Abstract

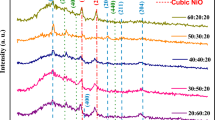

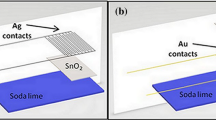

Indium tin oxide (ITO) nanocrystalline coatings were synthesized on a silicon oxide substrate with and without addition of saccharin. The effect of saccharin additive (0–0.1 M) on the average grain size of the coatings was investigated by X-ray diffraction (XRD). A field emission scanning electron microscope (FESEM) was used to characterize the surface morphology. Optical properties were studied using ultraviolet–visible (UV) spectroscopy. The electrical resistance of ITO thin films coated on quartz substrates was measured using four-point probe technique. Saccharin was added to the sol–gel solution as a grain-refining and pore-producing agent. Carbon monoxide (CO) gas sensitivity was investigated for ITO porous thin films, and the best saccharin-modified microstructure showed a sensitivity of (RAir/RCO) 65.2 for 100-ppm CO concentration at 250 °C.

Similar content being viewed by others

Data availability

Data available on request due to privacy/ethical restrictions. The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to [restrictions, e.g., their containing information that could compromise the privacy of research participants].

Abbreviations

- SAC:

-

Saccharin

- ITO:

-

Indium tin oxide

- ITO-SAC X:

-

ITO samples with X molar saccharin in sol–gel procedure

- CO:

-

Carbon monoxide

References

M. Sibiński, K. Znajdek, S. Walczak, M. Słoma, M. Górski, A. Cenian, J. Mater. Sci. B 177, 1292 (2012). https://doi.org/10.1016/j.mseb.2012.03.037

M. Katayama, Thin Solid Films 341, 140 (1999). https://doi.org/10.1016/S0040-6090(98)01519-3

Y.H. Tak, K.B. Kim, H.G. Park, K.H. Lee, J.R. Lee, Thin Solid Films 411, 12 (2002). https://doi.org/10.1016/S0040-6090(02)00165-7

T. Minami, Thin Solid Films 516, 5822 (2008). https://doi.org/10.1016/j.tsf.2007.10.063

D.J. Lee, J. Park, H.S. Kim, D.H. Lee, M. Park, H. Chang, J.H. Jin, J.R. Sohn, K. Heo, B.Y. Lee, Sens. Actuators B 216, 482 (2015). https://doi.org/10.1016/j.snb.2015.04.057

C.W. Lin, H.I. Chen, T.Y. Chen, C.C. Huang, C.S. Hsu, R.C. Liu, W.C. Liu, Sens. Actuators B 160, 1481 (2011). https://doi.org/10.1016/j.snb.2011.07.041

K.S. Yoo, S.H. Park, J.H. Kang, Sens. Actuators B 108, 159 (2005). https://doi.org/10.1016/j.snb.2004.12.105

S. Xu, Y. Shi, Sens. Actuators B 143, 71 (2009). https://doi.org/10.1016/j.snb.2009.08.057

G. Neri, A. Bonavita, G. Micali, G. Rizzo, E. Callone, G. Carturan, Sens. Actuators B 132, 224 (2008). https://doi.org/10.1016/j.snb.2008.01.030

K. Lee, V. Scardaci, H.Y. Kim, T. Hallam, H. Nolan, B.E. Bolf, G.S. Maltbie, J.E. Abbott, G.S. Duesberg, Sens. Actuators B 188, 571 (2013). https://doi.org/10.1016/j.snb.2013.07.048

K. Vijayalakshmi, C. Ravidhas, V.V. Pillay, D. Gopalakrishna, Thin Solid Films 519, 3378 (2011). https://doi.org/10.1016/j.tsf.2010.12.164

K. Vijayalakshmi, V.V. Pillay, Philos. Mag. Lett. 91, 682 (2011). https://doi.org/10.1080/09500839.2011.608731

S.G. Dasari, P. Nagaraju, V. Yelsani, M.V. Ramana Reddy, J. Mater. Sci.: Mater. Electron. 33(30), 23447 (2022)

B.C. Yadav, K. Agrahari, S. Singh, T.P. Yadav, J. Mater. Sci.: Mater. Electron. 27(5), 4172 (2016). https://doi.org/10.1007/s10854-016-4279-x

