Abstract

In this research, the effect of reprocessing on the properties of poly(lactic acid)/poly(ε-caprolactone) (PLA/PCL) blends reinforced with silk nanoparticles (NP) and silk microfibers (SF) was investigated. In this regard, the multiple extrusion process was applied to the PLA/PCL based composites and their morphology, thermal stability, intrinsic viscosity, water absorption, mass loss, barrier, and mechanical properties were studied and compared. The results of atomic force microscopy showed that silk nanoparticles were mainly located in the PLA matrix and partially at the phase interphase with a thickness of layers around 80 nm. The scanning electron microscopy results illustrated a good dispersion of NPs in the blend and poor adhesion between SFs and the polymer matrix. The thermogravimetric analysis results showed that the presence of bio-fillers stabilized the thermal properties of composites and decreased the thermo-mechanical degradation of recycled materials. Furthermore, the addition of NPs and SFs improved the barrier properties of materials and led to a decrease in the value of water absorption and mass loss of PCL/PCL composites. The results of microhardness and impact tests also demonstrated that the mechanical properties of neat PLA/PCL blends are deteriorated by increasing the number of reprocessing cycles; however, the incorporation of both NPs and SFs improved the mechanical performance of recycled PLA/PCL composites. The results suggest that the use of silk fillers represents a cost-effective and environmentally friendly way of improving the properties of reprocessed PLA-based plastic.

Similar content being viewed by others

References

Diaz CA, Pao HY, Kim S (2016) Film performance of poly (lactic acid) blends for packaging applications. J Appl Packag Res 8:4

Siracusa V, Rocculi P, Romani S, Dalla Rosa M (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19:634–643

Liu H, Chen N, Shan P et al (2019) Toward fully bio-based and supertough PLA blends via in situ formation of cross-linked biopolyamide continuity network. Macromolecules 52:8415–8429

Kamaly N, Yameen B, Wu J, Farokhzad OC (2016) Degradable controlled-release polymers and polymeric nanoparticles: mechanisms of controlling drug release. Chem Rev 116:2602–2663

Navarro-Baena I, Sessini V, Dominici F et al (2016) Design of biodegradable blends based on PLA and PCL: from morphological, thermal and mechanical studies to shape memory behavior. Polym Degrad Stab 132:97–108

Kelnar I, Kratochvil J, Kaprálková L et al (2017) Graphite nanoplatelets-modified PLA/PCL: effect of blend ratio and nanofiller localization on structure and properties. J Mech Behav Biomed Mater 71:271–278

Guarino V, Gentile G, Sorrentino L, Ambrosio L (2002) Polycaprolactone: synthesis, properties, and applications. Encycl Polym Sci Technol 17:1–36

Wu J, Chu C-C (2012) Block copolymer of poly (ester amide) and polyesters: synthesis, characterization, and in vitro cellular response. Acta Biomater 8:4314–4323

Wu D, Zhang Y, Zhang M, Yu W (2009) Selective localization of multiwalled carbon nanotubes in poly ($\varepsilon$-caprolactone)/polylactide blend. Biomacromol 10:417–424

Bouakaz BS, Habi A, Grohens Y, Pillin I (2017) Organomontmorillonite/graphene-PLA/PCL nanofilled blends: New strategy to enhance the functional properties of PLA/PCL blend. Appl Clay Sci 139:81–91

Wachirahuttapong S, Thongpin C, Sombatsompop N (2016) Effect of PCL and compatibility contents on the morphology, crystallization and mechanical properties of PLA/PCL blends. Energy Procedia 89:198–206

Shin BY et al (2017) Viscoelastic properties of PLA/PCL blends compatibilized with different methods. Korea-Australia Rheol J 29:295–302

Aversa C, Barletta M, Gisario A et al (2018) Improvements in mechanical strength and thermal stability of injection and compression molded components based on poly lactic acids. Adv Polym Technol 37:2158–2170

