanical properties of boron-rich boron carbides. J Eur Ceram Soc 37:4514–4523

Ergun C (2008) Effect of Ti ion substitution on the structure of hydroxylapatite. J Eur Ceram Soc 28:2137–2149

Saha J, Bhowmik K, Das I, De G (2014) Pd-Ni alloy nanoparticle doped mesoporous SiO2 film: the sacrificial role of Ni to resist Pd-oxidation in the C–C coupling reaction. Dalton Trans 43:13325–13332

Najafi A, Fard FG, Rezaie HR, Ehsani N (2012) Synthesis and characterization of SiC nano powder with low residual carbon processed by sol–gel method. Powder Technol 219:202–210

Soraru GD, Dallabona N, Gervais C, Babonneau F (1999) Organically modified SiO2−B2O3 gels displaying a high content of borosiloxane (B−O−Si) Bonds. Chem Mater 11:910–919

Ji G, Ji H, Li M, Li X, Sun X (2013) Synthesis of zirconium diboride nano-powders by novel complex sol–gel technology at low temperature. J Sol–Gel Sci Technol 69:114–119

Gao Y, Etzold A, Munhollon T, Rafaniello W, Haber R (2016) Processing factors influencing the free carbon contents in boron carbide powder by rapid carbothermal reduction. Diam Relat Mater 61:14–20

Watts JL, Talbot PC, Alarco JA, Mackinnon IDR (2015) In-situ carbon control in the preparation of precursors to boron carbide by a non-aqueous solution technique. J Mater Sci Eng A 5:8–20

Mauri F, Vast N, Pickard CJ (2001) Atomic structure of icosahedral B4C boron carbide from a first principles analysis of NMR spectra. Phys Rev Lett 87:085506

Khan AU, Domnich V, Haber RA (2017) Boron carbide-based armors: problems and possible solutions. Am Ceram Soc Bull 96:30–35

Shirai K, Sakuma K, Uemura N (2014) Theoretical study of the structure of boron carbide B13C2. Phys Rev B: Condens Matter 90:064109

Shirai K, Katayama-Yoshida H (2000) Effects of the geometries of boron-rich crystals on the lattice dynamics. J Solid State Chem 154:20–25

An Q, Goddard WA (2017) Improved Ductility of B12 Icosahedra-based superhard materials through icosahedral slip. J Phys Chem C 121:11831–11838

Telle R (1990) Structure and properties of Si-doped boron carbide. In: Freer R (ed) The physics and chemistry of carbides, nitrides and borides. Springer, Netherlands, Dordrecht

Kovziridze ZD, Mestvirishvili Z, Tabatadze G, Nizharadze NS, Mshvildadze M, Nikoleishvili E (2013) Improvement of boron carbide mechanical properties in B4C-TiB2 and B4C-ZrB2 systems J Electron Cool Therm Control 03:43–48

Acknowledgements

This work was supported by the Research Project Department of Istanbul Technical University [Grant no. 39372].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Parlakyigit, A.S., Ergun, C. In situ synthesis of B4C–SiC, B4C–TiB2, and B4C–ZrB2 composites from organic–inorganic hybrid precursor via a simple bottom-up approach. J Sol-Gel Sci Technol 92, 745–759 (2019). https://doi.org/10.1007/s10971-019-05143-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05143-8