Abstract

Currently, several treatment processes for oil absorption have been introduced by researchers among which the utilization of natural three-dimensional porous absorbers has received significant attention due to their low cost, high absorption capacity, environmental friendliness, and biodegradability. In this work, lignin as a renewable bioresource with the potential for application in various value-added applications was chosen for the fabrication of sodium alginate/lignin aerogel. In this research, the lignin utilized was derived from the precipitation of black liquor. To optimize the yield of lignin, various parameters such as pH, aging time, temperature, and acid type were investigated using the Taguchi methodology. The experiments were carried out at the estimated optimum conditions indicated the highest yield of lignin precipitation, which was 82.05%, at a pH of three, an aging time of 120 min, a temperature of 75 ℃, and an acid type of H2SO4. In the second stage, robust and stable hydrophobic sodium alginate/lignin aerogel was fabricated using different cross-linker agents (CaCl2, FeCl3, and glutaraldehyde), with a facile freeze-drying method, and a chemical vapor deposition hydrophobic modification. The SA/lignin-CaCl2, SA/lignin-FeCl3, and SA/lignin- glutaraldehyde aerogels possessed high porosity values that exceeded 96%, low density (24.1–25.8 mg/cm3), and absorption capacity for sunflower oil was 24.48 (g/g), 26.34 (g/g), and 25.15 (g/g), respectively. These results imply that the cost-effective aerogel holds significant potential for oil recovery applications and environmental protection.

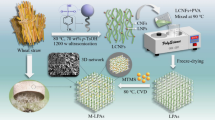

Graphical Abstract

Similar content being viewed by others

References

Bacosa HP, Ancla SMB, Arcadio CGLA, Dalogdog JRA, Ellos DMC, Hayag HDA, Adhikari PL (2022) From surface water to the deep sea: a review on factors affecting the biodegradation of spilled oil in marine environment. J Mar Sci Eng 10:426

Chen C, Weng D, Mahmood A, Chen S, Wang J (2019) Separation mechanism and construction of surfaces with special wettability for oil/water separation. ACS Appl Mater Interfaces 11:11006–11027

Zhang H, Bian J, Wan H (2021) Hydrochemical appraisal of groundwater quality and pollution source analysis of oil field area: a case study in Daqing City, China. Environ Sci Pollut Res 28:18667–18685

Guan Y, Cheng F, Pan Z (2019) Superwetting polymeric three dimensional (3d) porous materials for oil/water separation: a review. Polymer 11:806

Shayesteh H, Rahbar-Kelishami A, Norouzbeigi R (2022) Superhydrophobic/superoleophilic micro/nanostructure nickel particles for oil/water mixture and emulsion separation. Ceram Int 48:10999–11008

Pudza MY, Zainal Abidin Z, Abdul Rashid S, Md Yasin F, Noor ASM, Issa MA (2020) Eco-friendly sustainable fluorescent carbon dots for the adsorption of heavy metal ions in aqueous environment. Nanomater 10:315

Silas K, Pudza MY, Mohammed HD (2022) Effective application of Jatropha curcas husk activated ZnCl2 for adsorption of methylene blue: isotherm, kinetics and development of empirical model. Chem Rev Lett 5:153–160

Wu J, Dong Y, Xu M, Xia J, Liu Z, Cao Y (2021) Aerogels made from soybean stalk with various lignocellulose aggregating states for oil spill clean-up. Cellulose 28:9873–9891

Ahmed MA, Mearaj S, Thithai V, Weon CJ (2022) Production and characteristic features of lignin-PVA aerogels for oil spillage applications. Mater Chem Phys 289:126455

Ferreira ES, Cranston ED, Rezende CA (2020) Naturally hydrophobic foams from lignocellulosic fibers prepared by oven-drying. ACS Sustain Chem Eng 8:8267–8278

Wang R, Chen C, Pang Z, Wang X, Zhou Y, Dong Q, Guo M, Gao J, Ray U, Xia Q, Lin Z (2022) Fabrication of cellulose–graphite foam via ion cross-linking and ambient-drying. Nano Lett 22:3931–3938

