Abstract

Silicon-based preceramic polymers are an important type of precursor used in the processing of novel polymer-derived ceramics (PDCs), which includes the cross-linking and pyrolysis of the precursor. An integral study of physicochemical and rheological properties of a silicon-based preceramic regarding the variables that control the crosslinking and the characterization pyrolyzed material were accomplished. The precursor synthetized by the sol–gel method was characterized by density measurement, SEC, ATR-FTIR, NMR, and DSC. Flow properties in function of temperature and time, and viscoelastic properties as a function of deformation, frequency, temperature and time were studied by rotational and oscillatory testing, respectively. Also, the crosslinking process in the presence of a catalyst was studied by ATR-FTIR and dynamic tests. The phases generated at high temperature were characterized by XRD, Raman spectroscopy, and EDS. The results indicate that the studied precursor could be considered as a preceramic polymer for developing SiOC-based PDCs.

Similar content being viewed by others

References

Riedel R, Mera G, Hauser R, Klonczynski A (2006) Silicon-based polymer-derived ceramics: synthesis properties and applications—a review. J Ceram Soc Japan 114:425–444

Colombo P, Mera G, Riedel R, Sorarù GD (2010) Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. J Am Ceram Soc 93:1805–1837

Colombo P, Riedel R, Sorarù GD, Kleebe H-J (2010) Polymer derived ceramics: from nano-structures to applications. DEStech Publications Inc., Lancaster

Vakifahmetoglu C, Zeydanli D, Colombo P (2016) Porous polymer derived ceramics. Mater Sci Eng: R Rep 106:1–30

Mera G, Navrotsky A, Sen S et al. (2013) Polymer-derived SiCN and SiOC ceramics—structure and energetics at the nanoscale. J Mater Chem A 1:3826–3836

Ionescu E (2012) Polymer-derived ceramics. In: Riedel R, Chen I-W (eds) Ceramics Science and Technology. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, pp 457–500

Li J, Lu K, Lin T, Shen F (2015) Preparation of micro-/mesoporous SiOC bulk ceramics. J Am Ceram Soc 98:1753–1761

Sorarù GD, D’Andrea G, Campostrini R et al. (1995) Structural characterization and high-temperature behavior of silicon oxycarbide glasses prepared from sol–gel precursors containing Si–H bonds. J Am Ceram Soc 78:379–387

Bernardo E, Fiocco L, Parcianello G et al. (2014) Advanced ceramics from preceramic polymers modified at the nano-scale: a review. Materials 7:1927–1956

Colombo P, Bernardo E, Parcianello G (2013) Multifunctional advanced ceramics from preceramic polymers and nano-sized active fillers. J Eur Ceram Soc 33:453–469

Kaur S, Riedel R, Ionescu E (2014) Pressureless fabrication of dense monolithic SiC ceramics from a polycarbosilane. J Eur Ceram Soc 34:3571–3578

Hossain SS, Sarkar S, Oraon NK, Ranjan A (2016) Pre-ceramic polymer-derived open/closed cell silicon carbide foam: microstructure, phase evaluation, and thermal properties. J Mater Sci 51:9865–9878

Mantzel N, Schröckert F, Bucharsky EC et al. (2018) Reduction of the sintering temperature for the manufacturing of carbon-rich dense SiOC bulk ceramics. Adv Eng Mater 20:1800369

Zhao Z, Niu M, Wang H et al. (2019) Preparation and the effects of ion irradiation on bulk SiOC ceramics. J Eur Ceram Soc 39:832–837

Su D, Li Y-L, An H-J et al. (2010) Pyrolytic transformation of liquid precursors to shaped bulk ceramics. J Eur Ceram Soc 30:1503–1511

Li X, Pei X, Zhong X et al. (2019) Highly effective free-radical-catalyzed curing of hyperbranched polycarbosilane for near stoichiometric SiC ceramics. J Am Ceram Soc 102:1041–1048

Konegger T, Williams LF, Bordia RK (2015) Planar, polysilazane-derived porous ceramic supports for membrane and catalysis applications. J Am Ceram Soc 98:3047–3053

Janakiraman N, Aldinger F (2009) Fabrication and characterization of fully dense Si–C–N ceramics from a poly(ureamethylvinyl)silazane precursor. J Eur Ceram Soc 29:163–173

Jiang T, Hill A, Fei W et al. (2010) Making bulk ceramics from polymeric precursors. J Am Ceram Soc 93:3017–3019

Balan C, Riedel R (2006) Rheological investigations of a polymeric precursor for ceramic materials: experiments and theoretical modeling. J Optoelectron Adv Mater 8:561–567

Balan C, Völger KW, Kroke E, Riedel R (2000) Viscoelastic properties of novel silicon carbodiimide gels. Macromolecules 33:3404–3408

Harshe R, Balan C, Riedel R (2004) Amorphous Si(Al)OC ceramic from polysiloxanes: bulk ceramic processing, crystallization behavior and applications. J Eur Ceram Soc 24:3471–3482

Reschke V, Bordia RK, Scheffler F, Scheffler M (2015) Rheology and crosslinking of a low-viscosity SiOC preceramic polymer. Ceram Int 42:7620–7625

Winter HH, Chambon F (1986) Analysis of linear viscoelasticity of a crosslinking polymer at the gel point. J Rheol 30:367–382

Kickelbick G (2007) Introduction to hybrid materials. In: Hybrid materials. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, pp. 1–48

