Abstract

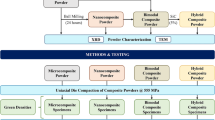

Nanocomposites made of poly(ethylene terephthalate) (PET) and graphene nanoplatelets (GNPs) were fabricated through micro-compounding and micro-injection molding. With an objective of improving the interactions between GNP sheets and PET chains, PET pellets were ground into a fine powder. PET pellets and powders were mixed with GNPs at 2%, 5%, 7.5%, and 10% (wt.%), molded to fabricate the nanocomposites, and then tested using several analytical characterization tools. Mechanical testing showed greater improvement through powder mixing, resulting in a 58% increase in the elastic modulus of the nanocomposites at 10% weight fraction. Thermal behavior of the nanocomposites was evaluated through differential scanning calorimetry (DSC), and it was observed that addition of GNPs into PET powders at 10% increased the crystallinity of the PET 50%. Confocal microscopy confirmed that mixing GNP with PET powders results in a more uniform distribution of the GNPs in the matrix compared to the mixture with PET pellets. X-ray diffraction (XRD) analysis confirmed the presence of GNPs with preferred orientation within the PET matrix.

GNP distribution analysis in melt-compounded PET nanocomposites

Similar content being viewed by others

References

Chen J, Gardner DJ (2008) Dynamic mechanical properties of extruded nylon–wood composites. Polym Compos 29(4):372–379

Maniar KK (2004) Polymeric nanocomposites: a review. Polym-Plast Technol Eng 43(2):427–443

Houphouët-Boigny C, Plummer CJG, Wakeman MD, Månson JAE (2007) Towards textile-based fiber-reinforced thermoplastic nanocomposites: melt spun polypropylene-montmorillonite nanocomposite fibers. Polym Eng Sci 47(7):1122–1132

Kojima Y, Usuki A, Kawasumi M, Okada A, Kurauchi T, Kamigaito O (1993) One-pot synthesis of nylon 6–clay hybrid. J Polym Sci A Polym Chem 31(7):1755–1758

Fiedler B, Gojny FH, Wichmann MHG, Nolte MCM, Schulte K (2006) Fundamental aspects of nano-reinforced composites. Compos Sci Technol 66(16):3115–3125

Njuguna J, Pielichowski K, Desai S (2008) Nanofiller-reinforced polymer nanocomposites. Polym Adv Technol 19(8):947–959

Vaia RA, Wagner HD (2004) Framework for nanocomposites. Mater Today 7(11):32–37

Yuan R, Liu H, Yu P, Wang H, Liu J (2018) Enhancement of adhesion, mechanical strength and anti-corrosion by multilayer superhydrophobic coating embedded electroactive PANI/CNF nanocomposite. J Polym Res 25(7):151

Chen R, Ye C, Xin Z, Zhao S, Xia J, Meng X (2018) The effects of octadecylamine functionalized multi-wall carbon nanotubes on the conductive and mechanical properties of ultra-high molecular weight polyethylene. J Polym Res 25(6):135

Prasanna BP, Avadhani DN, Chaitra K, Nagaraju N, Kathyayini N (2018) Synthesis of polyaniline/MWCNTs by interfacial polymerization for superior hybrid supercapacitance performance. J Polym Res 25(5):123

Kam K-W et al (2017) Comparison study: effect of un-vulcanized and vulcanized NR content on the properties of two-matrix filled epoxy/natural rubber/graphene nano-platelets system. J Polym Res 25(1):15

Grala M, Bartczak Z, Różański A (2016) Morphology, thermal and mechanical properties of polypropylene/SiO2 nanocomposites obtained by reactive blending. J Polym Res 23(2):25

Mallakpour S, Barati A (2012) Preparation and characterization of optically active poly(amide-imide)/TiO2 bionanocomposites containing N-trimellitylimido-L-isoleucine linkages: using ionic liquid and ultrasonic irradiation. J Polym Res 19(2):9802

