Abstract

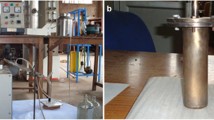

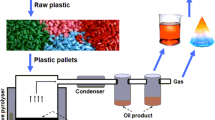

Chemical recycling of is one of the promising ways for waste plastics disposal. In this work, the kinetics and reaction mechanism of polyolefins pyrolysis was studied in detail by sectional heating process. Thermal degradation properties were analyzed by thermo gravimetric analysis (TGA) and pyrolysis reactor. The overall kinetic of the process was studied by Ozawa-Flynn-Wall (OFW) method and Coats-Redfern method. The apparent activation energy (E) and pre-exponential factor (A) were 212 kJ/mol, 4.90×1017 min-1 and 251 kJ/mol, 5.49×1020 min-1, respectively. Step heating process was used in pyrolysis reactor with three different temperatures: 430, 450 and 470 ℃, corresponding to the beginning, fastest and ending degradation temperature obtained by TGA results. GC-MS results showed that the main products were oil except for that in film specimen at 430 ℃. C12 products were dominant for all specimens. The highest yield of aliphatic hydrocarbon was 78% for raw specimens at 470 ℃ and 62% for film specimens at 450 ℃. The content of alkanes increased from 19.8% to 25.3% with increasing operation temperature for raw specimens, while the yield of alkenes was about 68% and nearly unchanged under different temperatures. The recovery of oil products could be a potential source of transport fuel.

Similar content being viewed by others

Data Availability

Data will be available on the request.

References

Al-Salem S, Antelava A, Constantinou A, Manos G, Dutta A (2017) A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J Environ Manage 197:177–198

Idumah CI (2022) Recent advancements in thermolysis of plastic solid wastes to liquid fuel. J Therm Anal Calorim 147(5):3495–3508

Ashworth DC, Elliott P, Toledano MB (2014) Waste incineration and adverse birth and neonatal outcomes: a systematic review. Environ Int 69:120–132

Maqsood T, Dai J, Zhang Y, Guang M, Li B (2021) Pyrolysis of plastic species: A review of resources and products. J Anal Appl Pyrolysis 159

Vouvoudi EC, Achilias DS (2020) Polymer packaging waste recycling: study of the pyrolysis of two blends via TGA. J Therm Anal Calorim 142(5):1891–1895

Thompson RC, Moore CJ, Vom Saal FS, Swan SH (2009) Plastics, the environment and human health: current consensus and future trends. Philos Trans R Soc B: Biol Sci 364(1526):2153–2166

Benavides PT, Sun P, Han J, Dunn JB, Wang M (2017) Life-cycle analysis of fuels from post-use non-recycled plastics. Fuel 203:11–22

Abbas-Abadi M. Seifali (2021) The effect of process and structural parameters on the stability, thermo-mechanical and thermal degradation of polymers with hydrocarbon skeleton containing PE, PP, PS, PVC, NR, PBR and SBR. J Therm Anal Calorim 143(4):2867–2882

Agblevor FA, Mante O, Abdoulmoumine N, McClung R (2010) Production of stable biomass pyrolysis oils using fractional catalytic pyrolysis. Energy Fuels 24(7):4087–4089

Wang G, Dai Y, Yang H, Xiong Q, Wang K, Zhou J, Li Y, Wang S (2020) A review of recent advances in biomass pyrolysis. Energy Fuels 34(12):15557–15578

Soni VK, Singh G, Vijayan BK, Chopra A, Kapur GS, Ramakumar S (2021) Thermochemical recycling of waste plastics by pyrolysis: a review. Energy Fuels 35(16):12763–12808

Zhang Y, Ji G, Chen C, Wang Y, Wang W, Li A (2020) Liquid oils produced from pyrolysis of plastic wastes with heat carrier in rotary kiln. Fuel Process Technol 206

Zhang Y, Ji G, Ma D, Chen C, Wang Y, Wang W, Li A (2020) Exergy and energy analysis of pyrolysis of plastic wastes in rotary kiln with heat carrier. Process Saf Environ Prot 142:203–211

Chang C-C, Wu S-R, Lin C-C, Wan H-P, Lee H-T (2012) Fast pyrolysis of biomass in pyrolysis gas: Fractionation of pyrolysis vapors using a spray of bio-oil. Energy Fuels 26(5):2962–2967

Demirbas A (2009) Biorefineries: Current activities and future developments. Energy Convers Manage 50(11):2782–2801

Das P, Tiwari P (2018) The effect of slow pyrolysis on the conversion of packaging waste plastics (PE and PP) into fuel. Waste Manag 79:615–624

