Abstract

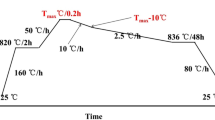

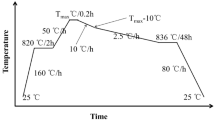

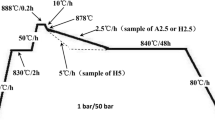

Four batches of Bi-2212 precursor powders prepared by both the co-precipitation method (CP) and the spray pyrolysis technology (SP) with two compositions (Bi:Sr:Ca:Cu = 2.17:1.94:0.89:2.00, 2.07:1.94:0.89:2.00) were obtained. The feature of the powder was firstly characterized. The faster phase evolution and lower melting temperature range (△T) of the precursor powder prepared by SP proved that Bi-2212 powder can be obtained by SP with both a higher preparation efficiency and better composition homogeneity. Then the current-carrying property and microstructure of these wires made from these powders were analyzed comprehensively. The property of the wires was proved to be influenced by the feature of these precursor powders a lot. Wires made by the precursor powder with the better composition homogeneity and higher phase purity were confirmed to hold a larger processing window (Tp). In addition, the decrease of the planar size of Bi-2212 crystals was discovered to improve both the machining homogeneity and texture of the wire. What’s more, both the better composition homogeneity of the precursor powder and the larger width of Bi-2212 crystals were found to improve both the interior texture and connectivity of Bi-2212 filaments. For the first time, the article provided quite specific directions to improve the quality of the precursor powder so as to both broaden Tp and enhance the current-carrying property of Bi-2212 wires.

Similar content being viewed by others

Data Availability

All data generated or used during the study appear in the submitted article.

References

Larbalestier, D.C., Jiang, J., Trociewitz, U.P., Kametani, F., Scheuerlein, C., Dalban-Canassy, M., Matras, M., Chen, P., Craig, N.C., Lee, P.J., Hellstrom, E.E.: Isotropic round-wire multifilament cuprate superconductor for generation of magnetic fields above 30 T. Nat. Mater. 13(4), 375–381 (2014)

Huang, S.Z., Qin, J.G., Zhu, Y.L., Li, J.G.: Development situation and quality control of CICC in the future fusion reactors. Cryo. & Supercond. 44(6), 27–33 (2016)

Chen, P., Trociewitz, U.P., Lu, J., Bosque, E.S., Jiang, J., Hellstrom, E.E., Larbalestier, D.C.: Experimental study on potential heat treatment issues of large Bi-2212 coils. IEEE Trans. Appl. Supercond. 27(4), 4601405 (2017)

Liu, H., Ma, H., Liu, F., Shi, Y., Qin, J., Wu, Y., Li, J., Lei, L.: Experimental study on Bi-2212 cable-in-conduit conductor. IEEE Trans. Appl. Supercond. 28(4), 4802104 (2018)

Qin, J., Wu, Y., Li, J., Dai, C., Liu, F., Liu, H., Liu, P., Li, C., Hao, Q., Zhou, C., Liu, S.: Manufacture and test of Bi-2212 cable-in-conduit conductor. IEEE T. Appl. Supercon. 27(4), 1–5 (2017)

Qin, J., Shi, Y., Wu, Y., Li, J., Wang, Q., He, Y., Dai, C., Liu, F., Liu, H., Mao, Z., Nijhuis, A., Zhou, C., Devred, A.: First AC loss test and analysis of a Bi2212 cable-in-conduit conductor for fusion application. Supercond. Sci. Technol. 31(1), 015010 (2018)

Rong, J., Huang, X., Song, Y., Yang, H., Lu, K.: AC losses calculation of Bi-2212 cable-in-conduit conductor used in CFETR. Fusion. Eng. Des. 141, 109–115 (2019)

Tian, Z.J., Wang, W.T., Huo, B.L., Liu, L., Yang, Y., Zhao, Y.: Effect of dilute Co3+ doping on structure and superconducting properties of GdBCO thin films. Cryo. & Supercond. 49(7), 5–9 (2021)

