Abstract

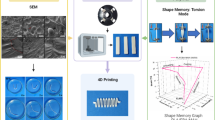

Polycaprolactone (PCL) and thermoplastic polyurethane (TPU), are the most common shape-memory materials, but towards PCL/TPU blends, little attention was paid to the FDM printability and shape memory properties. Therefore, according to the PCL/TPU composites with different compositions, this work focus on the process parameters in fabricating composites filament and 3D printing (FDM), properties characterization analysis (i.e., TGA, DSC, FTIR, SEM, mechanical features, shape-memory effects). Combining TGA with FTIR analysis, we can find out that the FDM printing process does not affect the thermal properties of PCL/TPU composites, and no new chemical groups appeared. By mechanical testing, the tensile strength decreased with the increasing TPU content of the blends, which is also consistent with SEM measurements. Moreover, the DSC measurements can assist in testing the shape memory recovery ratio and shape memory fixity rate of each PCL/TPU composite and verify there is no evident effect of 3D printing process parameters on shape memory effects. Finally,3D printing (FDM) functional structures further demonstrate the shape memory properties of the new composite. In summary, this work can provide some experimental foundation and process guidance of one category of new material.

Similar content being viewed by others

References

Pandini S, Passera S, Messori M et al (2012) Two-way reversible shape memory behaviour of crosslinked poly (ε-caprolactone). Polymer 53(9):1915–1924

Meng H, Li G (2013) A review of stimuli-responsive shape memory polymer composites. Polymer 54(9):2199–2221

Wang Y, Wang Y, Wei Q et al (2021) Effects of the composition ratio on the properties of PCL/PLA blends: a kind of thermo-sensitive shape memory polymer composites. J Polym Res 28(12):1–13

Cheng Z, Zhang D, Lv T et al (2018) Superhydrophobic shape memory polymer arrays with switchable isotropic/anisotropic wetting. Adv Func Mater 28(7):1705002

Wang W, Liu D, Liu Y et al (2015) Electrical actuation properties of reduced graphene oxide paper/epoxy-based shape memory composites. Compos Sci Technol 106:20–24

Conti S, Lenz M, Rumpf M (2016) Hysteresis in magnetic shape memory composites: Modeling and simulation. J Mech Phys Solids 89:272–286

Han XJ, Dong ZQ, Fan MM et al (2012) pH-induced shape-memory polymers. Macromol Rapid Commun 33(12):1055–1060

Beblo RV, Weiland LM (2011) Light activated shape memory polymer characterization—part II. J appl mechan 78(6)

Wei ZG, Sandstroröm R, Miyazaki S (1998) Shape-memory materials and hybrid composites for smart systems: Part I Shape-memory materials. J Mater Sci 33(15):3743–3762

Schurch KE, Ashbee KHG (1977) A near perfect shape-memory ceramic material. Nature 266(5604):706–707

Löwenberg C, Balk M, Wischke C et al (2017) Shape-memory hydrogels: evolution of structural principles to enable shape switching of hydrophilic polymer networks. Acc Chem Res 50(4):723–732

Gu X, Mather PT (2012) Entanglement-based shape memory polyurethanes: synthesis and characterization. Polymer 53(25):5924–5934

Zhu Y, Hu J, Yeung LY et al (2007) Effect of steaming on shape memory polyurethane fibers with various hard segment contents. Smart Mater Struct 16(4):969

Panahi-Sarmad M, Goodarzi V, Amirkiai A et al (2019) Programing polyurethane with systematic presence of graphene-oxide (GO) and reduced graphene-oxide (rGO) platelets for adjusting of heat-actuated shape memory properties. Eur Polymer J 118:619–632

Chen S, Hu J, Liu Y et al (2007) Effect of molecular weight on shape memory behavior in polyurethane films. Polym Int 56(9):1128–1134

Sáenz-Pérez M, Laza JM, García-Barrasa J et al (2018) Influence of the soft segment nature on the thermomechanical behavior of shape memory polyurethanes. Polym Eng Sci 58(2):238–244

Maitland DJ, Metzger MF, Schumann D et al (2002) Photothermal properties of shape memory polymer micro-actuators for treating stroke. Lasers in Surgery and Medicine: The Official Journal of the American Society for Laser Medicine and Surgery 30(1):1–11

Wache HM, Tartakowska DJ, Hentrich A et al (2003) Development of a polymer stent with shape memory effect as a drug delivery system. J Mater Sci - Mater Med 14(2):109–112

Hendrikson WJ, Rouwkema J, Clementi F et al (2017) Towards 4D printed scaffolds for tissue engineering: exploiting 3D shape memory polymers to deliver time-controlled stimulus on cultured cells. Biofabrication 9(3):031001

Wu JJ, Huang LM, Zhao Q et al (2018) 4D printing: history and recent progress. Chin J Polym Sci 36(5):563–575