Harussani M, Sapuan S, Rashid U, Khalina A, Ilyas R (2022) Pyrolysis of polypropylene plastic waste into carbonaceous char: Priority of plastic waste management amidst COVID-19 pandemic. Sci Total Environ 803

Peng Y, Wang Y, Ke L, Dai L, Wu Q, Cobb K, Zeng Y, Zou R, Liu Y, Ruan R (2022) A review on catalytic pyrolysis of plastic wastes to high-value products. Energy Convers Manag 254

Suriapparao DV, Kumar TH, Reddy BR, Yerrayya A, Srinivas BA, Sivakumar P, Prakash SR, Rao CS, Sridevi V, Desinghu J (2022) Role of ZSM5 catalyst and char susceptor on the synthesis of chemicals and hydrocarbons from microwave-assisted in-situ catalytic co-pyrolysis of algae and plastic wastes. Renew Energy 181:990–999

Cai N, Li X, Xia S, Sun L, Hu J, Bartocci P, Fantozzi F, Williams PT, Yang H, Chen H (2021) Pyrolysis-catalysis of different waste plastics over Fe/Al2O3 catalyst: High-value hydrogen, liquid fuels, carbon nanotubes and possible reaction mechanisms. Energy Convers Manag 229

Zhang Y, Fu Z, Wang W, Ji G, Zhao M, Li A (2021) Kinetics, Product Evolution, and Mechanism for the Pyrolysis of Typical Plastic Waste. ACS Sustain Chem Eng 10(1):91–103

He X-C, Chen D-Z (2022) ReaxFF MD study on the early stage co-pyrolysis of mixed PE/PP/PS plastic waste. J Fuel Chem Technol 50(3):346–356

Harmon RE, SriBala G, Broadbelt LJ, Burnham AK (2021) Insight into polyethylene and polypropylene pyrolysis: Global and mechanistic models. Energy Fuels 35(8):6765–6775

Ding Z, Liu J, Chen H, Huang S, Evrendilek F, He Y, Zheng L (2021) Co-pyrolysis performances, synergistic mechanisms, and products of textile dyeing sludge and medical plastic wastes. Sci Total Environ 799

Miandad R, Barakat M, Aburiazaiza AS, Rehan M, Ismail I, Nizami A (2017) Effect of plastic waste types on pyrolysis liquid oil. Int Biodeter Biodegr 119:239–252

Pinto F, Costa P, Gulyurtlu I, Cabrita I (1999) Pyrolysis of plastic wastes. 1. Effect of plastic waste composition on product yield. J Anal Appl Pyrolysis 51(1-2):39-55

Donaj PJ, Kaminsky W, Buzeto F, Yang W (2012) Pyrolysis of polyolefins for increasing the yield of monomers’ recovery. Waste Manag 32(5):840–846

Ciliz NK, Ekinci E, Snape CE (2004) Pyrolysis of virgin and waste polypropylene and its mixtures with waste polyethylene and polystyrene. Waste Manag 24(2):173–181

Honus S, Kumagai S, Fedorko G, Molnár V, Yoshioka T (2018) Pyrolysis gases produced from individual and mixed PE, PP, PS, PVC, and PET—Part I: Production and physical properties. Fuel 221:346–360

Maniscalco M, La Paglia F, Iannotta P, Caputo G, Scargiali F, Grisafi F, Brucato A (2021) Slow pyrolysis of an LDPE/PP mixture: Kinetics and process performance. J Energy Inst 96:234–241

Valanciene E, Miknius L, Pedisius N (2016) The influence of zeolite catalyst on kinetics and thermodynamics of polypropylene waste thermal degradation. J Therm Anal Calorim 124(1):341–354

Jung S-H, Cho M-H, Kang B-S, Kim J-S (2010) Pyrolysis of a fraction of waste polypropylene and polyethylene for the recovery of BTX aromatics using a fluidized bed reactor. Fuel Process Technol 91(3):277–284

Simon C, Kaminsky W, Schlesselmann B (1996) Pyrolysis of polyolefins with steam to yield olefins. J Anal Appl Pyrol 38(1–2):75–87

Chu S, Zhang B, Zhao X, Soo HS, Wang F, Xiao R, Zhang H (2022) Photocatalytic Conversion of Plastic Waste: From Photodegradation to Photosynthesis. Adv Energy Mater 12(22):2200435