Wang, M.J., Wang, W.T., Liu, L., Tian, Z.J., Zhao, Y.: The electromagnetic properties of YGdBCO coated conductors with periodic micro-holes arrays. J. Alloy. Compd. 877, 160138 (2021)

Shen, T., Garcia Fajardo, L.: Superconducting accelerator magnets based on high-temperature superconducting Bi-2212 round wires. Instruments. 4(2), 1–22 (2020)

Rochester, J., Myers, C., Sumption, M., Shen, T., Majoros, M., Collings, E.W.: The magnetization of Bi:2212 rutherford cables for particle accelerator applications. IEEE Trans. Appl. Supercond. 31(5), 1–5 (2021)

Shen, T., Jiang, J., Kametani, F., Trociewitz, U.P., Larbalestier, D.C., Hellstrom, E.E.: Heat treatment control of Ag–Bi2Sr2CaCu2Ox multifilamentary round wire: investigation of time in the melt. Supercond. Sci. Technol. 24(11), 115009 (2011)

Shen, T., Li, P., Ye, L.: Heat treatment control of Bi-2212 coils: I. Unravelling the complex dependence of the critical current density of Bi-2212 wires on heat treatment. Cryogenics 89, 95–101 (2018)

Jiang, J., Hossain, S.I., Oloye, T.A., Oz, Y., Barua, S., Cooper, J., Miller, E., Huang, Y., Parrell, J.A., Kametani, F., Trociewitz, U.P., Hellstrom, E.E., Larbalestier, D.C.: Effects of wire diameter and filament size on the processing window of Bi-2212 round wire. IEEE Trans. Appl. Supercond. 31(5), 1–6 (2021)

Jiang, J., Francis, A., Alicea, R., Matras, M., Kametani, F., Trociewitz, U.P., Hellstrom, E.E., Larbalestier, D.C.: Effects of filament size on critical current density in overpressure processed Bi-2212 round wire. IEEE Trans. Appl. Supercond. 27(4), 6400104 (2017)

Li, Z.B., Liu, G.Q., Jiao, G.F., Xu, X.Y., Hao, Q.B., Bai, L.F., Yao, K., Li, C.S.: Influence of the precursor powder composition on the microstructure and the critical current density of Bi2212 wires. J. Mater. Sci. -Mater. El. 33(26), 21111–21126 (2022)

Jiang, J., Bradford, G., Hossain, S.I., Brown, M.D., Cooper, J., Miller, E., Huang, Y., Miao, H., Parrell, J.A., White, M., Hunt, A., Sengupta, S., Revur, R., Shen, T., Kametani, F., Trociewitz, U.P., Hellstrom, E.E., Larbalestier, D.C.: High-performance Bi-2212 round wires made with recent powders. IEEE T. Appl. Supercon. 29(5), 6400405 (2019)

Oloye, T.A., Matras, M., Jiang, J., Hossain, S.I., Su, Y., Trociewitz, U.P., Hellstrom, E.E., Larbalestier, D.C., Kametani, F.: Correlation of critical current density to quasi-biaxial texture and grain boundary cleanliness in fully dense Bi-2212 wires. Supercond. Sci. Technol. 34(3), 035018 (2021)

Liu, G.Q., Jin, L.H., Xu, X.Y., Jiao, G.F., Zheng, H.L., Hao, Q.B., Cui, L.J., Yu, Z.M., Li, C.S.: Comparison of intermediate phase evolution in Bi-2212 powders prepared by spray pyrolysis and co-precipitation methods for high performance wires. Rare. Metal. Mat. Eng. 1, 92–97 (2022)

Zhang, Y., Johnson, S., Naderi, G., Chaubal, M., Hunt, A., Schwartz, J.: High critical current density Bi2Sr2CaCu2Ox/Ag wire containing oxide precursor synthesized from nano-oxides. Supercond. Sci. Technol. 29(9), 095012 (2016)

Matras, M.: Investigation of Ag-sheathed multi-filamentaral Bi2Sr2CaCu2O8-x superconducting round wires processed with overpressure, for high field magnets. PhD Thesis 1–128 (2016)