Wallace WE, Guttman CM, Antonucci JM (2000) Polymeric silsesquioxanes: degree-of-intramolecular-condensation measured by mass spectrometry. Polymer 41:2219–2226

Eisenberg P, Erra-Balsells R, Ishikawa Y et al. (2002) Silsesquioxanes derived from the bulk polycondensation of [3-(Methacryloxy)propyl]trimethoxysilane with concentrated formic acid: evolution of molar mass distributions and fraction of intramolecular cycles. Macromolecules 35:1160–1174

Bautista Y, Gozalbo A, Mestre S et al. (2017) Improvement in char strength with an open cage silsesquioxane flame retardant. Materials (Basel) 10:1–14

Innocenzi P, Brusatin G, Licoccia S et al. (2003) Controlling the thermal polymerization process of hybrid organic−inorganic films synthesized from 3-Methacryloxypropyltrimethoxysilane and 3-Aminopropyltriethoxysilane. Chem Mater 15:4790–4797

El hadad A, Carbonell D, Barranco V et al. (2011) Preparation of sol–gel hybrid materials from γ-methacryloxypropyltrimethoxysilane and tetramethyl orthosilicate: study of the hydrolysis and condensation reactions. Colloid Polym Sci 289:1875–1883

Nishiyama N, Horie K, Asakura T (1987) Hydrolysis and condensation mechanisms of a silane coupling agent studied by 13C and 29Si NMR. J Appl Polym Sci 34:1619–1630

Peng J, Xu K, Cai H et al. (2014) Can an intact and crystalline octakis(methacryloxypropyl) silsesquioxane be prepared by hydrolysis-condensation of a trimethoxysilane precursor? RSC Adv 4:7124–7131

Gualandris V, Hourlier-Bahloul D, Babonneau F (1999) Structural investigation of the first stages of pyrolysis of Si-C-O preceramic polymers containing Si-H bonds. J Sol–Gel Sci Technol 14:39–48

Fanovich MA, Pellice SA, Galliano PG, Williams RJJ (2002) Organic/inorganic hybrid materials based on silsesquioxanes derived from (3-Methacryloxypropyl) trimethoxysilane and their blends with vinylester resins. J Sol–Gel Sci Technol 23:45–52

Mezger T (2006) The rheology handbook: for users of rotational and oscillatory rheometers, 2nd ed. Vincentz Network, Hannover

Ferry JD (1980) Viscoelastic properties of polymers, 3rd ed. John Wiley & Sons, Inc, New York, NY

Macosko CW (1994) Rheology: principles easurements, and applications. Wiley-VCH, New York, NY

Kobayashi K, Huang C, Lodge TP (1999) Thermoreversible gelation of aqueous methylcellulose solutions. Macromolecules 32:7070–7077

Young RJ, Lovell PA (2011) Introduction to polymers, Third Edition. CRC Press, Boca Raton

Vakifahmetoglu C, Pippel E, Woltersdorf J, Colombo P (2010) Growth of one-dimensional nanostructures in porous polymer-derived ceramics by catalyst-assisted pyrolysis. Part I: Iron catalyst. J Am Ceram Soc 93:959–968

Vakifahmetoglu C, Colombo P, Carturan SM et al. (2010) Growth of one-dimensional nanostructures in porous polymer-derived ceramics by catalyst-assisted pyrolysis. Part II: cobalt catalyst. J Am Ceram Soc 93:3709–3719

Siddiqi SA, Hendry A (1985) The influence of iron on the preparation of silicon nitride from silica. J Mater Sci 20:3230–3238

Weimer AW, Eisman GA, Susnitzky DW et al. (1997) Mechanism and kinetics of the carbothermal nitridation synthesis of α-silicon nitride. J Am Ceram Soc 80:2853–2863

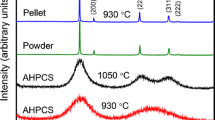

Bois L, Maquet J, Babonneau F, Bahloul D (1995) Structural characterization of sol-gel derived oxycarbide glasses. 2. Study of the thermal stability of the silicon oxycarbide phase. Chem Mater 7:975–981

Seo WS, Koumoto K (1996) Stacking faults in β-SiC formed during carbothermal reduction of SiO2. J. Am. Ceram. Soc. 79:1777–1782

Pujar VV, Cawley JD (2001) Computer simulations of diffraction effects due to stacking faults in β-SiC: II, experimental verification. J Am Ceram Soc 84:2645–2651

Martin H-P, Müller E, Irmer G, Babonneau F (1997) Crystallisation behaviour and polytype transformation of polymer-derived silicon carbide. J Eur Ceram Soc 17:659–666

Ferrari AC, Robertson J (2004) Raman spectroscopy of amorphous, nanostructured, diamond-like carbon, and nanodiamond. Philos Trans A Math Phys Eng Sci 362:2477–2512

Acknowledgements

The authors gratefully acknowledge Dr. M. Valiente Malmagro (Research Group of Separation Techniques in Chemistry, UAB, Barcelona, Spain) for accomplishing the 1H, 13C, 29Si NMR tests used in this work. This study was funded by the National Scientific and Technical Research Council, CONICET, Argentina (PIP 0128), and the National Agency of Scientific and Technological Promotion, ANPCyT, Argentina (PICT 2790).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rivera, J.O.B., Talou, M.H., Hung Hung, Y.M.X. et al. Study of a silicon-based preceramic for the processing of polymer-derived ceramics. J Sol-Gel Sci Technol 91, 446–460 (2019). https://doi.org/10.1007/s10971-019-05051-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05051-x