Abstract

Direct mixing (de novo) and Solvent Assisted Ligand Exchange (SALE) are the main methods used for the synthesis of Mixed-Linker Zeolitic Imidazolate Frameworks (ML-ZIFs). ML-ZIFs with combined –NO2 and –Br/–Cl functionalities were prepared via both synthetic routes. Thereafter the CO2 uptake of the ML-ZIFs were compared, as well as their abilities to fixate CO2 with epoxide substrates. The de novo synthesis resulted in ML-ZIFs with SOD topologies, 60: 40 (–NO2: –Br/–Cl) functionality ratios, higher porosities, better thermal stability and higher CO2 uptake than equivalent SALE products. SALE resulted in smaller ML-ZIF crystallites, only ~ 10% incorporation of –Br/–Cl functionalized imidazolate linkers, and phase change during activation. ML-ZIF-7Cl, obtained from direct mixing, resulted in the highest CO2 uptake (90 cm3 g−1), in line with its higher porosity. ML-ZIF-7Cl, in combination with tetrabutylammonium bromide (TBAB), showed a high catalytic activity (TOF of 446 h−1) for the fixation of CO2 with propylene oxide and was reusable for up to 4 cycles without loss in activity.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The removal of carbon dioxide from the atmosphere is essential in minimizing the impact of global warming due to the use of fossil fuels [1, 2]. In the last two decades, ZIFs, a subfamily of Metal–Organic Frameworks (MOFs), with divalent metal centres tetrahedrally connected by imidazolate-based linkers, have garnered much interest for CO2 separation, adsorption/capture and utilization applications [3,4,5].

ZIFs have high porosity, tuneable functionality, high thermal and mechanical properties, making them ideal for industrial CO2 capture and sequestration (CCS) as well as CO2 capture and utilization (CCU) applications [6]. CCU technologies have the added advantage of valorizing CO2 and compensating for CCS costs [7, 8]. The use of ZIF catalysts for forming cyclic carbonates through the cycloaddition of CO2 with epoxide substrates is one type of CCU that has gained much attention recently for its green chemistry, 100% atom economy and high value-added products [9, 10]. Cyclic carbonates are valuable chemicals with applications in metal extraction, electrolytes in lithium-ion batteries and supercritical fluid separation [11, 12].

Extensive experimental and computational studies have shown that both CO2 fixation and uptake by ZIFs are subject to the functionality of their linkers [13,14,15,16]. ZIFs with electron-withdrawing groups (EWG) achieved the highest CO2 uptakes in the following order of linker functionality: NO2 > Cl > Br > CN > H > CH3 [17,18,19]. This has been attributed to the high quadrupole moment of ZIFs with EWG, resulting in a higher interaction of CO2 and polar functionality [20]. The cycloaddition of CO2 with epoxide substrates requires a catalyst with both Lewis acid (LA) and Lewis base (LB) sites, LAs open the epoxide ring, whereas LBs activate CO2 [21, 22]. ZIFs are bifunctional catalysts with dual LA (–NH of imidazole linker) and LB (metal centre) sites, making them suitable for cycloaddition reactions [23].

The use of mixed–linker ZIFs with combined EWG (–NO2) and electron-donating (–CH3) functionalities has shown that Electron density (ED) symmetry also plays a part in the CO2 uptake and fixation of ZIFs. Solvent Assisted Ligand Exchange (SALE) of ZIF-8 (with Zn(CH3Im)2 composition) with NO2Im resulted in an asymmetric ED, which led to a 155% increase in CO2 capacity of ZIF-8 [24, 25]. Similarly, ML-ZIF 3 with Zn(mIm)0.82(NO2Im)1.18 composition has shown a 72% increase in CO2 uptake compared to. ZIF-108 (with only NO2Im linkers) and a 140% increase compared to ZIF-8 (with only mIm linkers) [26, 27]. This study aims to combine the high-performing linker functionalities (–NO2 and –Br/–Cl) on one ZIF structure and investigate its effect on CO2 uptake and conversion.

There are two routes for a multi-linker ZIF synthesis: direct incorporation of the two linkers during the synthesis process (de novo) and post-synthetic modification (PSM) of a single-linker ZIF. The de novo method is a one-pot synthesis reaction, where the mixture of linkers is combined with the metal source. The crystal structure is then determined by how the two linkers compete in structure-directing and interact with each other [6]. SALE is a type of PSM, where a single-linker ZIF is reacted with an excess secondary linker in a suitable solvent system [28]. SALE occurs via a heterogeneous nucleation process, where the parent material is used as seeds [29]. To the best of our knowledge, this is the first report of de novo or SALE synthesis of ZIFs with combined 2-nitroimidazole (NO2Im) and 2-bromoimidazole (BrIm)/2-chloroimidazole (ClIm) linkers, respectively.

Herein, we present a comparative study (thermal stability, linker ratio, topology, porosity, and CO2 uptake) of de novo and SALE routes for synthesizing mixed-linker ZIFs with combined –NO2 and –Br/Cl functionalities. In addition, the catalytic activities of de novo and SALE prepared ML-ZIFs in the fixation of CO2 with an epoxide substrate are reported.

2 Experimental

2.1 Materials and Equipment

All chemicals and solvents were purchased from AmBeed USA or Sigma-Aldrich/Merck and used without further purification.

Reflection data of single crystals were collected on either a Bruker D8 Venture 4 K Photon III C28 diffractometer or on a Bruker D8 Quest diffractometer. Both instruments are equipped with a graphite monochromator using a Mo-Kα generator utilizing a wavelength of λ = 0.71073 Å. The data was collected using phi and omega scans at 100 K. COSMO [30] was utilized for multiple hemisphere data collection of the reciprocal space. Bruker SAINT-Plus and XPREP [31] were employed for frame integration and data reduction. SADABS [32] was used for phase correction by using the multi-scan method. SHELXT [33] was used to solve the crystal structures by means of intrinsic phasing. WinGX [34], Olex2 [35] and SHELXL-2018/3 [34] were used for the refinement of the crystal structures. DIAMOND 4.0 software [36] was utilized to generate crystal structure images. In the crystal structure images all thermal ellipsoids are drawn with 50% probability level unless stated otherwise. In all structures, the hydrogen atoms were positioned geometrically and refined using a riding model: C–H aromatic distances are placed at 0.95 Å. The H atom isotropic displacement parameters were fixed at Uiso(H) = 1.2 Ueq(C). When appropriate, the hydrogen atoms bound to non-carbon atoms were located and placed according to the Fourier electron difference map.

