Abstract

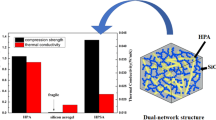

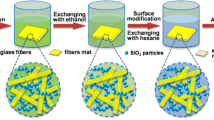

Novel three-dimensional halloysite nanotubes (HNTs)/silica composite aerogels were fabricated to strengthen the nanostructure and overcome inherent fragility of silica aerogel by a sol–gel method using tetraethyl orthosilicate (TEOS) and 1,4-Phenylene diisocyanate (PPDI)-modified HNTs (p-HNTs) as the main materials, followed by an environmentally friendly ambient pressure drying (APD). The modification and dispersion of HNTs were investigated by using FTIR, SEM, TEM. Meanwhile, the morphology, mechanical properties, and thermal conductivity of aerogels were also studied. The results showed that the p-HNTs were uniformly dispersed in the silica aerogel. This resulted in composites with unique interpenetrating network microstructure that could give an enhanced mechanical properties to aerogels. The compressive strength was found to vary from 400 kPa to 1.45 MPa and thermal conductivity from 0.025 to 0.038 W/m K. In addition, randomly oriented p-HNTs can obviously reduce both the linear shrinkage and density of composite aerogels. The composites with outstanding properties prepared by APD are potential for building applications.

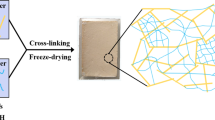

Graphical Abstract

Similar content being viewed by others

References

Kistler S (1931) Coherent expanded aerogels and jellies. Nature 127:741

Yun S, Luo H, Gao Y (2015) Low-density, hydrophobic, highly flexible ambient-pressure-dried monolithic bridged silsesquioxane aerogels. J Mater Chem A 3:3390–3398

Guo H, Meador MA, McCorkle L, Quade DJ, Guo J, Hamilton B, Cakmak M, Sprowl G (2011) Polyimide aerogels cross-linked through amine functionalized polyoligomeric silsesquioxane. ACS Appl Mater Interfaces 3(2):546–552

Gibiat V, Lefeuvre O, Woignier T, Pelous J, Phalippou J (1995) Acoustic properties and potential applications of silica aerogels. J Non-Cryst Solids 186:244–255

Ihara T, Gao T, Grynning S, Jelle BP, Gustavsen A (2015) Aerogel granulate glazing facades and their application potential from an energy saving perspective. Appl Energy 142:179–191

Gao T, Jelle BP, Sandberg LIC, Gustavsen A (2013) Monodisperse hollow silica nanospheres for nano insulation materials: synthesis, characterization, and life cycle assessment. ACS Appl Mater Interfaces 5(3):761–767

ElKhatat AM, Al-Muhtaseb SA (2011) Advances in tailoring resorcinol-formaldehyde organic and carbon gels. Adv Mater 23(26):2887–2903

Hu X, Zheng S, Zhu L, Tanyi AR, Lan H et al (2013) Adsorption of 2-phenylethyl alcohol on silica aerogel from saturated solution in supercritical CO2. J Supercrit Fluids 79:41–45

Sabri F, Leventis N, Hoskins J, Schuerger AC, Sinden-Redding M, Britt D, Duran RA (2011) Spectroscopic evaluation of polyurea crosslinked aerogels, as a substitute for RTV-based chromatic calibration targets for spacecraft. Adv Space Res 47(3):419–427

Sabri F, Marchetta J, Smith KM (2013) Thermal conductivity studies of a polyurea cross-linked silica aerogel-RTV 655 compound for cryogenic propellant tank applications in space. Acta Astronaut 91:173–179

Leventis N, Sotiriou-Leventis C, Zhang G, Rawashdeh A-MM (2002) Nanoengineering strong silica aerogels. Nano Lett 2(9):957–960

Meador MAB, Capadona LA, McCorkle L, Papadopoulos DS, Leventis N (2007) Structure-property relationships in porous 3D nanostructures as a function of preparation conditions: isocyanate cross-linked silica aerogels. Chem Mater 19(9):2247–2260

Nguyen BN, Meador MAB, Medoro A, Arendt V, Randall J, McCorkle L, Shonkwiler B (2010) Elastic behavior of methyltrimethoxysilane based aerogels reinforced with tri-isocyanate. ACS Appl Mater Interfaces 2(5):1430–1443

Wang X, Zhang H, Jana SC (2013) Sulfonated syndiotactic polystyrene aerogels: properties and applications. J Mater Chem A 1(44):13989