Ferreira ES, Rezende CA (2018) Simple preparation of cellulosic lightweight materials from eucalyptus pulp. ACS Sustain Chem Eng 6:14365–14373

Chhajed M, Verma C, Sathawane M, Singh S, Maji PK (2022) Mechanically durable green aerogel composite based on agricultural lignocellulosic residue for organic liquids/oil sorption. Mar Pollut Bull 180:113790

Issa MA, Zainal Abidin Z, Sobri S, Rashid S, Adzir Mahdi M, Azowa Ibrahim N, Pudza MY (2019) Facile synthesis of nitrogen-doped carbon dots from lignocellulosic waste. Nanomaterials 9:1500

Ge J, Zhao HY, Zhu HW, Huang J, Shi LA, Yu SH (2016) Advanced sorbents for oil-spill cleanup: recent advances and future perspectives. Adv Mater 28:10459–10490

Zhao ZM, Meng X, Scheidemantle B, Pu Y, Liu ZH, Li BZ, Ragauskas AJ (2022) Cosolvent enhanced lignocellulosic fractionation tailoring lignin chemistry and enhancing lignin bioconversion. Bioresour Technol 347:126367

Owhe EO, Kumar N, Lynam JG (2021) Lignin extraction from waste biomass with deep eutectic solvents: molecular weight and heating value. Biocatal Agric Biotechnol 32:101949

Castaldo R, Avolio R, Cocca M, Errico ME, Lavorgna M, Šalplachta J, Gentile G (2022) Hierarchically porous hydrogels and aerogels based on reduced graphene oxide, montmorillonite and hyper-crosslinked resins for water and air remediation. J Chem Eng 430:133162

Singhania RR, Patel AK, Raj T, Chen CW, Ponnusamy VK, Tahir N, Dong CD (2022) Lignin valorisation via enzymes: a sustainable approach. J Fuels 311:122608

Ahmed MA, Rehman MSU, Terán-Hilares R, Khalid S, Han JI (2017) Optimization of twin gear-based pretreatment of rice straw for bioethanol production. Energy Convers Manag 141:120–125

Nguyen ST, Do ND, Thai NT, Thai QB, Huynh HKP, Phan AN (2020) Green aerogels from rice straw for thermal, acoustic insulation and oil spill cleaning applications. Mater Chem Phys 253:123363

Asif Z, Chen Z, An C, Dong J (2022) Environmental impacts and challenges associated with oil spills on shorelines. J Mar Sci Eng 10:762

Imran M, Islam A, Panyue Z, Ismail F, Zhang G, ud Din E, (2021) Green fabrication, characterization and water-oil separation properties of superhydrophilic/oleophobic grapefruit peel-derived aerogel. Appl Surf Sci 566:150721

Yi L, Yang J, Fang X, Xia Y, Zhao L, Wu H, Guo S (2020) Facile fabrication of wood-inspired aerogel from chitosan for efficient removal of oil from Water. J Hazard Mater 385:121507

Hu L, He R, Lu Z, Zhang K, Bai X (2019) Step-freeze-drying method for carbon aerogels: a study of the effects on microstructure and mechanical property. RSC Adv 9:9931–9936

Simón-Herrero C, Caminero-Huertas S, Romero A, Valverde JL, Sánchez-Silva L (2016) Effects of freeze-drying conditions on aerogel properties. J Mater Sci 51:8977–8985

Alassod A, Khalaji MS, Tusiime R, Huang W, Xu G (2021) Polypropylene/lignin/POSS nanocomposites: Thermal and wettability properties, application in water remediation. Materials 14:3950

Alassod A, Islam SR, Farooq A, Xu G (2020) Fabrication of polypropylene/lignin blend sponges via thermally induced phase separation for the removal of oil from contaminated water. SN Appl Sci 2:1–10