PXRD patterns were collected on a Bruker D2 Phaser powder X-ray diffractometer at 25 °C, with Cu radiation (λ = 1.54 Å). TEM images were obtained from Philips (FEI) CM100 microscope equipped with a MegaView III digital camera and pictures were analyzed with ZEISS ZEN core V2.6 software for particle size determination. 1H NMR spectra were measured on a 400 MHz Bruker AVANCE III NMR spectrometer (operating at 25 °C) with a 5 mm BBI H-BB-D probe with z-gradients. The 1H chemical shifts were reported relative to SiMe4 at 0.0 ppm as external standard and utilizing the solvent peak as internal standard where applicable. All insoluble ML-ZIF derivatives were digested in D2O: D2SO4 (9:1) prior to NMR measurements.

All samples were activated prior to porosity analyses by solvent exchange with methanol (3 × 50 cm3) and evacuation at 150 °C. Porosity and surface area measurements were performed on a Micromeritics ASAP 2020 Surface Area and Porosity Analyser. Porosity data was analyzed with MicroActive V2.0 for physisorption with nitrogen and carbon dioxide. The Brunauer − Emmett − Teller (BET) surface area was determined using the recently developed BET surface identification (BETSI) software [37]. N2 adsorption was measured with relative pressure at 77 K and CO2 adsorption with absolute pressure at 273 and 293 K, respectively, with the warm and cold free space determined separately with helium. T-plot external surface areas and micropore volumes were calculated with the t-plot method of the Microactive programme using the Harkins and Jura thickness equation. Thermal stability tests were performed on a TA TGA5500 analyzer under N2 atmosphere.

2.2 De Novo Synthesis of Mixed-Linker ZIFs

Mixed-linker (ML) ZIFs were synthesized using a solvothermal method from literature with equal linker ratios (Scheme 1) [17]. For the synthesis of ML-ZIF-7, Zn(NO3)0.6H2O (0.9460 g, 3.2 mmol), 2-nitroimidazole (NO2Im, 0.4523 g, 4.0 mmol) and 2-chloroimidazole (ClIm, 0.4100 g, 4.0 mmol) were separately dissolved in DMF (20 cm3). The solutions were then mixed in a Teflon reactor. The reactor was sealed and solvothermally heated at 100 °C for 72 h. The reactor was then allowed to cool to room temperature, the formed crystals were separated by centrifugation and washed with DMF (2 × 100 cm3). The crystalline product was air-dried overnight to yield light yellow crystals of ML-ZIF-7Cl (Zn(NO2Im)1.24(ClIm)0.76), (0.6007 g, 67%, based on Zn2+). Similarly, ML-ZIF-8Br was synthesized by using 2-bromoimidazole (BrIm, 0.4100 g, 4.0 mmol) in place of ClIm to yield ML-ZIF-8Br crystals with Zn(NO2Im)1.16(BrIm)0.84 composition (0.8260 g, 82%, based on Zn2+).

2.3 SALE Synthesis of ML-ZIFs

Firstly, nano-sized ZIF-108 was synthesized using an adopted procedure from literature giving an average particle size of 69 nm [26]. SALE was performed by suspending nZIF-108 (0.300 g, 1.0 mmol) in DMF (30 cm3) by an ultra-sonic probe for three minutes before transferring it to a Teflon cup (Scheme 2). Subsequently, ClIm (0.318 g, 3.0 mmol) was dissolved in DMF (30 cm3) and added to the ZIF-108 suspension. The Teflon cup was then sealed in a stainless-steel reactor and heated to 60 °C for 72 h. After cooling, the SALE products were collected by centrifugation, washed with DMF (3 × 100 cm3), followed by further centrifugation and air dried to yield ZIF-108-Cl (0.2080 g, 69%)). A similar SALE reaction with BrIm (0.456, 3.0 mmol) yielded ZIF-108-Br (0.2069, 69%).

2.4 CO2-Epoxide Cycloaddition Reaction

The catalytic activity of de novo and SALE synthesized ML-ZIFs with tetrabutylammonium bromide (TBAB) was tested using optimized reaction conditions (120 °C, 17 bar, 0.2 mol %, 0.5 h) for solvent-less CO2-propylene-oxide (PrO) cycloaddition in a 25 cm3 Parr reactor with magnetic stirrer (Scheme 3) [38]. PrO (5 cm3, 72 mmol), ML-ZIF-7 (40.5 mg, 0.144 mmol) and TBAB (46.4 mg, 0.144 mmol), were placed in the sealed reactor with a CO2 inlet. The reactor was first purged with CO2 to replace air with CO2 inside the reactor. The reactor was then charged with 17 bar of CO2 and heated to 120 °C for 30 min. After cooling the reactor to room temperature, excess gas was vented and the recovered liquid was analysed via 1H NMR.

3 Results and Discussions

3.1 Synthesis of Mixed-Linker ZIFs

The mixed linker ZIFs were synthesized with 1:1 linker ratio for the de novo synthesis to afford both linkers an equal chance of incorporation. For the SALE of ZIF-108, 3 × excess secondary linker (ClIm/BrIm) was used as it is adequate for the diffusion-limited ligand exchange process [39, 40]. SALE was performed at 60 °C, as ligand exchange at high temperature result in surface etching of the ZIF [40]. Both de novo and SALE syntheses were performed for 72 h for a synthesis-time independent comparison of the two routes. All ML-ZIF syntheses were performed with a DMF solvent system, as all the linkers (NO2Im, ClIm and BrIm) used in this work are soluble in DMF, and SALE is dependent on the solubility of the linkers in solution [41].

Thermal gravimetric analyses (TGA) show that the de novo synthesized ML-ZIFs are thermally stable up to 330–340 °C. While ML-ZIFs prepared via SALE are thermally stable up to 300 °C. (Fig. 1) The lower thermal stability of the SALE derivatives can be attributed to the presence of partly coordinated linkers.

3.2 X-Ray Diffraction

3.2.1 Single Crystal XRD

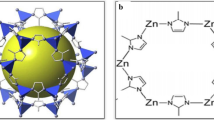

Both products from the de novo syntheses, ML-ZIF-7 and ML-ZIF-8, form a sodalite (SOD) topology with I \(\overline{4 }\) 3 m space group, making them isostructures of ZIF-8 and ZIF-108, respectively [17, 42]. The external morphology of the crystals of ML-ZIF-7 and ML-ZIF-8 is given in Fig. 2. The subunit of the two crystal structures is depicted with their respective major and minor disorder occupancies in Fig. 3. The primary disorder occupancies are 0.64 and 0.62 for ML-ZIF-7 and 8, respectively. Each subunit is defined as a whole imidazolate anion with a zinc cation coordinating with each of the aromatic nitrogen atoms of the imidazole. The general crystallographic and refinement parameters for the two crystal structures are given in SI, Table S1. Both crystal structures’ unit cell parameters are similar; however, the ML-ZIF-7 structures’ unit cell lengths are slightly shorter, resulting in a slightly smaller unit cell volume, and this can be attributed to the larger atomic radius of bromide compared to chloride.