Y. Zhang, Q. Li, Z. Tian, P. Hu, X. Qin, F. Yun, SN Appl. Sci. 2, 1 (2020). https://doi.org/10.1007/s42452-020-2050-7

I. Madhi, M. Saadoun, B. Bessaïs, Sens. Lett. 9, 1726 (2011). https://doi.org/10.1166/sl.2011.1741

M. Ramirez-Del-Solar, E. Blanco, Submicron Porous Materials: Porous Thin Film from Sol Gel (Springer, Cham, 2017), pp.157–161

L.J. Meng, M.P. dos Santos, Thin Solid Films 322, 56 (1998). https://doi.org/10.1016/S0040-6090(97)00939-5

P. Thilakan, S. Kalainathan, J. Kumar, P. Ramasamy, J. Electron. Mater. 24(6), 719 (1995). https://doi.org/10.1007/BF02659730

J. Vetrone, Y. Chung, J. Vac. Sci. Technol. A 9, 3041 (1998)

N. Xia, R.A. Gerhardt, Mater. Res. Express 3, 116408 (2016). https://doi.org/10.1088/2053-1591/3/11/116408

M. Afrouzmehr, N. Yasrebi, M.H. Sheikhi, Ceram. Int. 47, 30504 (2021). https://doi.org/10.1016/j.ceramint.2021.07.228

Z. Jiao, M. Wu, J. Gu, X. Sun, Sens. Actuators B 94, 216 (2003). https://doi.org/10.1016/S0925-4005(03)00343-5

J.H. Lee, Y.H. Kim, S.J. Ahn, T.H. Ha, H.S. Kim, J. Mater. Sci. B 199, 37 (2015). https://doi.org/10.1016/j.mseb.2015.04.011

A.K. Kulkarni, K.H. Schulz, T.S. Lim, M. Khan, Thin Solid Films 345, 273 (1999). https://doi.org/10.1016/S0040-6090(98)01430-8

N.M. Ahmed, F.A. Sabah, H.I. Abdulgafour, A. Alsadig, A. Sulieman, M. Alkhoaryef, Results Phys. 13, 102159 (2019). https://doi.org/10.1016/j.rinp.2019.102159

M. Ahmed, A. Bakry, A. Qasem, H. Dalir, Opt. Mater. (Amst.) 113, 110866 (2021). https://doi.org/10.1016/j.optmat.2021.111053

S. Najwa, A. Shuhaimi, N.A. Talik, N. Ameera, M. Sobri, M. Rusop, Appl. Surf. Sci. 479, 1220 (2019). https://doi.org/10.1016/j.apsusc.2019.01.123

E. Callone, G. Carturan, M. Ischia, A. Sicurelli, J. Mater. Res. 21, 1726 (2006). https://doi.org/10.1557/jmr.2006.0217

G. Neri, A. Bonavita, G. Micali, G. Rizzo, E. Callone, G. Carturan, Sens. Actuators B 1, 224 (2008). https://doi.org/10.1016/j.snb.2008.01.030

S.M. Hassan Zadeh Shirazi, M.E. Bahrololoom, M.H. Shariat, Surf. Eng. Appl. Electrochem. 52(5), 434 (2016). https://doi.org/10.1007/s11661-021-06202-y

S.H. Kim, H.J. Sohn, Y.C. Joo, Y.W. Kim, T.H. Yim, H.Y. Lee, T. Kang, Surf. Coat. Technol. 199, 43 (2005). https://doi.org/10.1016/j.surfcoat.2004.11.035

A.M. Rashidi, A. Amadeh, Surf. Coat. Technol. 3, 353 (2009). https://doi.org/10.1016/j.surfcoat.2009.07.036

B. Şahin, Sci. World J. (2013). https://doi.org/10.1155/2013/172052

S.M. Joshi, G.W. Book, R.A. Gerhardt, Thin Solid Films 520, 2723 (2012). https://doi.org/10.1016/j.tsf.2011.11.052

M. Duta, M. Anastasescu, J.M. Calderon-Moreno, L. Predoana, S. Preda, M. Nicolescu, H. Stroescu, V. Bratan, I. Dascalu, E. Aperathitis, M. Modreanu, M. Zaharescu, M. Gartner, J. Mater. Sci.: Mater. Electron. 27(5), 4913 (2016). https://doi.org/10.1007/s10854-016-4375-y

