Abstract

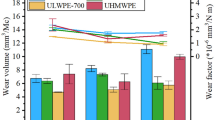

The mechanical properties of medical grade ultrahigh molecular weight polyethylene (UHMWPE) are critical for the safety and integrity of UHMWPE implantation. Accordingly, the mechanical features of UHMWPE are tested under repeated stress-controlled and strain-controlled compression at room temperature. Some important effect factors, such as stress rate, mean stress, stress amplitude, strain rate, mean strain, strain range and multiple load steps are further considered in detail. Results indicate that the lower stress rate causes the greater accumulated plastic strain and the accumulated plastic strain rate becomes increasingly lower with increasing number of cycles. The strain range and accumulated plastic strain rate decrease rapidly in the first stage, and then become almost steady during the second stage. Especially, the accumulated plastic strain rate per cycle for each case is less than 0.01 %/cycle after the initial 100 cycles. This means that the plastic strain accumulates very slowly and the shakedown behavior always occurs. Moreover, obvious cyclic softening and stress relaxation behaviors can be observed under cyclic strain-controlled compression during the first 50 cycles. This indicates that the accumulated plastic stain in the initial 100 cycles and the cyclic stress relaxation during the first 50 cycles should be assessed for the functionality of UHMWPE implantation.

Similar content being viewed by others

References

Pruitt LA. Deformation, yielding, fracture and fatigue behavior of conventional and highly cross-linked ultra high molecular weight polyethylene. Biomaterials. 2005;26:905–15.

Sobieraj MC, Rimnac CM. Ultra high molecular weight polyethylene:mechanics, morphology, and clinical behavior. J Mech Behav Biomed Mater. 2009;2:433–43.

Atwood SA, Van Citters DW, Patten EW, Furmanski J, Ries MD, Pruitt LA. Tradeoffs amongst fatigue, wear, and oxidation resistance of cross-linked ultra-high molecular weight polyethylene. J Mech Behav Biomed Mater. 2011;4:1033–45.

Medel FJ, Peña P, Cegoñino J, Gómez-Barrena E, Puértolas JA. Comparative fatigue behavior and toughness of remelted and annealed highly crosslinked polyethylenes. J Biomed Mater Res B Appl Biomater. 2007;83:380–90.

Ansari F, Chang J, Huddleston J, Van Citters D, Ries M, Pruitt L. Fractography and oxidative analysis of gamma inert sterilized posterior-stabilized tibial insert post fractures: report of two cases. Knee. 2013;20:609–13.

Pruitt LA, Ansari F, Kury M, Mehdizah A, Patten EW, Huddlestein J. Clinical trade-offs in cross-linked ultrahigh-molecular-weight polyethylene used in total joint arthroplasty. J Biomed Mater Res B Appl Biomater. 2013;101:476–84.

Furmanski J, Anderson M, Bal S, Greenwald AS, Halley D, Penenberg B. Clinical fracture of cross-linked UHMWPE acetabular liners. Biomaterials. 2009;30:5572–82.

Ansari F, Gludovatz B, Kozak A, Ritchie RO, Pruitt LA. Notch fatigue of ultrahigh molecular weight polyethylene (UHMWPE) used in total joint replacements. J Mech Behav Biomed Mater. 2016;60:267–79.

Furmanski J, Kraay MJ, Rimnac CM. Crack initiation in retrieved cross-linked highly cross-linked ultrahighmolecular-weight polyethylene acetabular liners: an investigation of 9 cases. J Arthroplast. 2011;26:796–801.

Sobieraj MC, Murphy JE, Brinkman JG, Kurtz SM, Rimnac CM. Monotonic and fatigue behavior of five clinically relevant conventional and highly crosslinked UHMWPEs in the presence of stress concentrations. J Mech Behav Biomed Mater. 2013;28:244–53.

Pascual FJ, Przybilla C, Gracia-Villa L, Puértolas JA, Fernández-Canteli A. Probabilistic assessment of fatigue initiation data on highly crosslinked ultrahigh molecular weight polyethylenes. J Mech Behav Biomed Mater. 2012;15:190–98.

Lockard CA, Sanders AP, Raeymaekers B. An experimental approach to determining fatigue crack size in polyethylene tibial inserts. J Mech Behav Biomed Mater. 2016;54:106–14.

