Abstract

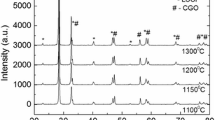

La0.6Sr0.4Co0.2Fe0.8O3-δ (LSCF) is a perovskite-type oxide that exhibits excellent mixed ionic–electronic conducting properties and is a suitable cathode material for intermediate temperature solid oxide fuel cells. This study investigates the microstructural, optical, mechanical, and electrical properties of an LSCF–samarium-doped ceria (SDC) composite cathode. LSCF–SDC composite cathode powders were prepared by mixing 50 wt% SDC electrolyte with LSCF cathode powders obtained by the rotary evaporation technique. The band gap of the prepared powders was determined via diffuse reflectance UV–visible spectroscopy. The chemical composition, mechanical properties, and electrochemical properties of the sintered pellets were characterized using Raman spectroscopy, Vickers hardness, and impedance spectroscopy, respectively. X-ray diffraction and Rietveld analysis showed that phase purity was only 96%. Moreover, a small fraction of tetragonal phase impurity was observed on the LSCF powders. Impurities significantly affected the phase stability and microstructure of the LSCF–SDC composite cathode. The addition of the SDC electrolyte enhanced the densification of the composite cathode, thereby improving mechanical properties. However, the addition of SDC exerted different effects on the DC electrical conductivity and area-specific resistance (ASR) of the composite cathode. At 800 °C, the ASR value of the LSCF was only 2% that of the LSCF–SDC composite cathode. Overall, the electrical properties of the LSCF–SDC composite cathode are closely related to the crystal structure, purity, and microstructure of LSCF cathode powders.

Similar content being viewed by others

References

Mahmud LS, Muchtar A, Somalu MR (2017) Challenges in fabricating planar solid oxide fuel cells: a review. Renew Sustain Energy Rev 72:105–116

Orera VM, Laguna-Bercero MA, Larrea A (2014) Fabrication methods and performance in fuel cell and steam electrolysis operation modes of small tubular solid oxide fuel cells: a review. Front Energy Res 2:1–13

Hussain AM, Pan K-J, Robinson IA et al. (2016) Stannate-based ceramic oxide as anode materials for oxide-ion conducting low-temperature solid oxide fuel cells. J Electrochem Soc 163:F1198–F1205

Szymczewska D, Karczewski J, Chrzan A, Jasinski P (2017) CGO as a barrier layer between LSCF electrodes and YSZ electrolyte fabricated by spray pyrolysis for solid oxide fuel cells. Solid State Ion 302:113–117

Sun C, Hui R, Roller J (2010) Cathode materials for solid oxide fuel cells: a review. J Solid State Electrochem 14:1125–1144

Jamale AP, Jadhav ST, Dubal SU et al. (2015) Studies on the percolation limit of Ce0.9Gd0.1O1.95 in La0.6Sr0.4Co0.2Fe0.8O3–δ–Ce0.9Gd0.1O1.95 nanocomposites for solid oxide fuel cells application. J Phys Chem Solids 85:96–101

Dutta A, Mukhopadhyay J, Basu RN (2009) Combustion synthesis and characterization of LSCF-based materials as cathode of intermediate temperature solid oxide fuel cells. J Eur Ceram Soc 29:2003–2011

Xu Q, Huang Dping, Zhang F et al. (2008) Structure, electrical conducting and thermal expansion properties of La0.6Sr0.4Co0.8Fe0.2O3-δ-Ce0.8Sm0.2O2-δ composite cathodes. J Alloy Compd 454:460–465

Liu J, Co AC, Paulson S, Birss VI (2006) Oxygen reduction at sol–gel derived La0.8Sr0.2Co0.8Fe0.2O3 cathodes. Solid State Ion 177:377–387

Baharuddin NA, Muchtar A, Somalu MR, Seyednezhad M (2017) Influence of mixing time on the purity and physical properties of SrFe0.5Ti0.5O3-δ powders produced by solution combustion. Powder Technol 313:382–388

Asadi AA, Behrouzifar A, Iravaninia M et al. (2012) Preparation and oxygen permeation of LSCF perovskite-type membranes: experimental study and mathematical modeling. Ind Eng Chem Res 51:3069–3080

