Abstract

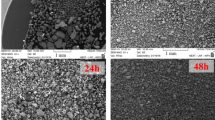

Preparation, phase and microstructural analysis, microhardness, electrical conductivity investigation of Ag7Si0.4Ge0.6S5I nanocrystalline powders and corresponding ceramic materials are reported. The Ag7Si0.4Ge0.6S5I microcrystalline powder were grinded in a ball milling (for 30 and 60 min) to an average particle size ∼ 190 and ∼ 110 nm (determined by SEM). The phase homogeneity of the nanocrystalline powders was established by XRD. Ceramics were fabricated by cold pressing (400 MPa) and following sintering (700 °C). Recrystallization process leads to increasing the crystallites size in ceramics to the values of ∼ 2.09 and ∼ 1.72 μm from initial 190 and 110 nm. Ceramics are characterized by low porosity 7.2 ± 2.5% (for 2.09 μm) and 6.9 ± 2.5% (for 1.72 μm) and chemical homogeneity. Microhardness investigation of both ceramics shown a presence of «normal» indentation size effect. The frequency dependences of the total electrical conductivity are characterized by a sharp increase in electrical conductivity with increasing frequency. The corresponding values of ionic (σion), electronic (σel) conductivity, activation energy (Ea) was determined. Established that ionic conductivity of fabricated from ~ 190 nm powder (7.78 × 10−2 S cm–1) is higher than for ~ 110 nm (7.52 × 10−2 S cm–1). A comparison of the electrical parameters (σion, σel, σion/σel, Ea) of the single crystalline and ceramic materials (with different grain sizes) was performed.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article. The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

J.C. Bachman, S. Muy, A. Grimaud, H.-H. Chang, N. Pour, S.F. Lux, O. Paschos, F. Maglia, S. Lupart, P. Lamp, L. Giordano, Y. Shao-Horn, Chem. Rev. (2016). https://doi.org/10.1021/acs.chemrev.5b00563

J. Kawamura, Encyclopedia of Materials: Composites, ed. by D. By, Brabazon (Elsevier, Sendai, 2017), pp. 293–313

H. Yang, N. Wu, Energy Sci. Eng. (2022). https://doi.org/10.1002/ese3.1163

J. Liu, T. Wang, J. Yu, S. Li, H. Ma, X. Liu, Materials (2023). https://doi.org/10.3390/ma16062510

Y.-K. Sun, A.C.S. Energy Lett. (2020). https://doi.org/10.1021/acsenergylett.0c01977

Y. Chen, K. Wen, T. Chen, X. Zhang, M. Armand, S. Chen, Energy Storage Mater. (2020). https://doi.org/10.1016/j.ensm.2020.05.019

C. Li, Z. Wang, Z. He, Y. Li, J. Mao, K. Dai, C. Yan, J. Zheng, Sustain. Mater. (2021). https://doi.org/10.1016/j.susmat.2021.e00297

H. Huo, J. Janek, Natl. Sci. Rev. (2023). https://doi.org/10.1093/nsr/nwad098

T. Yu, X. Yang, R. Yang, X. Bai, G. Xu, S. Zhao, Y. Duan, Y. Wu, J. Wang, J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.161013

Y. Guo, S. Wu, Y.-B. He, F. Kang, L. Chen, H. Li, Q.-H. Yang, eScience (2022). https://doi.org/10.1016/j.esci.2022.02.008

C. Bubulinca, N.E. Kazantseva, V. Pechancova, N. Joseph, H. Fei, M. Venher, A. Ivanichenko, P. Saha, Batteries (2023). https://doi.org/10.3390/batteries9030157