Godovsky DY (2000) Device applications of polymer-nanocomposites. In: Biopolymers·PVA hydrogels, anionic polymerisation nanocomposites. Advances in polymer science, vol 153. Springer, Berlin, Heidelberg, pp 163–205

Kuila T, Srivastava SK, Bhowmick AK, Saxena AK (2008) Thermoplastic polyolefin based polymer–blend-layered double hydroxide nanocomposites. Compos Sci Technol 68(15):3234–3239

Wang HW, Zhou HW, Peng RD, Mishnaevsky Jr L (2011) Nanoreinforced polymer composites: 3D FEM modeling with effective interface concept. Compos Sci Technol 71(7):980–988

Pezzin SH, Amico SC, Coelho LAF, de Andrade MJ (2011) Nanoreinforcements for nanocomposite materials. In: Bergmann CP, Andrade MJ (eds) Nanostructured Materials for Engineering Applications. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 119–131

Allen MJ, Tung VC, Kaner RB (2009) Honeycomb carbon: a review of graphene. Chem Rev 110(1):132–145

Meyer JC, Geim AK, Katsnelson MI, Novoselov KS, Booth TJ, Roth S (2007) The structure of suspended graphene sheets. Nature 446(7131):60–63

Irifune T, Kurio A, Sakamoto S, Inoue T, Sumiya H (2003) Materials: Ultrahard polycrystalline diamond from graphite. Nature 421(6923):599–600

Lee C, Wei X, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321(5887):385–388

Tsoukleri G, Parthenios J, Papagelis K, Jalil R, Ferrari AC, Geim AK, Novoselov KS, Galiotis C (2009) Subjecting a graphene monolayer to tension and compression. Small 5(21):2397–2402

Xu X, Pereira LF, Wang Y, Wu J, Zhang K, Zhao X, Bae S, Bui CT, Xie R, Thong JT, Hong BH, Loh KP, Donadio D, Li B, Özyilmaz B (2014) Length-dependent thermal conductivity in suspended single-layer graphene. Nat Commun 5:3689

Faugeras C, Faugeras B, Orlita M, Potemski M, Nair RR, Geim AK (2010) Thermal conductivity of graphene in corbino membrane geometry. ACS Nano 4(4):1889–1892

Bandla S, Hanan JC (2012) Microstructure and elastic tensile behavior of polyethylene terephthalate-exfoliated graphene nanocomposites. J Mater Sci 47(2):876–882

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Electric field effect in atomically thin carbon films. science 306(5696):666–669

Balandin AA, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau CN (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8(3):902–907

Xiao X, Li Y, Liu Z (2016) Graphene commercialization. Nat Mater 15(7):697–698

Segal M (2009) Selling graphene by the ton. Nat Nanotechnol 4(10):612–614

Bandla S, Winarski RP, Hanan JC (2013) Nanotomography of polymer nanocomposite nanofibers. Springer New York, New York

Bjorksten Research Laboratories (1956) Polyesters and their applications. Reinhold Pub. Corp., New York

Bandla S, Allahkarami M, Hanan JC (2015) Thermal crystallinity and mechanical behavior of polyethylene terephthalate. Springer International Publishing, Cham

Bandla S, Allahkarami M, Hanan JC (2015) Thermal crystallinity and mechanical behavior of polyethylene terephthalate. In: Qi JH et al (eds) Challenges in Mechanics of Time-Dependent Materials, Volume 2: Proceedings of the 2014 Annual Conference on Experimental and Applied Mechanics. Springer International Publishing, Cham, pp 141–146

Zekriardehani S, Jabarin SA, Gidley DR, Coleman MR (2017) Effect of chain dynamics, crystallinity, and free volume on the barrier properties of poly(ethylene terephthalate) Biaxially oriented films. Macromolecules 50(7):2845–2855