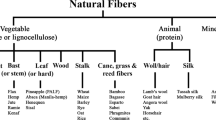

Mohanty AK, Misra M, Hinrichsen GI (2000) Biofibres, biodegradable polymers and biocomposites: an overview. Macromol Mater Eng 276:1–24

Beltrán FR, de la Orden MU, Lorenzo V et al (2016) Water-induced structural changes in poly (lactic acid) and PLLA-clay nanocomposites. Polymer (Guildf) 107:211–222

Żenkiewicz M, Richert J, Rytlewski P et al (2009) Characterisation of multi-extruded poly (lactic acid). Polym Test 28:412–418

Badia JD, Strömberg E, Karlsson S, Ribes-Greus A (2012) Material valorisation of amorphous polylactide. influence of thermo-mechanical degradation on the morphology, segmental dynamics, thermal and mechanical performance. Polym Degrad Stab 97:670–678

Soroudi A, Jakubowicz I (2013) Recycling of bioplastics, their blends and biocomposites: a review. Eur Polym J 49:2839–2858

Beltrán FR, Gaspar G, Chomachayi MD et al (2020) Influence of addition of organic fillers on the properties of mechanically recycled PLA. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-020-08025-7

John MJ, Thomas S (2008) Biofibres and biocomposites. Carbohydr Polym 71:343–364

Tesfaye M, Patwa R, Kommadath R et al (2016) Silk nanocrystals stabilized melt extruded poly (lactic acid) nanocomposite films: Effect of recycling on thermal degradation kinetics and optimization studies. Thermochim Acta 643:41–52

Dhar P, Tarafder D, Kumar A, Katiyar V (2016) Thermally recyclable polylactic acid/cellulose nanocrystal films through reactive extrusion process. Polymer (Guildf) 87:268–282

Magoshi J, Magoshi Y, Nakamura S (1981) Physical properties and structure of silk. VII. Crystallization of amorphous silk fibroin induced by immersion in methanol. J Polym Sci Polym Phys Ed 19:185–186

Dadras Chomachayi M, Solouk A, Akbari S et al (2017) Electrospun nanofibers comprising of silk fibroin/gelatin for drug delivery applications: thyme essential oil and doxycycline monohydrate release study. J Biomed Mater Res Part A 106:1092–1103

Chomachayi MD, Solouk A, Mirzadeh H (2016) Electrospun silk-based nanofibrous scaffolds: fiber diameter and oxygen transfer. Prog Biomater 5:71–80

Chomachayi MD, Solouk A, Mirzadeh H (2019a) Improvement of the electrospinnability of silk fibroin solution by atmospheric pressure plasma treatment. Fibers Polym 20:1594–1600

Balali S, Davachi SM, Sahraeian R et al (2018) Preparation and characterization of composite blends based on polylactic acid/polycaprolactone and silk. Biomacromol 19:4358–4369

Tesfaye M, Patwa R, Gupta A et al (2017) Recycling of poly (lactic acid)/silk based bionanocomposites films and its influence on thermal stability, crystallization kinetics, solution and melt rheology. Int J Biol Macromol 101:580–594

Chomachayi MD, Jalali-arani A, Beltrán FR et al (2020) Biodegradable nanocomposites developed from PLA/PCL blends and silk fibroin nanoparticles: study on the microstructure, thermal behavior, crystallinity and performance. J Polym Environ 205:1–13

Chomachayi MD, Solouk A, Mirzadeh H (2019b) Mathematical modeling of electrospinning process of silk fibroin/gelatin nanofibrous mat: comparison of the accuracy of GMDH and RSM models. J Ind Text. https://doi.org/10.1177/1528083719851856

Haque MM-U, Puglia D, Fortunati E, Pracella M (2017) Effect of reactive functionalization on properties and degradability of poly (lactic acid)/poly (vinyl acetate) nanocomposites with cellulose nanocrystals. React Funct Polym 110:1–9

