Abstract

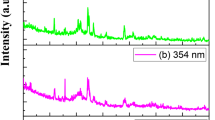

TiN films with low infrared emissivity were obtained using reactive magnetron sputtering. The influence of deposited thickness (309, 645, 1248, and 2011 nm) on the preferred orientation, morphology, structure, resistivity, and infrared emissivity of TiN films was studied. The resistivity and infrared emissivity of TiN films could be altered by varying the deposited thickness. Film with thickness of 645 nm showed (200) preferred orientation. Due to internal stress, the preferred orientation converted to (111) and (220) plane when the film thicknesses were 1248 and 2011 nm. The crystallization was poor and the grain size was small when the deposited thickness was 309 nm, resulting in high resistivity and infrared emissivity. The crystalline grains with preferred orientation of (200) plane of TiN films showed a closely arranged cellular morphology, while the crystalline grain morphology with (111) and (220) preferred orientation showed a mixture structure of triangular cone and prism. TiN film with (200) preferred orientation had higher density and smaller roughness than that with (111) and (220) preferred orientation, which was beneficial for low-resistivity and low-emissivity properties. It is concluded that TiN film with (200) preferred orientation has lower resistivity and infrared emissivity than that with (111) and (220) preferred orientation. When the deposited thickness of TiN films reaches 1248 nm, the thickness inhibition occurred and the change of the resistivity and infrared emissivity was not obvious.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Z.B. Huang, W.C. Zhou, X.F. Tang, Effects of annealing time on infrared emissivity of the Pt film grown on Ni alloy. Appl. Surf. Sci. 256, 2025–2030 (2010). https://doi.org/10.1016/j.apsusc.2009.09.042

Z.B. Huang, W.C. Zhou, X.F. Tang, F. Luo, D.M. Zhu, High-temperature application of the low-emissivity Au/Ni films on alloys. Appl. Surf. Sci. 256, 6893–6898 (2010). https://doi.org/10.1016/j.apsusc.2010.04.107

M. Zhang, G. Yang, L. Zhang, J.H. Zhang, Yin et al., Application of ZrB2 thin film as a low emissivity film at high temperature. Appl. Surf. Sci. 527, 146763 (2020). https://doi.org/10.1016/j.apsusc.2020.146763

K.W. Sun, X.F. Tang, C.L. Tang, Yang, D. Yang, Jin, Preparation and performance of low-emissivity Al-doped ZnO films for energy-saving glass. Ceram. Int. 44, 19597–19602 (2018). https://doi.org/10.1016/j.ceramint.2018.07.207

K.W. Sun, W.C. Zhou, X.F. Tang, F. Luo, Application of indium tin oxide (ITO) thin film as a low emissivity film on Ni-based alloy at high temperature. Infrared Phys.Techn. 78, 156–161 (2010). https://doi.org/10.1016/j.infrared.2016.07.021

M.B. Cinali, O.D. Coskun, Optimization of physical properties of sputtered silver films by change of deposition power for low emissivity applications. J. Alloys Compd. 485, 92–100 (2019). https://doi.org/10.1016/j.jallcom.2020.157073

S. Hanauer, C. Celle, C. Crivello, H. Szambolics, D. Munoz-Rojas, D. Bellet, J.P. Simonato, Transparent and mechanically resistant silver-nanowire-based low-emissivity coatings. ACS Appl. Mater. Inter. 13, 21971–21978 (2021). https://doi.org/10.1021/acsami.1c02689

X.H. Bu, Y.M. Zhou, M. He, Z.J. Chen, T. Zhang, Optically active SiO2 /TiO2 /polyacetylene multilayered nanospheres: preparation, characterization, and application for low infrared emissivity. Appl. Surf. Sci. 288, 444–451 (2014). https://doi.org/10.1016/j.apsusc.2013.10.053

L.P. Chen, Z.Y. Ren, X.M. Liu, K. Wang, Q. Wang, Infrared-visible compatible stealth based on Al-SiO2 nanoparticle composite film. Opt. Commun. 482, 456–475 (2021). https://doi.org/10.1016/j.optcom.2020.126608