Su H, Li T, Zhu L, Wang S (2021) Catalytic Reforming of the Aqueous Phase Derived from Diluted Hydrogen Peroxide Oxidation of Waste Polyethylene for Hydrogen Production. Chemsuschem 14(19):4270–4279

Zhou Y, Li G, Jin L, Zhou J, Wang J, Li Y, Hu H (2018) In situ analysis of catalytic effect of calcium nitrate on Shenmu coal pyrolysis with pyrolysis vacuum ultraviolet photoionization mass spectrometry. Energy Fuels 32(2):1061–1069

Yao D, Yang H, Chen H, Williams PT (2018) Co-precipitation, impregnation and so-gel preparation of Ni catalysts for pyrolysis-catalytic steam reforming of waste plastics. Appl Catal B 239:565–577

Caldeira VP, Santos AG, Oliveira DS, Lima RB, Souza LD, Pergher SB (2017) Polyethylene catalytic cracking by thermogravimetric analysis. J Therm Anal Calorim 130(3):1939–1951

Paula TP, Marques MFV, da Costa Marques MR (2019) Influence of mesoporous structure ZSM-5 zeolite on the degradation of Urban plastics waste. J Therm Anal Calorim 138(5):3689–3699

Aisien ET, Otuya IC, Aisien FA (2021) Thermal and catalytic pyrolysis of waste polypropylene plastic using spent FCC catalyst. Environ Technol Innov 22

Ozawa Takeo (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38(11):1881–1886

Flynn JH, Wall LA (1966) A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci Part C: Polym Lett 4(5):323–328

Maniscalco M, Mistretta L, Iannotta P, Caputo G, Scargiali F, Grisafi F, Brucato A (2020) Experimental study of the pyrolysis of waste bitumen for oil production. J Energy Inst 93(6):2456–2463

Zheng Y, Tao L, Yang X, Huang Y, Liu C, Zheng Z (2018) Study of the thermal behavior, kinetics, and product characterization of biomass and low-density polyethylene co-pyrolysis by thermogravimetric analysis and pyrolysis-GC/MS. J Anal Appl Pyrol 133:185–197

Apaydin-Varol E, Polat S, Pütün A (2014) Pyrolysis kinetics and thermal decomposition behavior of polycarbonate-a TGA-FTIR study. Therm Sci 18

Mordi RC, Dwyer J, Fields R (1994) H-ZSM-5 catalysed degradation of low density polyethylene, polypropylene, polyisobutylene and squalane: Influence of polymer structure on aromatic product distribution. Polym Degrad Stab 46(1):57–62

Sakata Y, Uddin MA, Muto A (1999) Degradation of polyethylene and polypropylene into fuel oil by using solid acid and non-acid catalysts. J Anal Appl Pyrol 51(1–2):135–155

Ranzi E, Dente M, Faravelli T, Bozzano G, Fabini S, Nava R, Cozzani V, Tognotti L (1997) Kinetic modeling of polyethylene and polypropylene thermal degradation. J Anal Appl Pyrol 40:305–319

Tsuchiya Y, Sumi K (1968) Thermal decomposition products of polyethylene. J Polym Sci Part A‐1: Polym Chem 6(2):415–424

Ylitervo P, Richards T (2021) Gaseous products from primary reactions of fast plastic pyrolysis. J Anal Appl Pyrol 158

Zhou Q, Zheng L, Wang Y-Z, Zhao G-M, Wang B (2004) Catalytic degradation of low-density polyethylene and polypropylene using modified ZSM-5 zeolites. Polym Degrad Stab 84(3):493–497

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Granted No. 51875297).

Funding

National Natural Science Foundation of China, 51875297, Fengfu Yin.

Author information

Authors and Affiliations

Contributions

Fengfu Yin: Conceptualization, Methodology, Investigation, Data curation, Writing–editing, Fangshuo Fan: Experimental analysis and discussion, Writing – original draft, preparation. Xiaoliang Yuan, Han Wu, Tianhao Chang: Experimental analysis, Analysis of data and discussion. Dong Liang, Junwei Lei: Experimental analysis and discussion, Writing– review & editing, Supervision.

Corresponding authors

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The quality of pyrolysis products was significantly improved via step heating pyrolysis.

• Oil is the primary cracking product with a yield up to 78wt%.

• C12 is the primary products of pyrolysis oil, accounting for 45wt%.

• Molecular scission model was proposed for pyrolysis of mixed plastics.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yin, F., Fan, F., Yuan, X. et al. Pyrolysis of raw and film PP/LDPE mixtures by step heating process. J Polym Res 30, 247 (2023). https://doi.org/10.1007/s10965-023-03587-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03587-9