C. Yu, F. Zhao, J. Luo, L. Zhang, X. Sun, Nano Energy. (2021). https://doi.org/10.1016/j.nanoen.2021.105858

J. Liang, X. Li, K.R. Adair, X. Sun, Acc. Chem. Res. (2021). https://doi.org/10.1021/acs.accounts.0c00762

L. Malavasi, C.A.J. Fisher, M.S. Islam, Chem. Soc. Rev. (2010). https://doi.org/10.1039/B915141A

X. He, Y. Zhu, Y. Mo, Nat. Commun. (2017). https://doi.org/10.1038/ncomms15893

B. Zhang, R. Tan, L. Yang, J. Zheng, K. Zhang, S. Mo, Z. Lin, F. Pan, Energy Storage Mater. (2018). https://doi.org/10.1016/j.ensm.2017.08.015

Q. Zhang, D. Cao, Y. Ma, A. Natan, P. Aurora, H. Zhu, Adv. Mater. (2019). https://doi.org/10.1002/adma.201901131

H.-J. Deiseroth, S.-T. Kong, H. Eckert, J. Vannahme, C. Reiner, T. Zaiss, M. Schlosser, Angew Chem. Int. Ed. Engl. (2008). https://doi.org/10.1002/anie.200703900

L. Zhou, N. Minafra, W.G. Zeier, L.F. Nazar, Acc. Chem. Res. (2021). https://doi.org/10.1021/acs.accounts.0c00874

P. Adeli, J.D. Bazak, K.H. Park, I. Kochetkov, A. Huq, G.R. Goward, L.F. Nazar, Angew Chem. Int. Ed. (2019). https://doi.org/10.1002/anie.201814222

A. Loutati, O. Guillon, F. Tietz, D. Fattakhova-Rohlfing, Open. Ceram. (2022). https://doi.org/10.1016/j.oceram.2022.100313

M. Hou, F. Liang, K. Chen, Y. Dai, D. Xue, Nanotechnology (2020). https://doi.org/10.1088/1361-6528/ab5be7

L. Haarmann, K. Albe, Solid State Ion. (2021). https://doi.org/10.1016/j.ssi.2021.115604

L. Zhang, Y. Liu, Y. You, A. Vinu, L. Mai, Interdiscip. Mater. (2023). https://doi.org/10.1002/idm2.12046

G. Sun, X. Yang, N. Chen, S. Yao, X. Wang, X. Jin, G. Chen, Y. Xie, F. Du, Energy Storage Mater. (2021). https://doi.org/10.1016/j.ensm.2021.06.003

Z. Zhang, E. Ramos, F. Lalère, A. Assoud, K. Kaup, P. Hartman, L.F. Nazar, Energy Environ. Sci. (2018). https://doi.org/10.1039/C7EE03083E

C. Li, R. Li, K. Liu, R. Si, Z. Zhang, Y.-S. Hu, Interdiscip. Mater. (2022). https://doi.org/10.1002/idm2.12044

S. Ohno, A. Banik, G.F. Dewald, M.A. Kraft, T. Krauskopf, N. Minafra, P. Till, M. Weiss, W.G. Zeier, Prog Energy. (2020). https://doi.org/10.1088/2516-1083/ab73dd

X. Feng, H. Fang, N. Wu, P. Liu, P. Jena, J. Nanda, D. Mitlin, Joule (2022). https://doi.org/10.1016/j.joule.2022.01.015

Y. Xu, M. Titirici, J. Chen, F. Cora, P.L. Cullen, J.S. Edge, K. Fan, L. Fan et al., J. Phys. Energy. (2023). https://doi.org/10.1088/2515-7655/acbf76

H. Yuan, H. Li, T. Zhang, G. Li, T. He, F. Du, S. Feng, J. Mater. Chem. A (2018). https://doi.org/10.1039/C8TA01418C

B. Radhakrishnan, S.P. Ong, Front. Energy Res. (2016). https://doi.org/10.3389/fenrg.2016.00016

R.D. Shannon, A. Acta Crystallogr, A. Acta Crystallogr. (1976). https://doi.org/10.1107/S0567739476001551

A. Selmi, L. Ajili, N. Sdiri, M. Férid, K. Horchani-Naifer, Solid State Commun. (2022). https://doi.org/10.1016/j.ssc.2022.114688