A.F. Zhu, H.L. Xing, Q. Fan, X.L. Ji, P. Yang, Conductive polyaniline coated on aluminum substrate as bi-functional materials with high-performance microwave absorption and low infrared emissivity. Synth. Met. 271, 1–8 (2021). https://doi.org/10.1016/j.synthmet.2020.116640

R. Alvarez, J.C. González, J.P. Espinós, A.R. González-Elipe, A. Cueva, F. Villuendas, Growth of silver on ZnO and SnO2 thin films intended for low emissivity applications. Appl. Surf. Sci. 268, 407–515 (2013). https://doi.org/10.1016/j.apsusc.2012.12.156

L. Hultman, Thermal stability of nitride thin films. Vacuum 57, 1–30 (2000). https://doi.org/10.1016/S0042-207X(00)00143-3

L.J. Meng, A. Azevedo, M.P. Santos, Deposition and properties of titanium nitride films produced by dc reactive magnetron sputtering. Vacuum. 46, 233–239 (1995). https://doi.org/10.1016/0042-207X(94)00052-2

J.E. Sundgren, Structure and properties of TiN coatings. Thin Solid Films 128, 21–44 (1985). https://doi.org/10.1016/0040-6090(85)90333-5

F. Pinakidou, Influence of composition and growth conditions on TiN nanocrystallite formation in TiN-metal films. Thin Solid Films. 727, 138645 (2021). https://doi.org/10.1016/j.tsf.2021.138645

Z.H. Xu, Q.H. Zhang, L. Luo, Y. Liu, J. Wan, Microstructure and corrosion resistance of TiN/TiO nano-composite film on AZ31 magnesium alloy 2. Surf Coatings Technol 406, 126681 (2021). https://doi.org/10.1016/j.surfcoat.2020.126681

O. Comakli, Improved structural, mechanical, corrosion and tribocorrosion properties of Ti45Nb alloys by TiN, TiAlN monolayers, and TiAlN/TiN multilayer ceramic films. Ceram. Int. 47, 4149–4415 (2020). https://doi.org/10.1016/j.ceramint.2020.09.292

N. Wolff, P. Jordt, J. Jetter, H. Vogt, A. Lotnyk, K. Seemann, S. Ulrich, E. Quandt, B.M. Murphy, L. Kienle, Nanostabilization of tetragonal distorted FeCo variants in ultra-thin FeCo/TiN multilayer films. Zeitschriftenaufsatz 172, 110871 (2021). https://doi.org/10.1016/j.matchar.2021.110871

T. Meydan, H. Kockar, The influence of production conditions on the magnetic properties of sputtered and laser deposited thin films. J. Optoelectron. Adv. Mater. 6(2), 633–636 (2004)

H. Kockar, T. Meydan, The rotation and clamping effect on the magnetic properties of iron films deposited onto a rotating substrate. Phys. B 321, 124–128 (2002). https://doi.org/10.1016/S0921-4526(02)00836-0

H. Kockar, Rotation speed-induced uniaxial in-plane anisotropy in thin films deposited onto a rotating substrate. J. Supercond. 17, 531–536 (2004). https://doi.org/10.1023/B:JOSC.0000041792.93118.2b

H. Kockar, T. Meydan, Factors affecting magnetic properties of evaporated iron films. J. Magn. Magn. Mater. 242, 183–186 (2002). https://doi.org/10.1016/S0304-8853(01)01172-6

S. Das, S. Guha, R. Ghadai, A. Sharma, Influence of nitrogen gas over microstructural, vibrational and mechanical properties of CVD titanium nitride (TiN) thin film coating. Ceram. Int. 47, 16809–16819 (2021). https://doi.org/10.1016/j.ceramint.2021.02.254

N. Arshi, J. Lu, Y.K. Joo, C.G. Lee, J.H. Yoon, F. Ahmed, Study on structural, morphological and electrical properties of sputtered titanium nitride films under different argon gas flow. Mater. Chem. Phys. 134, 839–844 (2012). https://doi.org/10.1016/j.matchemphys.2012.03.078

