Abstract

Gold nanoparticles (AuNPs) were synthesized via laser ablation technique. PEO/CMC-AuNPs nanocomposites were prepared using the casting method. Water was chosen as a solvent because it was considered an eco-friendly solvent compared to other organic solvents. SEM micrographs reveal uniformly distributed AuNPs on the sample surface. 3D images were used to estimate the roughness parameters. The \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\) values decrease at high frequencies due to the short time allotted for dipole aligning. The behavior of tan\(\delta\) was attributed to more dipoles that cannot follow the oscillating electric field. The values of M′ approach zero at low frequencies due to the insignificant effect of electrode polarization. The presence of semicircles below the real axis M′ implies a dispersion in relaxation time, indicating that the dielectric relaxation process follows the non-Debye model. The two regions' curves imply that the samples contain an electrical conduction mechanism of the hopping type. The conductivity was increased with the increase of AuNPs due to an increase in transition probability for hopping electrons. From the obtained results, the PEO/CMC-AuNPs nanocomposites can be considered superior to others in different biological applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanomaterials research has recently developed a science-based approach to nanotechnology, using discoveries in materials measurement and synthesis that were created to assist commercial research [1,2,3]. Frequently, nanomaterials exhibit unique optical, electrical, thermophysical, or mechanical capabilities. There has recently been a scientific revolution in recent findings in the field of nanotechnology, which develops separate materials at the nanoscale level with one dimension less than 100 nm, depending on the general shape and size; these materials may be 0D, 1D, 2D, and 3D [4].

Pulsed laser ablation in liquids is a scientific technique for producing nanoparticles of diverse forms, including quantum dots [3, 5, 6]. Laser ablation is a popular technique for creating nanoparticles from sheet metal in various liquids. Laser ablation is a typical technique for creating nanoparticles from sheet metal in various liquids. Nanoparticles are increasingly employed as fillers in various applications, including perfect sensors, catalysts, and electrical devices. Nanoparticles may be prepared and manufactured in various methods (chemical and physical techniques or laser ablation). Laser ablation in liquid solution [7] (a safe and environmentally friendly approach for creating nanoparticles) is a potential nanotechnology research technique [8]. The high-energy laser in this technology works on the production and formation of nanoparticles in liquid when it falls under-investigated circumstances (energy, wavelength, laser repetition rate, ablation time, and liquid type) [9,10,11]. The ablation rate is the total mass of material that the laser drops on each pulse. The nanoparticles produced in this manner have unique and distinct features that are difficult to get using chemical procedures. Polyethylene oxide (PEO) is a non-ionic polymer with a high molecular weight. It is hydrophilic, linear, and non-crossing in aqueous and organic solutions [12]. PEO is made by polymerizing ethylene oxide using a metallic catalyst and opening the ethylene oxide ring. All C–O cross bonds and C–C bonds in PEO chains form a helical structure [12,13,14,15,16]. PEO is non-toxic, non-immunogenic, and water and polar solvent-soluble. PEO is the first successful effort to demonstrate the presence of single-chain monocrystalline crystals [16,17,18,19].

The most common cellulose ether is carboxymethyl cellulose (CMC). CMC is employed in a variety of medication delivery and tissue engineering applications. CMC is a water-soluble anionic cellulose derivative [20]. The degree of substitution and the homogeneity of the substitution distribution all influence CMC solubility. CMC's water solubility would rise as DP dropped and carboxymethyl substitution and substitution uniformity rose. At any temperature, CMC is soluble in water. Because it is particularly hygroscopic. CMC is a polymer that is less expensive, non-toxic, biodegradable, and renewable. The disadvantage of CMC film is that it has weak mechanical characteristics. Silk fibroin has been recognized as a potentially useful biomaterial due to its excellent mechanical qualities, reduced flammability, outstanding biocompatibility, and increased biodegradability. It may be converted into a hydrogel, film, or scaffold depending on the needs of diverse applications. Nanoparticles are a good filler for nanocomposites because they improve their structural, optical, and electrical properties [21, 22].

The CMC/PEO polymeric blend was studied in a ratio of 70:30, which gave good mechanical properties, thermal stability, and electrical properties due to the presence of amorphous regions and thus increased the movement of ions, which will increase with the increase of the fillers [23].

