Abstract

We measured the temperature dependence of the resistance in thinned samples of a layered transition metal dichalcogenide 1T-TiSe2. As a result, a thermal hysteresis of resistance was discovered in most samples with a thickness of 10 μm or less, but not in samples thicker than 100 μm. The onset temperature of this hysteresis was almost the same as the onset temperature of the charge density wave (CDW) transition, suggesting that this hysteresis is related to the CDW. All the samples with hysteresis exhibited one or a few jumps of resistance in the 110–190 K range in cooling. Moreover, the hysteresis was related not only to the history of temperature below the CDW transition temperature, but also to that above the transition temperature. To interpret these anomalous results, we discuss the effect of impurities on the domain structure of the CDW.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, the changes in the properties of the layered transition metal dichalcogenides (MX2) due to the decrease in layer thickness have been one of the major research topics. For example, the changes in charge density wave (CDW) transition temperatures due to thinning to nanometer order were investigated in 1T-TiSe2 [e.g., 1, 2] and 1T-VSe2 [3]. As a result, it was discovered that thinning increases the CDW transition temperature in TiSe2 and decreases that in VSe2, and the relationship between the CDWs and the interlayer coupling was discussed based on these different thickness dependencies. Moreover, in 1T-TaS2 which exhibits a CDW transition and a Mott transition, it was found that thinning induces multiple metastable states [4]. As described above, thinning has induced unexpected properties of layered materials, and therefore, it is expected that new properties will be found by investigating thinned materials with various measurement methods.

In the present study, we targeted TiSe2. TiSe2 exhibits a 2a0 × 2a0 × 2c0 modulation (where a0 and c0 are lattice constants) of charge density and a periodic lattice distortion at temperatures below ~200 K, which have been attributed to CDW [5,6,7]. TiSe2 has a valence band whose top is near the Fermi level and a conduction band whose bottom is just below the Fermi level [8]. Therefore, both holes and electrons exist as carriers at high temperatures and their numbers depend on temperature [8]. The temperature dependence of the resistance shows a hump structure with a peak at about 165 K [5], which is proposed to be caused by the decrease in carriers due to the opening of CDW gaps [5] and the temperature dependence of carriers [8]. This hump structure has been reported in the previous studies, but it has not been reported that the height of the hump differs between cooling and heating.

Many previous studies have reported the properties of TiSe2 thinned to nanometer order [e.g., 1, 2]. On the other hand, there are few reports on the properties of samples thinned to micrometer order although it was reported that the CDW transition temperature changed as the thickness changed in micrometer range [1]. Therefore, we investigated the temperature dependence of the resistance for TiSe2 thinned to several micrometers in the present study.

2 Experimental

We prepared single crystals of TiSe2 synthesized by I2 vapor transport. First, we sealed the materials of Ti (0.432 g, 99.9%), Se (1.568 g, 99.9%) and I (3 mg/cc, 99.8%) in an evacuated quartz tube with an inner diameter of 1.5 cm and a length of 15 cm. The tube was then heated so that the temperature of materials at the one end of the tube was 700 ℃, and the temperature at the other end was 600 ℃. After maintained at the temperature for 7 days, the tube was quenched in water. In this way, we obtained single crystals at the lower temperature end.

For the characterization of our crystals, the temperature dependence of the magnetic susceptibility (χ) was measured for samples thicker than 100 μm using a MPMS SQUID magnetometer (Quantum Design). The applied static magnetic field was 0.5 T.

We measured the resistances of thin samples with a thickness of 10 μm or less and thick samples with a thickness of 100 μm or more by a dc four-probe technique, using a laboratory-made resistance measurement system or a PPMS (Quantum Design). Clean and thin samples were prepared by cleaving and were simply placed on substrates without any glue. Gold wires with a diameter of 20 μm were then attached to the samples as terminals with carbon paste. The attached wires prevented the samples from going anywhere. The sample thickness was measured with a digital microscope. The temperature was measured using a Cernox resistance sensor.

3 Results

Figure 1 shows the temperature dependence of the χ for TiSe2 samples thicker than 100 μm. As temperature decreased, the χ decreased in the high-temperature range (T > 95 K) and increased in the low-temperature range (T < 95 K). The slope of the χ–T curve became steep at about 205 K.

