Abstract

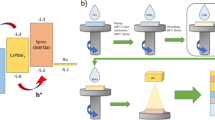

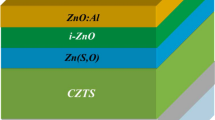

The chalcogen concentration in kesterites plays a very crucial role in band engineering and tailoring the material properties. Therefore, performance and power conversion efficiency of solar cells made from Cu2ZnSn(SxSe1-x)4 (CZTSSe) as absorber material also strongly depends on the S/Se ratio. Here, we have investigated the role of Se incorporation on the structural and optical properties of Cu2ZnSnS4 (CZTS) thin film using simple, cost-effective and viable non-vacuum dip coating technique. The aim here is to achieve CZTSSe film with S/(S + Se) ~ 30% and to accomplish that Mo-coated glass substrate is dipped into the precursor solution that contains Cu/Zn/Sn/S:: 2:1:1:10 molar ratio and then heat treated on nitrogen atmosphere in the presence of different amount of elemental Se powder. It is noticed that lattice parameters, morphology and band gap of CZTSSe films vary with respect to S/(S + Se) ratio into the film and are assessed through X-ray diffraction (XRD), Raman spectroscopy, field emission scanning electron microscopy (FESEM), energy dispersive X-Ray spectroscopy (EDAX) and UV–Vis spectroscopy, respectively. It is found that CZTSSe film with S/(S + Se) ~ 30% having 1.27 eV band gap can be formed by annealing the as-dipped precursor film (of 1 × 1 cm2 area) in the presence of 15 mg elemental selenium powder.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting of this study are available within the article and are genuine without published elsewhere.

References

W. Wang, M.T. Winkler, O. Gunawan, T. Gokmen, T.K. Todorov, Y. Zhu, D.B. Mitzi, Adv. Energy Mater. 4, 1301465 (2013)

M. Yousefi, M. Minbashi, Z. Monfared, N. Memarian, A. Hajjiah, Sol. Energy. 208, 884 (2020)

G. Ren, D. Zhuang, M. Zhao, Y. Wei, Y. Wu, X. Li, X. Lyu, C. Wang, Y. Li, J. Power Sources. 479, 228747 (2020)

S. Chen, A. Walsh, J.-H. Yang, X.G. Gong, L. Sun, P.-X. Yang, J.-H. Chu, S.-H. Wei, Phys. Rev. B. 83, 125201 (2011)

S. Siebentritt, Thin Solid Films 535, 1 (2013)

L. Yin, G. Cheng, Y. Feng, Z. Li, C. Yang, X. Xiao, RSC Adv. 5, 40369 (2015)

S. Chaudhari, P.K. Kannan, S.R. Dey, Thin Solid Films 636, 144 (2017)

S. Chaudhari, S. Palli, P.K. Kannan, S.R. Dey, Thin Solid Films 600, 169 (2016)

S. Chaudhari, P.K. Kannan, S.R. Dey, Thin Solid Films. 612, 456 (2016)

C. Dun, N.A.W. Holzwarth, Y. Li, W. Huang, D.L. Carroll, J. Appl. Phys. 115, 193513 (2014)

E. Chagarov, K. Sardashti, R. Haight, D.B. Mitzi, A.C. Kummel, J. Chem. Phys. 145, 64704 (2016)

L. Wang, Y. Lin, Appl. Surf. Sci. 354, 14 (2015)

P.K. Kannan, S. Chaudhari, S.R. Dey, Bull. Mater. Sci. 42(11), 1 (2019)

P.K. Kannan, S. Chaudhari, S.R. Dey, Thin Solid Films 649, 81 (2018)

Y.P. Lin, T.E. Hsieh, Y.C. Chen, K.P. Huang, Sol. Energy Mater. Sol. Cells. 162, 55 (2017)

G. Liang, P. Fan, J. Hu, J. Zhao, X. Zhang, Z. Luo, H. Ma, J. Luo, Z. Zheng, D. Zhang, Sol. Energy. 136, 650 (2016)

G. Altamura, J. Vidal, Chem. Mater. 28, 3540 (2016)

R. Sun, M. Zhao, D. Zhuang, Q. Gong, L. Guo, J. Alloys Compd. 695, 3139 (2017)

T.C. Mangan, B.E. McCandless, K.D. Dobson, R.W. Birkmire, J. Appl. Phys. 118, 065303 (2015)

A. Tombak, Y. Selim, M. Fatih, T. Kilicoglu, Mater. Sci. Semicond. Process. 28, 98 (2014)

B. Ananthoju, J. Mohapatra, M.K. Jangid, D. Bahadur, N.V. Medhekar, M. Aslam, Sci. Rep. 6, 35369 (2016)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaudhari, S., Kannan, P.K., Madhuri, K. et al. Formulation of selenium-rich Cu2ZnSn(SxSe1-x)4 film through non-vacuum dip coating technique. J Mater Sci: Mater Electron 32, 19102–19109 (2021). https://doi.org/10.1007/s10854-021-06427-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06427-y