Abstract

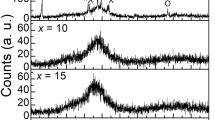

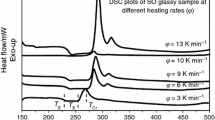

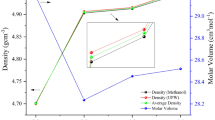

In present investigation, the formation of tellurite (TeO2) glass system was studied without using any external network former & modifier and systematically analyzed by varying the quenching-cooling media. Five samples using TeO2 melt were prepared employing the different quenching media such as mold at 200 °C, at room temperature, at ice slab, in ice water, and direct in ice slab abbreviated as G1, G2, G3, G4, and G5, respectively. Structural, thermal, optical and electrical properties were studied in order to understand their physical behavior. These samples were found dense enough which manifest the compactness and network rigidity of the structure. X-ray diffractograms confirmed the pure glass (amorphous) phase for sample G5, whereas an amorphous structure with some crystalline phases was observed for other samples. Elemental confinement and oxidation state of tellurium was verified by XPS analysis of the samples. An increase in crystallization temperature (Tc) and considerable shifting in the glass transition temperature (Tg) were observed with the increase in quenching temperature. Optical studies suggested the presence of both direct and indirect allowed transitions in the synthesized samples. All samples were also found to possess high refractive index values (> 2). FTIR and Raman studies confirmed the bonding of the glass and semicrystalline-glass samples and corroborated with the experimental findings. The factors responsible for the formation of glass and crystalline glasses of TeO2 were pointed out and discussed in detail. A correlation between the structural changes and the physical characteristics of all TeO2 glass and crystalline-glass samples has been established.

Similar content being viewed by others

References

A. Pan, A. Ghosh, Phys. Rev. B-Condens. Matter Mater. Phys. 60, 3224 (1999)

H. Takebe, S. Pujino, K. Morinaga, J. Am. Ceram. Soc. 77, 2455 (1994)

B. Ferreira, E. Fargin, B. Guillaume, G. Le. Flem, V. Rodriguez, M. Couzi, T. Buffeteau, L. Canioni, L. Sarger, G. Martinelli, Y. Quiquempois, H. Zeghlache, L. Carpentier, J. Non. Cryst. Solids 332, 207 (2003)

N. Berka\"\ine, E. Orhan, O. Masson, P. Thomas, J. Junquera, Phys. Rev. B 83, 245205 (2011).

P.A. Thomas, J. Phys. C Solid State Phys. 21, 4611 (1988)

J.E. Stanworth, Nature 169, 581 (1952)

S. Sakida, S. Hayakawa, T. Yoko, J. Am. Ceram. Soc. 84, 836 (2001)

S. Sakida, S. Hayakawa, T. Yoko 42, 836 (2001)

G. W. Brady, 300, (1994).

Y. Li, W. Fan, S. Honggang, X. Cheng, P. Li, X. Zhao, J. Appl. Phys. 107, 93506 (2010)

J.P. Poley, Nature 174, 268 (1954)

N. Elkhoshkhany, S.Y. Marzouk, M.A. Khattab, S.A. Dessouki, Mater. Charact. 144, 274 (2018)

A.K. Yadav, P. Singh, RSC Adv. 5, 67583 (2015)

R. A. H. El-Mallawany, Tellurite Glasses Handbook: Physical Properties and Data (CRC press, 2011).

A.K. Yadav, P.A. Jha, P. Singh, J. Mater. Sci. Mater. Electron. 28, 7419 (2017)

R. Kumar, A.K. Bhatnagar, J. Alloys Compd. 623, 49 (2015)

S. Moufok, L. Kadi, B. Amrani, and K. D. Khodja, Results Phys. 13, 102315 (2019).

S. Ghosh and A. Ghosh, J. Chem. Phys. 126, (2007).

J.C. Champarnaud-Mesjard, S. Blanchandin, P. Thomas, A. Mirgorodsky, T. Merle-Méjean, B. Frit, J. Phys. Chem. Solids 61, 1499 (2000)

R.K. Ramamoorthy, A.K. Bhatnagar, J. Alloys Compd. 623, 49 (2015)

M. Ceriotti, F. Pietrucci, M. Bernasconi, (n.d.).

B.R. Sahu, L. Kleinman, Phys. Rev. B 69, 193101 (2004)

E. Menéndez-Proupin, G. Gutiérrez, E. Palmero, J.L. Peña, Phys. Rev. B 70, 35112 (2004)

M. Marple, M. Jesuit, I. Hung, Z. Gan, S. Feller, S. Sen, J. Non. Cryst. Solids 513, 183 (2019)

A.K. Yadav, P.A. Jha, S. Murugavel, P. Singh, Solid State Ionics 296, 54 (2016)