The hexagonal (open pore) and square packing (closed pore) motives of both ML-ZIFs are illustrated in Fig. 4. Some small but significant crystallographic bonding distances and angle differences can be observed between ML-ZIF-7, ML-ZIF-8 and other structures found on the Cambridge Structural Database (CSD) [43]. A selection of these distances and angles has been summarised in Table 1.

ML-ZIF-7 and ML-ZIF-8 adopt very similar structural parameters to ZIF-108, with some variations being introduced by the presence of Br/Cl atoms. The Zn1-Zn1’ distance for ZIF-108 (6.1135(1) Å) is longer than those of ML-ZIF-7 and ML-ZIF-8 (6.0638(1) and 6.0815(5) Å), respectively. A similar trend in the Zn1-Zn1’ distance is observed with the structures of ZIF-8_Cl and ZIF-8_Br being 6.024(1) and 6.039(1) Å. The Zn1-N1 distance of ML-ZIF-7 and ML-ZIF-8 are 2.007(6) and 1.999(7) Å which tends toward the value seen in ZIF-108 of 2.023(1) Å and not the shorter distances of ZIF-8_Cl and ZIF-8_Br (1.942(3) and 1.987(4) Å), respectively. The pore diameters of ML-ZIF-7 and ML-ZIF-8 (5.8035(1) and 5.8111(5) Å) are slightly smaller than ZIF-108 (5.8812(1) Å) but are significantly larger than any of the other structures found in 1 (between 5.5502(1) and 5.76(2) Å).

As with the bonding distances, the two structures reported here have angles that mimic those of ZIF-108. The N1-Zn1-N1’ angle for ML-ZIF-7 and 8 are 105.9(2) and 106.5(2) °, respectively, whereas ZIF-108’s angle is 104.06(5)°. This is smaller than ZIF-8_Cl and ZIF-8_Br angles that are 108.4(1) and 107.6(1) °. The hexagonal and square plane angles show the same trend. For ML-ZIF-7 the hexagonal (73.8(9) °) and square (63.7(9) °) plane angles are identical, within error margins, to ZIF-108’s plane angles (73.6(1) and 64.3(1) °). However, ML-ZIF-8’s plane angles (71.1(8) and 69.5(7) °) deviate from this, possibly due to the larger bromide atomic radii. The effect of the nuclear radii can be seen in the angles of ZIF-8_Cl, ZIF-8_Br and Zn(I2), which decrease in the hexagonal plane angles (70.3(4), 66.9(5) and 67.5(1) °) and increase in the square plane angles (70.9(4), 77.5(3) and 76.5(13) °).

These parameters show that the electron-withdrawing NO2 group is useful in increasing the pore size of chloride and bromide-containing ZIFs, while retaining some differences in electronic character (compared to NO2 only), which could be useful for gas adsorption.

The unit cell packing of the ML-ZIF-7 and ML-ZIF-8 structures are very similar, as expected, both with SOD topology. In the figure below (Fig. 5) the unit cell packing of both the crystal structures are depicted as line drawings for the sake of clarity. The open hexagonal pores are situated at the corners of the unit cell and the closed square pores are parallel to the faces of the unit cell. Also included in the figure is the polyhedra of the metal cations. These tetragonal-polyhedra are generated by the N-atoms of the imidazolate ligands coordinated to each Zn-cation to highlight the metal positions.

3.2.2 Powder XRD

Directly synthesized ML-ZIFs formed a SOD topology, in agreement with the result obtained from single crystal XRD. (Fig. 6) The ligand exchanged ZIF-108 derivatives retained the SOD topology of ZIF-108. Peak broadening is only observed with the PXRD pattern of SALE products, indicating that the particles are nano-sized.

After activation, the de novo synthesized ML-ZIFs maintained the SOD topology, whereas the ZIF-108 SALE derivatives undergoes a phase change to an unknown, disordered structure. (Fig. 7) The disorder is characterized by a shift of the 110 peak from 7.2° to 6.5° and a significant broadening of all peaks. The phase change has previously been attributed to a strong interaction of the ZIF with methanol during the activation process resulting in amorphization of the structure [29]. These structural instabilities are inherent to the parent ZIF-108, which undergoes a similar structural change in polar solvents and above 100 °C [47]. Similar to ZIF-108, the SOD topology of the SALE products can be restored by immersing them in DMF. (SI, Fig.S1).

3.3 Nuclear Magnetic Resonance (NMR)

After digestive 1H NMR, ML-ZIFs linker ratio was determined from the CH=CH peak integrals of NO2Im (Fig. 8i) and halogenated imidazoles, respectively. (Fig. 8, i–iii) Directly synthesized ML-ZIFs showed a ~ 60: 40 (NO2Im: XIm) linker ratio. These results are in line with the occupancy of the two linkers observed with single-crystal XRD. The higher incorporation of the NO2Im linker in both ML-ZIFs can be attributed to the higher reactivity of NO2Im and favourable ZIF structure formed with NO2Im over the halogenated linkers [26]. The two SALE products showed low (≤ 10%) incorporation of the halogenated linker. This can be attributed to the exchange being limited to the external surface of ZIF-108, due to the bulkier halogen functionality and steric effect between the -NO2 and incoming –Cl/Br functionality [48].

3.4 Transmission Electron Microscopy

TEM images of the ML-ZIFs and SALE products revealed the hexagonal and spherical particles, with average particle sizes of 450–480 nm for the de novo prepared ML-ZIFs and 108–125 nm for SALE products. (Fig. 9) Both SALE products showed a significant increase on the size of ZIF-108 (69 nm), indicating a possible core–shell structure, where SALE predominantly occur on the external surface area of the MOF [40]. The SALE synthesis method resulted in nano-sized particles (Fig. 9 C and D), with both de novo syntheses resulting in particles about five times larger (Fig. 9 A and B). This can be ascribed to the particle size of SALE products being limited by the mother ZIF-108, compared to the de novo products, where there is no limiting agent.