Angrisani Armenio, A., Leveratto, A., de Marzi, G., Traverso, A., Bernini, C., Celentano, G., Malagoli, A.: Investigation of transport mechanisms induced by filament-coupling bridges-network in Bi-2212 wires. Supercond. Sci. Technol. 35(3), 035002 (2022)

Hao, Q.B., Li, C.S., Xu, X.Y., Liu, G.Q., Jiao, G.F., Zheng, H.L., Zhang, S.N., Li, G.S., Zhang, C.P., Yu, Z.M., Bai, L.F., Feng, J.Q., Zhang, P.X.: Effect of pre-annealing on microstructure, mechanical properties and current-carrying properties of Bi-2212 wires. Fusion. Eng. Des. 156, 111606 (2020)

Matras, M.R., Jiang, J., Larbalestier, D.C., Hellstrom, E.E.: Understanding the densification process of Bi2Sr2CaCu2Ox round wires with overpressure processing and its effect on critical current density. Supercond. Sci. Technol. 29(10), 105005 (2016)

Meingast, C., Junod, A., Walker, E.: Superconducting fluctuations and uniaxial-pressure dependence of Tc of a Bi2Sr2CaCu2O8+x single crystal from high-resolution thermal expansion. Physica C 272, 106–114 (1996)

Babaeipour, M., Ross, D.K.: A determination of the variation in the lattice parameters of Bi2Sr2CaCu2O8+x (Bi-2212) as a function of temperature and oxygen content. Physica C 425(3–4), 130–134 (2005)

Tenbrink, J., Krauth, H.: Thermal expansion properties of Bi-2212 in Ag or an Ag-alloy matrix. Supercond. Sci. Technol. 7, 754–758 (1994)

Zhang, S., Li, C., Hao, Q., Ma, X., Lu, T., Zhang, P.: Optimization of Bi-2212 high temperature superconductors by potassium substitution. Supercond. Sci. Technol. 28(4), 1–10 (2015)

Ge, J., Gutierrez, J., Li, M., Zhang, J., Moshchalkov, V.V.: Vortex phase transition and isotropic flux dynamics in K0.8Fe2Se2 single crystal lightly doped with Mn. Appl. Phys. Lett. 103(5), 052602:1–5 (2013)

Kim, S.S., Srinivasan, T.T., Newnham, R.E.: Weak-link nature of ac susceptibility in the grain-oriented YBa2Cu3O7 superconducting ceramics. Phys. Stat. Sol. 123, 275–283 (1991)

Aksenova, T.D., Bratukhin, P.V., Shavkin, S.V., Melnikov, V.L., Antipova, E.V., Khlebova, N.E., Shikov, A.K.: Texture formation in Bi2Sr2Ca1Cu2Ox Ag tapes prepared by partial melt process. Physica C 205(3–4), 271–279 (1993)

Acknowledgements

The author sincerely acknowledges all the authors for contribution to the work in this article. We also would like to thank to eceshi (www.eceshi.com) for the TG/DSC testing.

Funding

This work was financially supported by the National natural Science foundation of China (No. 52002333), the Key R&D project of Shaanxi Province (No. 2023-YBGY-428), the Science and Technology Planning Project in Weiyang District of Xi’an (No.202107), the National Key R&D Program of China (Grant No. 2021YFB3800201), the National natural Science foundation of China (No. 51902267, No. 52277029), the National Key R&D Program of China (No. 2017YFE0301402), the Major Science and Technology Projects of Shaanxi Province (Grant No. 2020zdzx04-04–02), and the Strategic Priority Research Program of the Chinese Academy of Sciences (CAS, Grant No. XDB250020200).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Liu, G., Yao, K. et al. Influence of the Precursor Powder on the Processing Window and Current-Carrying Property of Bi-2212 Wires. J Supercond Nov Magn 36, 843–861 (2023). https://doi.org/10.1007/s10948-023-06531-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-023-06531-6