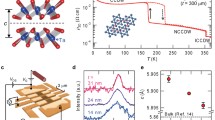

We measured the resistances of three samples with a thickness of 100 μm or more (thick samples) and 11 samples with a thickness of 10 μm or less (thin samples). As shown in Fig. 2a–c, the temperature dependence of the resistance showed a hump structure with a peak at about 165 K for all the thick and thin samples as seen in the previous studies [5]. For all the thick samples, the height of the hump in cooling was the same as that in heating as shown in Fig. 2a. On the other hand, for nine of the 11 thin samples, the height of the hump differed between cooling and heating as shown in Fig. 2b and c. The difference in the height of the hump was reproduced in different measurement systems. There were cases where the hump in heating was higher than that in cooling and vice versa. The insets in Fig. 2b and c show the difference in resistance between heating and cooling. The temperature at which the difference began to occur was 208 \(\pm\) 4 K. The value of the difference did not show a monotonical change for the sample thickness although the difference was triggered by thinning.

Typical temperature dependence of the resistance of TiSe2. a Results for sample No. 4 with a thickness of ~ 220 μm. b Results for sample No. 1 with a thickness of ~10 μm. The inset shows the difference in the resistance between heating and cooling. c Results for sample No. 6 with a thickness of ~ 2 μm. d Enlarged view for sample No. 1 (Color figure online)

As shown in Fig. 2d, the R–T curve in all the samples with the difference in hump height showed one or a few jumps of resistance whose widths were 0.5–5% of the resistance at 280 K, only in the 110–190 K range in cooling. The sizes and appearance temperatures of the jumps changed with each measurement even in the same sample. For 73% of the observed jumps, the resistance on the colder side than the jump was higher than that on the hotter side.

We investigated the temperature dependence of the resistance under various measurement conditions. The height of hump was independent of heating rate from 0.5 to 1 K/min, cooling rate from 0.5 to 5 K/min and current density from 0.38 to 1.9 × 102 A/cm2 as shown in Fig. 3a and b. Figure 3c shows the R–T curves when the sample was cooled from 300 to 4.5, 84, 118 or 154 K and then heated to 300 K. The hump in heating became monotonously lower as the lowest temperature that the sample experienced just before increased. Thus, the difference in resistance between heating and cooling monotonously decreased as the lowest temperature that the sample experienced just before increased as shown in Fig. 3d. Figure 3e shows the results when the sample was heated from 4.5 to 188, 220, 250 or 300 K and then cooled to 4.5 K. The hump in cooling became monotonously lower as the highest temperature that the sample experienced just before increased. Thus, the difference in resistance between heating and cooling monotonously increased as the highest temperature that the sample experienced just before increased as shown in Fig. 3f.

Results of resistance measurements for sample No. 1 under various measurement conditions. a Temperature dependence of the resistance for various current densities. b Temperature dependence of the resistance for various heating and cooling rates. c Temperature dependence of the resistance when the sample was cooled from 300 to 4.5, 84, 118 or 154 K and then heated to 300 K. d Difference in resistance between heating and cooling derived from panel (c). The jumps of the difference were due to the jumps of the resistance in cooling. e Temperature dependence of the resistance when the sample was heated from 4.5 K to 188, 220, 250 or 300 K and then cooled to 4.5 K. f Difference in resistance between heating and cooling derived from panel (e) (Color figure online)

4 Discussion

In the χ–T curve for our crystals, the slope changed at about 205 K (Fig. 1). The same χ–T curve was reported in a previous study, and the temperature at which the slope changed corresponded to the appearance temperature of the satellite peak of the CDW observed by X-ray diffraction, that is, the onset temperature of the CDW transition [6]. Therefore, our result of χ indicates that the onset temperature of the CDW transition in our samples is about 205 K.

We found a difference in resistance between cooling and heating in most of the thin samples (Fig. 2b and c). The onset temperature of this difference in resistance was 208 \(\pm\) 4 K, which was almost the same as the onset temperature of the CDW transition of ~ 205 K. Therefore, it is suggested that this difference in resistance is related to the CDW.

Possible causes of the difference in resistance below the CDW transition temperature include the suppression of the phase transition due to rapid cooling rate, the sliding of CDW and the phase transition due to Joule heating, which are observed in other CDW compounds [4, 9,10,11]. However, they will not be the cause in our thin TiSe2 samples because the value of the resistance was independent of cooling rate and current density (Fig. 3a and b).