Several researchers have prepared and characterized new nanocomposite materials prepared by green synthesis as an environmentally friendly method for applications such as an effective photocatalyst to change the color of organic dye pollutants in wastewater and has antibacterial activities [24,25,26,27,28]. In view of this, we intend to offer an electrical study and dielectric properties of the influence of gold nanoparticles produced by pulsed laser ablation techniques in liquid (water was chosen as a solvent because it was considered an eco-friendly solvent compared to other organic solvents) on a polyethylene oxide/carboxymethyl cellulose (PEO/CMC) polymer blend in our current research. The PEO/CMC-AuNPs nanocomposites can be considered superior to others in different biological applications.

2 Experimental work

2.1 Materials

Polyethylene oxide (PEO) was obtained from New Jersey, USA by ACROS Company with a molecular weight Mw ≈ 600.000 g/mol in the form of white powder. Poly Carboxymethyl cellulose (CMC) was manufactured in Germany by LANXESS Company with a molecular weight Mw ≈ 250.000 g/mol, and a density ≈ 1.59 g/cm3. To prepare the PEO/CMC blend and its nanocomposite samples, double distilled water (DDW) was used as a common solvent. The gold plate was bought with high purity (99.999%).

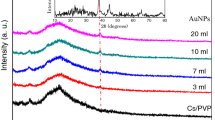

2.2 Preparation of gold nanoparticles (AuNPs)

A laser ablation technique has been used to manufacture gold nanoparticle AuNPs. Gold (target) has a high purity (99.99%) and an appropriate dimension of 4 × 4 × 1 (mm). The gold target was polished and sonicated in organic solvents before ablation, washed with chlorobenzene and distilled water many times to remove any residuals or contaminations at the gold surface. The target was irradiated with the Nd: YAG nanosecond pulsed laser (PRII 8000 Continuum laser; Electro-optics, Inc.). In compliance with the following terms: 1064 nm basic wavelength, power 4 W, Pulse frequency 10 Hz, and the pulse width 6 nm. A convex length of 10 cm was used to concentrate the laser beam perpendicular to the gold target. The amount of water in the ablation vessel was 20 ml, the parts of gold were soaked in the beaker in nearly 15 mm of high water, and Laser beams then ablated the gold. Water was chosen because it was considered an eco-friendly solvent compared to other organic solvents. Besides, it can be considered superior in different biological applications.

2.3 Preparation of PEO/CMC-AuNPs nanocomposite films

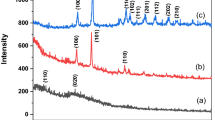

Nanocomposite samples consist of precalculated amounts of equal mass fractions of both PEO and CMC (50/50 wt%) in addition to the dopant AuNPs through the ordinary casting technique using water as a common solvent at ambient room temperature. Both PEO and CMC were dissolved separately in (DDW) and blended via vigorous stirring for about 2 h using a magnetic until a homogeneous viscous liquid was formed. The blend of PEO/CMC was divided equally into 5 beakers. The appropriate amounts of AuNPs (10, 15, 20, and 25 ml) were dropped through a glass pipette into the previously prepared PEO/CMC mixture in the beakers. Obtained solutions were poured into Petri dishes and placed in a leveled dryer adjusted at 50 °C for about 3 days to ensure complete evaporation of solvent traces. Obtained thin films appear to be easily removed from Petri dishes without deformation [6, 14, 29].

2.4 Characterization techniques

A scanning electron microscope (JEOL JSM-6510LV, USA) set to 20 kV accelerating voltage was used to examine the morphology of the samples. The surface of the samples was coated with a thin layer of gold (3.5 nm) to minimize sample charging effects due to the electron beam. A programmable automatic broadband dielectric spectrometer (Novocontrol turnkey concept 40 system) was used to study the electrical characteristics of Ac in a dry nitrogen atmosphere over a frequency range of 0.1 Hz to 10 MHz at temperatures ranging from 298 to 423 K (temperature was controlled via the QUATRO Cryosystem). The studied samples were placed in a holder particularly constructed to limit stray capacitance.

3 Results and discussion

3.1 Scanning electron microscope (SEM)

A scanning electron microscope (SEM) is used to investigate the surface morphology and structure of the investigated samples [30]. Figure 1a–d depicts the scanning electron microscopy micrograph of the surface of the pure PEO/CMC blend and the blend loaded with varying amounts of Gold nanoparticles (AuNPs) (10, 20, and 25 ml) at magnification 500 times. As shown in Fig. 1a, the surface of the blend is smooth with no phase separation due to the miscibility of polymeric materials PEO and CMC. Uniform distributed granules on the blend surface were observed with the addition of AuNPs. The number and size of the granules increase with the increasing concentration of gold nanoparticles, which means a homogeneous growth mechanism. Also, Fig. 1a–d represents two and three-dimensional images that can be used to estimate the roughness parameters, including the roughness average (Ra), root mean square roughness (Rq), the maximum height of the roughness (Rt), maximum roughness valley depth (Rv), maximum roughness peak height (Rp), and the average maximum height of the roughness (Rtm). The measured roughness parameters are listed in Table 1. SEM images show that the evolution of surface roughness is dependent on the different concentrations of nano-filler in the polymeric matrix. The changes that occurred at the surface of filled samples indicated that the dopant and polymer blend had interacted and complexed [31,32,33].

