Abstract

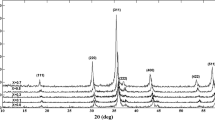

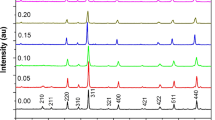

The mixed ferrite sample Ni0.5−xMgxCu0.2Cd0.3Fe2O4 (0.0 ≤ x ≤ 0.5, in the steps 0.1) has been synthesized employing sol–gel auto-combustion process. From XRD diffractograms, it has been observed the simple cubic spinel structure of the ferrite samples. With the substitution of Mg ion, both the experimental and theoretical lattice constant increased. For x = 0.0, the value of experimental lattice constant has been found 8.459 Å, which increases to a value 8.490 Å for x = 0.5. The surface morphology has been studied by FESEM images. Besides, the chemical composition and the elemental distribution of the sample have been revealed by EDS study. From the vibration band, the formation of spinel ferrite has been confirmed from the FT-IR spectra. It is seen that the samples exhibit ferrimagnetic behavior at room temperature, which has been shown by the magnetic measurement done by VSM. Dielectric constant, dielectric loss tangent, ac conductivity, and impedance Spectroscopy have been analyzed within the range 20 Hz–15 MHz. In the lower frequency region, a typical dielectric dispersion based on Maxwell–Wagner type interfacial polarization has been observed. Dielectric loss tangent exhibits an analogous sort of behavior as that of dielectric constant. The grain and grain boundary effect on electric properties have been studied from the complex impedance analysis. It has been seen that both the grain resistance and grain boundary resistance increase with the substitution of Mg2+ content. A rise in ac conductivity has been observed with the increase in frequency.

Similar content being viewed by others

References

P.K. Chakrabarti, B.K. Nath, S. Brahma, S. Das, K. Goswami, U. Kumar, P. Mukhopadhyay, D. Das, M. Ammar, F. Mazaleyrat, J. Phys.: Condens. Matter 18, 5253–5267 (2006). https://doi.org/10.1088/0953-8984/18/22/023

M.A. Rehman, M.A. Malik, M. Akram, K. Khan, A. Maqsood, Phys. Scr. 83, 015602 (2011). https://doi.org/10.1088/0031-8949/83/01/015602

H. Su, X. Tang, H. Zhang, L. Jia, Z. Zhong, J. Magn. Magn. Mater. 322(13), 1779–1783 (2010). https://doi.org/10.1016/j.jmmm.2009.12.029

K.M. Akther Hossain, T.S. Biswas, T. Yanagida, H. Tanaka, H. Tabata, T. Kawai, Mater. Chem. Phys. 120(2–3), 461–467 (2010). https://doi.org/10.1016/j.matchemphys.2009.11.040

Q. Xiwei, J. Zhou, Y. Zhenxing, G. Zhilun, L. Longtu, J. Magn. Magn. Mater. 251(3), 316–322 (2002). https://doi.org/10.1016/S0304-8853(02)00854-5

M.A. Gabal, J. Magn. Magn. Mater. 321(19), 3144–3148 (2009). https://doi.org/10.1016/j.jmmm.2009.05.047

A.H. Lu, E.L. Salabas, F. Schüth, Angew. Chem. Ger. Ed. 46, 1222–1244 (2007). https://doi.org/10.1002/anie.200602866

S.M. Peymani-Motlagh, A. Sobhani-Nasab, M. Rostami, H. Sobati, M. Eghbali-Arani, M. Fasihi-Ramandi, M.R. Ganjali, M. Rahimi-Nasrabadi, J. Mater. Sci. Mater. Electron. (2019). https://doi.org/10.1007/s10854-019-01005-9

H. Moradmard, S.F. Shayesteh, P. Tohidi, Z. Abbas, M. Khaleghi, J. Alloys Compd. 650, 116–122 (2015). https://doi.org/10.1016/j.jallcom.2015.07.269

R.M. Rosnan, Z. Othaman, R. Hussin, A.A. Ati, A. Samavati, S. Dabagh, S. Zare, Chin. Phys. B 25(4), 047501–047507 (2016). https://doi.org/10.1088/1674-1056/25/4/047501

P. Chavan, L.R. Naik, P.B. Belavi, G. Chavan, C.K. Ramesha, R.K. Kotnala, J. Electron. Mater. (2016). https://doi.org/10.1007/s11664-016-4886-6

B. Thangjam, I. Soibam, Int. J. Appl. Eng. Res. 12(23), 13201–13206 (2017)

S.M. Kabbur, U.R. Ghodake, R.C. Kambale, S.D. Sartale, L.P. Chikhale, S.S. Suryavanshi, J. Electron. Mater. 46(10), 5693–5704 (2017). https://doi.org/10.1007/s11664-017-5616-4

