Abstract

Trace impurity patterns are important nuclear forensic signatures in uranium ore concentrates (UOCs) and Certified Reference Materials (CRMs) are used to validate the analysis methods employed by end users. Herein, we discuss the certification campaign for three new UOC CRMs from the National Research Council Canada: UCLO-1 (https://doi.org/10.4224/crm.2020.uclo-1), UCHI-1 (https://doi.org/10.4224/crm.2020.uchi-1), and UPER-1 (https://doi.org/10.4224/crm.2020.uper-1). This study involved 15 laboratories from 10 countries, using sector-field and (triple) quadrupole inductively-coupled plasma mass spectrometry to analyze 64 trace element impurities. We discuss the importance of the acids used for sample digestion, difficulties analyzing in a high uranium matrix, and data combination and uncertainty evaluation for this large dataset.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The post-Cold War disintegration of the Soviet Union was followed by an increase in illicit possession and transport of unregulated nuclear and radioactive material[1, 2]. Attempts to combat this concerning trend garnered increased interest in nuclear forensic practices in the mid-1990s[1].

Initially, nuclear forensic methods focused on measurements of the purity and isotopic composition of uranium and plutonium, as well as on the physical morphology characteristics of the bulk materials[2, 3]. While this can provide a great deal of useful information, this type of data is often insufficient to conclusively identify the origin and associated processing details of the nuclear material[3, 4]. More recently, nuclear forensic investigations have included a profile of the trace element impurities to aid provenance determination, and these efforts have been largely successful[3,4,5,6,7,8]. The trace element information gathered can be compared to a database containing profiles of well-characterized materials[2, 4, 5] and/or can be subjected to a principal components analysis, which allows the large dataset to be reduced to a more interpretable form[5]. These comparisons can comprise any number of components of the overall dataset, and the specific analytes of interest which can be used to best predict a material’s origin can differ depending on the material origin, which is all the more reason why it is essential to obtain as much information about a sample as possible.

Trace element profiles have been found not be particularly useful in the characterization of uranium ores and ore concentrates, as certain trace elements can be indicative of the ore type, manufacture process, or materials added to the uranium ore concentrate (UOC) production flow. For example, ores from northern Saskatchewan (Canada) display high levels of As and Ni[7, 9]. Indeed, the importance of the trace elements was also highlighted in the 4th Collaborative Materials Exercise of the Nuclear Forensics International Technical Working Group (ITWG)[10].

Although the utility of trace element measurements has been proven, there are a number of challenges facing nuclear forensic investigators. Databases of information relating to the characterization of various nuclear materials are continuously growing, but perhaps the greatest challenge is actually obtaining enough data of reasonable quality about a sample to allow database comparisons. Methods for the analysis of trace elements (defined as being less than 0.1% of the matrix composition[1]) in uranium materials have been developed, and generally involve acid digestion of the solid materials followed by dilution and analysis by inductively-coupled plasma mass spectrometry (ICP-MS). The high uranium levels in these samples cause difficulties during the analysis, including signal suppression and isobaric spectral interferences, which makes it difficult to obtain accurate results and achieve low limits of detection[11].

ASTM’s Standard Test Method for Determination of Impurities in Nuclear Grade Uranium Compounds by Inductively Coupled Plasma Mass Spectrometry (ASTM C1287-18)[12] describes a method for analyzing 67 elements in nuclear-grade uranium materials without matrix separation. Part of a good quality assurance protocol involves the use of Certified Reference Materials (CRMs) during the sample analysis, but there is currently a limited supply of uranium matrix CRMs available for this purpose. These include CUP-2 (Canadian Certified Reference Materials Project / the Analytical Subcommittee of the Canadian Uranium Producers Metallurgical Committee)[13], a UOC with values provided for 15 analytes, CRM-124 (New Brunswick Laboratory, U.S. Department of Energy)[14], a series of U3O8 matrix materials with 24 impurities spiked at various levels, as well as a series of uranium matrix materials from the Commission d’Etablissement des Méthodes d’Analyse[15], including four U3O8 materials (named Agaric, Bolet, Chanterelle, and Morille) with certified values for 23 to 29 elemental impurities. In addition, there are a number of other uranium salt materials, each with significantly fewer certified impurity values available. Unfortunately, the suite of elements covered by these CRMs is limited, and some currently-available UOC CRMs may suffer from a lack of homogeneity[16]. Recently, there was a campaign by the IAEA, in collaboration with Oak Ridge National Laboratory and the Canadian Nuclear Safety Commission (CNSC), to prepare UOC CRMs for a larger suite of analytes. There, 69 impurities were analyzed in an inter-laboratory comparison, with consensus values obtained for 64 and 65 of those analytes in each material, respectively (29 and 14 of those values were assigned as upper limits), as described by Bürger et al.[17]. Unfortunately, the availability of these materials is limited.

To work towards fulfilling the requirement of a more far-reaching uranium matrix CRM, the National Research Council Canada (NRC) partnered with CNSC to prepare three UOC CRMs, named UCLO-1 (U3O8), UCHI-1 (U3O8), and UPER-1 (UO4), which contain varying concentrations of elemental impurities[18,19,20]. Through collaboration between NRC and another 14 expert laboratories worldwide, information on 64 trace elements in these materials was obtained and is provided on the certificates of analysis (53 for UCLO-1, 59 each for UCHI-1 and UPER-1). Apart from the impurities, the three CRMs will also provide information on uranium content and isotopic composition[21]. However, in this manuscript we focus exclusively on trace metal impurities.

Experimental

The scale of the inter-laboratory study resulted in a sizable experimental section. Here, we outline only the most important details of each individual method, describe the features and important considerations relevant to this type of analysis, and discuss the data combination and evaluation of measurement uncertainty. For a comprehensive description of each method of analysis, we refer the reader to the supplementary information.

Methods of Analysis

Sample preparation in all laboratories involved an acid digest of the UOC materials in HNO3, with some laboratories adding HF, HCl, or H2SO4. Some samples were digested on a hot plate (hot block), while others were subjected to a microwave digestion protocol. Generally, this is consistent with the ASTM Standard Method (ASTM C1287-18)[12], which suggests the use of HNO3 and HF, and either a hot plate or microwave-assisted digestion. Samples were diluted to varying degrees, depending on the detection limits of the employed instrumentation and tolerance to high levels of uranium. Overall, this ranged from about 1000-fold dilution of the initial powdered sample to 106-fold dilution. Following the acid digestion, some laboratories used column separation to remove uranium from the sample matrix, providing a much cleaner sample for the analysis.

Quantification was performed using a variety of calibration techniques. External calibration was most common and usually involved the use of an internal standard. Some laboratories added uranium to their standards to achieve matrix-matching whereas others employed the method of standard additions. Table 1 provides a general outline of the sample preparation and analysis approaches employed.