3.2 Dielectric spectra analysis

In general, complex permittivity (\({\varepsilon }^{*}\)) is used to characterize a material's dielectric behavior in terms of the real dielectric constant \(({\varepsilon }^{{\prime}})\) and imaginary dielectric loss \({(\varepsilon }^{{\prime\prime} })\). Complex permittivity (\({\varepsilon }^{*}\)) can characterize a material's dielectric behavior as [29, 34]:

The following equation can be used to calculate the real dielectric constant \({(\varepsilon }^{{{\prime}}})\) [35, 36]:

where C represents capacitance, d represents the thickness of the films, A represents the area of the electrode cross-sectional, and \({\varepsilon }_{0}\) represents free space permittivity \({(\varepsilon }_{0}=8.85\times {10}^{-12} \,\text{ F/m})\). The dielectric loss \({(\varepsilon }^{{\prime\prime} })\) may be calculated using

where \(\omega\) is the angular frequency.

Figures 2 and 3a–e depict the frequency (Log f) dependence of \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\), respectively, at different temperatures (298, 323, 373, and 423 °C) over a frequency range of 0.1 Hz to 10 MHz for the pure PEO/CMC blend and its nanocomposite samples containing Gold nanoparticles (PEO/CMC-AuNPs). It is noticed that at low frequencies the \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\) values are increased while they reduce at higher frequencies. These findings suggest the same trend for all of the samples analyzed. The high values of \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\) at low frequencies may be due to charge carriers that collect inside the bulk sample at interfaces (interfacial polarization) [37,38,39] and the sample-to-electrode interface (space charge polarization) [40]. This behavior can be explained as follows, at low frequencies, the high value of \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\) is owing to the field's sluggish alternation, which gives ample time for persistence and induces dipoles to align with the applied field. Whereas the \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\) values decrease at high frequencies due to the short time allotted for dipole aligning. At higher frequencies, the periodic reversal of the electric field occurs so rapidly that dipoles are not able to follow the changes in the field. Increases in frequency led to the values of \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\) to become constant due to the interfacial or space charge polarization effect. Also, it is observed that the dielectric loss (\({\varepsilon }^{{\prime\prime} })\) increases progressively with AuNPs content.

The loss tangent (tanδ) is the ratio of the loss factor to the relative permittivity, and the electric energy is lost to the energy stored in a periodic field. The variation of loss tangent (tanδ) is calculated from the equation [35, 41]:

Figure 4a–e illustrates the frequency (Log f) dependent on the dielectric loss tangent (tan\(\delta\)) at different temperatures. It is obvious that in the low-frequency range, the (tan\(\delta\)) value is high. While at higher frequencies, the values of (tan\(\delta\)) are low because more dipoles cannot follow the oscillating electric field.

3.3 Complex electric modulus spectra analysis

The complex electric modulus (\({{M}}^{*}\)) has been used to investigate the phenomenon of ion relaxation. The following equation depicts the complex electric modulus [42].

where \(j=\sqrt{-1}, {{M}}^{{{\prime}}} \, \mathrm{ and} \,\) \({{M}}^{{\prime\prime} }\) are the real and imaginary components of the electric modulus as given by the following relationships:

The electric modulus formalism provides further information about the material's relaxation processes. Figure 5a–e illustrates the relationship between the real part of the dielectric modulus (M′) and the frequency at different temperatures for all samples. This figure shows that the values of M′ for all temperatures tend to approach zero at low frequencies due to the insignificant effect of electrode polarization. As the frequency rises, M′ progressively increases until it reaches the maximum constant value of M*. This might be due to the lack of space charge effects. The conductivity relaxation can explain the dispersion between these frequencies. The values of M′ decrease as temperature increases within the range of the frequency. This phenomenon can be explained in terms of charge carriers' short-range mobility.