S. Hoseinzadeh, R. Ghasemiasl, A. Bahari, A.H. Ramezani, J. Mater. Sci. Mater. Electron. 28, 14446 (2017)

S. Hoseinzadeh, R. Ghasemiasl, A. Bahari, A.H. Ramezani, J. Mater. Sci. Mater. Electron. 28, 14855 (2017)

S. Hoseinzadeh, A.H. Ramezani, J Nanostruct 9, 276 (2019)

V. Rodriguez, M. Couzi, F. Adamietz, M. Dussauze, G. Guery, T. Cardinal, P. Veber, K. Richardson, P. Thomas, J. Raman Spectrosc. 44, 739 (2013)

M. N. Garaga, U. Werner-zwanziger, J. Wilson, A. Deceanne, B. Hauke, K. Bozer, S. Feller, (2017).

L. Červinka, J. Dusil, J. Non. Cryst. Solids 21, 125 (1976)

A. Gualtieri, GSAS Tutorials Examples 748, (2003).

I.C. Madsen, N.V.Y. Scarlett, A. Kern, Zeitschrift Fur Krist. 226, 944 (2011)

R. El-Mallawany, Mater. Chem. Phys. 53, 93 (1998)

Y. Wang, S. Dai, F. Chen, T. Xu, Q. Nie, Mater. Chem. Phys. 113, 407 (2009)

M. El-Hagary, M. Emam-Ismail, E.R. Shaaban, A. El-Taher, Radiat. Phys. Chem. 81, 1572 (2012)

A.S. Hassanien, A.A. Akl, Superlattices Microstruct. 89, 153 (2016)

F. Urbach, Phys. Rev. 92, 1324 (1953)

H. Rawson, Properties and Applications of Glass (Elsevier Science & Technology, 1980).

M. Vithal, P. Nachimuthu, T. Banu, R. Jagannathan, J. Appl. Phys. 81, 7922 (1997)

E.A. Davis, N.F. Mott, Philos. Mag. A J. Theor. Exp. Appl. Phys. 22, 903 (1970)

A. Jha, S. Shen, M. Naftaly, Phys. Rev. B Condens. Matter Mater. Phys. 62, 6215 (2000)

V. Dimitrov, S. Sakka, J. Appl. Phys. 79, 1736 (1996)

R. El-Mallawany, J. Appl. Phys. 72, 1774 (1992)

J.A. Duffy, J. Solid State Chem. 62, 145 (1986)

A.G. Kalampounias, G. Tsilomelekis, S. Boghosian, J. Chem. Phys. 142, 154503 (2015)

M. Ceriotti, F. Pietrucci, M. Bernasconi, Phys. Rev. B Condens. Matter Mater. Phys. 73, 1 (2006)

P. Charton, L. Gengembre, P. Armand, J. Solid State Chem. 168, 175 (2002)

Y. Himei, Y. Miura, T. Nanba, A. Osaka, J. Non. Cryst. Solids 211, 64 (1997)

R.A. El-Mallawany, Infrared Phys. 29, 781 (1989)

H. Mohamed-Kamari, H.M. Oo, W.M.D. Wan-Yusoff, Int. J. Mol. Sci. 13, 4623 (2012)

P. Singh, B.P. Singh, Raghvendra, Solid State Ion. 227, 39 (2012)

P. Thomas and K. Varma, J. Adv. Dielectr. 02, (2013).

R.N. Hampton, W. Hong, G. Saunders, R.A. Elmallawany, J. Non-Crystalline Solids J - Non-Cryst Solids 94, 307 (1987)

F. Kremer, A. Schönhals, Broadband Dielectric Spectroscopy (2003).

A.K. Yadav, P. Singh, J. Mater. Sci. Mater. Electron. 26, 9443 (2015)

R.A. El-Mallawany, L.M. Sharaf El-Deen, M.M. Elkholy, J. Mater. Sci. 31, 6339 (1996)

M. Prashant Kumar, T. Sankarappa, B. Vijaya Kumar, N. Nagaraja, Solid State Sci. 11, 214 (2009)

Acknowledgements

The authors gratefully acknowledge the CSIR, New Delhi, for project No. 03(1402)/17/EMR-II for financial support. We are thankful to DST-FIST (SR/FST/PSI-203/215(C)) for providing the departmental funding. One of the authors, VT, Acknowledges the support of Dr. Pradeep Kumar for his help in sample preparation. The authors are thankful to Dr. Saral Kr. Gupta, Banasthali Vidyapith for helping in Raman measurements. The authors are also thankful to the Central Instrumentation Facility Centre (CIFC) IIT (BHU), Varanasi, India.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tomar, V., Pandey, R. & Singh, P. Influence of quenching rate and quenching media on formation of TeO2 glasses. J Mater Sci: Mater Electron 32, 17726–17740 (2021). https://doi.org/10.1007/s10854-021-06309-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06309-3