J. Smit, H.P.J. Wijn, Ferrites (Wiley, New York, 1959), p. 136

S. Mirzaee, S.F. Shayesteh, S. Mahdavifar, Polymer 55(16), 3713–3719 (2014). https://doi.org/10.1016/j.polymer.2014.06.039

A.V. Raut, R.S. Barkule, D.R. Shengule, K.M. Jadhav, J. Magn. Magn. Mater. 358–359, 87–92 (2014). https://doi.org/10.1016/j.jmmm.2014.01.039

K. Raju, G. Venkataiah, D.H. Yoon, Ceram. Int. 40(7A), 9337–9344 (2014). https://doi.org/10.1016/j.ceramint.2014.01.157

N. Rezlescu, E. Rezlescu, C. Pasnicu, M. Craus, J. Phys, Condens. Mater. 6, 5707–5716 (1994). https://doi.org/10.1088/0953-8984/6/29/013

A.R. Denton, N.W. Ashcroft, Phys. Rev. A 43(6), 3161 (1991). https://doi.org/10.1103/PhysRevA.43.3161

P. Roy, J. Bera, J. Magn. Magn. Mater. 298, 38–42 (2006). https://doi.org/10.1016/j.jmmm.2005.03.007

B.D. Cullity, The Elements of X-ray Diffraction (Addison-Wesley Pub. Co. Inc, London, 1956), p. 42

N.M. Deraz, A. Alarifi, J. Anal. Appl. Pyrolysis 94, 41–47 (2012). https://doi.org/10.1016/j.jaap.2011.10.004

S. Zare, A.A. Ati, S. Dabagh, R.M. Rosnan, Z. Othaman, J. Mol. Struct. 1089, 25–31 (2015). https://doi.org/10.1016/j.molstruc.2015.02.006

Y. Wada, S. Nishimatsu, Grain growth mechanism of heavily phosphorous implanted polycrystalline silicon. J. Electron. Soc. 125, 1499 (1978). https://doi.org/10.1016/j.jmmm.2016.08.035

M.Y. Lodhi, K. Mahmood, A. Mahmood, H. Malik, M.F. Warsi, I. Shakir, M. Asghar, M.A. Khan, Curr. Appl. Phys. 14, 716 (2014). https://doi.org/10.1016/j.cap.2014.02.021

W.B. White, W.A. De Angelis, Spectrochim. Acta Part A 23(4), 985 (1967). https://doi.org/10.1016/0584-8539(67)80023-0

C.G. Ramankutty, S. Sugunan, Appl. Catal. A: Gen. 218(1–2), 39–51 (2001). https://doi.org/10.1016/S0926-860X(01)00610-X

R.D. Waldron, Phys. Rev. 99(6), 1727 (1955). https://doi.org/10.1103/PhysRev.99.1727

M. Kaur, S. Rana, P.S. Tarsikka, Ceram. Int. 38(5), 4319–4323 (2012). https://doi.org/10.1016/j.ceramint.2012.02.013

Y. Cheng, Y. Zhao, Y. Zhang, X. Cao, J. Colloid Interface Sci. 344(2), 321 (2010). https://doi.org/10.1016/j.jcis.2009.12.044

P. Priyadharsini, A. Pradeep, P.S. Rao, G. Chandrasekaran, Mater. Chem. Phys. 116(1), 207–213 (2009). https://doi.org/10.1016/j.matchemphys.2009.03.011

O.M. Hemeda, M.Z. Said, M.M. Barakat, J. Magn. Magn. Mater. 224(2), 132 (2001). https://doi.org/10.1016/S0304-8853(00)00578-3

U.R. Ghodake, N.D. Chaudhari, R.C. Kambale, J.Y. Patil, S.S. Suryavanshi, J. Magn. Magn. Mater. 407, 60–68 (2016). https://doi.org/10.1016/j.jmmm.2016.01.022

A. Pradeep, P. Priyadharsini, G. Chandrasekaran, J. Magn. Magn. Mater. 320(21), 2774–2779 (2008). https://doi.org/10.1016/j.jmmm.2008.06.012

J. Smit, H.P.J. Wijn, Ferrites (Philips Technical Library, Eindhovan, 1959), p. 149

K. Maaz, W. Khalid, A. Mumtaz, S.K. Hasanain, J. Liu, J.L. Duan, Physica E 41, 593–599 (2009). https://doi.org/10.1016/j.physe.2008.10.009