Choe Y-J, Lee K-J, Hwang H-J (2016) Cr poisoning on Nd2Ni0.95Cu0.05O4+δ cathode for solid oxide fuel cells. Arch Metall Mater 61:629–634

Promsuy S, Tangtrakarn A, Mongkolkachit C et al. (2016) A new sol–gel precursor for preparation of La0.56Sr0.42Co0.2Fe0.8O3–δ film. J Sol–Gel Sci Technol 78:187–194

Kim Y-M, Kim-Lohsoontorn P, Baek S-W, Bae J (2011) Electrochemical performance of unsintered Ba0.5Sr0.5Co0.8Fe0.2O3–δ, La0.6Sr0.4Co0.8Fe0.2O3–δ, and La0.8Sr0.2MnO3–δ cathodes for metal-supported solid oxide fuel cells. Int J Hydrog Energy 36:3138–3146

Liu W, Zhao Z, Tu B et al. (2015) Enhanced performance and stability of interlayer free La0.6Sr0.4Co0.2Fe0.8O3-δ-Ce0.8Zr0.2O2-δ cathode for solid oxide fuel cells. Int J Hydrog Energy 40:4861–4867

Qiang F, Sun K, Zhang N et al. (2007) Characterization of electrical properties of GDC doped A-site deficient LSCF based composite cathode using impedance spectroscopy. J Power Sources 168:338–345

Deshmukh R, Wagh P, Naik J (2016) Solvent evaporation and spray drying technique for micro- and nanospheres/particles preparation: a review. Dry Technol 34:1758–1772

Chen G, Wang W (2007) Role of freeze drying in nanotechnology. Dry Technol 25:29–35

Hamid NA, Muchtar A, Daud WRW, Muhamad N (2009) Pencirian mikrostruktur katod La-Sr-Co-Fe-O bagi sel fuel oksida pepejal bersuhu sederhana (IT-SOFC). Sains Malays 38:857–861

Dieffenbacher A, Pocklington WD (1991) Standard methods for the analysis of oils, fats and derivatives, 7th edn. Blackwell, London

Mosiałek M, Dudek M, Wojewoda-Budka J (2013) Composite La0.6Sr0.4Co0.8Fe 0.2O3/Ag cathode for SOFCs with Ce0.8Sm 0.2O1.9 electrolyte. Arch Metall Mater 58:275–281

Pakzad A, Salamati H, Kameli P, Talaei Z (2010) Preparation and investigation of electrical and electrochemical properties of lanthanum-based cathode for solid oxide fuel cell. Int J Hydrog Energy 35:9398–9400

Vargas RA, Chiba R, Andreoli M, Seo ESM (2007) Synthesis and characterization of Nd1-xSrxMnO3 and La1-xSrxCo1-yFeyO3 Powders. Rev Matér 12:8–21

Kumar S, Dwivedi GD, Joshi AG et al. (2017) Study of structural, dielectric, optical properties and electronic structure of Cr-doped LaInO3 perovskite nanoparticles. Mater Charact 131:108–115

Richter J, Holtappels P, Graule T et al. (2009) Materials design for perovskite SOFC cathodes. Mon fur Chem 140:985–999

Abdul Samat A, Somalu MR, Muchtar A et al. (2016) LSC cathode prepared by polymeric complexation method for proton-conducting SOFC application. J Sol–Gel Sci Technol 78:382–393

Perry NH, Ishihara T (2016) Roles of bulk and surface chemistry in the oxygen exchange kinetics and related properties of mixed conducting perovskite oxide electrodes. Materials 9:1–24

Ahmad SI, Mohammed T, Bahafi A, Suresh MB (2017) Effect of Mg doping and sintering temperature on structural and morphological properties of samarium-doped ceria for IT-SOFC electrolyte. Appl Nanosci 7:243–252

Liu M, Liu Z, Liu M, Nie L (2013) Fabrication and characterization of functionally-graded LSCF cathodes by tape casting. Int J Hydrog Energy 38:1082–1087

Zhang J, Huang X, Zhang H et al. (2017) The effect of powder grain size on the microstructure and electrical properties of 8 mol% Y2O3-stabilized ZrO2. RSC Adv 7:39153–39159

Köferstein R, Jäger L, Ebbinghaus SG (2013) Magnetic and optical investigations on LaFeO3 powders with different particle sizes and corresponding ceramics. Solid State Ion 249-50:1–5