W.J. Chou, G.P. Yu, J.H. Huang, Mechanical properties of TiN thin film coatings on 304 stainless steel substrates. Surf. Coat. Technol. 149, 7–13 (2002). https://doi.org/10.1016/S0257-8972(01)01382-2

J.H. Huang, S.L. Zou, W.W. Xiao, X.S. Liu, D.W. Tang, Sputtering parameters effect on microstructural parameters of TiN coating via the Williamson-Hall analysis. Mater. Res. Express. 7, 106402 (2020). https://doi.org/10.1088/2053-1591/abbd09

Y.L. Jeyachandran, S.K. Narayandass, D. Mangalaraj, S. Areva, J.A. Mieluarski, Properties of titanium nitride films prepared by direct current magnetron sputtering. Mat.Sci.Eng.A-Struct. 445, 223–236 (2007). https://doi.org/10.1016/j.msea.2006.09.021

L.L. Lu, F. Luo, Y.C. Qing, W.C. Zhou, D.M. Zhu, Study on the electromagnetic interference shielding effectiveness of TiN film. J. Mater. Sci. Mater. Electron. 29, 9052–9057 (2018). https://doi.org/10.1007/s10854-018-8931-5

L.L. Lu, F. Luo, Z.B. Huang, W.C. Zhou, D.M. Zhu, Influence of the nitrogen flow rate on the infrared emissivity of TiNx films. Infrared Phys. Techn. 88, 144–148 (2018). https://doi.org/10.1016/j.infrared.2017.11.015

W.M. Mao, X.M. Zhang, Quantitative analysis of texture of crystalline materials, 2nd edn. (Metallurgical Industry Press, Beijing, 1995), pp. 20–45

Y. Wang, W. Tang, L. Zhang, Crystalline size effects on texture coefficient, electrical and optical properties of sputter-deposited Ga-doped ZnO thin films. J. Mater. Sci. Technol. 31, 175–178 (2015). https://doi.org/10.1016/j.jmst.2014.11.009

J. Xu, M. Gao, L.L. Lu, Y.L. Wang, X. Liu, Study on the resistivity and infrared emissivity of TiNx films at different sputtering power. Infrared Phys.Techn. 119, 103946 (2021). https://doi.org/10.1016/j.infrared.2021.103946

G. Abadias, Stress and preferred orientation in nitride-based PVD coatings. Surf. Coatings Technol. 202, 2223–2235 (2008). https://doi.org/10.1016/j.surfcoat.2007.08.029

Y. Xi, Y. Bai, K. Gao, X. Pang, H. Yang, L. Yan, A.A. Volinsky, In-situ stress gradient evolution and texture-dependent fracture of brittle ceramic thin films under external load. Ceram. Int. 44, 8176–8183 (2018). https://doi.org/10.1016/j.ceramint.2018.01.265

J.P. Zhao, X. Wang, Z.Y. Chen, S.Q. Yang, T.S. Shi, X.H. Liu, Overall energy model for preferred growth of TiN films during filtered arc deposition. J. Phys. D. 30, 5–12 (1997). https://doi.org/10.1088/0022-3727/30/1/002

Z.D. Guan, Z.T. Zhang, J.S. Jiao, Physical Properties of Inorganic Materials, 1st edn. (Tsinghua University Press, Beijing, 1992), pp. 451–467

Y.L. Shi, F.Y. Yan, Technologies and materials of film, 1st edn. (Chemical Industry Press, Beijing, 2015), pp. 370–380

Author information

Authors and Affiliations

Contributions

CL: Conceptualization, methodology, writing—original draft preparation. QJ: Data curation, software. DJ: Supervision, validation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest exited that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Jia, Q. & Jian, D. Influence of thickness on the resistivity and infrared emissivity of TiN films. J Mater Sci: Mater Electron 33, 3606–3616 (2022). https://doi.org/10.1007/s10854-021-07554-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07554-2