3.5 Porosity Analysis

Both de novo prepared ML-ZIFs and SALE products (from ZIF-108) have a type-I N2 isotherms. (Fig. 10) In comparison to the reported BET surface area of ZIF-108 (724 m2 g−1), both ML-ZIFs show significantly larger surface areas, with a 77% (ML-ZIF-7Cl) and 44% (ML-ZIF-8Br) increase [26]. Of the de novo prepared ZIFs, ML-ZIF-7Cl exhibited the highest BET surface area (1283 m2 g−1) and micropore volume of 0.43 cm3 g−1. (Table 2, SI Fig. S2–S5) Both de novo prepared ML-ZIFs show superior BET surface areas, compared to their SALE derived analogues (ZIF-108-Cl and ZIF-108-Br) [44].

The ZIF-108 SALE derivatives both have lower BET surface areas than the mother ZIF-108, with a 60 and 47% decrease for ZIF-108-Cl and ZIF-108-Br, respectively (Fig. 10A). This can be attributed to the phase change of the ZIF-108 derivatives during the activation process, as observed in Fig. 8. Noticeable hysteresis is observed with the desorption cycle of ZIF-108_Cl, possibly due to the presence of mesoporous cavities, resulting from the phase change during activation.

The gate opening phenomenon refers to the distortion of the MOF structure at a specific gate opening pressure, resulting in a flexible structure capable of greater molecular uptake [49, 50]. This can be observed in the N2 isotherm with logarithmically-scaled relative pressure (p/p°) on the x-axis, with each step or "jump" in adsorption corresponding to the gate-opening/flexibility pressure [51]. The N2 isotherm of ML-ZIF-7Cl exhibits a sharp step (at 0.0005–0.005 p/p°), indicating the flexibility of the framework (Fig. 10B). Similarly, ML-ZIF-8Br also shows a slight step (0.04–0.05 p/p°) at higher loading, resulting in a hysteresis loop in the desorption cycle. Chaplais et al. have demonstrated the gate-opening phenomenon for ZIF-Cl (Zn(ClIm)2), while ZIF-Br (Zn(BrIm)2) showed no flexibility [44, 52]. Therefore, the flexibility of ML-ZIF-7Cl can be attributed to the possible swing/rotation of both the ClIm and NO2Im linkers, while the slight flexibility of ML-ZIF-8Br can be ascribed to the NO2Im linker rather than the BrIm linker.

3.6 CO2 Adsorption

At low pressures (0–200 mmHg) SALE synthesized ML-ZIFs show similar CO2 uptakes than de novo ML-ZIFs. (Fig. 11) At higher pressures (200–900 mmHg) the de novo prepared ML-ZIFs maintain a linear increase while the SALE derivatives level off due to their lower porosities. ML-ZIF-8Br and ML-ZIF-7Cl have 60 and 70% higher CO2 uptakes than the 53 cm3 g−1 of ZIF-108 (Table 2). The 90 cm3 g−1 CO2 uptake of ML-ZIF-7Cl can be attributed to its higher porosity and gate-opening effect. At a higher analysis temperature (293 K), both de novo prepared ML-ZIFs show similar uptakes. (SI, Fig. S6).

The CO2 uptakes of the SALE derived ML-ZIFs, ZIF-108-Br (50 cm3 g−1) and ZIF-108-Cl (55 cm3 g−1), are similar to that of ZIF-108 (53 cm3 g−1), despite their lower BET surface and phase change during activation (Table 2).This highlights the effect of the lowly incorporated halogenated linkers in enhancing the CO2 uptake. The higher CO2 uptake of the Cl-containing ML-ZIF-7Cl and ZIF-108-Cl, when compared to their Br-containing counterparts, is in line with the computational studies done by Tsai et al., which showed that –Cl functionalised ZIFs result in stable adsorption energies over other halogen functionalities [53].

3.7 CO2 Conversion via Cycloaddition Reactions

While CO2 is known to be a major contributor to global warming, it is also considered as a renewable, non-toxic, and abundant feedstock for fine chemical production [54]. However, due to its high kinetic and thermodynamic stability, converting CO2 into useful chemicals requires significant energy input [55]. One promising approach to overcome this challenge is through the catalytic fixation of CO2 into cyclic carbonates, which are versatile chemicals with a range of applications, including use as intermediates, polar aprotic solvents, polymers, electrolytes, and fuel additives. Currently, cyclic carbonates are synthesized through either transesterification of diols using toxic solvents or cycloaddition of epoxide substrates with CO2 [9, 56]. ZIFs, due to their stability, ease of separation, and recyclability, are considered as effective heterogeneous catalysts for CO2-epoxide cycloaddition [11, 12].

The catalytic activity of de novo and SALE synthesized ML-ZIFs for the PrO-CO2 cycloaddition reaction (Scheme 3) was tested using optimized reaction conditions (Table 3) [27]. De novo synthesised ML-ZIFs show very low catalytic activity for PrO-CO2 cycloaddition, while the ZIF-108 derivatives show no catalytic activity at all. The inactivity of the ML-ZIFs can be attributed to the weakening of LB sites (imidazolate linkers) due to the high electronegativity of –NO2, and –Cl/–Br functionalities [57, 58]. Thus, upon addition of a Lewis base co-catalyst, tetrabutylammonium bromide (TBAB), the catalytic activities of the ML-ZIFs were hugely enhanced [59, 60].

Combining TBAB with the ML-ZIFs resulted in a minimum 28% increase in the catalytic activity of TBAB on its own. This can be attributed to the high surface area and CO2 capacity of the ML-ZIFs, enhancing the interaction of CO2 with the epoxide substrates. In line with its higher BET surface area and CO2 uptake, ML-ZIF-7/TBAB resulted in the highest catalytic activity, with Turnover Frequency (TOF) of 446 h−1. The combination of SALE products (ZIF-108-Cl and ZIF-108-Br) with TBAB result in slightly lower activity than for the de novo ML-ZIFs, while the selectivity was maintained.

3.7.1 Catalyst Reusability

The reusability of the high-performing ML-ZIF-7/TBAB catalyst combination was evaluated by isolating and reactivating the catalyst using centrifugation, washing with dichloromethane (DCM) and drying at 60 °C. The ML-ZIF-7/TBAB catalyst combination is reusable for up to four cycles with a slight drop in activity, while the selectivity remained at 95% (Fig. 12). FTIR analyses show that both fresh and recovered catalyst (after 3rd reuse) have similar peaks, confirming the chemical integrity of the catalyst during the reuse (SI, Fig. S7). The slight decrease in catalytic activity can be attributed to the catalyst’s mass loss (< 5%). The SALE product, ZIF-108-Cl, on the other hand, undergoes significant degradation during the cycloaddition reaction, and no catalyst could be recovered for reusability tests.