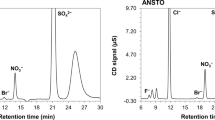

Overall, four different types of analytical instruments were used for the trace element analysis of the UOC materials. All but one laboratory used ICP-MS. Single quadrupole (Q) ICP-MS instruments were operated in a normal mode or with the use of collision/reaction cell (CRC) to reduce molecular interferences either by means of collision-based dissociation or charge transfer in a pressurized cell or by means of ion energy control using electric potential barriers. Triple quadrupole (QQQ) ICP-MS instruments were similarly employed in either ‘no–gas’ (NG) mode, or using a number of different gases in the second quadrupole, reducing polyatomic interferences and arriving at highly selective determination of analytes. Sector-field (SF) ICP-MS instruments were employed due to their ability to attain high mass resolution and detect analytes without interference from various polyatomic ions. Depending on the analyte, these instruments were operated in low, medium, or high resolution modes (m/Δm = 300, 4000, and 10,000 respectively). Finally, one laboratory used total reflection x-ray fluorescence for the analysis of the UOC digests. A breakdown of the instrument type used by each laboratory is provided in Table 1. Additionally, Table S1 outlines the isotopes monitored by each laboratory and relevant polyatomic interferences for each isotope, as well as the mass resolution mode used for SF-ICP-MS or gas mode used for the single or triple quadrupole ICP-MS methods.

Consensus Value Determination and Uncertainty Evaluation

The statistical models underlying data reductions recognize the possibility that the reported uncertainties inevitably overlook some sources of uncertainty. This manifests itself in the spread of the reported results beyond what the reported uncertainties might suggest. For a variety of reasons, most of the measurements in this study are challenging and the application of standard data reduction methods, such as the DerSimonian-Laird mean, are inadequate due to the presence of large laboratory-specific deviations. As a result, we have sought a robust statistical model for data reduction. Laplace random effects model for inter-laboratory studies[22] meets this requirement as it provides a consensus value that is an uncertainty-weighted median with allowance for laboratory-specific random effects. The uncertainty associated with the certified values combined the contributions from the consensus value which was further augmented by the uncertainty due to between-unit homogeneity which was obtained as described in the sections below.

Results and Discussion

CRM Preparation

The three UOC CRMs: UCLO-1 (U3O8), UCHI-1 (U3O8), and UPER-1 (UO4) are derived from industrial-grad uranium materials selected according to their chemical profiles. These starting materials were blended at Saskatchewan Research Council facility in Saskatoon, Saskatchewan, Canada, to aid homogeneity. 25 g aliquots of the UOCs were then packaged in clean amber glass bottles. Note that users require a licence to handle these materials as their radiation levels are 570–620 kBq per bottle.

CRM Certification

The three CRM candidate materials were processed and shipped to collaborators for analysis. Homogeneity and stability were both assessed at NRC. Homogeneity was examined via the analysis of multiple bottles throughout the CRM series, all processed and analyzed in repeatability conditions. Long-term stability will be assessed by analyzing additional bottles of the material at regular intervals (every few years) throughout the lifetime of the CRMs.

Characterization of the materials was conducted by all participants. Once the initial round of analyses was complete, data were collected and shared to all laboratories in a machine-readable format for further data cleanup and outlier removal. Along with the initial sharing of data, representatives from each laboratory met in a data review meeting in Ottawa, Canada (February 2020) where the integrity of the results was discussed. Following this data review meeting, some adjustments were made to the reported results by the participating laboratories. This included, as an example, revisions to the uncertainty evaluations, moisture correction, reprocessing some results based on overlooked spectral interference, or removal of other data altogether. While additional measurements were not immediately possible due to the restrictions imposed by the COVID19 pandemic, the re-evaluation of existing data provided a significant improvement to the overall dataset.

Once the reported results from individual laboratories were finalized, the data were scrutinized on an element-by-element basis.

Uncertainty due to Sample Homogeneity

When preparing a new CRM, one of the main goals is to provide a material which fulfills the needs of analysts, such filling gaps left uncovered by previously released CRMs. For example, replicate data provided by Lawrence Livermore National Laboratory[23] and a recent inter-laboratory collaborative study[16] suggest that there may be considerable inhomogeneity between units of the CUP-2 CRM. This makes usability complicated as the certificate[13] presents the values without associated uncertainties to account for this inhomogeneity. Conversely, the Commission d’ETAblissement des Méthodes d’Analyse[15] and New Brunswick Laboratories[14] include uncertainty due to inhomogeneity as part of the combined uncertainty budget for their UOC CRMs. Similar levels of relative uncertainty between these materials suggest similar contributions from (in)homogeneity; however, it should be noted that because the uncertainty budget is not broken down, it is possible that the distribution of sources of uncertainty differ between materials. The uncertainty budgets for UCLO-1, UCHI-1, and UPER-1 include the contributions from inhomogeneity.

A homogeneity study was conducted on the suite of CRMs to assess potential variations of the analyte levels between the CRM units and to assess potential trends associated with the CRM production (i.e. unforeseen bias during blending or contamination during bottling). Results of this assay demonstrated good homogeneity in all three materials. No trends were observed to indicate inhomogeneity (i.e. decreasing/increasing mass fraction with increasing bottle number, which would suggest moisture loss or progressive contamination). In all cases, the relative uncertainty due to homogeneity was less than 10%.

Following the evaluation of at least 20 units of each CRM, which was evaluated using the DerSimonian-Laird implementation of the random effects model[24], the obtained relative uncertainties due to homogeneity were regressed against the associated mass fraction of each analyte using Horwitz-type power law[25, 26]. The resulting trend was used to assign the value for the expected uncertainty due to between-unit homogeneity for each element (Fig. 1).

Outliers

It is not uncommon to observe an outlying data point during the analysis of multiple replicates of a single sample. This can result from a variety of factors such as the inadvertent contamination during sample preparation, uncorrected isobaric interferences, or momentary signal instability of the mass spectrometer during analysis. Considering the large size of the dataset in this project, a number of such outliers was observed: approximately 0.8% of reported values were noted to deviate from the associated consensus value by more than 100%. Upon discussion of the results at the data review meeting, it was noticed that the majority of the outliers were Cr, Ni, and Fe. A scanning electron microscopy analysis of the UOC materials revealed the occasional presence of small metal flakes in the otherwise fairly homogeneous powders suggesting that these flakes were likely the result of corrosion of the stainless steel drums in which the UOC materials had been stored following their processing, before transport to the NRC for bottling.