Figure 6a–e displays the relation between the imaginary part of the dielectric modulus (M′′) and the frequency at different temperatures. For temperatures of 298 K to 373 K, just one relaxation process was observed, while appearing two relaxation processes at the highest temperature 423 K. An increase in frequency leads to a rise in M′′, which reaches its maximum value M′′ max and subsequently declines. The position of the peak shifts to a higher frequency, and the peak height increases as the temperature rises. This reveals the presence of thermally activated dielectric relaxation and the charge carriers' hopping mechanism. In the low-frequency range, the charge carriers (ions) move to long-range mobility, whereas in the high-frequency range, charge carriers are trapped in potential wells and can move freely within the well for a short distance. The peak height decreases for the loaded samples compared to the pure blend, suggesting that the AuNPs contribute to the relaxation process.

Figure 7a–e shows the dependency of M′′ on M′ (Cole–Cole diagram) for the pure blend and samples having varying concentrations of AuNPs. This figure reveals the presence of semicircles with their centers below the real axis M′ [12, 43]. This implies a dispersion in relaxation time, indicating that the dielectric relaxation process in such materials follows the non-Debye model. The two relaxations can be seen at a high temperature (T = 423 K). The beginning of the second relaxation can be noticed at low temperatures, while two relaxation peaks appear more clearly for all samples at the higher temperature. Due to significant interactions at the interfaces, these relaxation peaks shifted to lower frequencies as temperature rises. The relaxation that occurs at high frequency is attributed to dipole reorientation. It is obvious that when amounts of AuNPs were added, these peaks overlapped.

3.4 AC conductivity results

The complex conductivity \({\sigma }^{*}\) was expressed as follows [43,44,45,46]:

where \({\sigma }^{{\prime}}\left(\omega \right)\) 'and \({\sigma }^{{\prime\prime} }\left(\omega \right)\) represent the real and imaginary portions of the conductance. The real part of the conductivity \({\sigma }^{{\prime}}\left(\omega \right)\) has frequently been analyzed separately as two different components:

where \({\sigma }_\text{dc}\) implies dc conductivity, which is frequency independent, and \({\sigma }_\text{ac}\) implies ac conductivity, which is frequency dependent and follows a power law in the form of [43].

where \(\omega =2{\pi f}\) is the angular frequency, A is constant, and s is the frequency exponent that ranges from zero to one (0 ≤ s ≤ 1) and indicates the degree of interaction between mobile ions and the lattices that surround them.

Figure 8a–e illustrates the curve of the conductivity log (\({\sigma }_\text{ac}\)) versus log (f) at different temperatures, for all samples. The electrical conductivity increases with increasing frequency for temperatures of 298 K and 323 K. On the other hand, the conductivity curves can be split into two regions at temperatures 373 K and 423 K. In the low frequencies, the first region exhibits approximately constant conductivity, whereas in the high frequencies, the second region exhibits increasing conductivity as a dispersion region that follows Jonscher's power law. This implies that the material contains an electrical conduction mechanism of the hopping type. Also, it is observed that the conductivity of the loaded samples is higher than that of the virgin blend. The enhancement in conductivity may be attributed to an increase in the amorphous phase of the polymeric matrix (due to the inclusion of AuNPs), which lowers the energy barrier and permits ion transport. At high frequencies, s is the frequency exponent, which is calculated from the fitted slope of the linear part of the log (\({\sigma }_\text{ac}\)) vs. log (f). These values of s are listed in Table 2. They are in the (0.89–0.50) range. As demonstrated in Fig. 9, values obtained of s are shown as a function of temperature. It is evident that the s values are smaller than one and decrease, as the temperature increases. These results show strong agreement with the correlated barrier hopping (CBH) mechanism [16, 46].

Log (σ) vs. inverse absolute temperature is plotted in Fig. 10 for virgin blend and PEO/CMC/AuNPs thin films, in the temperature range of 298 to 423 K. The Arrhenius relation depicts the temperature dependence of AC conductivity as the following [47,48,49,50]:

where \({\sigma }_{0}\) is a constant, \({E}_{\mathrm{a}}\) is the conduction activation energy, k is the Boltzmann constant, and T is the absolute temperature. \({E}_{\mathrm{a}}\) values are calculated from the slope of straight lines in the figure, and their values are shown in Table 3. It can be seen that all examined samples showed a direct link between conductivity values and rising temperature, which may be explained by using the free volume theory. The temperature rises cause polymer chain segmental motion and AuNP dissociation to improve, resulting in a conductivity increase. This behavior indicates the amorphous region within the polymer responsible for conductivity. From the figure, it is clear that the conductivity increases with the increased content of filler due to an increase in transition probability for hopping electrons across the polymer matrix. Figure 11 depicts the dependency of activation energy (Ea) on the AuNPs concentration. Increases in gold nanoparticle content resulted in a reduction in the values of activation energy.