Raasch J, Ivey M, Aldrich D et al (2015) Characterization of polyurethane shape memory polymer processed by material extrusion additive manufacturing. Addit Manuf 8:132–141

Yang Y, Chen Y, Wei Y et al (2016) 3D printing of shape memory polymer for functional part fabrication. The Int J Adv Manuf Technol 84(9):2079–2095

Kashyap D, Kumar PK, Kanagaraj S (2018) 4D printed porous radiopaque shape memory polyurethane for endovascular embolization. Addit Manuf 24:687–695

Christ JF, Aliheidari N, Ameli A et al (2017) 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater Des 131:394–401

Gul JZ, Sajid M, Choi KH (2019) Retracted Article: 3D printed highly flexible strain sensor based on TPU–graphene composite for feedback from high speed robotic applications. J Maters Chem C 7(16):4692–4701

Xu B, Huang WM, Pei YT et al (2009) Mechanical properties of attapulgite clay reinforced polyurethane shape-memory nanocomposites. Eur Polymer J 45(7):1904–1911

Yildirim ED, Besunder R, Guceri S et al (2008) Fabrication and plasma treatment of 3D polycaprolactane tissue scaffolds for enhanced cellular function. Virtual and Physical Prototyping 3(4):199–207

Tian G, Zhu G, Ren T et al (2019) The effects of PCL diol molecular weight on properties of shape memory poly (ε-caprolactone) networks. J Appl Polym Sci 136(6):47055

Ajili SH, Ebrahimi NG, Soleimani M (2009) Polyurethane/polycaprolactane blend with shape memory effect as a proposed material for cardiovascular implants. Acta Biomater 5(5):1519–1530

Ansari M, Golzar M, Baghani M et al (2018) Shape memory characterization of poly (ε-caprolactone) (PCL)/polyurethane (PU) in combined torsion-tension loading with potential applications in cardiovascular stent. Polym Testing 68:424–432

Jing X, Mi HY, Huang HX et al (2016) Shape memory thermoplastic polyurethane (TPU)/poly (ε-caprolactone) (PCL) blends as self-knotting sutures. J Mechanical Behavior of Biomed Mater 64:94–103

Mosleh Y, Ebrahimi NG, Mahdavian A et al (2014) TPU/PCL/nanomagnetite ternary shape memory composites: studies on their thermal, dynamic-mechanical, rheological and electrical properties. Iran Polym J 23(2):137–145

Xu X, Fan P, Ren J et al (2018) Self-healing thermoplastic polyurethane (TPU)/polycaprolactone (PCL)/multi-wall carbon nanotubes (MWCNTs) blend as shape-memory composites. Compos Sci Technol 168:255–262

Ren D, Chen Y, Li H et al (2019) High-efficiency dual-responsive shape memory assisted self-healing of carbon nanotubes enhanced polycaprolactone/thermoplastic polyurethane composites. Colloids Surf A 580

Haroosh H J, Dong Y (2015) Systematic Development of Electrospun PLA/PCL Fiber Hybrid Mats: Preparation, Material Characterization, and Application in Drug Delivery. Biodegradable Polyesters

Navarro-Baena I, Sessini V, Dominici F et al (2016) Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym Degrad Stab 132:97–108

Huang L, Yi N, Wu Y et al (2013) Multichannel and repeatable self-healing of mechanical enhanced graphene-thermoplastic polyurethane composites. Adv Mater 25(15):2224–2228

Ur Rehman H, Chen Y, Hedenqvist MS et al (2018) Self-Healing Shape Memory PUPCL Copolymer with High Cycle Life. Adv Func Mater 28(7):1704109

Yuan X, Sang Z, Zhao J et al (2017) Synthesis and properties of non-isocyanate aliphatic thermoplastic polyurethane elastomers with polycaprolactone soft segments. J Polym Res 24(6):1–11

Acknowledgements

This project was sponsored by the National Natural Science Foundation of China (Grant No. 51905438), the Key Research and Development Program of Shanxi Province (Grant No. 2022GY-228), the Fundamental Research Funds for the Central Universities (Grant No.31020210506006), the National Key Research and Development Program of China (Grant No. 2019QY(Y)0502). We would like to thank the Analytical & Testing Center of Northwestern Polytechnical University for DSC, SEM and TGA tests.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest exist.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 22707 KB)

Supplementary file1 (MP4 4983 KB)

Supplementary file1 (MP4 5075 KB)

Supplementary file1 (MP4 4986 KB)

Supplementary file1 (MP4 4991 KB)

Supplementary file1 (MP4 5017 KB)

Supplementary file1 (MP4 5011 KB)

Rights and permissions

About this article

Cite this article

Wang, Y., Zhang, J., Li, M. et al. 3D printing thermo-responsive shape memory polymer composite based on PCL/TPU blends. J Polym Res 29, 243 (2022). https://doi.org/10.1007/s10965-022-03095-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03095-2