The above conclusions are supported by an examination of the data (Fig. 2) looking at the individual results from NRC-1. A plot of the mass fractions of Cr, Ni, and Fe in UCLO-1, sorted by sample number (where each sample was an individual aliquot of UOC powder), indicated that significantly higher values are observed for these elements in some samples. Other elements analyzed in the sample, such as Cu shown here in example, do not display the same phenomenon, indicating that this is a case of contamination – likely by a small metal flake as noted above – rather than an overall bias for that sample aliquot.

Stability

An isochronous stability study was not performed for this material as previous work on similar matrices has confirmed the stability of trace elements[18,19,20]. In terms of long-term stability, a re-analysis of the trace element profiles in UCLO-1, UCHI-1, and UPER-1 will be conducted 5–10 years after the initial set of analyses to confirm that results are not significantly different from the original findings.

Characterization

As previously noted, the characterization of the trace element profiles of CRMs UCLO-1, UCHI-1, and UPER-1 was performed by several laboratories. Prior to outlier removal, 5604 measurement results were present in the database for trace elements (6348 when including the QC samples). This entire dataset, after filtering, is available, open access, through the DOI landing pages for each CRM[18,19,20]. There, plots are presented for every element with at least one data point, showing values and associated uncertainties measured by each laboratory, as are the consensus values and combined standard uncertainties.

In this section, we discuss the technical details of the analysis, including difficulties that were encountered, unique observations, and sources of uncertainty. It is based on these technical details that data was subsequently filtered to arrive at consensus values and uncertainty estimates for each element, as is discussed in more detail after these technical notes.

Analytical Considerations

Column Separation

In order to remove the high concentrations of U from the sample matrix following acid digestion, some laboratories implemented a column separation protocol. Important to consider when performing this type of sample preparation is the potential for analyte losses during all steps of this procedure. In an ideal situation, this could be accounted for through isotope dilution analysis (spiking the sample with isotopically labelled standard prior to sample preparation). Notwithstanding the fact that 18 of the elements analysed here are monoisotopic, the large suite of analytes being targeted here made this type of analysis unfeasible. Therefore, in this type of scenario it is helpful to determine the analyte recoveries following column separation, ideally through spiking experiments. This is particularly important when new analytes are being examined which a research group has not previously analyzed using the procedure being implemented. Here, it appears that the column separation protocols were successful. When comparing the data obtained when following a column separation procedure, results are not systematically biased higher or lower than those obtained without column separation, once outliers were removed (Fig. 3a). When instead examining only data which were discarded as outliers (Fig. 3b), there appears to be a slight bias towards higher reported values when column separation was implemented. This could indicate increased instances of contamination due to the more extensive sample handling required for column separation. It is unlikely that this trend is indicative of an overall low bias of the non-column separated data as it is consistent throughout the range of atomic weights measured; if this were the case, it is expected that the bias would be larger for elements which experience greater interference from other components in the sample – these types of interferences are discussed in detail, below. Additionally, the use of column separation did not appear to make a significant difference in limits of detection obtained for this matrix. When comparing average values, there were roughly the same numbers of analytes for which detection limits were lower when employing column separation (31 of 64) than without column separation.

Based on this, it can be concluded that, analytically, there is no advantage in implementing a column separation protocol for the measurement of a large suite of trace elements in a UOC matrix. This conclusion may seem counter-intuitive, given that column separation is implemented specifically to improve precision and accuracy in chemical analysis, but it is important to note that it is based on the assumption that the list of analytes being examined is extensive. In scenarios where a much smaller number of contaminants are to be measured in UOC materials, where more effort can be expended optimizing the method to those specific analytes, it is reasonable to expect that column separation could provide improved results. Practically, an advantage of column separation is that it prevents the contamination of instrumental components with uranium from the matrix. The disadvantage is the significant increase in the time and effort required for sample preparation prior to instrumental analysis. Therefore, while our general recommendation is to use direct analysis protocols such as that described by ASTM Method C1287[12], column separation can be implemented, without decreased in data quality, in specific scenarios where the analysts feel it is beneficial.

Composite Samples

Aliquots of 10 individual digests were combined and diluted for analysis in an attempt to carry out physical averaging of samples. Since the samples used to prepare these composites were also analyzed individually (albeit, using a different calibration method), bottle-to-bottle variations could still be observed and there was no loss of homogeneity data.

The use of a composite sample in such a manner is useful because it allows for the coverage of several CRM units in a single analysis. Additionally, it allows analysts to focus more effort on the high quality measurements without the time costs associated with the analysis of a large number of samples. Here, good results were obtained and are displayed by NRC-3 and NRC-4.

ICP-MS Drift

As noted above, the high U matrix in these UOC digests resulted in some significant signal suppression and enhancement (from isobaric and polyatomic interferences) in ICP-MS, as well as instrumental drifts that were larger than are typically observed for low-matrix, routine analyses. Therefore, it was vital to monitor and correct for these drifts by repeatedly measuring the signal for a standard solution at intervals throughout the analysis. Similarly, the use of internal standards can be an effective method to correct for changes in analyte signal intensity during analysis.

Most ICP-MS instruments equipped with a collision/reaction cell, either prior to the single quadrupole or as the 2nd quadrupole in QQQ instruments, have the ability to switch between gas modes during analysis – so a single sample can be analyzed in normal as well as CRC mode, or with several different gasses (such as on the Agilent 8800 where four cell gas lines are available). This does require some settling time to allow the pressure in the cell (or 2nd quadrupole) to stabilize, but in general this is fairly quick: 20–30 s is deemed sufficient for the Agilent 8800, for example. While this would not be considered a problem during typical low-matrix analysis, the large instrumental drifts noted above mean that adding even 30 s per sample to the overall run time can make a fairly significant difference overall. Therefore, each gas mode was performed as a separate analysis to allow for a cleaning of cones and re-establishing of a baseline between batches.

Blank Subtraction

Due to the nature of the matrix-matched external calibration, in some scenarios (particularly for laboratories who employed lower dilution factors and therefore had higher U matrices) it was necessary to take a somewhat unconventional approach to blank subtraction. Commercial-grade uranium single element standards, U metals, and other sources of U used for matrix-matching contain impurities, which, in typical scenarios would be diluted to the point of having negligible contributions to the overall signals for these other analytes. Here, however, the matrix contained 0.1 to 800 ppm uranium (depending on the laboratory), meaning that for some analysts, the contributions of these impurities were not insignificant. For the calibration solutions themselves, a simple (matrix) blank subtraction was sufficient, but the digested UOC samples required a different approach, as the impurities in these samples were specifically the target of this analysis and would likely be underestimated following a conventional blank subtraction. Therefore, the blank used for subtraction was simply the acid solution (e.g. 1% HNO3 / 3% HCl). The large degree of signal suppression caused by the presence of (for example) ~ 800 ppm uranium in the samples necessitated the application of a correction factor prior to blank subtraction. This was determined by first measuring the signal for all analytes in a matrix without uranium (1% HNO3 / 3% HCl), then measuring the signal for the same concentration of these analytes in the sample matrix (800 ppm U in 1% HNO3 / 3% HCl), after the plasma had stabilized following the addition of the uranium to the rinse solution. The ratio between these signals was considered to be the suppression factor and was used to correct the analyte signals observed in the blank (1% HNO3 / 3% HCl) prior to subtraction from all UOC samples.

