Abstract

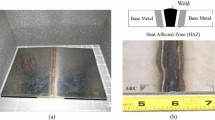

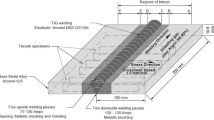

A nondestructive evaluation (NDE) technique is presented that can detect sensitization in welded austenitic stainless steel components for 100% evaluation of in situ parts in real time during production or in service. The sensitization of austenitic stainless steels due to welding or heat treatment has mostly been eliminated by industry standards for manufacturing these alloys that require a carbon content well below the threshold at which sensitization would occur. Such alloys are especially important in naval applications because of their corrosion resistance. However, critical stainless steel components used in naval applications where component failure would be catastrophic are currently not allowed to be fabricated by welding because, until now, there has been no proven, efficient NDE method to verify that each weld in each stainless steel component has not been sensitized and thus weakened. In this study, induction infrared thermography (IIRT) was demonstrated to be an effective NDE tool for detecting sensitized steel in the heat-affected zone (HAZ) of welds in three types of stainless steel plate. The in situ IIRT scan results matched the conventional metallographic analysis of the HAZ in welds in samples of low-carbon 316L austenitic steel, high-carbon 440C martensitic steel, and high-carbon 301 austenitic steel.

Similar content being viewed by others

References

Fontana, M.G., Greene, N.D.: Corrosion Engineering, p. 61. McGraw Hill, New York (1978)

Devine, T.M.: The mechanism of sensitization of austenitic stainless steel. Corros. Sci. 30, 135–151 (1990)

Welding of austenitic stainless steel, Part 2. Job Knowledge article 104, TWI Group Websites, The Welding Institute, technical-knowledge/job-knowledge/welding-of-austenitic-stainless-steel-part-2-104

Tedmon Jr., C.S., Vermilyea, D.A., Rosolowski, J.H.: Intergranular corrosion of austenitic stainless steel. J. Electrochem. Soc. 118(2), 192–202 (1971)

Yin, Y., Faulkner, R.G., Moreton, P., Armson, I., Coyle, P.: Grain boundary chromium depletion in austenitic alloys. J. Mater. Sci. 45, 5872–5882 (2010)

Requirements for fabrication welding and inspection, and casting inspection and repair for machinery, piping, and pressure vessels. NAVSEA Tech Pub S9074-AR-GIB-010/278, Materials Group S-8, Naval Sea Systems Command, Washington, DC, Table VI (1995)

Tucker, W.C., Lockhart, P.K.: Induction Thermography Technique for Detecting Sensitization of Stainless Steel in the Heat Affected Zone After Welding, NUWC-NPT Tech Memo 17-038. Naval Undersea Warfare Center Division, Newport, RI (2017)

ASM Handbook Volume 4: Heat Treating. ASM International, Aimere, Netherlands, Table 4 (1991)

Lippold, J.C., Kotecki, D.J.: Welding Metallurgy and Weldability of Stainless Steels. Wiley, Hoboken, NJ (2005)

Garcia, C., Tiedra, M.P., Blanco, Y., Martin, O., Martin, F.: Intergranular corrosion of welded joints of austenitic stainless steels studied by using an electrochemical minicell. Corros. Sci. 50, 2390–2397 (2008)

Standard test method for electrochemical reactivation (EPR) for detecting sensitization of AISI type 304 and 304L stainless steels. ASTM G108, ASTM International, West Conshocken, PA (1994)

Aydoğdu, G.H., Aydinol, M.K.: Determination of susceptibility to intergranular corrosion and electrochemical reactivation behavior of AISI 316L type stainless steel. Corros. Sci. 48, 3565–3583 (2006)

Standard practices for detecting susceptibility to intergranular attack in austenitic stainless steels. ASTM A262-15, ASTM International, West Conshocken, PA (2015)

Structural welding code—steel. AWS D1.1, American Welding Society, Miami, FL (2010)

Specification sheet for 440C martensitic stainless steel alloy. Interlloy Engineering Steels and Alloys, Melbourne, Australia (2016)

