Abstract

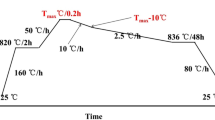

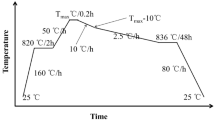

We have successfully utilized an hot isostatic pressing (HIP) technique to fabricate Bi2Sr2CaCu2O8+δ (Bi-2212) wires under 50 bar pressure, resulting in a significant enhancement of their current-carrying capacity by nearly 2.5 times. Our study compares the microstructure and superconducting properties of the wires processed under HIP and atmospheric pressure. The results demonstrate that the critical current density (JC) of the wires treated with HIP increases from 1416 A mm−2 (at 1 bar) to 3592 A mm−2 at 4.2 K and 5 T. Initially, this increase was attributed to the reduction of void regions in the wires treated under 50 bar HIP. However, further analysis revealed that the decrease in voids resulting from HIP only accounts for 23% of the total increase in JC, implying that density improvement plays a minor role in the overall JC enhancement. In comparison to the wires processed under atmospheric pressure, the current-carrying ability of the wires treated with HIP is significantly enhanced due to the combined effect of void reduction and the dendritic structure surrounding the Bi-2212 filaments. By increasing the cooling rate from 2.5 h−1 to 5 °C h−1, we further increased the engineering critical current density (JE) of the Bi-2212 wires by 20%, reaching 975 A mm−2 (at 4.2 K and 5 T). This improvement is attributed to the effective reduction of the dendritic structure surrounding the filaments in the wires treated under 50 bar HIP, achieved by adjusting the grain growth rate during the cooling process. These findings provide valuable insights for the development of high-performance Bi-2212 wires for superconducting applications.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

D.C. Larbalestier, J. Jiang, U.P. Trociewitz, F. Kametani, C. Scheuerlein, M. Dalban-Canassy, M. Matras, P. Chen, N.C. Craig, P.J. Lee, E.E. Hellstrom, Isotropic round-wire multifilament cuprate superconductor for generation of magnetic fields above 30T. Nat. Mater. 13(375), 81–88 (2014). https://doi.org/10.1038/nmat3887

Y. Kim, U.P. Trociewitz, E.S. Bosque, D. Davis, L. English, E. Hellstrom, J. Jiang, F. Kametani, E. Martin, J. Jones, A. Juliao, G. Bradford, S. Barua, I. Hossain, G.M.Y. Oz, J. Gillman, J.L.J. Lu, L.C.P. Lee, D.C. Larbalestier, Bi-2212 coil technology development efforts at the national high magnetic field laboratory, international conference on magnet technology, MT26:Mon-Mo-Or2-04 (2019)

A. Godeke, High temperature superconductors for commercial magnets. Supercond. Sci. Technol. 36(11), 113001 (2023). https://doi.org/10.1088/1361-6668/acf901

T. Shen, L.G. Fajardo, C. Myers, A. Hafalia Jr., J.L.R. Fernández, D. Arbelaez, L. Brouwer, S. Caspi, P. Ferracin, S. Gourlay, Design, fabrication, and characterization of a high-field high-temperature superconducting Bi-2212 accelerator dipole magnet. Phys. Rev. Accel. Beams 25(12), 122401 (2022). https://doi.org/10.1103/PhysRevAccelBeams.25.122401

J. Rochester, C. Myers, T. Shen, M. Majoros, E. Collings, M. Sumption, Flux creep in a Bi-2212 Rutherford cable for particle accelerator applications. IEEE Trans. Appl. Supercond. 32(4), 6400205 (2022). https://doi.org/10.1109/TASC.2022.3159267

Z.-C. Zhang, D.-S. Yang, H.-S. Zhou, J.-G. Qin, G.-N. Luo, Degradation mechanism of the superconducting performance of a Bi2212 cable under magnetic fields. Supercond. Sci. Technol. 35(3), 035004 (2022). https://doi.org/10.1088/1361-6668/ac4ad2

D. Yang, M. Yu, H. Ma, Z. Zhang, M. Wang, S. Liu, H. Jin, P. Gao, C. Zhou, F. Liu, H. Liu, Q. Hao, C. Li, S. Kanazawa, W. Chen, A. Nijhuis, J. Li, J. Qin, Performance of first Bi-2212 cable with pre-over pressure and over pressure heat treatment. Supercond. Sci. Technol. 35(1), 015007 (2022). https://doi.org/10.1088/1361-6668/ac30ea

C. Tarantini, S. Barua, T.A. Oloye, F. Kametani, J. Jiang, E.E. Hellstrom, D.C. Larbalestier, Variation of effective filament diameter, irreversibility field, anisotropy, and pinning efficiency in Bi-2212 round wires. Supercond. Sci. Technol. 37(1), 015021 (2023). https://doi.org/10.1088/1361-6668/ad13b2

H. Miao, K.R. Marken, M. Meinesz, B. Czabaj, S. Hong, M.O. Rike, J. Bock, Studies of precursor composition effect on Jc in Bi-2212/Ag wires and tapes. Adv. Cryog. Eng. 50B, 673–682 (2005). https://doi.org/10.1063/1.2192409

J. Jiang, G. Bradford, S.I. Hossain, M.D. Brown, J. Cooper, E. Miller, Y. Huang, H. Miao, J.A. Parrell, M. White, A. Hunt, S. Sengupta, R. Revur, T. Shen, F. Kametani, U.P. Trociewitz, E.E. Hellstrom, D.C. Larbalestier, High-performance Bi-2212 round wires made with recent powders. IEEE Trans. Appl. Supercond. 29(5), 6400405 (2019). https://doi.org/10.1109/TASC.2019.2895197