4 Conclusion

The laser ablation technique produced pure gold nanoparticles (AuNPs). New nanocomposite films were created based on a PEO/CMC blend with varying concentrations of the produced AuNPs. SEM was used to analyze the surface morphology and the structure of the nanocomposite films. The quantity and size of these granules increase as the contents of AuNPs increase. The roughness parameters including the roughness average (Ra), root means square roughness (Rq), the maximum height of the roughness (Rt), maximum roughness valley depth (Rv), maximum roughness peak height (Rp), and the average maximum height of the roughness (Rtm) were estimated. The values of both \({\varepsilon }^{{\prime}}\) and \({\varepsilon }^{{\prime\prime} }\) were increased at low frequencies due to charge carriers that collect inside the bulk sample, while they reduce at higher frequencies due to the short time allotted for dipole aligning. The values of M′ at all temperatures tend to approach zero at low frequencies due to the insignificant effect of electrode polarization. Two relaxations were observed at a high temperature. The beginning of the second relaxation can be noticed at low temperatures, while two relaxation peaks appear more clearly at higher temperatures. The relaxation peaks shifted to lower frequencies as the temperature rises. The relaxation that occurs at high frequency is attributed to dipole reorientation. The conductivity curves were split into two regions at temperatures. In the low frequencies, the first region exhibits approximately constant conductivity, whereas at the high frequencies, the second region exhibits increasing significantly conductivity as a dispersion region that follows Jonscher's power law implying that the samples contain an electrical conduction mechanism of the hopping type. Water was chosen as a solvent because it was considered an eco-friendly solvent compared to other organic solvents.

Data availability

The data underlying this study are available in the article itself.

References

M.Z. Alhamid, B.S. Hadi, A. Khumaeni, Synthesis of silver nanoparticles using laser ablation method utilizing Nd:YAG laser, in AIP conference proceedings. (2019). https://doi.org/10.1063/1.5141626

X. Bai, T. Li, Z. Dang, Y.X. Qi, N. Lun, Y.J. Bai, Ionic conductor of Li2SiO3 as an effective dual-functional modifier to optimize the electrochemical performance of Li4Ti5O12 for high-performance Li-ion batteries. ACS Appl. Mater. Interfaces 9, 1426–1436 (2017). https://doi.org/10.1021/acsami.6b10795

I.S. Elashmawi, A.A. Menazea, Different time’s Nd:YAG laser-irradiated PVA/Ag nanocomposites: Structural, optical, and electrical characterization. J. Mater. Res. Technol. 8, 1944–1951 (2019). https://doi.org/10.1016/j.jmrt.2019.01.011

I. Khan, K. Saeed, I. Khan, Nanoparticles: properties, applications and toxicities. Arab. J. Chem. 12, 908–931 (2019). https://doi.org/10.1016/j.arabjc.2017.05.011

A.A. Menazea, A.M. Ismail, I.S. Elashmawi, The role of Li4Ti5O12 nanoparticles on enhancement the performance of PVDF/PVK blend for lithium-ion batteries. J. Mater. Res. Technol. 9, 5689–5698 (2020). https://doi.org/10.1016/j.jmrt.2020.03.093

A.M. Abdelghany, A.A. Menazea, A.M. Ismail, Synthesis, characterization and antimicrobial activity of chitosan/polyvinyl alcohol blend doped with Hibiscus sabdariffa L. extract. J. Mol. Struct. 1197, 603–609 (2019). https://doi.org/10.1016/j.molstruc.2019.07.089

C. Liang, Y. Shimizu, T. Sasaki, N. Koshizaki, Synthesis, characterization, and phase stability of ultrafine TiO2 nanoparticles by pulsed laser ablation in liquid media. J. Mater. Res. 19, 1551–1557 (2004). https://doi.org/10.1557/JMR.2004.0208

A.A. Menazea, A.M. Ismail, N.S. Awwad, H.A. Ibrahium, Physical characterization and antibacterial activity of PVA/Chitosan matrix doped by selenium nanoparticles prepared via one-pot laser ablation route. J. Mater. Res. Technol. 9, 9598–9606 (2020). https://doi.org/10.1016/j.jmrt.2020.06.077

K. Siuzdak, M. Sawczak, M. Klein, G. Nowaczyk, S. Jurga, A. Cenian, Preparation of platinum modified titanium dioxide nanoparticles with the use of laser ablation in water. Phys. Chem. Chem. Phys. 16, 15199–15206 (2014). https://doi.org/10.1039/c4cp01923g