3.7.2 Versatility of ML-ZIF-7/TBAB Catalyst

The versatility of the ML‑ZIF‑7/TBAB catalyst was tested for the fixation of CO2 with various functionalized epoxide substrates. (Table 4) ML‑ZIF‑7/TBAB show good conversion of terminal epoxides with the higher TOF (446 h−1) attained from the conversion of epoxides with electron-donating functional groups (H, CH3). Low activity was observed for bulky epoxides fixation due to the epoxide’s steric hindrance [61].

3.7.3 Comparison with Other ZIF Catalyst

Compared to previously reported ZIF-based catalysts for CO2-PrO cycloaddition, the catalytic activity (in terms of TOF) of ML-ZIF-7Cl/TBAB ranks only behind that of ML-ZIF-4 and ML-ZIF-5Co, as shown in Table 5. However, while the latter two catalysts demonstrate high activity, they are not reusable beyond two cycles due to significant structural decomposition during the catalytic reaction. In contrast, ML-ZIF-7Cl/TBAB is capable of being reused for up to four cycles while maintaining its chemical integrity, making it an ideal choice for high-scale industrial applications.

4 Conclusions

By using either De novo synthesis and SALE synthesis a combination of NO2Im and ClIm or BrIm linkers could be successfully incorporated in the ML-ZIF structure. Both methods resulted in ML-ZIFs with SOD topology. The de novo synthesis method is efficient in forming a mixed linker distribution with high chemical (in polar solvents) and thermal stability (up to 340 °C). The core- (–NO2 functionalized) shell (–Cl/ –Br functionalized) structured SALE products showed low incorporation of the halogenated linker, about 60% increase on the ZIF-108 particle size and phase change during activation.

De novo synthesized ML-ZIFs showed higher porosity and larger particle sizes (~ 450 nm) than the ZIF-108 derivative SALE products. The chlorinated ML-ZIF-7Cl formed a flexible framework with a structural rotation at 0.0005–0.005 p/p0 of N2 adsorption. ML-ZIFs with ClIm linkers resulted in higher CO2 adsorption and fixation than their corresponding BrIm containing ML-ZIFs, in line with their high porosity, electronegativity, and flexibility.

Both de novo and SALE synthesised ML-ZIFs on their own showed no catalytic activities for the fixation of CO2 with PrO. However, in combination with TBAB co-catalyst, a 28–40% increase in the catalytic activity of TBAB was achieved. ML-ZIF-7/TBAB resulted in the highest activity for CO2-PrO cycloaddition with a TOF of 446 h−1 and 95% selectivity. The catalyst combination was reusable for up to 4 cycles with a slight loss in activity and was versatile for the fixation of CO2 with various functionalised terminal epoxide substrates.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Y.S. Bae, R.Q. Snurr, Development and evaluation of porous materials for carbon dioxide separation and capture. Angew. Chem. Int. Ed. 50, 11586–11596 (2011). https://doi.org/10.1002/anie.201101891

S.D. Kenarsari, D. Yang, G. Jiang, S. Zhang, J. Wang, A.G. Russell, Q. Wei, M. Fan, Review of recent advances in carbon dioxide separation and capture. RSC Adv. 3, 22739–22773 (2013). https://doi.org/10.1039/c3ra43965h

H.N. Abdelhamid, Removal of carbon dioxide using zeolitic imidazolate frameworks: adsorption and conversion via catalysis. Appl. Organomet. Chem. (2022). https://doi.org/10.1002/AOC.6753

M. Ding, R.W. Flaig, H.L. Jiang, O.M. Yaghi, Carbon capture and conversion using metal-organic frameworks and MOF-based materials. Chem. Soc. Rev. 48, 2783–2828 (2019). https://doi.org/10.1039/c8cs00829a

K.S. Park, Z. Ni, A.P. Cote, J.Y. Choi, R. Huang, F.J. Uribe-Romo, H.K. Chae, M. O’Keeffe, O.M. Yaghi, ZIFs—first synthesis. Proc. Natl. Acad. Sci. 103, 10186–10191 (2006). https://doi.org/10.1073/pnas.0602439103

B.R. Pimentel, A. Parulkar, E.K. Zhou, N.A. Brunelli, R.P. Lively, Zeolitic imidazolate frameworks: next-generation materials for energy-efficient gas separations. Chemsuschem 7, 3202–3240 (2014). https://doi.org/10.1002/cssc.201402647

V. Masson-Delmotte, P. Zhai, H.-O. Pörtner, D. Roberts, J. Skea, P.R. Shukla, A. Pirani, W. Moufouma-Okia, C. Péan, R. Pidcock, S. Connors, J.B.R. Matthews, Y. Chen, X. Zhou, M.I. Gomis, E. Lonnoy, T. Maycock, M. Tignor, T. Waterfield, IPCC report global warming of 1.5°C, 2018. www.environmentalgraphiti.org.

K. Kiatkittipong, M.A.A.M. Shukri, W. Kiatkittipong, J.W. Lim, P.L. Show, M.K. Lam, S. Assabumrungrat, Green pathway in utilizing CO2 via cycloaddition reaction with epoxide-a mini review. Processes (2020). https://doi.org/10.3390/PR8050548

M.H. Beyzavi, C.J. Stephenson, Y. Liu, O. Karagiaridi, J.T. Hupp, O.K. Farha, Metal-organic framework-based catalysts: chemical fixation of CO2 with epoxides leading to cyclic organic carbonates. Front. Energy Res. 3, 1–10 (2015). https://doi.org/10.3389/fenrg.2014.00063

M. Ding, S. Chen, X.Q. Liu, L.B. Sun, J. Lu, H.L. Jiang, Metal-organic framework-templated catalyst: synergy in multiple sites for catalytic CO2 fixation. Chemsuschem 10, 1898–1903 (2017). https://doi.org/10.1002/cssc.201700245

H. Yuan, Y. Wu, X. Pan, L. Gao, G. Xiao, Pyridyl ionic liquid functionalized ZIF-90 for catalytic conversion of CO2 into cyclic carbonates. Catal. Lett. 150, 3561–3571 (2020). https://doi.org/10.1007/s10562-020-03259-z

G.Y. Hwang, R. Roshan, H.S. Ryu, H.M. Jeong, S. Ravi, M. Kim, D.W. Park, A highly efficient zeolitic imidazolate framework catalyst for the co-catalyst and solvent free synthesis of cyclic carbonates from CO2. J. CO2 Util. 15, 123–130 (2016). https://doi.org/10.1016/j.jcou.2016.02.005