M.J. Alam, D.C. Cameron, Thin Solid Films 377–378, 455 (2000). https://doi.org/10.1016/S0040-6090(00)01369-9

D.C. Agrawal, Introduction to Nanoscience and Nanomaterials 1 (World Scientific, 2013), pp. 177–120

V. Senthilkumar, P. Vickraman, M. Jayachandran, C. Sanjeeviraja, Vacuum 84, 864 (2010). https://doi.org/10.1016/j.vacuum.2009.11.017

I. Madhi, M. Saadoun, B. Bessais, Procedia Eng 47, 192 (2012). https://doi.org/10.1016/j.proeng.2012.09.116

Z.H. Li, D.Y. Ren, Trans. Nonferrous Met. Soc. 16, 1358 (2006). https://doi.org/10.1016/S1003-6326(07)60020-X

Y.S. Jung, S.S. Lee, J. Cryst. Growth 259, 343 (2003). https://doi.org/10.1016/j.jcrysgro.2003.07.006

M.M. Öztaş, Chin. Phys. Lett. 25, 4090 (2008)

M.J. Alam, D.C. Cameron, Thin Solid Films 420–421, 76 (2002). https://doi.org/10.1016/S0040-6090(02)00737-X

B.W.N. Hemasiri, J.-K. Kim, J.-M. Lee, Micro Nano Lett. (2017). https://doi.org/10.1007/s40820-017-0174-0

N. Revathi, P. Prathap, Y.P.V. Subbaiah, K.T.R. Reddy, J. Phys. D 41, 155404 (2008). https://doi.org/10.1088/0022-3727/41/15/155404

S. Dietrich, M. Kusnezoff, U. Petasch, A. Michaelis, Sensors 21, 497 (2021). https://doi.org/10.3390/s21020497

M. Kumar, B.R. Mehta, V.N. Singh, R. Chatterjee, S. Milikisiyants, K.V. Lakshmi, J.P. Singh, Appl. Phys. Lett. 96, 123114 (2010). https://doi.org/10.1063/1.3371717

A.S. Mokrushin, N.A. Fisenko, P.Y. Gorobtsov, T.L. Simonenko, O.V. Glumov, N.A. Melnikova, N.P. Simonenko, K.A. Bukunov, E.P. Simonenko, V.G. Sevastyanov, N.T. Kuznetsov, Talanta 221, 121455 (2021). https://doi.org/10.1016/j.talanta.2020.121455

S. Sharma, M. Madou, Philos. Trans. R. Soc. A 370, 2448 (2012). https://doi.org/10.1098/rsta.2011.0506

N. Barsan, U. Weimar, J. Electroceram. 7(3), 143 (2001). https://doi.org/10.1007/s10832-009-9583-x

C. Xu, J. Tamaki, N. Miura, N. Yamazoe, Sens. Actuators B 3, 147 (1991). https://doi.org/10.1016/0925-4005(91)80207-Z

A. Mirzaei, S. Park, G.J. Sun, H. Kheel, C. Lee, J. Hazard. Mater. 305, 130 (2016). https://doi.org/10.1016/j.jhazmat.2015.11.044

H. Yamaura, Y. Iwasaki, S. Hirao, H. Yahiro, Sens. Actuators B 153, 465 (2011). https://doi.org/10.1016/j.snb.2010.10.044

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

ZD and MEB conceived the presented idea. MEB encouraged ZD to investigate the effect of saccharin on thin-film coating and supervised the findings of this work. ZD and IM carried out the experiments. IM designed and performed the experiments and analyzed the data. ZD and IM performed the measurements. MEB was involved in planning and supervised the work. ZD and IM processed the experimental data, performed the analysis, drafted the manuscript, and designed the figures. ZD and IM manufactured the samples and characterized them using SEM, UV–vis, 4 Point prob, and gas sensing spectroscopy. IM performed the XRD characterization and data analyzed. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Damshekan, Z., Moghim, I. & Bahrololoom, M.E. Preparation of porous indium tin oxide thin films via saccharin-aided sol–gel process for carbon monoxide gas sensing applications. J Mater Sci: Mater Electron 34, 937 (2023). https://doi.org/10.1007/s10854-023-10261-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10261-9