Beltrán FR, Lorenzo V, de la Orden MU, Martinez-Urreaga J (2016) Effect of different mechanical recycling processes on the hydrolytic degradation of poly (l-lactic acid). Polym Degrad Stab 133:339–348

Tao Y, Xu W, Yan Y, Cao Y (2012) Preparation and characterization of silk fibroin nanocrystals. Polym Int 61:760–767

Patwa R, Kumar A, Katiyar V (2018) Effect of silk nano-disc dispersion on mechanical, thermal, and barrier properties of poly (lactic acid) based bionanocomposites. J Appl Polym Sci 135:46671

DadrasChomachayi M, Jalali-arani A, Urreaga JM (2020) The effect of silk fibroin nanoparticles on the morphology, rheology, dynamic mechanical properties, and toughness of poly (lactic acid)/poly ($\varepsilon$-caprolactone) nanocomposite. J Appl Polym Sci 137:49232

Vyazovkin S, Wight CA (1999) Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta 340:53–68

Budrugeac P (2000) The evaluation of the non-isothermal kinetic parameters of the thermal and thermo-oxidative degradation of polymers and polymeric materials: its use and abuse. Polym Degrad Stab 71:185–187

Rockwood DN, Preda RC, Yücel T et al (2011) Materials fabrication from Bombyx mori silk fibroin. Nat Protoc 6:1612–1631

Nakayama D, Wu F, Mohanty AK et al (2018) Biodegradable composites developed from PBAT/PLA binary blends and silk powder: compatibilization and performance evaluation. ACS Omega 3:12412–12421

Badia JD, Ribes-Greus A (2016) Mechanical recycling of polylactide, upgrading trends and combination of valorization techniques. Eur Polym J 84:22–39

Chen E-C, Wu T-M (2007) Isothermal crystallization kinetics and thermal behavior of poly (ɛ-caprolactone)/multi-walled carbon nanotube composites. Polym Degrad Stab 92:1009–1015

Senthil Muthu Kumar T, Rajini N, Siengchin S et al (2019) Influence of Musa acuminate bio-filler on the thermal, mechanical and visco-elastic behavior of poly (propylene) carbonate biocomposites. Int J Polym Anal Charact 24:439–446

Tesfaye M, Patwa R, Dhar P, Katiyar V (2017) Nanosilk-grafted poly (lactic acid) films: influence of cross-linking on rheology and thermal stability. ACS Omega 2:7071–7084

Botta L, Scaffaro R, Sutera F, Mistretta MC (2018) Reprocessing of PLA/graphene nanoplatelets nanocomposites. Polymers (Basel) 10:18

Jamshidian M, Tehrany EA, Imran M et al (2012) Structural, mechanical and barrier properties of active PLA–antioxidant films. J Food Eng 110:380–389

Starkova O, Buschhorn ST, Mannov E et al (2013) Water transport in epoxy/MWCNT composites. Eur Polym J 49:2138–2148

Gupta KM, Pawar SJ (2005) A nonlinear diffusion model incorporating edge and surface texture effects to predict absorption behaviour of composites. Mater Sci Eng A 412:78–82

Siracusa V (2012) Food packaging permeability behaviour: a report. Int J Polym Sci. https://doi.org/10.1155/2012/302029

Pillin I, Montrelay N, Bourmaud A, Grohens Y (2008) Effect of thermo-mechanical cycles on the physico-chemical properties of poly (lactic acid). Polym Degrad Stab 93:321–328

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dadras Chomachayi, M., Jalali-arani, A. & Martínez Urreaga, J. A Comparison of the Effect of Silk Fibroin Nanoparticles and Microfibers on the Reprocessing and Biodegradability of PLA/PCL Blends. J Polym Environ 29, 2585–2597 (2021). https://doi.org/10.1007/s10924-021-02053-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02053-1