Abstract

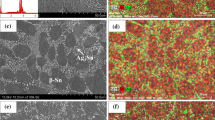

The effects of Ag on the microstructure of solder matrix and shear strength of solder joint were studied. The Sn–58Bi solder ribbons were prepared by rapid solidification. The eutectic structure (β-Sn + Bi) was significantly refined by adding 1.0 wt% Ag to the Sn–58Bi solder. The refinement mechanism was investigated with a differential scanning calorimetry. The result showed that the addition of Ag reduced the nucleation undercooling of structure, which promoted the nucleation. In addition, the metastable phase particles of Ag6.7Sn formed during rapid solidification were dispersed at the Bi phase boundary, which hindered the growth of Bi phase. With 1.0 wt% Ag, the shear strength of Sn–58Bi solder joint increased by 13.3%. The Bi phase was found to be reduced in size and passivated by adding Ag, and it resulted in more phase boundaries and hindered the crack propagation during the stretching process. Moreover, the second phase particles of Ag3Sn formed after brazing and remelting had dispersion strengthening effect. However, the addition of Ag did not change the fracture mode of rapidly solidified Sn–58Bi solder, which was still intergranular brittle fracture.

Similar content being viewed by others

References

T.L. Yang, J.Y. Wu, C.C. Li, S. Yang, C.R. Kao, J. Alloys Compd. 647, 681–685 (2015)

H.Y. Sun, Q. Li, Y.C. Chan, J. Mater. Sci. Mater. Electron. 25(10), 4380–4390 (2014)

Q. Zhang, H. Zou, Z.F. Zhang, J. Mater. Res. 25(2), 303–314 (2010)

L.Z. Yang, W. Zhou, Y. Ma, X.Z. Li, Y.H. Liang, W.Q. Cui, P. Wu, Mater. Sci. Eng. A 667, 368–375 (2016)

T.H. Chuang, H.F. Wu, J. Electron. Mater. 40(1), 71–77 (2011)

X. Chen, F. Xue, J. Zhou, Y. Yao, J. Alloys Compd. 633, 377–383 (2015)

T. Hu, Y. Li, Y.C. Chan, F. W, Microelectron. Reliab. 55(8), 1226–1233 (2015)

L. Yang, J. Dai, Y.C. Zhang, Y.F. Jing, J.G. Ge, H.X. Liu, J. Electron. Mater. 44(7), 2473–2478 (2015)

L. Yang, W. Zhou, Y. Liang, W. Cui, P. Wu, Mater. Sci. Eng. A 642, 7–15 (2015)

D. Ma, P. Wu, J. Alloys Compd. 671, 127–136 (2016)

Y. Ma, X. Li, W. Zhou, L. Yang, P. Wu, Mater. Des. 113, 264–272 (2017)

Y.G. Lee, J.G. Park, C.W. Lee, J.P. Jung, Met. Mater. Int. 17(1), 117–121 (2011)

K. Liang, X.Z. Tang, L.J. Yu, N. Wang, W.C. Hu, J. Alloys Compd. 509, 9836–9841 (2011)

D. Bhardwaj, H. Soda, A. Mclean, Mater. Charact. 61(9), 882–893 (2010)

J. Cai, G.C. Ma, Z. Liu, H.F. Zhang, A.M. Wang, Z.Q. Hu, Mater. Sci. Eng. A 456(1), 364–367 (2007)

C.L. Xu, H.Y. Wang, F. Qiu, Y.F. Yang, Q.C. Jiang, Mater. Sci. Eng. A 417(1), 275–280 (2006)

Z.M. Zhou, Y.P. Wang, J. Gao, M. Kolbe, Mater. Sci. Eng. A 398(1–2), 318–322 (2005)

R.M. Shalaby, J. Alloys Compd. 505(1), 113–117 (2010)

K. Shibuya, F. Kogiku, M. Yukumoto, S. Miyake, M. Ozawa, T. Kan, Mater. Sci. Eng. 98(4), 25–28 (1988)

W.R. Myung, M.K. Ko, Y. Kim, S.B. Jung, J. Mater. Sci. Mater. Electron. 26(11), 8707–8713 (2015)

Y. Li, Y.C. Chan, J. Alloys Compd. 645, 566–576 (2015)

B.L. Silva, V.C.E.D. Silva, A. Garcia, J.E. Spinelli, J. Electron. Mater. 46(3), 1754–1769 (2017)

A.A. El-Daly, W.M. Desoky, A.F. Saad, N.A. Mansor, N.A. Mansor, H.M. Abd-Elmoniem, H. Hashem, Mater. Des. 80, 152–162 (2015)

X.X. Tu, D.Q. Yi, J. Wu, B. Wang, J. Alloys Compd. 698, 317–328 (2017)

J. Shen, Y. Pu, H. Yin, D. Luo, J. Chen, J. Alloys Compd. 614, 63–70 (2014)

Z.Q. Cui, Metallography and Heat Treatment (China Machine Press, Beijing, 2000), pp. 178–206

D.S. Balint, V.S. Deshpande, Int. J. Plast. 24(12), 2149–2172 (2008)

X. Deng, N. Chawla, K.K. Chawla, M. Koopman, Acta. Mater. 52(14), 4291–4303 (2004)

Acknowledgements

The authors would like to express their thanks to the National Natural Science Foundation of China (Grant No. 51475345).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, S., Song, T., Xiong, W. et al. Effects of Ag on the microstructure and shear strength of rapidly solidified Sn–58Bi solder. J Mater Sci: Mater Electron 30, 6701–6707 (2019). https://doi.org/10.1007/s10854-019-00981-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00981-2