M. Kim, S. Osone, T. Kim, H. Higashi, T. Seto, Synthesis of nanoparticles by laser ablation: a review. KONA Powder Part. J. (2017). https://doi.org/10.14356/kona.2017009

I.S. Elashmawi, A.M. Ismail, Study of the spectroscopic, magnetic, and electrical behavior of PVDF/PEO blend incorporated with nickel ferrite (NiFe2O4) nanoparticles. Polym. Bull. (2022). https://doi.org/10.1007/s00289-022-04139-9

I.S. Elashmawi, A.A. Al-Muntaser, A.M. Ismail, Structural, optical, and dielectric modulus properties of PEO/PVA blend filled with metakaolin. Opt. Mater. (Amst) 126, 112220 (2022). https://doi.org/10.1016/j.optmat.2022.112220

K.N. Kumar, M. Kang, K. Sivaiah, M. Ravi, Y.C. Ratnakaram, Enhanced electrical properties of polyethylene oxide (PEO) + polyvinylpyrrolidone (PVP): Li + blended polymer electrolyte films with addition of Ag nanofiller. Ionics (Kiel) (2016). https://doi.org/10.1007/s11581-015-1599-4

I.S. Elashmawi, L.H. Gaabour, Raman, morphology and electrical behavior of nanocomposites based on PEO/PVDF with multi-walled carbon nanotubes. Results Phys. 5, 105–110 (2015). https://doi.org/10.1016/j.rinp.2015.04.005

I.S. Elashmawi, N.H. Elsayed, F.A. Altalhi, The changes of spectroscopic, thermal and electrical properties of PVDF/PEO containing lithium nanoparticles. J. Alloys Compd. 617, 877–883 (2014). https://doi.org/10.1016/j.jallcom.2014.08.088

I.S. Elashmawi, E.M. Abdelrazek, A.M. Hezma, A. Rajeh, Modification and development of electrical and magnetic properties of PVA/PEO incorporated with MnCl2. Physica B 434, 57–63 (2014). https://doi.org/10.1016/j.physb.2013.10.038

K.N. Kumar, K.S. Misook, K.Y.C. Ratnakaram, Improved electrical properties of Fe nanofiller impregnated PEO + PVP: Li + blended polymer electrolytes for lithium battery applications. Appl. Phys. A (2016). https://doi.org/10.1007/s00339-016-0212-7

R.S. Hafez, N.A. Hakeem, A.A. Ward, A.M. Ismail, F.H.A. El-kader, Dielectric and thermal properties of PEO/PVDF blend doped with different concentrations of Li4Ti5O12 nanoparticles. J. Inorg. Organomet. Polym. Mater. 30, 4468–4480 (2020). https://doi.org/10.1007/s10904-020-01637-z

Q. Ye, H. Liang, S. Wang, C. Cui, C. Zeng, T. Zhai, H. Li, Fabricating a PVDF skin for PEO-based SPE to stabilize the interface both at cathode and anode for Li-ion batteries. J. Energy Chem. 70, 356–362 (2022). https://doi.org/10.1016/j.jechem.2022.02.037

M.O. Farea, A.M. Abdelghany, A.H. Oraby, Optical and dielectric characteristics of polyethylene oxide/sodium alginate-modified gold nanocomposites. RSC Adv. 10, 37621–37630 (2020). https://doi.org/10.1039/d0ra07601e

S. Jha, V. Bhavsar, D. Tripathi, Dielectric properties of MWCNT dispersed conducting polymer nanocomposites films of PVA-CMC-PPy. Mater. Today Proc. 45, 4824–4829 (2021). https://doi.org/10.1016/j.matpr.2021.01.294

R.A. Pashameah, M. El-Sharnouby, A. El-Askary, M.A. El-Morsy, H.A. Ahmed, A.A. Menazea, Optical, structural, electrical characterization of (polyvinyl alcohol-carboxymethyl cellulose-manganese dioxide) nanocomposite fabricated via laser ablation. J. Inorg. Organomet. Polym. Mater. (2022). https://doi.org/10.1007/s10904-022-02311-2

Q.A. Alsulami, A. Rajeh, Results in physics synthesis of the SWCNTs/TiO2 nanostructure and its effect study on the thermal, optical, and conductivity properties of the CMC/PEO blend. Results Phys. 28, 104675 (2021). https://doi.org/10.1016/j.rinp.2021.104675

M.A. Mahdi, S. Raheleh, L.S. Jasim, M. Salavati-niasari, ScienceDirect nanocomposites using almond extract with dual eco-friendly applications: photocatalytic and antibacterial activities. Int. J. Hydrog. Energy 47, 14319–14330 (2022). https://doi.org/10.1016/j.ijhydene.2022.02.175