Istrate OM, Paton KR, Khan U, O’Neill A, Bell AP, Coleman JN (2014) Reinforcement in melt-processed polymer–graphene composites at extremely low graphene loading level. Carbon 78:243–249

Al-Jabareen A et al (2013) Improving the oxygen barrier properties of polyethylene terephthalate by graphite nanoplatelets. J Appl Polym Sci 128(3):1534–1539

Wu T, Ke Y (2006) The absorption and thermal behaviors of PET–SiO2 nanocomposite films. Polym Degrad Stab 91(9):2205–2212

Ou CF, Ho MT, Lin JR (2004) Synthesis and characterization of poly(ethylene terephthalate) nanocomposites with organoclay. J Appl Polym Sci 91(1):140–145

Herrero M, Martínez-Gallegos S, Labajos FM, Rives V (2011) Layered double hydroxide/polyethylene terephthalate nanocomposites. Influence of the intercalated LDH anion and the type of polymerization heating method. J Solid State Chem 184(11):2862–2869

Guan G-H, Li C-C, Zhang D (2005) Spinning and properties of poly(ethylene terephthalate)/organomontmorillonite nanocomposite fibers. J Appl Polym Sci 95(6):1443–1447

Qu M-H, Wang YZ, Wang C, Ge XG, Wang DY, Zhou Q (2005) A novel method for preparing poly(ethylene terephthalate)/BaSO4 nanocomposites. Eur Polym J 41(11):2569–2574

Chen X, Li C, Shao W, He J (2007) Preparation and properties of poly(ethylene terephthalate)/ATO nanocomposites. J Appl Polym Sci 105(5):2783–2790

Mun SJ, Jung YM, Kim JC, Chang JH (2008) Poly(ethylene terephthalate) nanocomposite fibers with functionalized multiwalled carbon nanotubes via in-situ polymerization. J Appl Polym Sci 109(1):638–646

Aoyama S, Park YT, Ougizawa T, Macosko CW (2014) Melt crystallization of poly(ethylene terephthalate): comparing addition of graphene vs. carbon nanotubes. Polymer 55(8):2077–2085

Wang Y, Gao J, Ma Y, Agarwal US (2006) Study on mechanical properties, thermal stability and crystallization behavior of PET/MMT nanocomposites. Compos Part B 37(6):399–407

Greco A, Timo A, Maffezzoli A (2012) Development and characterization of amorphous thermoplastic matrix graphene nanocomposites. Materials 5(10):1972–1985

Ge C, Shi L, Yang H, Tang S (2010) Nonisothermal melt crystallization kinetics of poly(ethylene terephthalate)/barite nanocomposites. Polym Compos 31(9):1504–1514

Higginbotham AL, Lomeda JR, Morgan AB, Tour JM (2009) Graphite oxide flame-retardant polymer nanocomposites. ACS Appl Mater Interfaces 1(10):2256–2261

Chen D, Zhu H, Liu T (2010) In situ thermal preparation of polyimide nanocomposite films containing functionalized graphene sheets. ACS Appl Mater Interfaces 2(12):3702–3708

Shabafrooz V, Bandla S, Hanan JC (2018) In-situ synthesis of poly(ethylene terephthalate) graphene nanocomposites, In: ANTEC 2018 - Proceedings of the 76th Annual Technical Conference & Exhibition, Orlando

Labde R, Lofgren EA, Jabarin SA (2012) Improved method for dispersing clay in a monomer or bis (2-hydroxyl ethyl terephthalate) before in situ polymerization of poly (ethylene terephthalate)/montmorillonite nanocomposites. J Appl Polym Sci 125(S1):E369–E381

Hindryckx F et al (1997) Polymerization-filled composites prepared with highly active filler-supported Al/Ti/mg catalysts. I. Synthesis of homogeneous polyethylene-based composites. J Appl Polym Sci 64(3):423–438