Y. Liu, J. Liu, M. Chang, C. Zheng, Effect of functionalized linker on CO2 binding in zeolitic imidazolate frameworks: density functional theory study. J. Phys. Chem. C. 116, 16985–16991 (2012). https://doi.org/10.1021/jp302619m

L.H. Wee, S. Vandenbrande, S.M.J. Rogge, J. Wieme, K. Asselman, E.O. Jardim, J. Silvestre-Albero, J.A.R. Navarro, V. Van Speybroeck, J.A. Martens, C.E.A. Kirschhock, Chlorination of a zeolitic-imidazolate framework tunes packing and van der Waals interaction of carbon dioxide for optimized adsorptive separation. J. Am. Chem. Soc. 143, 4962–4968 (2021). https://doi.org/10.1021/jacs.0c08942

A. Sirjoosingh, S. Alavi, T.K. Woo, Grand-canonical monte carlo and molecular-dynamics simulations of carbon-dioxide and carbon-monoxide adsorption in zeolitic imidazolate framework materials. J. Phys. Chem. C. 114, 2171–2178 (2010). https://doi.org/10.1021/jp908058n

W. Morris, B. Leung, H. Furukawa, O.K.M. Yaghi, N. He, H. Hayashi, Y. Houndonougbo, M. Asta, B.B. Laird, O.K.M. Yaghi, B. Leung, N. He, H. Furukawa, O.K.M. Yaghi, Y. Houndonougbo, N. He, H. Hayashi, Y. Houndonougbo, M. Asta, B.B. Laird, O.K.M. Yaghi, A combined experimental-computational investigation of carbon dioxide capture in a series of isoreticular zeolitic imidazolate frameworks. J. Am. Chem. Soc. 132, 11006–11008 (2010). https://doi.org/10.1021/ja104035j

R. Banerjee, A. Phan, B. Wang, C. Knobler, H. Furukawa, M. O’Keeffe, O.M. Yaghi, High-throughput synthesis of zeolitic imidazolate frameworks and application to CO2 capture. Science 319, 939–943 (2008). https://doi.org/10.1126/science.1152516

A. Phan, C.J. Doonan, F.J. Uribe-Romo, C.B. Knobler, M.O. O’Keeffe, O.M. Yaghi, Synthesis, structure, and carbon dioxide capture properties of zeolitic imidazolate frameworks. Acc. Chem. Res. 43, 58–67 (2010). https://doi.org/10.1021/ar900116g

B. Wang, H. Furukawa, A.P. Cotre, M. O’Keeffe, O.M. Yaghi, Colossal cages in zeolitic imidazolate frameworks as selective carbon dioxide reservoirs. Nature 453, 207–211 (2008). https://doi.org/10.1021/ja809459e

W. Morris, N. He, K.G. Ray, P. Klonowski, H. Furukawa, I.N. Daniels, Y.A. Houndonougbo, M. Asta, O.M. Yaghi, B.B. Laird, A combined experimental-computational study on the effect of topology on carbon dioxide adsorption in zeolitic imidazolate frameworks. J. Phys. Chem. C. 116, 24084–24090 (2012). https://doi.org/10.1021/jp307170a

L. Hu, Z. Yan, X. Mo, X. Peng, L. Chen, Morphology control synthesis of ZIF-8 as highly efficient catalyst for the cycloaddition of CO2 to cyclic carbonate. ChemCatChem 11, 3212–3219 (2019). https://doi.org/10.1002/cctc.201900735

L. Hu, L. Chen, X. Peng, J. Zhang, X. Mo, Y. Liu, Z. Yan, Bifunctional metal-doped ZIF-8: a highly efficient catalyst for the synthesis of cyclic carbonates from CO2 cycloaddition. Microporous Mesoporous Mater. 299, 110123 (2020). https://doi.org/10.1016/j.micromeso.2020.110123

Y.F. Lin, K.W. Huang, B.T. Ko, K.Y.A. Lin, Bifunctional ZIF-78 heterogeneous catalyst with dual Lewis acidic and basic sites for carbon dioxide fixation via cyclic carbonate synthesis. J. CO2 Util. 22, 178–183 (2017). https://doi.org/10.1016/j.jcou.2017.10.005

Y.W. Abraha, C. Tsai, J.W. Hans Niemantsverdriet, E.H.G. Langner, Correction to “optimized CO2 capture of the zeolitic imidazolate framework ZIF-8 modified by solvent-assisted ligand exchange.” ACS Omega. 6, 26821 (2021). https://doi.org/10.1021/acsomega.1c04545

C.W. Tsai, J.W. Niemantsverdriet, E.H.G. Langner, Enhanced CO2 adsorption in nano-ZIF-8 modified by solvent assisted ligand exchange. Microporous Mesoporous Mater. 262, 98–105 (2018). https://doi.org/10.1016/j.micromeso.2017.11.024

Y. Ban, Y. Li, Y. Peng, H. Jin, W. Jiao, X. Liu, W. Yang, Metal-substituted zeolitic imidazolate framework ZIF-108: gas-sorption and membrane-separation properties. Chem. Eur. J. 20, 11402–11409 (2014). https://doi.org/10.1002/chem.201402287

Y.W. Abraha, C. Tsai, E.H.G. Langner, Scalable synthesis of mixed—linker (Zn) ZIFs and their application in—CO2 adsorption and fixation. J. Porous Mater. 30, 149 (2023). https://doi.org/10.1007/s10934-022-01326-x

O. Karagiaridi, W. Bury, J.E. Mondloch, J.T. Hupp, O.K. Farha, Solvent-assisted linker exchange: an alternative to the de novo synthesis of unattainable metal-organic frameworks. Angew. Chem. Int. Ed. 53, 4530–4540 (2014). https://doi.org/10.1002/anie.201306923

Y. Ban, Y. Peng, Y. Zhang, H. Jin, A. Guo, W. Jiao, P. Wang, Y. Li, W. Yang, Dual-ligand zeolitic imidazolate framework crystals and oriented films derived from metastable mono-ligand ZIF-108. Microporous Mesoporous Mater. 219, 190–198 (2016). https://doi.org/10.1016/j.micromeso.2015.08.013

U. COSMO, Version 1.48, Bruker AXS Inc., Madison, Wisconsin, COSMO, (2003).

Bruker, SAINT-PLUS, Version 7.12 (including XPREP), Bruker AXS Inc., Madison, Wisconsin, USA, (2004).

Bruker. SADABS. Bruker AXS Inc., Madison, Wisconsin, USA, (2001).