While the height of the hump was independent of cooling rate and current density, the hump in heating became lower as the lowest temperature that the sample experienced just before increased, and the hump in cooling became lower as the highest temperature that the sample experienced just before increased (Fig. 3c and e). These results indicate that the resistance of our thin TiSe2 samples depends on the history of temperature, i.e., there is a thermal hysteresis of resistance related to the CDW.

The thermal hysteresis of resistance related to CDW has been observed in a few CDW compounds and has been proposed to be due to the switching between two different CDW configurations or between incommensurate, nearly commensurate and commensurate CDWs [4, 10,11,12]. On the other hand, it is suggested that the CDW-related hysteresis which appears in our thin TiSe2 samples has a different mechanism from the hysteresis in other CDW compounds, because the hysteresis in our samples had the following peculiar characteristics: (i) The hysteresis exhibited cases where the hump in heating was higher than that in cooling and vice versa (Fig. 2b and c). (ii) The hysteresis was related not only to the history of temperature below the CDW transition temperature, but also to that above the transition temperature (Fig. 3c–f). (iii) One or a few jumps of resistance were frequently observed (Fig. 2d). To interpret these peculiar characteristics, we speculate that the CDW forms a domain structure in our thin TiSe2 samples, and the size and pattern of the domains are affected by the distribution of impurities which changes between heating and cooling, and between samples. The following reports and suggestions by the previous studies support our speculation: (i) It was implied that the CDW has short-range order in thin TiSe2, from the experimental result that the CDW transition temperature changed due to the decrease in sample thickness [2]. (ii) TiSe2 crystals contain defects such as intercalated Ti atoms, substituted O atoms and I atoms and Se vacancies [13]. (iii) In CDW materials including TiSe2, CDW domains or domain boundaries form in impurities-rich regions, in short, impurities affect the pattern of short-range order CDWs [14, 15]. (iv) It was suggested that the impurities move depending on temperature in CuxTiSe2 [16]. (v) In another material, it was suggested that the concentration and the distribution of impurities varied among samples from the same batch [17]. Because the density of states is considered to depend on location in a CDW domain structure, as seen in CuxTiSe2 in which the CDW domains are induced by Cu doping [18], the resistance will vary depending on the size and pattern of the CDW domains. Thus, in our thin TiSe2 samples, the difference in the CDW domain structure between heating and cooling, and between samples will cause the difference in the height of the hump between heating and cooling, and between samples. In our speculation, the jumps of the resistance can be interpreted as a sudden partial change in the domain structure. Moreover, it can be interpreted that the effects of the history of temperature on the hysteresis are because the impurities move above and below the transition temperature.

5 Conclusion

We found a thermal hysteresis of resistance in most TiSe2 samples with a thickness of 10 μm or less. It is suggested that this hysteresis is related to the CDW because the onset temperature of the hysteresis was almost the same as the onset temperature of the CDW transition. The hysteresis had various peculiar characteristics. Further studies are required to clarify the nature of this peculiar hysteresis and the reason for its appearance in thin samples.

References

P. Goli, J. Khan, D. Wickramaratne, R.K. Lake, A.A. Balandin, Nano Lett. 12, 5941 (2012). https://doi.org/10.1021/nl303365x

P. Chen, Y.-H. Chan, M.-H. Wong, X.-Y. Fang, M.Y. Chou, S.-K. Mo, Z. Hussain, A.-V. Fedorov, T.-C. Chiang, Nano Lett. 16, 6331 (2016). https://doi.org/10.1021/acs.nanolett.6b02710

J. Yang, W. Wang, Y. Liu, H. Du, W. Ning, G. Zheng, C. Jin, Y. Han, N. Wang, Z. Yang, M. Tian, Y. Zhang, Appl. Phys. Lett. 105, 063109 (2014). https://doi.org/10.1063/1.4893027

M. Yoshida, R. Suzuki, Y. Zhang, M. Nakano, Y. Iwasa, Sci. Adv. 1, e1500606 (2015). https://doi.org/10.1126/sciadv.1500606

F.J. Di Salvo, D.E. Moncton, J.V. Waszczak, Phys. Rev. B 14, 4321 (1976). https://doi.org/10.1103/PhysRevB.14.4321