Zhang Y, Li H, Xu Z, Bu W, Liu C, Dong J, Hu Y (2014) Synthesis of low dispersity star-like polyethylene: a combination of click chemistry and a sol–gel process. Polym Chem 5(13):3963

Duan Y, Jana SC, Lama B, Espe MP (2013) Reinforcement of silica aerogels using silane-end-capped polyurethanes. Langmuir 29(20):6156–6165

Talebi Mazraeh-shahi Z, Mousavi Shoushtari A, Bahramian AR, Abdouss M (2015) Synthesis, pore structure and properties of polyurethane/silica hybrid aerogels dried at ambient pressure. J Ind Eng Chem 21:797–804

Guo H, Meador MA, McCorkle L, Quade DJ, Guo J, Hamilton B, Cakmak M, Sprowl G (2011) Polyimide aerogels cross-linked through amine functionalized polyoligomeric silsesquioxane. ACS Appl Mater Interfaces 3(2):546–552

Yan P, Zhou B, Du A (2014) Synthesis of polyimide cross-linked silica aerogels with good acoustic performance. RSC Adv 4(102):58252–58259

Zhang L, Wu J, Zhang X, Gong G, Liu J, Guo L (2015) Multifunctional, marvelous polyimide aerogels as highly efficient and recyclable sorbents. RSC Adv 5(17):12592–12596

Katti A, Shimpi N, Roy S, Lu H, Fabrizio EF, Dass A, Capadona LA, Leventis N (2006) Chemical, physical, and mechanical characterization of isocyanate cross-linked amine-modified silica aerogels. Chem Mater 18(2):285–296

Leventis N (2007) Three-dimensional core-shell superstructures: mechanically strong aerogels. Acc Chem Res 40(9):874–884

Nguyen BN, Meador MAB, Tousley ME, Shonkwiler B, McCorkle L, Scheiman DA, Palczer A (2009) Tailoring elastic properties of silica aerogels cross-linked with polystyrene. ACS Appl Mater Interfaces 1(3):621–630

Yi X, Zhang L, Wang F, Shen X, Cui S, Zhang J, Wang X (2014) Mechanically reinforced composite aerogel blocks by self-growing nanofibers. RSC Adv 4(89):48601–48605

Lu Z, Yuan Z, Liu Q, Hu Z, Xie F, Zhu M (2015) Multi-scale simulation of the tensile properties of fiber-reinforced silica aerogel composites. Mater Sci Eng, A 625:278–287

Parmenter KE, Milstein F (1998) Mechanical properties of silica aerogels. J Non-Cryst Solids 223(3):179–189

Yang X, Wei J, Shi D, Sun Y, Lv S, Feng J, Jiang Y (2014) Comparative investigation of creep behavior of ceramic fiber-reinforced alumina and silica aerogel. Mater Sci Eng A 609:125–130

Yuan B, Ding S, Wang D, Wang G, Li H (2012) Heat insulation properties of silica aerogel/glass fiber composites fabricated by press forming. Mater Lett 75:204–206

Ślosarczyk A, Wojciech S, Piotr Z, Paulina J (2015) Synthesis and characterization of carbon fiber/silica aerogel nanocomposites. J Non-Cryst Solids 416:1–3

Maleki H, Durães L, Portugal A (2014) An overview on silica aerogels synthesis and different mechanical reinforcing strategies. J Non-cryst Solids 385:55–74

Liu Y, Jiang X, Li B, Zhang X, Liu T, Yan X, Ding J, Cai Q, Zhang J (2014) Halloysite nanotubes@reduced graphene oxide composite for removal of dyes from water and as supercapacitors. J Mater Chem A 2(12):4264

Wang Q, Wang Y, Zhao Y, Zhang B, Niu Y, Xiang X, Chen R (2015) Fabricating roughened surfaces on halloysite nanotubes via alkali etching for deposition of high-efficiency Pt nanocatalysts. CrystEngComm 17(16):3110–3116

Zhou C, Sun T, Gao Q, Alshameri A, Zhu P, Wang H, Qiu X, Ma Y, Yan C (2014) Synthesis and characterization of ordered mesoporous aluminosilicate molecular sieve from natural halloysite. J Taiwan Inst Chem E 45(3):1073–1079

Vahedi V, Pasbakhsh P, Chai S-P (2015) Toward high performance epoxy/halloysite nanocomposites: new insights based on rheological, curing, and impact properties. Mater Des 68:42–53