Kurtz SM, Pruitt LA, Jewett CW, Crawford RP, Crane DJ, Edidin AA. The yielding, plastic flow, and fracture behavior of ultra-high molecular weight polyethylene used in total joint replacements. Biomaterials. 1998;19:1989–2003.

Wang A, Stark C, Dumbleton JH. Role of cyclic plastic deformation in the wear of UHMWPE acetabular cups. J Biomed Mater Res. 1995;29:619–26.

Krzypow DJ, Rimnac CM. Cyclic steady state stress-strain behavior of UHMW polyethylene. Biomaterials. 2000;21:2081–87.

Meyer RW, Pruitt LA. The effect of cyclic true strain on the morphology, structure, and relaxation behavior of ultra high molecular weight polyethylene. Polymer. 2001;42:5293–306.

Zhang SL, Xuan FZ. Interaction of cyclic softening and stress relaxation of 9-12% Cr steel under strain-controlled fatigue-creep condition: experimental and modeling. Int J Plasticity. 2017;98:45–64.

Zhao P, Xuan FZ. Ratchetting behavior of advanced 9-12% chromium ferrite steel under creep-fatigue loadings. Mech Mater. 2011;43:299–312.

Zheng XT, Wu KW, Wang W, Yu JY, Xu JM, Ma LW. Low cycle fatigue and ratcheting behavior of 35CrMo structural steel at elevated temperature. Nucl Eng Des. 2017;314:285–92.

Khutia N, Dey PP, Hassan T. An improved nonproportional cyclic plasticity model for multiaxial low-cycle fatigue and ratcheting responses of 304 stainless steel. Mech Mater. 2015;91:12–25.

Chen X, Jiao R, Kim KS. On the Ohno-Wang kinematic hardening rules for multiaxial ratcheting modeling of medium carbon steel. Int J Plasticity. 2005;21:161–84.

Chen G, Xu C, Qu H, Chen X. Ratcheting behavior of zirconium alloy tubes under combined cyclic axial load and internal pressure at 350°C. J Nucl Mater. 2017;491:138–48.

Zhang SL, Xuan FZ, Guo SJ, Zhao P. The role of anelastic recovery in the creep-fatigue interaction of 9-12% Cr steel at high temperature. Int J Mech Sci. 2017;122:95–103.

Wu DL, Xuan FZ, Guo SJ, Zhao P. Uniaxial mean stress relaxation of 9-12% Cr steel at high temperature: experiments and viscoplastic constitutive modeling. Int J Plasticity. 2016;77:156–73.

Wang W, Zheng XT, Yu JY, Lin W, Wang CG, Xu JM. Time-dependent ratcheting of 35CrMo structural steel at elevated temperature considering stress rates. Mater High Temp. 2017;34:172–8.

Song D, Kang GZ, Kan QH. Effects of peak stress and stress amplitude on multiaxial transformation ratchetting and fatigue life of superelastic NiTi SMA micro-tubes: experiments and life-prediction model. Int J Fatigue. 2016;96:252–60.

Rokhgireh H, Nayebi A, Chaboche JL. Application of a new distortional yield surface model in cyclic uniaxial and multiaxial loading. Int J Solids Struct. 2017;110-111:219–38.

Zhao P, Xuan FZ, Wu DL. Cyclic softening behaviors of modified 9-12% Cr steel under different loading modes: Role of loading levels. Int J Mech Sci. 2017;131-132:278–85.

Zheng XT, Wang JQ, Wang W, Ma LW, Lin W, Yu JY. Elastic-plastic-creep response of multilayered systems under cyclic thermo-mechanical loadings. J Mech Sci Tech. 2018;32:1227–34.

Zheng XT, Xuan FZ. Shakedown analysis of multilayered beams coupled with ductile damage. Nucl Eng Des. 2012;250:14–22.

Nayebi A, Abdi RE. Shakedown analysis of beams using nonlinear kinematic hardening materials coupled with continuum damage mechanics. Int J Mech Sci. 2008;50:1247–54.

Zheng XT, Chen HF, Ma ZY. Shakedown boundaries of multilayered thermal barrier systems considering interface imperfections. Int J Mech Sci. 2018;144:33–40.