Wang M, Yan C, Ma L (2012) Graphene nanocomposites. In: Hu N (eds) Composites and their properties. InTechOpen, Rijeka, pp 17–36

El Achaby M et al (2012) Mechanical, thermal, and rheological properties of graphene-based polypropylene nanocomposites prepared by melt mixing. Polym Compos 33(5):733–744

Hussain F, Hojjati M, Okamoto M, Gorga RE (2006) Review article: polymer-matrix nanocomposites, processing, manufacturing, and application: an overview. J Compos Mater 40(17):1511–1575

Vaia RA, Maguire JF (2007) Polymer nanocomposites with prescribed morphology: going beyond nanoparticle-filled polymers. Chem Mater 19(11):2736–2751

Wang Z, Stein A (2008) Morphology control of carbon, silica, and carbon/silica nanocomposites: from 3D ordered macro−/mesoporous monoliths to shaped mesoporous particles. Chem Mater 20(3):1029–1040

Mehta A, Gaur U, Wunderlich B (1978) Equilibrium melting parameters of poly(ethylene terephthalate). J Polym Sci Polym Phys Ed 16(2):289–296

Johra FT, Lee J-W, Jung W-G (2014) Facile and safe graphene preparation on solution based platform. J Ind Eng Chem 20(5):2883–2887

Nawani P, Burger C, Rong L, Chu B, Hsiao BS, Tsou AH, Weng W (2010) Characterization of nanoclay orientation in polymer nanocomposite film by small-angle X-ray scattering. Polymer 51(22):5255–5266

Bandla S, Allahkarami M, Hanan JC (2014) Out-of-plane orientation and crystallinity of biaxially stretched polyethylene terephthalate. Powder Diffract 29(2):123–126

Bandla S, Hanan JC (2015) X-ray nanotomography of the skin-core structure of injection molded composites. In: ANTEC 2015 - Proceedings of the 73rd Annual Technical Conference & Exhibition, Orlando, pp 1872–1875

Bandla, S., Injection molded poly(ethylene terephthalate)-graphene nanocomposites. 2015, Oklahoma State University. p. 144

Jiang, X. and L.T. Drzal, Properties of injection molded high density polyethylene nanocomposites filled with exfoliated graphene nanoplatelets, In Some critical issues for injection molding. 2012, InTech

Rajesh J et al (2012) Effect of injection molding parameters on nanofillers dispersion in masterbatch based PP-clay nanocomposites. Express Polym Lett 6(3):237–248

Haghnegahdar M, Naderi G, Ghoreishy MHR (2017) Fracture toughness and deformation mechanism of un-vulcanized and dynamically vulcanized polypropylene/ethylene propylene diene monomer/graphene nanocomposites. Compos Sci Technol 141(Supplement C):83–98

Martinez AB, Gamez-Perez J, Sanchez-Soto M, Velasco JI, Santana OO, Ll Maspoch M (2009) The essential work of fracture (EWF) method – analyzing the post-yielding fracture mechanics of polymers. Eng Fail Anal 16(8):2604–2617

Bárány T, Czigány T, Karger-Kocsis J (2010) Application of the essential work of fracture (EWF) concept for polymers, related blends and composites: a review. Prog Polym Sci 35(10):1257–1287

Acknowledgements

We acknowledge Angstron Materials for providing N006-p grade graphene nanoplatelets. We also, acknowledge Dr. Ranji Vaidyanathan, professor at the Materials Science and Engineering department at OSU, and Mr. Brent Johnson, an associate at OSU Microscopy Lab, for their continuous support and help with DSC testing and confocal microscopy imaging. This work is part of an industry-sponsored research program at Oklahoma State University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shabafrooz, V., Bandla, S., Allahkarami, M. et al. Graphene/polyethylene terephthalate nanocomposites with enhanced mechanical and thermal properties. J Polym Res 25, 256 (2018). https://doi.org/10.1007/s10965-018-1621-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1621-4