S. Joshi, M. Kumar, S. Chhoker, A. Kumar, M. Singh, J. Magn. Magn. Mater. (2016). https://doi.org/10.1016/j.jmmm.2016.11.090

Z.C. Xu, J. Appl. Phys. 93(8), 4746–4749 (2003). https://doi.org/10.1063/1.1562745

S.K. Nath, K.H. Maria, S. Noor, S.S. Sikder, S.S. Hoque, M.A. Hakim, J. Magn. Magn. Mater. 324(13), 2116–2120 (2012). https://doi.org/10.1016/j.jmmm.2012.02.023

J.C. Maxwell, Electricity and Magnetism, vol. 328 (Oxford University Press, New York, 1954)

C.G. Koops, On the dispersion of resistivity and dielectric constant of some semiconductors at audio frequencies. Phys. Rev. 83(1), 121–124 (1951). https://doi.org/10.1103/PhysRev.83.121

A.A. Kadam, S.S. Shinde, S.P. Yadav, P.S. Patil, K.Y. Rajpure, J. Magn. Magn. Mater. 329, 59–64 (2013). https://doi.org/10.1016/j.jmmm.2012.10.008

I. Soibam, Int. J. Mater Sci. Eng. 4(1), 54–59 (2016). https://doi.org/10.17706/ijmse.2016.4.1.54-59

B. Thangjam, I. Soibam., J. Nanomat. Article ID 5756197, 1–10 (2017). https://doi.org/10.1155/2017/5756197

C. Sujatha, K.V. Reddy, K.S. Babu, A.R.C. Reddy, K.H. Rao, Physica B 407, 1232–1237 (2012). https://doi.org/10.1016/j.physb.2012.01.108

K.M. Batoo, M.S. Ansari, Nano Res. Lett. 7(1), 112 (2012). https://doi.org/10.1186/1556-276X-7-112

K.W. Wagner, Ann. Phys. 40, 817–819 (1973)

S. Joshi, M. Kumar, H. Pandey, M. Singh, P. Pal, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2018.07.250

M.P. Reddy, G. Balakrishnaiah, W. Madhuri, M.V. Ramana, N.R. Reddy, K.V. Siva Kumar, V.R.K. Murthy, R.R. Reddy, J. Phys. Chem. Solids 71(9), 1373–1380 (2010). https://doi.org/10.1016/j.jpcs.2010.06.007

M.J. Miah, A.K.M.A. Hossai, Acta Metall. Sin. Engl. Lett. 29(6), 505–517 (2016). https://doi.org/10.1007/s40195-016-0408-z

P.R. Arjunwadkar, R.R. Patil, J. Alloys Compd. 611, 273–277 (2014). https://doi.org/10.1016/j.jallcom.2014.05.054

R.C. Kambale, P.A. Shaikh, C.H. Bhosale, K.Y. Rajpure, Y.D. Kolekar, Smart Mater. Struct. 18(11), 115028 (2009). https://doi.org/10.1088/0964-1726/18/11/115028

M. Hashim, Alimuddin, S. Kumar, S. Ali, B.H. Koo, H. Chung, R. Kumar, J. Alloys Compd. 511(1), 107–114 (2012). https://doi.org/10.1016/j.jallcom.2011.08.096

I.G. Austin, N.F. Mott, Adv. Phys. 18(71), 41–102 (1969). https://doi.org/10.1080/00018736900101267

A. Vermaa, O.P. Thakur, C. Prakash, T.C. Goel, R.G. Mendiratta, Mater. Sci. Engi. B. 116, 1–6 (2005). https://doi.org/10.1016/j.mseb.2004.08.011

C.A. Hogarth, M.H. Islam, S.S.M.S. Rahman, J. Mater. Sci. 28, 518–528 (1993). https://doi.org/10.1007/bf00357833

H. Böttger, V.V. Bryksin, Hopping Conduction in Solids (Akademie-Verlag, Berlin, 1985)

A.N. Patil, M.G. Patil, K.K. Patankar, V.L. Mathe, R.P. Mahajan, S.A. Patil, Bull. Mater. Sci. 23(5), 447–452 (2000)

Acknowledgements

We are thankful for the continual support of Chittagong University of Engineering and Technology (CUET), Chittagong 4349, Bangladesh.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hossen, M.M., Hossen, M.B. Study of structural and electrical properties along with magnetic properties of Ni0.5−xMgxCu0.2Cd0.3Fe2O4 nanoferrites synthesized by employing sol–gel auto-combustion method. J Mater Sci: Mater Electron 30, 20801–20815 (2019). https://doi.org/10.1007/s10854-019-02447-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02447-x