For laboratories where larger dilution factors resulted in lower U concentrations required for matrix-matching, not all steps of the protocol described above were necessary. However, these differences highlight the need for thorough pre-screening of samples and standards when developing new methods of analysis or examining new sample matrices.

Standard Addition Calculations

Calibration via standard addition is a robust method that can be used to directly account for matrix effects observed during sample analysis. Here, it was used by NRC-3 and NRC-4 for the determination of trace elements in a composite sample (aliquots of 10 digested UOC samples were combined for analysis). To allow for a straightforward determination of the uncertainty associated with this calibration method, plots were generated using the coordinate swapping approach described by Meija et al.[27], where the amount of analyte added was displayed on the y-axis and the ICP-MS signal on the x-axis, which allowed the concentration and its uncertainty to be directly determined from the intercept of the plot and its associated uncertainty, as calculated by the LINEST function in Excel.

HF and HCl Acids for Sample Digestion

As is noted in Table 1, the participating laboratories used a variety of different acid blends for the digestion of the UOC samples. While everyone used HNO3, some digestion sequences involved the important addition of HF and/or HCl. The use of HF during the digestion of UOC samples is needed for complete recovery and stabilization of certain elements, such as Zr and Hf[17]. Data from laboratories which did not use HF were discarded for Zr and Hf.

Conversely, the presence of HF and HCl can generate precipitates of certain elements, such as thorium fluoride and silver chloride[17, 28]. For this reason, ASTM C1287-18 recommends the preparation of four separate mixed standard calibration solutions, where the matrix solution is selected to avoid analyte precipitation[12]. For this investigation, some laboratories used this method (freshly prepared calibration by JRC-KRU), while others took a slightly different approach to avoid unwanted precipitations of these analytes. For example, NRC-1, NRC-2, NRC-3, and NRC-4 followed hotplate digestion, with an uncapping of the digestion vessels to evaporate off the majority of the liquid, then diluted samples in a mixture of HNO3 and HCl. Additionally, standard solutions were analyzed quickly after preparation in an attempt to avoid precipitation.

Matrix and Plasma Effects in ICP-MS

Where column separation was not employed prior to trace element analysis (as was the case for most of the participating laboratories), and where dilution factors were low (i.e. the 1000-fold dilution employed by NRC-1, NRC-2, NRC-3, and NRC-4), significant suppression effects were observed along with signal instability. For this reason, the sample introduction system was flushed with the matrix rinse solution before the start of sample analysis, as well as between samples during analysis. Performing the analyses with a “normal” rinse solution (acid without U) resulted in significant sample-to-sample variation.

Where dilution factors were high enough that the U matrix did not cause significant signal suppression and instability, such as the 8000x dilution (to ~ 100 ppm U) employed by, for example, JRC-KRU, LANL, and LLNL, a U-containing rinse solution was not required. However, steps were still taken to ensure adequate flushing between samples. For example, LANL used a three-step wash sequence consisting of one 10% HNO3 / 0.01 M HF wash followed by two 2% HNO3 washes, followed by a long sample uptake time where the sample or standard was flushed for 30–45 s to thoroughly coat the spray-chamber prior to data collection. Similarly, JRC-KRU used a long rinse time and preceded each sample/standard with a blank to ensure there were no memory effects occurring during analysis.

One factor that played an important role in the ability to achieve good results was the selection of a matrix-matched calibration solution, containing U at a similar concentration to what was present in the digested UOC samples – naturally, the importance of this matrix-matching increased with decreasing dilution factors for the samples. As this was the first time samples of this matrix composition had been analyzed by the group at NRC, some preliminary tests were conducted, comparing matrix matched and non-matched calibration curves for a few elements. Ba, Mn, and Zr were selected due to their relatively high concentrations in the three candidate CRMs, as well as the fact that they were analyzed in three different resolution modes by HR-ICP-MS (low, medium, and high, respectively, which allowed the role of resolution mode to be considered).

A comparison between matrix-matched and non-matrix matched calibration (at 800 ppm U for the 1000x dilution) did not yield any discernable differences when the samples were analyzed by ICP optical emission spectrometry (ICP-OES). Conversely, using SF-ICP-MS, slopes of calibration curves prepared using matrix matched standards were up to 50% lower than those prepared without the addition of 800 ppm U to the matrix, resulting in inaccurate calculations of analyte concentrations in samples when using the non-matrix matched curves. Large element-to-element variation was observed when comparing matrix-matched and non-matrix-matched calibration due to the differences in the degree of suppression occurring for various elements. At higher dilution factors these discrepancies mostly disappeared; at 100 ppm U, for example, very little difference was noted with and without matrix matching. Bürger et al.[11] provide a detailed examination of the signal suppression caused by increasing concentrations of U in the sample matrix.

One approach that has been taken to help improve detection limits during the analysis of uranium matrix samples is the use of cold plasma mode (where lower forward power is provided to the ICP). This results in a lower background and lower detection limits for low-mass elements due to the production of fewer argon-containing interferences. However, since the plasma has less energy for ionization in cold plasma mode, there is a greater potential for matrix effects from the samples themselves[29, 30].

Here, participating laboratories did not use cold plasma mode during their analyses, but matrix effects were still significant, as noted above. In the skimmer cone region, heavy matrix elements cause greater signal suppression than lighter elements, and lighter elements experience more suppression than heavy elements[31]. Therefore, in a high-uranium matrix signals for light elements and those with high ionization potentials are likely to be significantly suppressed, making detection of low concentrations difficult. With higher dilution factors, while the uranium-caused suppression is reduced, the now lower “at instrument” concentrations can still create challenges in detection capabilities.

Interferences in ICP-MS

Table S1 provides a comprehensive outline of the potential isobaric and polyatomic interferences that can affect the measurements of each of the elements analyzed during this investigation.