Cho NK, Chen HF. Shakedown, ratchet, and limit analyses of 90° back-to-back pipe bends under cyclic in-plane opening bending and steady internal pressure. Euro J Mech - A/Solids. 2017;67:231–42.

Zheng XT, Peng CF, Yu JY, Wang CG, Lin W. A unified shakedown assessment method for butt welded joints with various weld groove shapes. ASME J Pres Ves Tech. 2015;137:#021404.

Zheng XT, Peng HY, Yu JY, Lin W, Xu JM. Analytical Ratchet Limit for Pressurized Pipeline under Cyclic Nonproportional Loadings. J Pipeline Syst Eng Prac. 2017;8:04017002.

Schmalzried TP, Szuszczewicz ES, Northfield MR, Akizuki KH, Frankel RE, Belcher G. et al. Quantitative assessment of walking activity after total hip or knee replacement. J Bone Joint Surg. 1998;80:54–9.

Wall CM, Eberle DC, Treuhaft MB, Arps JH. Technique for high-sensitivity “in vitro” wear measurement of UHMWPE hip joint liners using radioactive tracer technology. Wear. 2005;259:964–71.

Pruitt L, Koo J, Rimnac CM, Suresh S, Wright TM. Cyclic compressive loading results in fatigue cracks in ultra high molecular weight polyethylene. J Orthc Res. 1995;13:143–6.

Baker DA, Hastings RS, Pruitt L. Compression and tension fatigue resistance of medical grade ultra high molecular weight polyethylene: the effect of morphology, sterilization, aging and temperature. Polymer. 2000;41:795–808.

Chen K, Kang G, Yu C, Lu F, Jiang H. Time-dependent uniaxial ratchetting of ultrahigh molecular weight polyethylene polymer: viscoelastic-viscoplastic constitutive model. J Appl Mech. 2016;83:#101003.

Paul JP. Forces transmitted by joints in the human body. Proc. Inst. Mech. Eng. 1967;181:8–13.

Kwon HJ, Jar PYB. On the application of fem to deformation of high-density polyethylene. Int J Solids Struct. 2008;45:3521–43.

Morlock M, Schneider E, Bluhm A, Vollmer M, Bergmann G, Muller V, Honl M. Duration and frequency of every day activities in total hip patients. J Biomech. 2001;34:873–81.

Kurtz SM, Villarraga ML, Herr MP, Bergström JS, Rimnac CM, Edidin AA. Thermomechanical behavior of virgin and highly crosslinked ultra-high molecular weight polyethylene used in total joint replacements. Biomaterials. 2002;23:3681–97.

Zheng XT, Dai WC, Ma LW, Wang W, Lin W, Yu JY. Compressive ratcheting and creep of non-asbestos fibre composite considering temperature effect. J Compos Mater. 2018; https://doi.org/10.1177/0021998318766227.

Zheng XT, Dai WC, Chen HF, Shen J. Ratcheting effect of reinforced graphite sheet with stainless steel insert (RGSWSSI) under cyclic compression at elevated temperature. Fatigue Fract Eng Mater Struct. 2018; https://doi.org/10.1111/ffe.12847.

Zheng XT, Wang HY, Wang W, Lin W, Ma LW, Xu JM. et al. Compressive ratcheting effect of expanded PTFE considering multiple load paths. Polym Test. 2017;61:93–99.

Zheng XT, Wen X, Gao JY, Yu JY, Lin W, Xu JM. Temperature-dependent ratcheting of PTFE gaskets under cyclic compressive loads with small stress amplitude. Polym Test. 2017;57:296–301.

Zheng XT, Wen X, Wang W, Gao JY, Lin W, Ma LW. et al. Creep-ratcheting behavior of PTFE gaskets under various temperatures. Polym Test. 2017;60:229–35.

Asada S, Yamashita N, Okamoto A, Nishiguchi I. Verification of alternative criteria for shakedown evaluation using flat head vessel. Proc ASME Pres Ves Pip Conf. 2002;439:17–22.

Acknowledgements

This work was financially supported by Wuhan Youth Science and Technology plan (2016070204010120) and the China Scholarship Council (201608420201).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, X., Wu, K., Wang, J. et al. Mechanical characteristics of medical grade UHMWPE under dynamic compression. J Mater Sci: Mater Med 30, 50 (2019). https://doi.org/10.1007/s10856-019-6254-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-019-6254-6