Zhang Y, Pan J, Yan Y, Shi W, Yu L (2014) Synthesis and evaluation of stable polymeric solid acid based on halloysite nanotubes for conversion of one-pot cellulose to 5-hydroxymethylfurfural. RSC Adv 4(45):23797

Zeng S, Reyes C, Liu J, Rodgers PA, Wentworth SH, Sun L (2014) Facile hydroxylation of halloysite nanotubes for epoxy nanocomposite applications. Polymer 55(25):6519–6528

Liu M, Jia Z, Jia D, Zhou C (2014) Recent advance in research on halloysite nanotubes-polymer nanocomposite. Prog Polym Sci 39(8):1498–1525

Ding X, Wang H, Chen W, Liu J, Zhang Y (2014) Preparation and antibacterial activity of copper nanoparticle/halloysite nanotube nanocomposites via reverse atom transfer radical polymerization. RSC Adv 4(79):41993–41996

Luo Z, Wang A, Wang C, Qin W, Zhao N, Song H, Gao J (2014) Liquid crystalline phase behavior and fiber spinning of cellulose/ionic liquid/halloysite nanotubes dispersions. J Mater Chem A 2(20):7327–7336

Zhang L, Wang T, Liu P (2008) Polyaniline-coated halloysite nanotubes via in situ chemical polymerization. Appl Surf Sci 255(5):2091–2097

Liu M, Jia Z, Liu F, Jia D, Guo B (2010) Tailoring the wettability of polypropylene surfaces with halloysite nanotubes. J Colloid Interface Sci 350(1):186–193

Barrientos-Ramírez S, Oca-Ramírez GMd, Ramos-Fernández EV, Sepúlveda-Escribano A, Pastor-Blas MM, González-Montiel A (2011) Surface modification of natural halloysite clay nanotubes with aminosilanes. Application as catalyst supports in the atom transfer radical polymerization of methyl methacrylate. Appl Catal A 406(1):22–33

Rooj S, Das A, Heinrich G (2011) Tube-like natural halloysite/fluoroelastomer nanocomposites with simultaneous enhanced mechanical, dynamic mechanical and thermal properties. Eur Polym J 47(9):1746–1755

Kango S, Kalia S, Celli A, Njuguna J, Habibi Y, Kumar R (2013) Surface modification of inorganic nanoparticles for development of organic–inorganic nanocomposites—a review. Prog Polym Sci 38(8):1232–1261

Yun S, Luo H, Gao Y (2014) Ambient-pressure drying synthesis of large resorcinol-formaldehyde-reinforced silica aerogels with enhanced mechanical strength and superhydrophobicity. J Mater Chem A 2(35):14542–14549

Albdiry MT, Yousif BF (2014) Role of silanized halloysite nanotubes on structural, mechanical properties and fracture toughness of thermoset nanocomposites. Mater Des 57:279–288

Liu M, Zhang Y, Zhou C (2013) Nanocomposites of halloysite and polylactide. Appl Clay Sci 75:52–59

Wang H, Shi L, Yan T, Zhang J, Zhong Q, Zhang D (2014) Design of graphene-coated hollow mesoporous carbon spheres as high performance electrodes for capacitive deionization. J Mater Chem A 2(13):4739–4750

Xu X, Liu Y, Lu T, Sun Z, Chua DHC, Pan L (2015) Rational design and fabrication of graphene/carbon nanotubes hybrid sponge for high-performance capacitive deionization. J Mater Chem A 3:13418–13425

Yusof Y, Johan MR (2014) Concentration-dependent properties of amorphous carbon nanotube/silica composites via the sol–gel technique. CrystEngComm 16(36):8570–8575

Guo K, Song H, Chen X, Du X, Zhong L (2014) Graphene oxide as an anti-shrinkage additive for resorcinol-formaldehyde composite aerogels. Phys Chem Chem Phys 16(23):11603–11608

Acknowledgments

This project was financially Supported by the National Natural Science Foundation of China (No.51472175) and the Tianjin Research Program of Application Foundation and Advanced Technology (No.15JCZDJC37200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, H., Chu, P., Li, H. et al. Novel three-dimensional halloysite nanotubes/silica composite aerogels with enhanced mechanical strength and low thermal conductivity prepared at ambient pressure. J Sol-Gel Sci Technol 80, 651–659 (2016). https://doi.org/10.1007/s10971-016-4154-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4154-5