Abstract

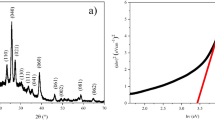

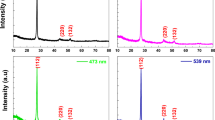

Co-evaporation method was used to deposit Ag-doped SnS thin films on soda lime glass substrates at 300 °C. The Ag doping concentration was systematically varied in the range of 0 to 9 wt% of SnS. The effect of Ag doping concentration on the morphological, structural, optical and electrical properties of the as-deposited films has been investigated. SEM and AFM studies showed that the surface morphology is influenced significantly by Ag doping and the surface roughness decreased from 97 nm to 59 nm with an increase in Ag doping level. The existence of Sn, S, and Ag in the deposited films was confirmed by Energy Dispersive Spectroscopy. The formation of SnS without the presence of any impurity phases was confirmed by XRD measurements and Raman analysis. The optical bandgap decreases from 1.97 to 1.83 eV with the increase in Ag doping. The electrical studies revealed that all the deposited films demonstrated p-type conductivity. A significant increase in mobility from 197 to 1360 cm2 V−1 s−1 was observed upon the increase in the doping concentration of Ag. Heterojunction devices were fabricated with 9% Ag:SnS thin film as the p-type layer and RF sputtered Al:ZnO thin film as the n-layer on the FTO substrate. The knee voltage of the diode was 0.9 V with an ideality factor of 8.7 and a rectification ratio of 23.9 at ± 2 V.

Similar content being viewed by others

Data availability

No data is used for the reported research work.

References

T.D. Nguyen, V.T. Dang, N.M. Hung et al., Surf. Interfaces (2021). https://doi.org/10.1016/j.surfin.2021.101151

D. Alagarasan, S. Varadharajaperumal, R. Aadhavan et al., Sens. Actuator A Phys. 349, 8 (2023). https://doi.org/10.1016/j.sna.2022.114065

A.P. Sreekala, B. Krishnan, R.F.C. Pelaes, D.A. Avellaneda, M.I.M. Palma, S. Shaji, Colloid Surf. A Physicochem. Eng. Asp. 639, 14 (2022). https://doi.org/10.1016/j.colsurfa.2022.128382

A.P. Sreekala, B. Krishnan, R.F.C. Pelaes, D.A. Avellaneda, J.A. Aguilar-Martinez, S. Shaji, Appl. Surf. Sci. 609, 13 (2023). https://doi.org/10.1016/j.apsusc.2022.155277

Z.H. Ye, H. Yu, J.H. Wei, Y. Xie, J. Lumines. 253, 7 (2023). https://doi.org/10.1016/j.jlumin.2022.119473

S. Sebastian, S. Vinoth, K.H. Prasad et al., Appl. Phys. A Mater. Sci. Process. 126, 12 (2020). https://doi.org/10.1007/s00339-020-03959-8

U. Chalapathi, B. Poornaprakash, S.H. Park, Sol Energy. 139, 238 (2016). https://doi.org/10.1016/j.solener.2016.09.046

R.E. Abutbul, E. Segev, L. Zeiri, V. Ezersky, G. Makov, Y. Golan, RSC Adv. 6, 5848 (2016). https://doi.org/10.1039/c5ra23092f

S. Gedi, V.R.M. Reddy, T.R.R. Kotte, S.H. Kim, C.W. Jeon, Ceram. Int. 42, 19027 (2016). https://doi.org/10.1016/j.ceramint.2016.09.059

S.R. Suryawanshi, S.S. Warule, S.S. Patil, K.R. Patil, ACS Appl. Mater. Interfaces (2014). https://doi.org/10.1021/am405039j

M. Messaoudi, S. Boudour, Microsc. Res. Tech. 86, 342 (2023). https://doi.org/10.1002/jemt.24275

M.A. Olgar, A. Ciri, M. Tomakin, R. Zan, J. Mol. Struct. 1241, 8 (2021). https://doi.org/10.1016/j.molstruc.2021.130631

A. Javed, N. Khan, S. Bashir, M. Ahmad, M. Bashir, Mater. Chem. Phys. 246, 9 (2020). https://doi.org/10.1016/j.matchemphys.2020.122831

D. Alagarasan, S.S. Hegde, S. Varadharajaperumal et al., Phys. Scr. 97, 13 (2022). https://doi.org/10.1088/1402-4896/ac6d19

Q.V. Luyen, P.T. Bui, V.T. Chu et al., Sens. Actuator A Phys. (2022). https://doi.org/10.1016/j.sna.2021.113319

B.H. Baby, A.M. Thomas, E.G. Amrutha, D.B. Mohan, Sol. Energy 205, 446 (2020). https://doi.org/10.1016/j.solener.2020.05.076

B. Barman, K.V. Bangera, Superlattices Microstruct. (2019). https://doi.org/10.1016/j.spmi.2019.106215

K.S. Kumar, A.G. Manohari, S. Dhanapandian, T. Mahalingam, Mater. Lett. 131, 167 (2014). https://doi.org/10.1016/j.matlet.2014.05.186

E. Jose, M. Mohan, M.A.G. Namboothiry, M.C.S. Kumar, J. Alloy Compd. (2020). https://doi.org/10.1016/j.jallcom.2020.154507

P. Nisha, P. Kumar, R.S. Sarkar Katiyar, Opt. Mater. 133, 7 (2022). https://doi.org/10.1016/j.optmat.2022.112792

F. Aslan, F. Arslan, A. Tumbul, A. Goktas, Opt. Mater. (2022). https://doi.org/10.1016/j.optmat.2022.112270

S. Acharya, N. Pradhan, J. Phys. Chem. C 115, 19513 (2011). https://doi.org/10.1021/jp2052147

B. Singh, J. Singh, R. Kaur, R.K. Moudgil, S.K. Tripathi, RSC Adv. 7, 53951 (2017). https://doi.org/10.1039/c7ra02904g

D. Alagarasan, S. Varadharajaperumal, K.D.A. Kumar et al., Opt. Mater. 121, 11 (2021). https://doi.org/10.1016/j.optmat.2021.111489

B.H. Baby, D.B. Mohan, Sol. Energy 194, 61 (2019). https://doi.org/10.1016/j.solener.2019.10.049

T.S. Reddy, M.C.S. Kumar, RSC Adv. 6, 95680 (2016). https://doi.org/10.1039/c6ra20129f

E. Jose, M.C.S. Kumar, J. Alloy Compd. 712, 649 (2017). https://doi.org/10.1016/j.jallcom.2017.04.097

B.H. Kumar, M.C.S. Kumar, Sens. Actuator A Phys. (2019). https://doi.org/10.1016/j.sna.2019.111643

R. Swapna, M.C.S. Kumar, Mater. Sci. Eng. B Adv. Funct. Solid State Mater. 178, 1032 (2013). https://doi.org/10.1016/j.mseb.2013.06.010

Acknowledgements

Neju Mathew Philip would like to acknowledge Department of Science and Technology, Government of India for the research fellowship through INSPIRE Fellowship (IF180054).

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Conceptualization: NMP, MCSK; Methodology: NMP, MCSK; Formal analysis and investigation: NMP; Writing—original draft preparation: NMP; Supervision: MCSK. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare that the authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Ethical approval

This article does not contain any studies involving animal or human participants performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Philip, N.M., Kumar, M.C.S. Tuning of electronic properties of co-evaporated Ag:SnS thin films for heterojunction devices. J Mater Sci: Mater Electron 35, 323 (2024). https://doi.org/10.1007/s10854-024-12078-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12078-6