G.M. Sheldrick, SHELXT-Integrated space-group and crystal-structure determination. Acta Crystallogr. A. 71, 3–8 (2015). https://doi.org/10.1107/S2053273314026370

L.J. Farrugia, WinGX and ORTEP for windows: an update. J. Appl. Crystallogr. 45, 849–854 (2012). https://doi.org/10.1107/S0021889812029111

R.O.V. Dolomanov, L.J. Bourhis, R.J. Gildea, J.A.K. Howard, H. Puschmann, OLEX2: a complete structure solution, refinement and analysis program. J. Appl. Crystallogr. 42, 339–341 (2009). https://doi.org/10.1107/S0021889808042726

K. Brandenburg, H. Putz, Diamond version 3. Crystal Impact GbR, Postfach. 1251, 53002 (2005)

J.W.M. Osterrieth, D.G.M. James Rampersad, N. Rampal, L. Skoric, B. Connolly, M. Allendorf, V. Stavila, J. Snider, R. Ameloot, J. Marreiros, C.O. Ania, D.C.S. Azevedo, E. Vilarrasa-García, B.F. Santos, X.-H. Bu, X. Zang, H. Bunzen, N.R. Champness, S.L. Griffin, B. Chen, R.-B. Lin, B. Coasne, S.M. Cohen, J.C. Moreton, Y.J. Colon, L. Chen, R. Clowes, F.-X. Coudert, Y. Cui, B. Hou, D. D’alessandro, P.W. Doheny, M. Dinca, C. Sun, C. Doonan, M. Huxley, J.D. Evans, P. Falcaro, R. Ricco, O.K. Farha, K.B. Idrees, T. Islamoglu, P. Feng, H. Yang, R. Forgan, D. Bara, S. Furukawa, E. Sanchez, J. Gascon, S. Telalovic, S.K. Ghosha, S. Mukherjee, M.R. Hill, M.M. Sadiq, P. Horcajada, P. Salcedo-Abraira, K. Kaneko, R. Kukobat, J. Kenvin, S. Keskin, S. Kitagawa, K. Otake, R.P. Lively, S.J.A. Dewitt, P.L. Llewellyn, B. Lotsch, S.T. Emmerling, A. Pütz, C. Martí-Gastaldo, N. Muñoz, J. Garcia-Martinez, N. Linares, D. Maspoch, J.A. Suarez, P. Moghadam, R. Oktavian, R. Morris, P. Wheatley, J. Navarro, C. Petit, D. Danaci, M. Rosseinsky, A. Katsoulidis, M. Schroder, X. Han, S. Yang, C. Serre, G. Mouchaham, D. Sholl, R. Thyagarajan, D. Siderius, R.Q. Snurr, R.B. Goncalves, V. Ting, J. Rowlandson, T. Uemura, T. Iiyuka, M. Van Der Veen, D. Rega, V. Vanspeybroeck, A. Lamaire, S. Rogge, K. Walton, L.W. Bingel, S. Wuttke, J. Andreo, O. Yaghi, B. Zhang, C. Yavuz, T. Nguyen, F. Zamora, C. Montoro, H.-C. Zhou, K. Angelo, D. Fairen-Jimenez, How reproducible are surface areas calculated from the BET equation? Adv. Mater. (2022). https://doi.org/10.1002/adma.202201502

Y.W. Abraha, C. Tsai, E.H.G. Langner, De novo syntheses of multi-linker Zn- and Co-based ZIFs with application in CO2 fixation. Microporous Mesoporous Mater. 346, 112319 (2022). https://doi.org/10.1016/j.micromeso.2022.112319

O. Karagiaridi, W. Bury, A.A. Sarjeant, C.L. Stern, O.K. Farha, J.T. Hupp, Synthesis and characterization of isostructural cadmium zeolitic imidazolate frameworks via solvent-assisted linker exchange. Chem. Sci. 3, 3256–3260 (2012). https://doi.org/10.1039/c2sc20558k

K.C. Jayachandrababu, D.S. Sholl, S. Nair, Structural and mechanistic differences in mixed-linker zeolitic imidazolate framework synthesis by solvent assisted linker exchange and de novo routes. J. Am. Chem. Soc. 139, 5906–5915 (2017). https://doi.org/10.1021/jacs.7b01660

P. Deria, J.E. Mondloch, O. Karagiaridi, W. Bury, J.T. Hupp, O.K. Farha, Beyond post-synthesis modification: evolution of metal-organic frameworks via building block replacement. Chem. Soc. Rev. 43, 5896–5912 (2014). https://doi.org/10.1039/c4cs00067f

Y. Ban, Y. Li, X. Liu, Y. Peng, W. Yang, Solvothermal synthesis of mixed-ligand metal-organic framework ZIF-78 with controllable size and morphology. Microporous Mesoporous Mater. 173, 29–36 (2013). https://doi.org/10.1016/j.micromeso.2013.01.031

C.R. Groom, I.J. Bruno, M.P. Lightfoot, S.C. Ward, The Cambridge structural database. Acta Crystallogr. Sect. B 72, 171–179 (2016). https://doi.org/10.1107/S2052520616003954

G. Chaplais, G. Fraux, J.L. Paillaud, C. Marichal, H. Nouali, A.H. Fuchs, F.X. Coudert, J. Patarin, Impacts of the imidazolate linker substitution (CH3, Cl, or Br) on the structural and adsorptive properties of ZIF-8. J. Phys. Chem. C. 122, 26945–26955 (2018). https://doi.org/10.1021/acs.jpcc.8b08706

N. Novendra, J.M. Marrett, A.D. Katsenis, H.M. Titi, M. Arhangelskis, T. Friščić, A. Navrotsky, Linker substituents control the thermodynamic stability in metal-organic frameworks. J. Am. Chem. Soc. 142, 21720–21729 (2020). https://doi.org/10.1021/jacs.0c09284

V.V. Butova, V.A. Polyakov, E.A. Bulanova, M.A. Soldatov, I.S. Yahia, H.Y. Zahran, A.F. Abd El-Rehim, H. Algarni, A.M. Aboraia, A.V. Soldatov, MW synthesis of ZIF-65 with a hierarchical porous structure. Microporous Mesoporous Mater. 293, 109685 (2020). https://doi.org/10.1016/j.micromeso.2019.109685

Y. Choi, K. Noh, J. Lee, J. Kim, Porosity properties of the conformers of sodalite-like zeolitic imidazolate frameworks. J. Am. Chem. Soc. 140, 14586–14589 (2018). https://doi.org/10.1021/jacs.8b08997