T. Nilges, S. Reiser, J.H. Hong, E. Gaudin, A. Pfitzner, Phys. Chem. Chem. Phys. (2002). https://doi.org/10.1039/B203556A

R.B. Beeken, J.J. Garbe, J.M. Gillis, N.R. Petersen, B.W. Podoll, M.R. Stoneman, J. Phys. Chem. Solids. (2005). https://doi.org/10.1016/j.jpcs.2004.10.010

M. Laqibi, B. Cros, S. Peytavin, M. Ribes, Solid State Ion. (1987). https://doi.org/10.1016/0167-2738(87)90077-4

I.P. Studenyak, A.I. Pogodin, M.J. Filep, O.P. Kokhan, O.I. Symkanych, M. Timko, P. Kopčanský, Semicond. Phys. Quantum Electron. Optoelectron. (2021). https://doi.org/10.15407/spqeo24.01.026

I.P. Studenyak, A.I. Pogodin, M.J. Filep, O.I. Symkanych, T.Y. Babuka, O.P. Kokhan, P. Kúš, J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.159784

A.I. Pogodin, M.J. Filep, V.I. Studenyak, O.I. Symkanych, I.P. Stercho, V.Y. Izai, O.P. Kokhan, P. Kúš, J. Alloys Compd. (2022). https://doi.org/10.1016/j.jallcom.2022.166873

W.F. Kuhs, R. Nitsche, K. Scheunemann, Mat. Res. Bull. (1979). https://doi.org/10.1016/0025-5408(79)90125-9

I. Hanghofer, M. Brinek, S.L. Eisbacher, B. Bitschnau, M. Volck, V. Hennige, I. Hanzu, D. Rettenwander, H.M.R. Wilkening, Phys. Chem. Chem. Phys. (2019). https://doi.org/10.1039/C9CP00664H

N. Minafra, S.P. Culver, T. Krauskopf, A. Senyshyn, W.G. Zeier, J. Mater. Chem. A (2018). https://doi.org/10.1039/C7TA08581H

S. Ohno, B. Helm, T. Fuchs, G. Dewald, M.A. Kraft, S.P. Culver, A. Senyshyn, W.G. Zeier, Chem. Mater. (2019). https://doi.org/10.1021/acs.chemmater.9b01857

Ð.A. Kraft, S. Ohno, T. Zinkevich, R. Koerver, S.P. Culver, T. Fuchs, A. Senyshyn, S. Indris, B.J. Morgan, W.G. Zeier, J. Am. Chem. Soc. (2018). https://doi.org/10.1021/jacs.8b10282

I.P. Studenyak, A.I. Pogodin, I.A. Shender, M.J. Filep, O.P. Kokhan, P. Kopčanský, Semicond. Phys. Quantum Electron. Optoelectron. (2021). https://doi.org/10.15407/spqeo24.03.241-247

I.P. Studenyak, A.I. Pogodin, I.A. Shender, V.I. Studenyak, M.J. Filep, O.I. Symkanych, O.P. Kokhan, P. Kúš, J. Solid State Chem. (2022). https://doi.org/10.1016/j.jssc.2022.122961

A.I. Pogodin, M.J. Filep, T.O. Malakhovska, V.V. Vakulchak, V. Komanicky, V.Y. Izai, Y.I. Studenyak, Y.P. Zhukova, I.O. Shender, V.S. Bilanych, O.P. Kokhan, P. Kúš, J. Phys. Chem. Solids. (2022). https://doi.org/10.1016/j.jpcs.2022.111042

G.L. Messing, S. Poterala, Y. Chang, T. Frueh, E.R. Kupp, B.H. Watson, R.L. Walton, M.J. Brova, A.-K. Hofer, R. Bermejo, R.J. Meyer, J. Mater. Res. (2017). https://doi.org/10.1557/jmr.2017.207

C.E. Özbilgin, K. Kobayashi, S. Tamura, N. Imanaka, T.S. Suzuki, J. Am. Ceram. Soc. (2021). https://doi.org/10.1111/jace.18001