Several polyatomic interferences are particularly important to consider when analyzing UOC samples. The presence of large uranium levels can have significant contributions to analyte signals. For example, the doubly-charged 238U2+ forms a major interference on 119Sn+, which is why this tin isotope was not selected for measurements of tin. In addition, 238U2+ peak tailing interferes with the neighboring 118Sn+ and 120Sn+. Similarly, 238U40Ar2+ interferes with the detection of 139La+. These two signals can be separated by mass in SF-ICP-MS when operated at the medium mass resolution (m/Δm = 4000)[28, 32] or through the use of a collision cell (with He to reduce the 238U40Ar2+ interference or with O2 to change the mass of the analyte by forming 139La16O+). Additionally, peak tailing from 238U16O2+ can interfere with 126Te+ and 128Te+.

Aside from the uranium matrix, other elements in the samples can interfere with each other. Elements such as Mo, Ta, Sr, Ba, and Zr tend to be present at high levels in UOC samples[17]. Hence, the spectral interferences from these elements or their oxides have to be evaluated. As an example, Zr levels are quite high in UCLO-1 and UPER-1 at over 0.1% (or 1000 mg kg− 1) and the doubly-charged 90Zr2+ can interfere with 45Sc+ or 94Zr2+ with 47Ti+. During this investigation, it was noted that the tailing from 90Zr16O+ had a significant impact on Ag measurements. This interference was noted by measuring the 107Ag/109Ag isotope ratios for the three UOC materials: an abnormally high ratio of 8.5 was observed for UPER-1 (compare that to the natural value of 1.0). As a result, subsequent analyses of silver were conducted using 109Ag isotope rather than 107Ag.

The analysis of lanthanides (rare earth elements) are challenging in UOC samples. The levels of these elements are rather low and it is often that case that column separation is implemented to separate them from the uranium matrix prior to analysis. Additionally, lanthanides are commonly separated into “light” and “heavy” aliquots, and separated from other interfering elements such as Mo and Ba, to eliminate the potential for oxide interferences[28, 33]. In the m/z = 146–170 region, spectral interferences are usually caused by BaO+ and BaOH+ ions[33]. In our UOC samples, Ba concentrations are less than 0.5 mg kg− 1 in UCLO-1 and UCHI-1, but 4.9 mg kg− 1 in UPER-1 (significantly higher than the REEs in all three samples). Given that oxide formation in ICP-MS occurs at an efficiency of 1–2%[33], BaO+ interferences are considered to be significant and, wherever possible, were minimized by using either a collision gas with Q(QQ)-ICP-MS or higher mass resolution mode in SF-ICP-MS.

Other interferences, not unique to UOC analyses, were also considered. For example, As, which is monoisotopic and suffers from 40Ar35Cl+ interference on m/z = 75, was analyzed exclusively in medium (by only one laboratory) or high resolution mode, which was necessary to ensure interference-free detection. Although the transition from low to high resolution decreases ion transmission efficiency by at least 50%,[29] this is often a necessary trade-off to make more reliable measurements.

Correlated Reported Results for Nd and Pr in UCHI-1

Results for Nd and Pr mass fractions in UCHI-1 display apparent trends: there are three distinct groupings of measurement results (we will denote these as “low”, “medium”, and “high”) as shown in Fig. 4. Since we were not able to provide a suitable explanation for this observation, these elements were not listed on the certificate. Nevertheless, we find it useful to discuss several plausible reasons for this grouping.

Looking to sample preparation, the use of HF may have played an important role here. All three laboratories in the “high” group used HF in their digestion protocol, while all three laboratories in the “low” group did not (though, interestingly, the “middle” group is split with two of three using HF; CNL did not). Compared to the other CRMs, the measured mass fractions of Nd and Pr in UCHI-1 are higher than in UCLO-1 and lower than in UPER-1, but individual laboratory results do not display the same pattern. Considering this observation, it is unlikely that the presence (or absence) of HF in the digestion medium is cause for the trends observed in UCHI-1.

In terms of the analysis itself, neither the type of ICP-MS nor the resolving power used in SF-ICP-MS seem to play a role in the observed groupings of these results. For Nd, all labs used low resolution, except LANL which used medium resolution (they also reported the highest value, though not significantly higher than JRC-KRU). For Pr, both LANL and EK used medium resolution modes, and reported the highest and lowest values measured by SF-ICP-MS.

Looking to the isotopes monitored for explanation does not provide much more clarity. Pr is monoisotopic, and the only significant interference is 125TeO+ (see Table S1), which is still fairly insignificant at an isotopic abundance of 7% for 125Te and low concentration of Te in UCHI-1 (although not reported due to the limited dataset, a value of about 0.3 mg kg− 1 could be determined after outliers were removed). For Nd, the laboratories measured different isotopes:

Low Group: IFIN-HH (143Nd + 144Nd + 146Nd), CNSC (146Nd), EK (145Nd).

Medium Group: NRC-3 (146Nd), CNL (146Nd), LLNL (143Nd).

High Group: NRC-1 (146Nd), JRC-KRU (143Nd), LANL (146Nd).

The TeO+ interference also occurs on 144Nd and 146Nd (with both 128Te and 130Te being the major isotopes of tellurium), but is still unlikely to be an explanation for these observed groupings.

Interestingly, IFIN-HH reported the lowest Nd and Pr values, measured very high Te in UCHI-1 (their result being about 100x higher than the next highest reported value and therefore considered an outlier). One explanation for the low reported values for Nd and Pr is the overcorrection of the Te interference.

Lead in the UOC CRMs

An examination of the trace element data, along with some isotope ratio data, determined that the Pb present in the three UOC CRMs was radiogenic. Initial screening isotope ratio data suggests certain values are far from those observed for non-radiogenic sources of lead. For example, while the non-radiogenic-derived 206Pb/204Pb ratio is about 18, values for UPER-1 and UCLO-1 were above 60 and 250, respectively, indicating an enrichment of 206Pb from the decay of 238U. Similarly, the 207Pb/204Pb ratio is slightly elevated in UPER-1, at approximately 18, rather than the non-radiogenic value of 16, with the elevated levels of 207Pb arising from the decay of 235U.

Based on the radiogenic nature of the lead in these three materials, mass spectrometry based quantitation required allowance for the anomalous isotope profile. This was achieved through the monitoring of all four stable isotopes of Pb and using the sum of their ICP-MS signal intensities in subsequent calculations. Interestingly, the ASTM standard method for impurity analysis in uranium compounds[12] only recommends monitoring 208Pb, rather than the sum of isotopes as was used here. While sufficient for some geologic samples, this will require revision if the method is to recommend the use of CRMs such as these, where the Pb is of radiogenic origin.

Data Evaluation and Combination

Traceability

NRC used SI-traceable primary standards either prepared in-house (purity assessed by glow-discharge mass spectrometry[34]) or acquired from another National Metrology Institute (NMI) such as NIST or BAM. For select elements where no NMI standards were available, commercial standards from several different sources were cross calibrated. Typically, differences of less than 2% were observed for the commercial standards; though a bias of up to 5% was measured for some of these solutions. These differences were carried as uncertainties associated with the primary calibrants.