301 stainless steel. AK Steel Product Data Bulletin (2012). http://www.aksteel.com/pdf/markets_products/stainless/austenitic/AK%20301%20Stainless%20Steel%20PDB.pdf

Usamentiaga, R., Venegas, P., Guerediaga, J., Vega, L., Molleda, J., Bulnes, F.G.: Infrared thermography for temperature measurement and non-destructive testing. Sensors 14, 12305–12348 (2014)

Oswald-Tranta, B.: Induction thermography for surface crack detection and depth determination. Appl. Sci. 8(2), 257–280 (2018)

Searchable database of material data sheets. http://www.matweb.com. Accessed 31 Oct 2018

L’vov, S.N., Nemchenko, V.F., Kislyi, P.S., Verkhoglyadova, T.S., Kosolapova, T.Y.: The electrical properties of chromium borides, carbides, and nitrides. Sov. Powder Metall. Met. Ceram. 1(4), 243–247 (1962)

Hirota, K., Mitani, K., Yoshinaka, M., Yamaguchi, O.: Simultaneous synthesis and consolidation of chromium carbides (Cr3C2, Cr7C3 and Cr23C6) by pulsed electric-current pressure sintering. Mater. Sci. Eng., A 399(1–2), 154–160 (2005)

Linstrom, P.J., Mallard, W.G., Eds., NIST Chemistry WebBook, NIST Standard Reference Database Number 69, June 2005, National Institute of Stand-ards and Technology, Gaithersburg MD, 20899. http://webbook.nist.gov. Accessed 01 Nov 2018

Lockhart, P.K.: Infrared thermography crack detection. NUWC-NPT Tech Memo 15-108, Naval Undersea Warfare Center Division, Newport, RI (2015)

Tsymbalist, M.M., Rudenskaya, N.A., Zuz’min, B.P., Pan’kov, V.A.: Low-temperature plasma spheroidizing of polydisperse powders of refractory materials. Prot. Met 39(4), 338–343 (2003)

Kosolapova, T.Y. (ed.): Handbook of High Temperature Compounds: Properties, Production, Applications. Hemisphere Publishing Corporation, New York, NY (1990)

Samsonov, G.V., Borisova, A.L., Zhidkova, T.G., et al., Fiziko-khimicheskie svoistva okislov. Spravoch nik (Physiochemical Properties of Oxides. Hand book), Metallurgiya, Moscow (1978)

Samsonov, G.V., Vinnitskii, I.M.: Tugoplavkie soedineniya. Spravochnik (Refractory Compounds. Handbook), Metallurgiya, Moscow (1976)

Ibarra-Castanedo, C., Piau, J.-M., Guilbert, S., Avdelidis, N.P., Genest, M., Bendada, A., Maldague, X.: Comparative study of active thermography techniques for the nondestructive evaluation of honeycomb structures. Res. Nondestr. Eval. 20, 1–31 (2009)

Balageas, D.: Defense and illustration of time-resolved pulsed thermography for NDE. Quantative Infrared Thermogr. J. 9(1), 3–32 (2012)

Acknowledgements

This work was sponsored by the Naval Undersea Warfare Center and funded by the Office of Naval Research. The authors thank Richard Brown, Chair of the University of Rhode Island Chemical Engineering Department, and his graduate students for preparing the metallurgical samples. Also, many thanks to Matt Roberts, for induction infrared thermography work done during his NREIP internship at NUWCDIVNPT, and to Kevin Wang of the Aerospace and Ocean Engineering Department at Virginia Tech, for his insights on electromagnetic and thermal physics. Finally, thanks to numerous members of the Naval Materials Community of Interest (NMCoI) for fielding questions about thermophysical material properties of chromium carbide precipitates.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Rights and permissions

About this article

Cite this article

Tucker, W.C., Lockhart, P. & Guzas, E. Evaluating Sensitized Chromium Steel Alloys with Induction Infrared Thermography. J Nondestruct Eval 38, 42 (2019). https://doi.org/10.1007/s10921-019-0581-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-019-0581-x