García-López E, Marcì G, Puleo F et al. (2015) La1–xSrxCo1–yFeyO3–δ: preparation, characterization and solar photocatalytic activity. Appl Catal B Environ 178:218–225

Li J, Sun L, Shenai PM et al. (2015) A first-principles study of oxygen vacancy induced changes in structural, electronic and magnetic properties of La2/3Su1/3MnO3. J Alloy Compd 649:973–980

Chen K, Lü Z, Ai N et al. (2007) Effect of SDC-impregnated LSM cathodes on the performance of anode-supported YSZ films for SOFCs. J Power Sources 167:84–89

Chen Z, Wang X, Giuliani F, Atkinson A (2015) Analyses of microstructural and elastic properties of porous SOFC cathodes based on focused ion beam tomography. J Power Sources 273:486–494

Chen Z, Wang X, Atkinson A, Brandon N (2016) Spherical indentation of porous ceramics: cracking and toughness. J Eur Ceram Soc 36:3473–3480

da Conceição L, Silva AM, Ribeiro NFP, Souza MMVM (2011) Combustion synthesis of La0.7Sr0.3Co0.5Fe0.5O3 (LSCF) porous materials for application as cathode in IT-SOFC. Mater Res Bull 46:308–314

Wu YC, Lin CC (2014) The microstructures and property analysis of aliovalent cations (Sm 3+, Mg2+, Ca2+, Sr2+, Ba 2+) co-doped ceria-base electrolytes after an aging treatment. Int J Hydrog Energy 39:7988–8001

Zeng P, Ran R, Chen Z et al. (2007) Significant effects of sintering temperature on the performance of La0.6Sr0.4Co0.2Fe0.8O3-δ oxygen selective membranes. J Memb Sci 302:171–179

Muhammed Ali SA, Anwar M, Baharuddin NA et al. (2018) Enhanced electrochemical performance of LSCF cathode through selection of optimum fabrication parameters. J Solid State Electrochem 22:263–273

Perry Murray E, Sever MJ, Barnett SA (2002) Electrochemical performance of (La,Sr)(Co,Fe)O3-(Ce,Gd)O3 composite cathodes. Solid State Ion 148:27–34

Shaikh SPS, Somalu MR, Muchtar A (2016) Nanostructured Cu-CGO anodes fabricated using a microwave-assisted glycine–nitrate process. J Phys Chem Solids 98:91–99

Hodge I, Ingram MD, West AR (1976) Impedance and modulus spectroscopy of polycrystalline solid electrolytes. J Electroanal Chem 74:125–143

Xiao G, Liu Q, Zhao F et al. (2011) Sr2Fe1.5Mo0.5O6 as cathodes for intermediate-temperature solid oxide fuel cells with La0.8Sr0.2Ga0.87Mg0.13O3 electrolyte. J Electrochem Soc 158:B455–B460

Cesário MR, MacEdo DA, Martinelli AE et al. (2012) Synthesis, structure and electrochemical performance of cobaltite-based composite cathodes for IT-SOFC. Cryst Res Technol 47:723–730

da Conceição L, Silva CRB, Ribeiro NFP, Souza MMVM (2009) Influence of the synthesis method on the porosity, microstructure and electrical properties of La0.7Sr0.3MnO3 cathode materials. Mater Charact 60:1417–1423

Acknowledgements

This work was supported by the Ministry of Higher Education, Malaysia under Fundamental Research Grant Scheme (FRGS/1/2015/TK10/UKM/01/2). The authors would like to extend their gratitude to the Center for Research and Instrumentation Management for the support and to UKM for excellent testing equipment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Highlights

-

LSCF cathode powder was prepared by rotary evaporation method.

-

Effects of SDC addition on optical and electrical properties were analyzed.

-

Addition of SDC influenced the conductivity and bandgap of the composite cathode.

-

Resistance increased from 0.066 Ω cm2 for LSCF to 4 Ω cm2 for LSCF–SDC composite.

Rights and permissions

About this article

Cite this article

S. A., M., Anwar, M., Raduwan, N. et al. Optical, mechanical and electrical properties of LSCF–SDC composite cathode prepared by sol–gel assisted rotary evaporation technique. J Sol-Gel Sci Technol 86, 493–504 (2018). https://doi.org/10.1007/s10971-018-4636-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4636-8