Similar approaches have been used by others for assessing and using commercial calibration standards[35]. The plurality of calibration standards used by participating laboratories is effectively folding calibrant related uncertainties and biases into the overall measurement uncertainty.

Data Combination and Evaluation

After completion of the measurement campaign, a joint evaluation of the data was conducted where decisions were made regarding removal of certain data, based on technical issues such as improper selection of isotopes for measurements or acids for sample digestion. Overall, after technical and statistical filtering, there were 4178 data points remaining (4849 when including QC samples). All of these can be found via the DOIs for the CRMs[18,19,20], organized by element, into plots showing the spread of the data.

The large size of this dataset presented unique challenges that exceeded practical computational limits of common software suites like Excel. This challenge was addressed by the development of an in-house data handling platform, written in R using and deployed via web browser using shinyapps, to carry out the data visualization, inspection, and statistical evaluation.

Determination of Consensus Values and Uncertainties

The datasets obtained from the analysis of the UOC materials by the participating laboratories were quite diverse and required a robust statistical model for the determination of consensus values; therefore, the Laplace random effects model[22] was chosen. Modelled by a double exponential distribution, the heavier tails associated with the Laplace model (compared to a Gaussian distribution) reduce the influence of outliers[36]. Another common approach taken for the determination of consensus values in certification campaigns (i.e. by Rivier et al.[35] and in other NRC CRMs, including U isotope ratio values in UCLO-1, UCHI-1, and UPER-1) is the use of the DerSimonian-Laird excess variance model[24]. While this model was tested for the trace elements data, ultimately the Laplace model proved to be the more robust approach.

As an example of our approach to the determination of a consensus value, Fig. 5 shows the distribution of the mass fraction of V measured by 12 of the participating laboratories. Ideally, interlaboratory comparison data follows a sigmoidal curve, but in this scenario, a few points fall on the low end of the range of measured values, skewing the trend. While the uncertainties cover a broad range, with some much larger than others, there are no apparent biases with the larger uncertainties falling at one end of the range of data. Using a Gaussian approach via the DerSimonian-Laird Random Effects model, as is typically used to determine consensus values for NRC CRMs, arrives at a value that is biased low (the gray line in Fig. 5) and is very close to the mean of the input values. Conversely, the Laplace Random Effects model provides a better estimate of the true value (noted by the orange line in Fig. 5, which runs through the laboratory value with the lowest uncertainty). The (relative) standard uncertainty determined via the Laplace approach is slightly higher at 3.7%, compared to 2.8% determined using a Gaussian approach. For elements where data did fall in the ideal sigmoidal pattern, results of these two models were practically identical; therefore the Laplace Random Effects model was used for all consensus value determinations.

Mass fractions of V in UPER-1, as measured by individual laboratories (blue points). Solid and dashed orange lines indicate the consensus mass fraction and associated combined uncertainty (k = 1) determined by the Laplace Random Effects Model and the gray line is the consensus mass fraction determined by the DerSimonian-Laird model (Gaussian)

When the dispersion in a set of data is greater than what is represented by the individual uncertainties, an additional component, known as the dark uncertainty, is added to the uncertainty budget[37]. Here, dark uncertainty was considered in addition to the more easily-defined uncertainty components arising from the characterization and homogeneity (within- and between-bottle variation).

After the final dataset, including consensus values and uncertainties, was established, the overall quality of each final value needed to be determined for the certificates of analysis. CRMs produced by NRC come with three categories of values: Certified, Reference, and Information. Additionally, for these UOC materials a fourth category was established: a released data category, where no consensus value is provided on the certificate, but individual laboratory values can be found in a supplementary file[18,19,20]. From NRC’s certificates[18,19,20],

Certified values are considered to be those for which the NRC has the highest confidence in accuracy and that all known and suspected sources of bias have been taken into account and are reflected in the stated expanded uncertainties. Certified values are the best estimate of the true value and uncertainty.

Reference values are those for which insufficient data are available to provide a comprehensive estimate of uncertainty.

Information values are those for which insufficient data are available to provide any estimate of uncertainty.

The large size of the dataset for these three UOC materials made it important that there was consistency in the categorization of values for the certificates. Therefore, after the data had been filtered, as described above, a set of guidelines was established to determine an analyte’s place in the four above-noted categories. These were as follows,

-

To be a Certified Value

-

there must be results from at least 4 laboratories,

-

the ratio between the largest and smallest reported laboratory results must be < 4, and

-

the relative combined standard uncertainty must be below 20%.

-

-

To be a Reference Value

-

the criteria to obtain a Certified value are not met,

-

there must be results from at least 3 laboratories, and

-

the ratio between the largest and smallest reported laboratory results must be < 4.

-

-

To be an Information Value

-

the criteria to obtain a Certified and Reference value are not met.

-

-

When data is inadequate to provide a Certified, Reference, or Information value,

-

the data is to be released as a supplement to the certificate if values from at least two laboratories are available,

-

otherwise the data is discarded.

-

Finally, with data combined and categorized, Certificates of Analysis were prepared for each CRM. Table 2 and Fig. 6a provide summaries of the combined data, as they are presented on these certificates[18,19,20].

In this iteration of the certificate of CRMs no “less than” values derived from detection limits are provided. Based on the use of the materials and interest in specific elements this might change over time.

Overview of Trace Elemental Impurities in NRC’s UOC CRMs

A suite of three materials were prepared with the goal of covering a broad range of analyte concentrations. For many elements this was achieved, with mass fractions spanning at least an order of magnitude between UCLO-1, UCHI-1, and UPER-1. Figure 6a gives a visual representation of the range of data, with elements sorted based on their mass fractions in UCHI-1. Figure 6b shows the ratio between the largest and smallest values for elements where the largest differences were observed, noting the 18 elements where this ratio is greater than 50.

Conclusions

Through the collaborative efforts of researchers from 15 laboratories and 10 countries, we analyzed the mass fractions of 64 trace elements in three new UOC CRMs, UCLO-1, UCHI-1, and UPER-1, not only providing consensus data through the Certificates of Analysis, but also sharing information about the individual measurements for each analyte through a database of supplementary information. These materials will serve as SI-traceable quality control measures during the analysis of uranium ore concentrates, specifically during nuclear forensic investigations.

