Abstract

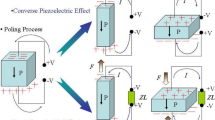

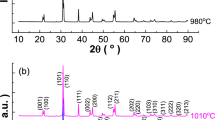

In this work, barium titanate thick films are produced at low-temperature using a modified sol–gel/ceramic powder technology named the composite route. In this process, a commercial BaTiO3 powder, doped or not by Li2O as sintering aid, is mixed with a stabilized titanium (IV) isopropoxide/barium acetate sol to obtain a composite ink. Two sols, using different solvents and chelating agents, are tested. Characterization of the evolution of theses sols with an increase in temperature is realized by thermal analyses (TGA and DTA) and X-ray diffraction. The four type of inks obtained are screen-printed on metallized alumina substrates and sintered. Microstructures and electrical properties of the sintered composite films are compared to those processed from a conventional ink obtained by dispersing the barium titanate powder in an organic vehicle. Measurements of dielectric/piezoelectric properties highlight higher charge coefficients d33 for composite thick films (69 vs. 45 pC/N for conventional thick films at close thickness values) despite a lower relative permittivity (340 vs. 658) certainly due to the presence of a single domain BaTiO3 nano-crystallites.

Highlights

-

BaTiO3 thick films are produced at low-temperature using a composite sol–gel/powder technology.

-

Composite thick films lead to higher d33 by comparison to conventional ones.

-

The relative permittivity of all composite thick films is lower than the conventional ones.

Similar content being viewed by others

References

Schroth A, Lee L, Matsumoto S, Maeda R (1999) Application of sol gel deposited thin PZT film for actuation of 1D and 2D scanners. Sens Actuator 73:144–152

Chu J, Wang ZJ, Maeda R, Kataota K, Itih T, Suga T (2000) Novel multi-bridge structured piezoelectric microdevices for scanning force microscopy. J Vac Sci Technol B 18:3604–3607

Setter N (2001) Electroceramics: looking ahead. J Eur Ceram Soc 21:1279–1293

Walter V, Delobelle P, Le Moal P, Joseph E, Collet M (2002) A piezo-mechanical characterization of PZT thick films screen-printed on alumina substrate. Sens Actuator A 96:157–166

Dorey RA, Rocks SA, Dauchy F, Wang D, Bortolani F, Hugo E (2008) Integrating functional ceramics into microsystems. J Eur Ceram Soc 28:1397–1403

Yao K, He X, Xu Y, Chen M (2005) Screen-printed piezoelectric ceramic thick films with sintering additives introduced through a liquid-phase approach. Sens Actuator A 118:342–348

Dorey RA, Stringfellow SB, Whatmore RW (2002) Effect of sintering aid and repeated sol infiltrations on the dielectric and piezoelectric properties of a PZT composite thick film. J Eur Ceram Soc 22:2921–2926

Zhang H, Jiang S (2009) Effect of repeated composite sol infiltrations on the dielectric and piezoelectric properties of a Bi0.5(Na0.82K0.18)0.5TiO3 lead free thick film. J Eur Ceram Soc 29:717–723

Kim SH, Koo CY, Lee J, Jiang W, Kingon AI (2011) Enhanced dielectric and piezoelectric properties of low-temperature processed Pb(Zr,Ti)O3 thick films prepared by hybrid deposition technique with chemical solution infiltration process. Mater Lett 65:3041–3043

Corker DL, Zhang Q, Whatmore RW, Perrin C (2002) PZT “composite” ferroelectric thick films. J Eur Ceram Soc 22:383–390

Directive 2011/65/EU of European Parliament and of the Council of 8 June 2011 on restriction of the use of certain hazardous substances in electrical and electronic equipment. Off J Eur Union 174:88–110

Trelcat JF, Courtois C, Rguiti M, Leriche A, Duvigneaud PH, Segato T (2012) Morphotropic phase boundary in the BNT-BT-BKT system. Ceram Int 38:2823–2827

Rödela J, Webbera KG, Dittmera R, Job W, Kimurac M, Damjanovic D (2015) Transferring lead-free piezoelectric ceramics into application. J Eur Ceram Soc 35:1659–1681

Zhang M, Wang H, Yang H, Wu X, Liu W, Yao X (2011) Dielectric properties of low-temperature sintered Ba0.6Sr0.4TiO3 thick films prepared by reactive sintering method. J Alloy Compd 509:344–347

Tick T, Peräntie J, Jantunen H, Uusimäki A (2008) Screen printed low-sintering-temperature barium strontium titanate (BST) thick films. J Eur Ceram Soc 28:837–842

Giridharan NV, Jayavel R (2002) Fabrication of ferroelectric (Pb,Ba)TiO3 thin films by sol–gel technique and their characterization. Mater Lett 52:57–61

Yang WD, Haile SM (2006) Influences of water content on synthesis of (Pb0.5,Ba0.5)TiO3 materials using acetylacetone as chelating agent in a sol–gel process. J Eur Ceram Soc 26:3203–3210

Valant M, Suvorov D, Pullar RC, Sarma K, Alford NM (2006) A mechanism for low-temperature sintering. J Eur Ceram Soc 26:2777–2783

Mosqueda HA, Vazquez C, Bosch P, Pfeiffer H (2006) Chemical sorption of carbon dioxide (CO2) on lithium oxide (Li2O). Chem Mater 18(9):2307–2310

Yoon DH, Zhang J, Lee BI (2003) Dielectric constant and mixing model of BaTiO3 composite thick films. Mater Res Bull 38:765–772

Bernaben N, Leriche A, Thierry B, Niepce JC, Waser R (1995) Fourth Conference of the European Ceramic Society. Gruppo Editoriale Faenza Editrice. pp 203–210

Maglia F, Tredici IG, Anselmi-Tamburini U (2013) Densification and properties of bulk nanocrystalline functional ceramics with grain size below 50 nm. J Eur Ceram Soc 33:1045–1066

Arlt G, Hennings D, De With G (1985) Dielectric properties of fine-grained barium titanate ceramics. J Appl Phys 58(4):1619–1625

Funding

This work is supported by European Union (FEDER) and Wallonie (Projet Revêtements Fonctionnels—LASESURF B).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Trelcat, JF., Basile, N., Gonon, M. et al. Sintering of BaTiO3 powder/sol composite thick films and their dielectric and piezoelectric properties. J Sol-Gel Sci Technol 93, 657–665 (2020). https://doi.org/10.1007/s10971-019-05123-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05123-y