S. Raheleh, Y. Mojgan, G. Omid, Z. Marzhoseyni, P.M.M. Hajizadeh-, scheme heterojunction nanocomposite with enhanced photocatalytic and antibacterial activities. J. Am. Ceram. Soc. (2021). https://doi.org/10.1111/jace.17696

S. Raheleh, H. Abbas, O. Amiri, M. Salavati-niasari, Synthesis, characterization and application of Co/Co3O4 nanocomposites as an effective photocatalyst for discoloration of organic dye contaminants in wastewater and antibacterial properties. J. Mol. Liq. 337, 116405 (2021). https://doi.org/10.1016/j.molliq.2021.116405

B. Nio, S. Raheleh, A. Sobhani, A. Alshamsi, Green sonochemical synthesis of BaDy2NiO5/Dy2O3 and BaDy2NiO5/NiO nanocomposites in the presence of core almond as a capping agent and their application as photocatalysts for the removal of organic dyes in water. RSC Adv. (2021). https://doi.org/10.1039/d0ra10288a

S. Rahele, O. Amiri, M. Salavati-niasari, Ultrasonics—sonochemistry nanostructures and study their photocatalytic activity. Ultrason. - Sonochem. 58, 104619 (2019). https://doi.org/10.1016/j.ultsonch.2019.104619

I.S. Elashmawi, E.M. Abdelrazek, H.M. Ragab, N.A. Hakeem, Structural, optical and dielectric behavior of PVDF films filled with different concentrations of iodine. Physica B (2010). https://doi.org/10.1016/j.physb.2009.08.037

B. Erim, Z. Ciğeroğlu, M. Bayramoğlu, Green synthesis of TiO2/GO/chitosan by using leaf extract of Olea europaea as a highly efficient photocatalyst for the degradation of cefixime trihydrate under UV-A radiation exposure: an optimization study with D-optimal design. J. Mol. Struct. (2021). https://doi.org/10.1016/j.molstruc.2021.130194

E. Panjaitan, A. Manaf, B. Soegijono, E. Kartini, Effect of additional poly vinyledene fluoride (PVDF) on LiCoO2 cathodes. Procedia Chem. 4, 60–64 (2012). https://doi.org/10.1016/j.proche.2012.06.009

M. Yue, H. Liu, Z. Yin, K. Wei, H. Guan, H. Lin, M. Shen, S. An, Q. Wu, S. Sun, Stabilizing hard magnetic SmCo5 nanoparticles by N—doped graphitic carbon layer. J. Am. Chem. Soc. (2020). https://doi.org/10.1021/jacs.0c02197

H. Widiyandari, O. Ade, A. Purwanto, Z. Abidin, Synthesis of PVDF/SiO2 nanofiber membrane using electrospinning method as a Li-ion battery separator. Mater. Today Proc. 44, 3245–3248 (2021). https://doi.org/10.1016/j.matpr.2020.11.448

I.S. Elashmawi, E.M. Abdelrazek, H.M. Ragab, N.A. Hakeem, Structural, optical and dielectric behavior of PVDF films filled with different concentrations of iodine. Physica B 405, 94–98 (2010)

M. Gökçen, T. Tunç, Enhancement of dielectric characteristics of polyvinyl alcohol (PVA) interfacial layer in Au/PVA/n-Si structures by Bi2O3disperse. Int. J. Appl. Ceram. Technol. 10, E64–E69 (2013). https://doi.org/10.1111/ijac.12009

A. Sedky, N. Afify, A.M. Ali, H. Algarni, On the dielectric behaviors of Zn1−x−yFexMyO ceramics for nonlinear optical and solar cell devices. Appl. Phys. A 128, 1–14 (2022). https://doi.org/10.1007/s00339-022-05260-2

A.A.A. Youssef, The permittivity and AC conductivity of the layered perovskite [(CH3)(C6H5)3P]2Hgl4. Zeitschrift fur Naturforsch A J. Phys. Sci. 57, 263–269 (2002). https://doi.org/10.1515/zna-2002-0510

S. Choudhary, Structural and dielectric properties of (PEO–PMMA)–SnO2 nanocomposites. Compos. Commun. 5, 54–63 (2017). https://doi.org/10.1016/j.coco.2017.07.004

M. Prabu, S. Selvasekarapandian, Dielectric and modulus studies of LiNiPO4. Mater. Chem. Phys. 134, 366–370 (2012). https://doi.org/10.1016/j.matchemphys.2012.03.003