Q.B. Hao, C.S. Li, S.N. Zhang, L.F. Bai, G.S. Li, G.Q. Liu, P.X. Zhang, Improve the uniformity of the cores and Je of Bi-2212 wires. Phys. Procedia 58, 166–169 (2014). https://doi.org/10.1016/j.phpro.2014.09.036

X. Liu, J. Liu, B. Shao, S. Zhang, Y. Zhang, H. Li, W. Zhang, H. Cao, J. Feng, C. Li, Improving Bi-2212 multi-filament wire quality and superconductivity by cryogenic drawing. J. Alloys Compd. 922, 166304 (2022). https://doi.org/10.1016/j.jallcom.2022.166304

T. Shen, J. Jiang, F. Kametani, U.P. Trociewitz, D.C. Larbalestier, J. Schwartz, E.E. Hellstrom, Filament to filament bridging and its influence on developing high critical current density in multifilamentary Bi2Sr2CaCu2Ox round wires. Supercond. Sci. Technol. 23, 025009 (2010). https://doi.org/10.1088/0953-2048/23/2/025009

W. Zhang, E.A. Goodilin, E.E. Hellstrom, Composition studies for Ag-sheathed Bi2Sr2CaCu2O8 conductors processed in 100% O2. Supercond. Sci. Technol. 8, 211–217 (1996). https://doi.org/10.1088/0953-2048/9/3/014

F. Kametani, T. Shen, J. Jiang, C. Scheuerlein, A. Malagoli, M.D. Michiel, Y. Huang, H. Miao, J.A. Parrell, E.E. Hellstrom, D.C. Larbalestier, Bubble formation within filaments of melt-processed Bi2212 wires and its strongly negative effect on the critical current density. Supercond. Sci. Technol. 24, 075009 (2011). https://doi.org/10.1088/0953-2048/24/7/075009

J. Kadar, C. Scheuerlein, M.O. Rikel, M.D. Michiel, Y. Huang, Comparison of microstructure, second phases and texture formation during melt processing of Bi-2212 mono- and multifilament wires. Supercond. Sci. Technol. 29, 105009 (2016). https://doi.org/10.1088/0953-2048/29/10/105009

F. Kametani, J. Jiang, M. Matras, D. Abraimov, E.E. Hellstrom, D.C. Larbalestier, Comparison of growth texture in round Bi2212 and flat Bi2223 wires and its relation to high critical current density development. Sci. Rep. 5, 8258 (2015). https://doi.org/10.1038/srep08285

A. Godeke, M.H.C. Hartman, M.G.T. Mentink, J. Jiang, M. Matras, E.E. Hellstrom, D.C. Larbalestier, Critical current of dense Bi-2212 round wires as a function of axial strain. Supercond. Sci. Technol. 28(3), 32001 (2015). https://doi.org/10.1088/0953-2048/28/3/032001

M.R. Matras, J. Jiang, D.C. Larbalestier, E.E. Hellstrom, Understanding the densification process of Bi2Sr2CaCu2Ox round wires with overpressure processing and its effect on critical current density. Supercond. Sci. Technol. 29, 105005 (2016). https://doi.org/10.1088/0953-2048/29/10/105005

E. Cecchetti, P.J. Ferreira, J.B.V. Sande, A model for texture development in BSCCO high-Tc superconductors. Supercond. Sci. Technol. 13, 1270–1278 (2000). https://doi.org/10.1088/0953-2048/13/8/326

S. Yamashita, T. Kasai, T. Fujii, T. Watanabe, A. Matsuda, Control of carrier concentration in Bi-2212. Physica C Supercond. Appl. 470, S170–S172 (2010). https://doi.org/10.1016/j.physc.2009.11.065

G. Naderi, J. Schwartz, Multiscale studies of processing-microstructure-transport relationships in over-pressure processed Bi2Sr2CaCu2Ox/Ag multifilamentary round wire. Supercond. Sci. Technol. 27(11), 115002 (2014). https://doi.org/10.1088/0953-2048/27/11/115002

Acknowledgements

This research was by National Natural Science Foundation of China (No. 52277029), Nation Key R&D Program of China (No. 2021YFB3800201), Major Science and technology projects of Shaanxi Province (Nos. 2020zdzx04-04-02 and 2024GX-YBXM-403), Shaanxi Natural Science Foundation Project (No.2020JM-650).

Funding

Funding information is not applicable/No funding was received.

Author information

Authors and Affiliations

Contributions

All authors contributed to the conception and design of the study. [Xiaoyan Xu], [Qingbin Hao], [Gaofeng Jiao], [Kai Yao], and [Guoqing Liu] were involved in sample preparation. Data analysis was performed by [Xiaoyan Xu] and [Qingbin Hao]. The initial draft of the manuscript was revised by [Qingbin Hao] and [Xiaoyan Xu], and the entire process was supervised by [Chengshan Li]. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Research involving human participants or animals

This paper contains no research involving human participants and/or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, Q., Xu, X., Jiao, G. et al. Impact of hot isostatic pressing on the microstructure and current-carrying capacity of Bi-2212 wires. J Mater Sci: Mater Electron 35, 746 (2024). https://doi.org/10.1007/s10854-024-12480-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12480-0