Alassod A, Khalaji MS, Islam SR, Xu G, Chaudary A, Alam MK, Alkhateeb W (2023) Polypropylene-chitosan sponges prepared via thermal induce phase separation used as sorbents for oil spills cleanup. Polym Bull 80:4949–4964

Alassod A, Khalaji MS, Wang Y, Balilonda A, Al Hinnawi MF, Yang S (2022) Functionalization of aminoalkylsilane-grafted cotton for antibacterial, thermal, and wettability properties. RSC Adv 12:20906–20918

Zhao W, Simmons B, Singh S, Ragauskas A, Cheng G (2016) From lignin association to nano-/micro-particle preparation: extracting higher value of lignin. Green Chem 18:5693–5700

Norgren M, Lindström B (2000) Dissociation of phenolic groups in kraft lignin at elevated temperatures. Holzforschung 54:519–527

Alekhina M, Ershova O, Ebert A, Heikkinen S, Sixta H (2015) Softwood kraft lignin for value-added applications: Fractionation and structural characterization. Ind Crops Prod 66:220–228

Lin SY, Dence CW (eds) (2012) Methods in lignin chemistry. Springer, Berlin

Pan X, Kadla JF, Ehara K, Gilkes N, Saddler JN (2006) Organosolv ethanol lignin from hybrid poplar as a radical scavenger: relationship between lignin structure, extraction conditions, and antioxidant activity. J Agric Food Chem 54:5806–5813

Akinosho H, Dumitrache A, Natzke J, Muchero W, Jawdy SS, Tuskan GA, Ragauskas AJ (2017) Effects of biomass accessibility and klason lignin contents during consolidated bioprocessing in Populus trichocarpa. ACS Sustain Chem Eng 5:5075–5081

Sun N, Rahman M, Qin Y, Maxim ML, Rodríguez H, Rogers RD (2009) Complete dissolution and partial delignification of wood in the ionic liquid 1-ethyl-3-methylimidazolium acetate. Green Chem 11:646–655

Sadeghifar H, Ragauskas A (2020) Perspective on technical lignin fractionation. ACS Sustain Chem Eng 8:8086–8101

Wang Y, Liu W, Zhang L, Hou Q (2019) Characterization and comparison of lignin derived from corncob residues to better understand its potential applications. Int J Biol Macromol 134:20–27

Bu L, Tang Y, Gao Y, Jian H, Jiang J (2011) Comparative characterization of milled wood lignin from furfural residues and corncob. J Chem Eng 175:176–184

Eugenio ME, Martín-Sampedro R, Santos JI, Wicklein B, Ibarra D (2021) Chemical, thermal and antioxidant properties of lignins solubilized during Soda/AQ pulping of orange and olive tree pruning residues. Molecules 26:3819

Wróblewska-Krepsztul J, Rydzkowski T, Michalska-Pożoga I, Thakur VK (2019) Biopolymers for biomedical and pharmaceutical applications: Recent advances and overview of alginate electrospinning. Nanomaterials 9:404

Liu YG, Hu XJ, Wang H, Chen AW, Liu SM, Guo YM, Zhou L (2013) Photoreduction of Cr (VI) from acidic aqueous solution using TiO2-impregnated glutaraldehyde-crosslinked alginate beads and the effects of Fe (III) ions. J Chem Eng 226:131–138

Yan Y, An Q, Xiao Z, Zheng W, Zhai S (2017) Flexible core-shell/bead-like alginate@ PEI with exceptional adsorption capacity, recycling performance toward batch and column sorption of Cr (VI). J Chem Eng 313:475–486

Paudyal H, Pangeni B, Inoue K, Kawakita H, Ohto K, Ghimire KN, Alam S (2013) Preparation of novel alginate based anion exchanger from Ulva japonica and its application for the removal of trace concentrations of fluoride from water. Bioresour Technol 148:221–227

Gao Q, Wang X, Wang H, Liang D, Zhang J, Li J (2019) Sulfhydryl-modified sodium alginate film for lead-ion adsorption. Mater Lett 254:149–153