M. Shen, C. Harris, H. Lin, K. Wei, M. Morales, N. Bronowich, S. Sun, Cu2O nanoparticle-catalyzed tandem reactions for the synthesis of robust polybenzoxazole. Nanoscale (2022). https://doi.org/10.1039/d2nr00492e

A.Y. Yassin, A.R. Mohamed, A.M. Abdelghany, E.M. Abdelrazek, Enhancement of dielectric properties and AC electrical conductivity of nanocomposite using poly (vinyl chloride-co-vinyl acetate-co-2-hydroxypropyl acrylate) filled with graphene oxide. J. Mater. Sci. Mater. Electron. 29, 15931–15945 (2018). https://doi.org/10.1007/s10854-018-9679-7

M. El-Sharnouby, A. El Askary, N.S. Awwad, H.A. Ibrahium, M.E. Moustapha, M.O. Farea, A.A. Menazea, A.M. Abdelghany, Enhanced electrical conductivity and dielectric performance of ternary nanocomposite film of PEMA/PS/silver NPs synthesized by laser ablation. J. Inorg. Organomet. Polym. Mater. 32, 2269–2278 (2022). https://doi.org/10.1007/s10904-022-02286-0

Y. Bakış, I.A. Auwal, B. Ünal, A. Baykal, Maxwell-Wagner relaxation in grain boundary of BaBixLaxYxFe12−3xO19 (0.0 ≤ x ≤ 0.33) hexaferrites. Composites B 99, 248–256 (2016). https://doi.org/10.1016/j.compositesb.2016.06.047

M. Ram, Structure and electrical conduction behavior of LiZnVO4 ceramic prepared by solution-based chemical route. J. Alloys Compd. 509, 5688–5691 (2011). https://doi.org/10.1016/j.jallcom.2011.02.128

S. Lahlali, L. Essaleh, M. Belaqziz, H. Chehouani, A. Alimoussa, K. Djessas, B. Viallet, J.L. Gauffier, S. Cayez, Dielectric and modulus analysis of the photoabsorber Cu2SnS3. Physica B 526, 54–58 (2017). https://doi.org/10.1016/j.physb.2017.09.069

F. Gami, N. Algethami, H.M. Ragab, A. Rajah, A.E. Tarabiah, Structural, optical and electrical studies of chitosan/polyacrylamide blend filled with synthesized selenium nanoparticles. J. Mol. Struct. 1257, 132631 (2022). https://doi.org/10.1016/j.molstruc.2022.132631

Y.M. Yusof, H.A. Illias, M.F.Z. Kadir, Incorporation of NH4Br in PVA-chitosan blend-based polymer electrolyte and its effect on the conductivity and other electrical properties. Ionics (Kiel) 20, 1235–1245 (2014). https://doi.org/10.1007/s11581-014-1096-1

M.J. Tommalieh, H.A. Ibrahium, N.S. Awwad, A.A. Menazea, Gold nanoparticles doped polyvinyl alcohol/chitosan blend via laser ablation for electrical conductivity enhancement. J. Mol. Struct. 1221, 128814 (2020). https://doi.org/10.1016/j.molstruc.2020.128814

E.M. Abdelrazek, I.S. Elashmawi, H.M. Ragab, Manifestation of MnCl2 fillers incorporated into the polymer matrices in their dielectric properties. Physica B 403, 3097–3104 (2008). https://doi.org/10.1016/j.physb.2008.03.012

S.B. Aziz, O.G. Abdullah, S. Al-zangana, Solid polymer electrolytes based on chitosan: NH4 Tf modified by various amounts of TiO2 filler and its electrical and dielectric characteristics. Int. J. Electrochem. Sci. 14, 1909–1925 (2019). https://doi.org/10.20964/2019.02.31

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

AMA prepared the samples, discussed the results, and reviewed the final manuscript before submission. ISE contributed toward data analysis, editing and discussion of the results, and final manuscript review before submission. AAA-S contributed toward sample preparation, formal analysis, investigation, and writing-original draft. HA collected and analyzed data and shared in editing the manuscript draft. All authors declare that they have no known competing financial interests or personal relationships that could appear to influence the work described in this paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdelghany, A.M., Elashmawi, I.S., Al-Shamari, A.A. et al. Dielectric behavior and AC conductivity of PEO/CMC polymer blend incorporated with gold nanoparticles produced by laser ablation. J Mater Sci: Mater Electron 34, 388 (2023). https://doi.org/10.1007/s10854-022-09797-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09797-z