S. Kitou, S. Kobayashi, T. Kaneko, N. Katayama, S. Yunoki, T. Nakamura, H. Sawa, Phys. Rev. B 99, 081111(R) (2019). https://doi.org/10.1103/PhysRevB.99.081111

C.G. Slough, B. Giambattista, A. Johnson, W.W. McNairy, C. Wang, R.V. Coleman, Phys. Rev. B 37, 6571(R) (1988). https://doi.org/10.1103/PhysRevB.37.6571

M.D. Watson, A.M. Beales, P.D.C. King, Phys. Rev. B 99, 195142 (2019). https://doi.org/10.1103/PhysRevB.99.195142

P. Monceau, N.P. Ong, A.M. Portis, A. Meerschaut, J. Rouxel, Phys. Rev. Lett. 37, 602 (1976). https://doi.org/10.1103/PhysRevLett.37.602

A.K. Geremew, S. Rumyantsev, F. Kargar, B. Debnath, A. Nosek, M.A. Bloodgood, M. Bockrath, T.T. Salguero, R.K. Lake, A.A. Balandin, ACS Nano 13, 7231 (2019). https://doi.org/10.1021/acsnano.9b02870

A. Mohammadzadeh, S. Baraghani, S. Yin, F. Kargar, J.P. Bird, A.A. Balandin, Appl. Phys. Lett. 118, 093102 (2021). https://doi.org/10.1063/5.0044459

B.Q. Lv, A. Zong, D. Wu, A.V. Rozhkov, B.V. Fine, S.-D. Chen, M. Hashimoto, D.-H. Lu, M. Li, Y.-B. Huang, J.P.C. Ruff, D.A. Walko, Z.H. Chen, I. Hwang, Y. Su, X. Shen, X. Wang, F. Han, H.C. Po, Y. Wang, P. Jarillo-Herrero, X. Wang, H. Zhou, C.-J. Sun, H. Wen, Z.-X. Shen, N.L. Wang, N. Gedik, Phys. Rev. Lett. 128, 036401 (2022). https://doi.org/10.1103/PhysRevLett.128.036401

B. Hildebrand, C. Didiot, A.M. Novello, G. Monney, A. Scarfato, A. Ubaldini, H. Berger, D.R. Bowler, C. Renner, P. Aebi, Phys. Rev. Lett. 112, 197001 (2014). https://doi.org/10.1103/PhysRevLett.112.197001

A.M. Novello, M. Spera, A. Scarfato, A. Ubaldini, E. Giannini, D.R. Bowler, Ch. Renner, Phys. Rev. Lett. 118, 017002 (2017). https://doi.org/10.1103/PhysRevLett.118.017002

L. Liu, C. Zhu, Z.Y. Liu, H. Deng, X.B. Zhou, Y. Li, Y. Sun, X. Huang, S. Li, X. Du, Z. Wang, T. Guan, H. Mao, Y. Sui, R. Wu, J.-X. Yin, J.-G. Cheng, S.H. Pan, Phys. Rev. Lett. 126, 256401 (2021). https://doi.org/10.1103/PhysRevLett.126.256401

S. Kitou, T. Hasegawa, A. Nakano, N. Katayama, S. Tsutsui, H. Sawa, Phys. Rev. B 101, 094108 (2020). https://doi.org/10.1103/PhysRevB.101.094108

A. Nomura, K. Yamaya, S. Takayanagi, K. Ichimura, S. Tanda, EPL 124, 67001 (2018). https://doi.org/10.1209/0295-5075/124/67001

S. Yan, D. Iaia, E. Morosan, E. Fradkin, P. Abbamonte, V. Madhavan, Phys. Rev. Lett. 118, 106405 (2017). https://doi.org/10.1103/PhysRevLett.118.106405

Funding

Open access funding provided by Tokyo University of Science.

Author information

Authors and Affiliations

Contributions

A.N. conceived the project, and A.N., S.D., S.O. and S.K. performed the experiments. A.N. wrote the manuscript and H.S. reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nomura, A., Demura, S., Ohta, S. et al. Emergence of a Thermal Hysteresis of Electrical Resistance by Thinning in 1T-TiSe2. J Low Temp Phys 213, 215–222 (2023). https://doi.org/10.1007/s10909-023-02999-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10909-023-02999-7