Lee BJ, Min GH, Kim TW (1996) Preparation and in vitro release of melatonin-loaded multivalent cationic alginate beads. Arch Pharm Res 19:280–285

Menakbi C, Quignard F, Mineva T (2016) Complexation of trivalent metal cations to mannuronate type alginate models from a density functional study. J Phys Chem B 120:3615–3623

Rajesh R, Dominic Ravichandran Y (2015) Development of a new carbon nanotube–alginate–hydroxyapatite tricomponent composite scaffold for application in bone tissue engineering. Int J Nanomed 10:7–15

Kumari S, Chauhan GS, Monga S, Kaushik A, Ahn JH (2016) New lignin-based polyurethane foam for wastewater treatment. RSC Adv 6:77768–77776

Tong Z, Chen Y, Liu Y, Tong L, Chu J, Xiao K, Chu X (2017) Preparation, characterization and properties of alginate/poly (γ-glutamic acid) composite microparticles. Mar Drugs 15:91

Livshin S, Silverstein MS (2008) Crystallinity and cross-linking in porous polymers synthesized from long side chain monomers through emulsion templating. Macromolecules 41:3930–3938

Voo WP, Lee BB, Idris A, Islam A, Tey BT, Chan ES (2015) Production of ultra-high concentration calcium alginate beads with prolonged dissolution profile. RSC Adv 5:36687–36695

Nastaj J, Przewłocka A, Rajkowska-Myśliwiec M (2016) Biosorption of Ni (II), Pb (II) and Zn (II) on calcium alginate beads: equilibrium, kinetic and mechanism studies. Pol J Chem Technol 18:81–87

Gordobil O, Moriana R, Zhang L, Labidi J, Sevastyanova O (2016) Assesment of technical lignins for uses in biofuels and biomaterials: structure-related properties, proximate analysis and chemical modification. Ind Crops Prod 83:155–165

Derkacheva O, Sukhov D (2008) Investigation of lignins by FTIR spectroscopy. Macromol Symposia 256:61–68

Kabiri S, Tran DN, Altalhi T, Losic D (2014) Outstanding adsorption performance of graphene–carbon nanotube aerogels for continuous oil removal. Carbon 80:523–533

Li H, Liu L, Yang F (2013) Covalent assembly of 3D graphene/polypyrrole foams for oil spill cleanup. J Mater Chem A 1:3446–3453

Wurm F, Rietzler B, Pham T, Bechtold T (2020) Multivalent ions as reactive crosslinkers for biopolymers—a review. Mol 25:1840

Gallagher L, Smith A, Kavanagh K, Devereux M, Colleran J, Breslin C, Richards KG, McCann M, Rooney AD (2021) Preparation and antimicrobial properties of alginate and serum albumin/glutaraldehyde hydrogels impregnated with silver (I) ions. Chemistry 3:672–686

Yang J, Xu P, Yao Y, Li Y, Shi B, Jia X, Song H (2020) A solar-heated Janus sponge with excellent floating stability for efficient cleanup of heavy oil. Mater Des 195:108979

Nguyen ST, Feng J, Le NT, Le AT, Hoang N, Tan VB, Duong HM (2013) Cellulose aerogel from paper waste for crude oil spill cleaning. Ind Eng Chem 52:18386–18391

Meng Y, Liu T, Yu S, Cheng Y, Lu J, Wang H (2020) A lignin-based carbon aerogel enhanced by graphene oxide and application in oil/water separation. Fuel 278:118376

Cheng Y, Lu L, Zhang W, Shi J, Cao Y (2012) Reinforced low density alginate-based aerogels: preparation, hydrophobic modification and characterization. Carbohydr Polym 88:1093–1099

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

MM: Experimental work, Methodology, Software, Writing original draft. RN: Conceptualization, Methodology, Writing-review and editing, Supervision. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Montazeri, M., Norouzbeigi, R. Fabrication and Characterization of Renewable Alginate-Lignin Aerogel for Efficient Oil Absorption. J Polym Environ (2023). https://doi.org/10.1007/s10924-023-03121-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-023-03121-4