References

International Atomic Energy Agency (2015) Nuclear Forensics in Support of Investigations: Implementing Guide. IAEA Nuclear Security Series. Vienna, Austria

Wallenius M, Mayer K, Ray I (2006) Nuclear forensic investigations: Two case studies. Forensic Sci Int 156:55–62. https://doi.org/10.1016/j.forsciint.2004.12.029

Švedkauskaitė-LeGore J, Rasmussen G, Abousahl S, Van Belle P (2008) Investigation of the sample characteristics needed for the determination of the origin of uranium-bearing materials. J Radioanal Nucl Chem 278:201–209. https://doi.org/10.1007/s10967-007-7215-y

Mayer K, Wallenius M, Ray I (2005) Nuclear forensics - A methodology providing clues on the origin of illicitly trafficked nuclear materials. Analyst 130:433–441. https://doi.org/10.1039/b412922a

Keegan E, Richter S, Kelly I, Wong H, Gadd P, Kuehn H, Alonso-Munoz A (2008) The provenance of Australian uranium ore concentrates by elemental and isotopic analysis. Appl Geochem 23:765–777. https://doi.org/10.1016/j.apgeochem.2007.12.004

Mercadier J, Cuney M, Lach P, Boiron MC, Bonhoure J, Richard A, Leisen M, Kister P (2011) Origin of uranium deposits revealed by their rare earth element signature. Terra Nova 23:264–269. https://doi.org/10.1111/j.1365-3121.2011.01008.x

Keegan E, Wallenius M, Mayer K, Varga Z, Rasmussen G (2012) Attribution of uranium ore concentrates using elemental and anionic data. Appl Geochem 27:1600–1609. https://doi.org/10.1016/j.apgeochem.2012.05.009

Spano TL, Simonetti A, Balboni E, Dorais C, Burns PC (2017) Trace element and U isotope analysis of uraninite and ore concentrate: Applications for nuclear forensic investigations. Appl Geochem 84:277–285. https://doi.org/10.1016/j.apgeochem.2017.07.003

Edwards CR, Oliver AJ (2000) Uranium processing: A review of current methods and technology. JOM 52:12–20. https://doi.org/10.1007/s11837-000-0181-2

Nelwamondo AN, Colletti LP, Lindvall RE, Vesterlund A, Xu N, Tan AHJ, Eppich GR, Genetti VD, Kokwane BL, Lagerkvist P, Pong BK, Ramebäck H, Tandon L, Rasmussen G, Varga Z, Wallenius M (2018) Uranium assay and trace element analysis of the fourth collaborative material exercise samples by the modified Davies-Gray method and the ICP-MS/OES techniques. J Radioanal Nucl Chem 315:379–394. https://doi.org/10.1007/s10967-018-5708-5

Bürger S, Riciputi LR, Bostick DA (2007) Determination of impurities in uranium matrices by time-of-flight ICP-MS using matrix-matched method. J Radioanal Nucl Chem 274:491–505. https://doi.org/10.1007/s10967-006-6930-0

ASTM International (2018) Standard Test Method for Determination of Impurities in Nuclear Grade Uranium Compounds by Inductively Coupled Plasma Mass Spectrometry. C1287-18. ASTM International, West Conshohocken, Pennsylvania, United States https://doi.org/10.1520/C1287-18

Canadian Certified Reference Materials Project (1988) CUP-2. Certified Reference Material: Uranium Ore Concentrate. Natural Resources Canada

New Brunswick Laboratory (2008) CRM 124: Uranium (U3O8) 24 Element Impurity. Standard United States Department of Energy

Commission d’Etablissement des Méthodes d’Analyse (2018) Reference Materials Catalogue. French Alternative Energies and Atomic Energy Commission. https://cetama.partenaires.cea.fr/Local/cetama/files/633/DO_22_-_MRC_catalogue_01-2018_v0_EN_final.pdf. Accessed 31 March 2021

Denton J, Bostick DA, Boulyga SF, Cunningham JA, Dimayuga I, Hexel CR, Hiess J, Jovanovic SV, Kaye P, Kell T, Kelly F, Kinman W, Kiser S, Lindvall RE, Macsik Z, Manard BT, Mayer K, Mercier J-F, Samuleev P, Saull PRB, Shi Y, Steiner RE, Ticknor BW, Totland M, Varga Z, Wallenius M, Wylie EM(2022) International Interlaboratory Compilation of Trace Element Concentrations in the CUP-2 Uranium Ore Concentrate Standard. J Radioanal Nucl Chem In Review

Bürger S, Boulyga FS, Peńkin MV, Bostick D, Jovanovic S, Lindvall R, Rasmussen G, Riciputi L (2014) Quantifying multiple trace elements in uranium ore concentrates: an interlaboratory comparison. J Radioanal Nucl Chem 301:711–729. https://doi.org/10.1007/s10967-014-3224-9

Nadeau K, Meija J, LeBlanc K, Yang L, Pagliano E, Aregbe Y, Babay PA, Broome C, Chartrand MMG, Chipley D, Choi JY, Denton JS, Fayek M, Francisco BBA, Fourny A, Fugaru V, Gartner B, Gautier EA, Grinberg P, Holsten A, Inglis JD, Jovanovic S, Keegan E, Kell T, Kimura Y, Kinman WS, Kieser WE, Kiser S, Knaack D, Kovacs-Szeles E, Lindvall RE, Loi E, Marks NE, Mayer K, Mercier J-F, Millar R, Orlovskaya L, Ramella JL, Reavie R, Richter S, Seo H, Serban AE, Shabaga B, Sharpe R, Shi Y, Singleton MJ, Tobi C, Toch A, Totland M, Varga Z, Venchiarutti C, Vesterlund A, Virgolici M, Vuletich A, Wallenius M, Yamazaki H, Zhao X, Mester Z (2020) UCLO-1: Natural Uranium Ore Concentrate (U3O8) Powder Certified Reference Material for Uranium Content, Uranium Isotope Ratios, and Trace Elements. National Research Council Canada. https://doi.org/10.4224/crm.2020.uclo-1

Nadeau K, Meija J, LeBlanc K, Yang L, Pagliano E, Aregbe Y, Babay PA, Broome C, Chartrand MMG, Chipley D, Choi JY, Denton JS, Fayek M, Francisco BBA, Fourny A, Fugaru V, Gartner B, Gautier EA, Grinberg P, Holsten A, Inglis JD, Jovanovic S, Keegan E, Kell T, Kimura Y, Kinman WS, Kieser WE, Kiser S, Knaack D, Kovacs-Szeles E, Lindvall RE, Loi E, Marks NE, Mayer K, Mercier J-F, Millar R, Orlovskaya L, Ramella JL, Reavie R, Richter S, Seo H, Serban AE, Shabaga B, Sharpe R, Shi Y, Singleton MJ, Tobi C, Toch A, Totland M, Varga Z, Venchiarutti C, Vesterlund A, Virgolici M, Vuletich A, Wallenius M, Yamazaki H, Zhao X, Mester Z (2020) UCHI-1: Natural Uranium Ore Concentrate (U3O8) Powder Certified Reference Material for Uranium Content, Uranium Isotope Ratios, and Trace Elements. National Research Council Canada. https://doi.org/10.4224/crm.2020.uchi-1

