Abstract

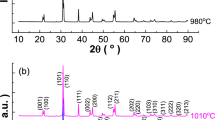

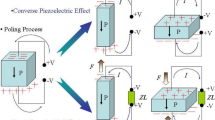

Bismuth titanate Bi4Ti3O12 (BIT) based lead-free piezoelectric ceramics with the formula Bi4Ti3-2xWxTaxO12 (abbreviated as BITWT-x, x = 0, 0.015, 0.03, 0.04, 0.045, 0.05) were fabricated by the conventional solid-state sintering method. The effect of W and Ta doping on the crystal structure and electrical properties of BITWT-x ceramics were investigated. BITWT-x ceramics had an orthogonal phase, and crystal structural distortion of W/Ta co-doped BITWT-x based ceramics was higher than that of BITWT-0 ceramics, which improved the ferroelectricity and the piezoelectric property. The ferroelectricity (Pr = 7.78 μC/cm2) of BITWT-0.03 ceramics was better than that (Pr = 0.84 μC/cm2) of BITWT-0 ceramics. The piezoelectric property (d33) was enhanced, and the highest d33 of BITWT-0.04 ceramics was 21.4 pC/N. Moreover, the d33 of the BITWT-x ceramics at 600 °C still kept 80% of its original d33 when the value of x was in the range of 0.03–0.045. Donor ions W6+ and Ta5+ reduced ionic conductivity (oxygen vacancies) and electron conductivity (holes), then increased the resistivity of BITWT-x ceramics (ρ400 °C = 1.82 × 108 Ω cm, x = 0.03). However, the enhanced effect reached a saturated state when x was 0.03. Thus, the BITWT-x ceramics were suitable for the high-temperature application.

Similar content being viewed by others

References

B. Jaffe, R.S. Roth, S. Marzullo, J. Appl. Phys. 25, 809 (1954)

T. Bove, W. Wolny, E. Ringgaard, A. Pedersen, J. Eur. Ceram. Soc. 21, 1469 (2001)

S. Zhang, F. Yu, J. Am. Ceram. Soc. 94, 3153 (2011)

R.E. Newnham, R.W. Wolfe, J.F. Dorrian, Mater. Res. Bull. 6, 1029 (1971)

E.C. Subbarao, J. Phys. Chem. Solids 23, 665 (1962)

E.C. Subbarao, Phys. Rev. B 122, 804 (1961)

R.L. Withers, J.G. Thompson, A.D. Rae, J. Solid, State Chem. 94, 404 (1991)

Y. Noguchi, M. Miyayama, Appl. Phys. Lett. 78, 1903 (2001)

Y. Kan, P. Wang, T. Xu, G. Zhang, D. Yan, J. Am. Ceram. Soc. 88, 1631 (2005)

T. Takenaka, K. Sakata, Jpn. J. Appl. Phys. 19, 31 (1980)

H.W. Shin, J.Y. Son, J. Mater. Sci.: Mater. Electron. 29, 2573 (2018)

T. Jardiel, A.C. Caballero, M. Villegas, J. Eur. Ceram. Soc. 27, 4115 (2007)

H.S. Shulman, M. Testorf, D. Damjanovic, N. Setter, J. Am. Ceram. Soc. 79, 3124 (1996)

J. Hou, R.V. Kumar, Y. Qu, D. Krsmsnovic, Scr Mater. 61, 664 (2009)

J. Hou, R.V. Kumar, Y. Qu, D. Krsmsnovic, J. Am. Ceram. Soc. 94, 2523 (2011)

H. Qi, Y. Qi, M. Xiao, J. Mater. Sci.: Mater. Electron. 25, 1325 (2014)

R. Ti, X. Lu, J. He, F. Huang, J. Mater. Chem. C 3, 11868 (2015)

F. Rehman, L. Wang, H. Jin, A. Bukhtiar, R. Zhang, Y. Zhao, J.B. Li, J. Am. Ceram. Soc. 100, 602 (2017)

R. Bokolia, M. Mondal, V.K. Rai, K. Sreenivas, J. Appl. Phys. 121, 5029 (2017)

X. Du, I.W. Chen, J. Am. Ceram. Soc. 81, 3260 (1998)

D.Y. Suárez, I.M. Reaney, W.E. Lee, J. Mater. Res. 16, 3139 (2001)

R.D. Shannon, Acta. Cryst. A32, 751 (1976)

S. Thathan, I. Mitsuru, J. Mater. Chem. 21, 10865 (2011)

J. Xing, Z. Tan, L. Xie, L. Jiang, J. Yuan, Q. Chen, J. Wu, W. Zhang, D. Xiao, J. Zhu, J. Am. Ceram. Soc. 101, 1632 (2018)

Shrinagar, A. Garg, R. Prasad, S. Auluck, Acta. Cryst. A64, 368 (2008)

Chen, Y. Zhi, L.E. Cross, Phys. Rev. B 62, 228 (2000)

S.E. Cummins, L.E. Cross, J. Appl. Phys. 39, 2268 (1968)

K.J. Min, Y. Kim, J.M. Sohn, S.I. Woo, J. Phys. D Appl. Phys. 37, 2588 (2004)

M. Osada, M. Tada, M. Kakihana, T. Watanabe, H. Funakubo, Jpn. J. Appl. Phys. 40, 5572 (2001)

Y. Yau, R. Palan, K. Tran, R.C. Buchanan, Appl. Phys. Lett. 85, 4714 (2004)

Zhu K., Zhang M. S., Deng Y., J. Zhou, Physica B 405, 1388 (2010)

J. Hou, Y. Qu, R. Vaish, K.B.R. Varma, D. Krsmanovic, R.V. Kumar, J. Am. Ceram. Soc. 93, 1414 (2010)

J. Zhang, Z. Pan, F.F. Guo, W.C. Liu, H. Ning, Y.B. Chen, M.H. Lu, B. Yang, J. Chen, S.T. Zhang, X. Xing, J. Rodel, W. Cao, Y.F. Chen, Nat. Commun. 6, 6615 (2015)

H. Yan, H. Zhang, M.J. Reece, X. Dong, Appl. Phys. Lett. 87, 082911 (2005)

Z. Zhou, X. Dong, H. Yan, H. Chen, C. Mao, J. Appl. Phys. 100, 044112 (2006)

Acknowledgement

This work was supported by the National Natural Science Foundation of China (No. 51332003) and Sichuan Science and Technology Program (2018G20140).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nie, R., Yuan, J. & Zhu, J. Influence of co-modification with tungsten and tantalum on the crystal structure and electrical properties of bismuth titanate ceramics. J Mater Sci: Mater Electron 30, 14445–14455 (2019). https://doi.org/10.1007/s10854-019-01814-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01814-y