Q.B. Chen, B. Meng, M.Y. Zhao, H. Xie, L.F. Bian, X. Yang, Ceram. Int. (2018). https://doi.org/10.1016/j.ceramint.2018.08.212

T. Šalkus, E. Kazakevičius, J. Banys, M. Kranjčec, A.A. Chomolyak, Y.Y. Neimet, I.P. Studenyak, Solid State Ion. (2014). https://doi.org/10.1016/j.ssi.2013.10.040

A.I. Pogodin, I.P. Studenyak, I.A. Shender, M.M. Pop, M.J. Filep, T.O. Malakhovska, O.P. Kokhan, P. Kopčanský, T.Y. Babuka, J. Mater. Sci. (2022). https://doi.org/10.1007/s10853-022-07059-1

A. Pogodin, M. Filep, T. Malakhovska, V. Vakulchak, V. Komanicky, S. Vorobiov, V. Izai, I. Shender, V. Bilanych, O. Kokhan, P. Kúš, Solid State Sci. (2023). https://doi.org/10.1016/j.solidstatesciences.2023.107203

M. El-Sherbiny, R. Hegazy, M. Ibrahim, A. Abuelezz, Int. J. Metrol. Qual. Eng. (2012). https://doi.org/10.1051/ijmqe/2012009

P. Vadhva, J. Hu, M.J. Johnson, R. Stocker, M. Braglia, D.J.L. Brett, A.J.E. Rettie, Chem. Electro Chem. (2021). https://doi.org/10.1002/celc.202100108

R.A. Huggins, Ionics (2002). https://doi.org/10.1007/BF02376083

M.E. Orazem, B. Tribollet, Electrochemical Impedance Spectroscopy (John Wiley & Sons, New Jersey, 2008), p. 542

F.T.L. Muniz, M.A.R. Miranda, C. Morilla dos, J.M. Santos, Sasaki, Acta Crystallogr. A (2016). https://doi.org/10.1107/S205327331600365X

U. Holzwarth, N. Gibson, Nat. Nanotech. (2011). https://doi.org/10.1038/nnano.2011.145

F.R.N. Nabarro, S. Shrivastava, S.B. Luyckx, Philos. Mag. (2006). https://doi.org/10.1080/14786430600577910

J. Petrík, P. Blaško, Å. Markulík, M. Šolc, P. Palfy, Crystals (2022). https://doi.org/10.3390/cryst12060795

A.S. Tana, F.H. Hammad, Phys. Status Solidi A (1990). https://doi.org/10.1002/pssa.2211190207

Y. Li, A.J. Bushby, D.J. Dunstan, Proc. R Soc. A (2016). https://doi.org/10.1098/rspa.2015.0890

Acknowledgements

The authors would also thank the Armed Forces of Ukraine for providing security to perform this work. This work has become possible only because resilience and courage of the Ukrainian Army.

Funding

This work at Pavol Jozef Šafárik University in Košice was supported by the grant of the Slovak Research and Development Agency under the contract (APVV-20-0324).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by AP, MF, TM, VV, VK, SV, VI, LS, IS, VB, OK, PK. The first draft of the manuscript was written by AP and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript. Supervision, Visualization, Investigation, Writing—Original draft: AP; Data curation, Visualization, Writing—Original draft: MF; Investigation, Visualization: TM; Investigation: VV; Methodology, Investigation: VK; Investigation: SV; Investigation, Software, Validation: VI; Methodology, Investigation: LS; Methodology, Visualization: IS; Visualization, Writing—Original draft: VB; Conceptualization, Methodology: OK; Writing—Review and Editing: PK.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pogodin, A., Filep, M., Malakhovska, T. et al. Crystallite size and recrystallization effect on electrical parameters of highly ion-conductive Ag7Si0.4Ge0.6S5I ceramics. J Mater Sci: Mater Electron 34, 1865 (2023). https://doi.org/10.1007/s10854-023-11364-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11364-z