Nadeau K, Meija J, LeBlanc K, Yang L, Pagliano E, Aregbe Y, Babay PA, Broome C, Chartrand MMG, Chipley D, Choi JY, Denton JS, Fayek M, Francisco BBA, Fourny A, Fugaru V, Gartner B, Gautier EA, Grinberg P, Holsten A, Inglis JD, Jovanovic S, Keegan E, Kell T, Kimura Y, Kinman WS, Kieser WE, Kiser S, Knaack D, Kovacs-Szeles E, Lindvall RE, Loi E, Marks NE, Mayer K, Mercier J-F, Millar R, Orlovskaya L, Ramella JL, Reavie R, Richter S, Seo H, Serban AE, Shabaga B, Sharpe R, Shi Y, Singleton MJ, Tobi C, Toch A, Totland M, Varga Z, Venchiarutti C, Vesterlund A, Virgolici M, Vuletich A, Wallenius M, Yamazaki H, Zhao X, Mester Z (2020) UPER-1: Natural Uranium Ore Concentrate (UO4) Powder Certified Reference Material for Uranium Content, Uranium Isotope Ratios, and Trace Elements. National Research Council Canada. https://doi.org/10.4224/crm.2020.uper-1

Zhang R, Nadeau K, Amilcar Gautier E, Babay PA, Ramella JL, Virgolici M, Serban AE, Fugaru V, Kimura Y, Venchiarutti C, Richter S, Aregbe Y, Varga Z, Wallenius M, Mayer K, Seo H, Choi JY, Tobi C, Fayek M, Sharpe R, Samperton KM, Genetti VD, Lindvall RE, Inglis JD, Denton JS, Reinhard AA, Francisco B, Zhao X, Kieser W, He J, Gao Y, Meija J, El-Jaby A, Yang L, Mester Z (2021) Certification of Uranium Isotope Amount Ratios in a Suite of Uranium Ore Concentrate Certified Reference Materials. Geostand Geoanal Res. https://doi.org/10.1111/ggr.12409

Rukhin AL, Possolo A (2011) Laplace random effects models for interlaboratory studies. Comput Stat Data Anal 55:1815–1827. https://doi.org/10.1016/j.csda.2010.11.016

Eppich G, Kips R, Lindvall R (2016) Compilation of LLNL CUP-2 Data. Lawrence Livermore National Security, Livermore, California

DerSimonian R, Laird N (1986) Meta-analysis in clinical trials. Control Clin Trials 7:177–188. https://doi.org/10.1016/0197-2456(86)90046-2

Horwitz W, Kamps LR, Boyer KW (1980) Quality assurance in the analysis of foods and trace constituents. J Assoc Off Anal Chem 63:1344–1354. https://doi.org/10.1093/jaoac/63.6.1344

Horwitz W (1982) Evaluation of Analytical Methods Used for Regulation of Foods and Drugs. Anal Chem 54:67–76. https://doi.org/10.1021/ac00238a002

Meija J, Pagliano E, Mester Z (2014) Coordinate swapping in standard addition graphs for analytical chemistry: A simplified path for uncertainty calculation in linear and nonlinear plots. Anal Chem 86:8563–8567. https://doi.org/10.1021/ac5014749

Boulyga SF, Cunningham JA, Macsik Z, Hiess J, Peńkin MV, Walsh SJ (2017) Development, validation and verification of an ICP-MS procedure for a multi-element analysis of uranium ore concentrates. J Anal At Spectrom 32:2226–2237. https://doi.org/10.1039/c7ja00180k

Manard BT, Metzger SC, Rogers KT, Ticknor BW, Bostick DA, Zirakparvar NA, Hexel CR (2020) Exploration of ICP platforms for measuring elemental impurities in uranium ore concentrates. Int J Mass spectrom 455. https://doi.org/10.1016/j.ijms.2020.116378

Tanner SD (1995) Characterization of ionization and matrix suppression in inductively coupled ‘cold’ plasma mass spectrometry. J Anal At Spectrom 10:905–921. https://doi.org/10.1039/JA9951000905

Gillson GR, Douglas DJ, Fulford JE, Halligan KW, Tanner SD (1988) Nonspectroscopic Interelement Interferences in Inductively Coupled Plasma Mass Spectrometry. Anal Chem 60:1472–1474. https://doi.org/10.1021/ac00165a024

Boulyga S, Konegger-Kappel S, Richter S, Sangély L (2015) Mass spectrometric analysis for nuclear safeguards. J Anal At Spectrom 30:1469–1489. https://doi.org/10.1039/c4ja00491d

Varga Z, Katona R, Stefánka Z, Wallenius M, Mayer K, Nicholl A (2010) Determination of rare-earth elements in uranium-bearing materials by inductively coupled plasma mass spectrometry. Talanta 80:1744–1749. https://doi.org/10.1016/j.talanta.2009.10.018

Sturgeon RE, Methven B, Willie SN, Grinberg P (2014) Assignment of purity to primary metal calibrants using pin-cell VG 9000 glow discharge mass spectrometry: A primary method with direct traceability to the SI international system of units? Metrologia 51:410–422. https://doi.org/10.1088/0026-1394/51/5/410

Rivier C, Désenfant M, Crozet M, Rigaux C, Roudil D, Tufféry B, Ruas A (2014) Use of an excess variance approach for the certification of reference materials by interlaboratory comparison. Accred Qual Assur 19:269–274. https://doi.org/10.1007/s00769-014-1066-3

Possolo A, Meija J (2020) Measurement Uncertainty: A Reintroduction. Sistema Interamericano de Metrologia - SIM, Montevideo, Uruguay. https://doi.org/10.4224/40001835

Thompson M, Ellison SLR (2011) Dark uncertainty. Accred Qual Assur 16:483–487. https://doi.org/10.1007/s00769-011-0803-0

Acknowledgements

Laurence Livermore National Laboratory’s contribution to this work was performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the U.S. Government. LLNL-JRNL-836978. Similarly, Los Alamos National Laboratory’s contribution is covered under LA-UR-21-21845.

Funding

Open Access provided by National Research Council Canada.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

LeBlanc, K.L., Nadeau, K., Meija, J. et al. Collaborative Study for Certification of Trace Elements in Uranium Ore Concentrate CRMs UCLO-1, UCHI-1, and UPER-1. J Radioanal Nucl Chem 331, 4031–4045 (2022). https://doi.org/10.1007/s10967-022-08446-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08446-3