J.A. Boissonnault, A.G. Wong-Foy, A.J. Matzger, Core-shell structures arise naturally during ligand exchange in metal-organic frameworks. J. Am. Chem. Soc. 139, 14841–14844 (2017). https://doi.org/10.1021/jacs.7b08349

H. Wu, R.S. Reali, D.A. Smith, M.C. Trachtenberg, J. Li, Highly selective CO2 capture by a flexible microporous metal-organic framework (MMOF) material. Chem. Eur. J. 16, 13951–13954 (2010). https://doi.org/10.1002/chem.201002683

N. Nijem, H. Wu, P. Canepa, A. Marti, K.J. Balkus, T. Thonhauser, J. Li, Y.J. Chabal, Tuning the gate opening pressure of metal-organic frameworks (MOFs) for the selective separation of hydrocarbons. J. Am. Chem. Soc. 134, 15201–15204 (2012). https://doi.org/10.1021/ja305754f

A. Boutin, F.-X. Coudert, M.-A. Springuel-Huet, A.V. Neimark, G. Ferey, A.H. Fuchs, The behavior of flexible MIL-53 ( Al ) upon CH4 and CO2 adsorption. J. Phys. Chem. C 114, 22237–22244 (2010). https://doi.org/10.1021/jp108710h

S.A. Moggach, T.D. Bennett, A.K. Cheetham, The effect of pressure on ZIF-8: increasing pore size with pressure and the formation of a high-pressure phase at 1.47 GPa. Angew. Chemie Int. Ed. 48, 7087–7089 (2009). https://doi.org/10.1002/anie.200902643

C.W. Tsai, E.H.G. Langner, R.A. Harris, Computational study of ZIF-8 analogues with electron donating and withdrawing groups for CO2 adsorption. Microporous Mesoporous Mater. 288, 109613 (2019). https://doi.org/10.1016/j.micromeso.2019.109613

H.N. Abdelhamid, Removal of carbon dioxide using zeolitic imidazolate frameworks: adsorption and conversion via catalysis. Appl. Organomet. Chem. (2022). https://doi.org/10.1002/aoc.6753

A. Zanon, S. Chaemchuen, B. Mousavi, F. Verpoort, 1 Zn-doped ZIF-67 as catalyst for the CO2 fixation into cyclic carbonates. J. CO2 Util. 20, 282–291 (2017). https://doi.org/10.1016/j.jcou.2017.05.026

B. Olaniyan, B. Saha, Comparison of catalytic activity of ZIF-8 and Zr/ZIF-8 for greener synthesis of chloromethyl ethylene carbonate by CO2 utilization. Energies 13, 521 (2020). https://doi.org/10.3390/en13030521

J.A. Plumley, J.D. Evanseck, Periodic trends and index of boron lewis acidity. J. Phys. Chem. A 113, 5985–5992 (2009). https://doi.org/10.1021/jp811202c

A.R. Jupp, T.C. Johnstone, D.W. Stephan, Improving the global electrophilicity index (GEI) as a measure of Lewis acidity. Inorg. Chem. 57, 14764–14771 (2018). https://doi.org/10.1021/acs.inorgchem.8b02517

K.M. Bhin, J. Tharun, K.R. Roshan, D.W. Kim, Y. Chung, D.W. Park, Catalytic performance of zeolitic imidazolate framework ZIF-95 for the solventless synthesis of cyclic carbonates from CO2 and epoxides. J. CO2 Util. 17, 112–118 (2017). https://doi.org/10.1016/j.jcou.2016.12.001

H. Ryu, R. Roshan, M. Il Kim, D.W. Kim, M. Selvaraj, D.W. Park, Cycloaddition of carbon dioxide with propylene oxide using zeolitic imidazolate framework ZIF-23 as a catalyst. Korean J. Chem. Eng. 34, 928–934 (2017). https://doi.org/10.1007/s11814-016-0339-4

R.R. Kuruppathparambil, R. Babu, H.M. Jeong, G.Y. Hwang, G.S. Jeong, M. Il Kim, D.W. Kim, D.W. Park, A solid solution zeolitic imidazolate framework as a room temperature efficient catalyst for the chemical fixation of CO2. Green Chem. 18, 6349–6356 (2016). https://doi.org/10.1039/c6gc01614f

R.R. Kuruppathparambil, T. Jose, R. Babu, G.Y. Hwang, A.C. Kathalikkattil, D.W. Kim, D.W. Park, A room temperature synthesizable and environmental friendly heterogeneous ZIF-67 catalyst for the solvent less and co-catalyst free synthesis of cyclic carbonates. Appl. Catal. B 182, 562–569 (2016). https://doi.org/10.1016/j.apcatb.2015.10.005

T. Jose, Y. Hwang, D.W. Kim, M. Il Kim, D.W. Park, Functionalized zeolitic imidazolate framework F-ZIF-90 as efficient catalyst for the cycloaddition of carbon dioxide to allyl glycidyl ether. Catal. Today. 245, 61–67 (2015). https://doi.org/10.1016/j.cattod.2014.05.022

R. Babu, S.H. Kim, J.F. Kurisingal, H.J. Kim, G.G. Choi, D.W. Park, A room temperature synthesizable zeolitic imidazolium framework catalyst for the solvent-free synthesis of cyclic carbonates. J. CO2 Util. 25, 6–13 (2018). https://doi.org/10.1016/j.jcou.2018.03.006

Acknowledgements

This work was financially supported by the National Research Foundation of South Africa (Grant Number: 121540 for Y.W. Abraha) and a SASOL University Collaboration Grant for E.H.G. Langner. The authors acknowledge the Inorganic Chemistry Section (UFS) for single-crystal XRD analyses, iThemba labs for PXRD analyses, and the Centre of Microscopy (UFS) for TEM images.

Funding

Open access funding provided by University of the Free State. This work was funded by the National Research Foundation of South Africa (Grant Number: 121540 for Y.W. Abraha) and a SASOL University Collaboration Grant for E.H.G. Langner.

Author information

Authors and Affiliations

Contributions

YWA: Data curation, Formal analysis, Writing—original draft, Writing—review & editing, Conceptualization. FJFJ: Data curation, Formal analysis Writing—original draft. AB: Writing—review & editing, Resources. EHGL: Writing—review & editing, Supervision, Project administration, Resources, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abraha, Y.W., Jacobs, F.J.F., Brink, A. et al. Effect of Solvent Assisted Linker Exchange (SALE) and De Novo Synthetic Routes on CO2 Uptake and Fixation by Mixed-Linker Zeolitic Imidazolate Frameworks. J Inorg Organomet Polym 33, 2058–2074 (2023). https://doi.org/10.1007/s10904-023-02653-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02653-5