Abstract

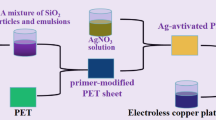

It is highly desired to simplify the technology of electroless plating on inert polymer. Herein we developed a new kind of catalytic solution (mixture of H2O, AgNO3 and 3-aminopropyltriethoxysilane), which can write onto inert polymer directly with good stability, resolution and catalytic performance. Then, a facile method combined with catalyst solution printing and electroless plating to fabricate selective metal (copper and nickel) coating on polymer (polypropylene and polyethylene terephthalate) surface. The growth behavior, electrical, and structural properties of plated coating were investigated. The minimum width of copper coating is 250 μm, thickness is 2.2 μm, resistivity is 2.6 × 10−6 Ω cm, adhesion of 2.2 μm thick coating maintain 5B. In addition, the selective metal coating have excellent bending and fatigue resistance.

Similar content being viewed by others

References

X. Zhao, F. Muench, S. Schaefer et al., Electroless decoration of macroscale foam with nickel nano-spikes: a scalable route toward efficient catalyst electrodes. Electrochem. Commun. 65, 39–43 (2016)

J.U. Yang, J.H. Cho, M.J. Yoo, Selective metallization on copper aluminate composite via laser direct structuring technology. Compos. Part B 110, 361–367 (2017)

X. Li, G. Wang, X. Wang et al., Flexible supercapacitor based on MnO2 nanoparticlesvia electrospinning. Mater. Chem. A 1(35), 10103–10106 (2013)

X. Sun, L. Zhang, S. Tao, S. Li, A general surface swelling-induced electroless deposition strategy for fast fabrication of copper circuits on various polymer substrates. Adv. Mater. Interfaces 4, 1700052 (2017)

T. Zhang, X. Wang, T. Li, Q. Guo, T. Yang, Fabrication of flexible copper-based electronics with high-resolution and high-conductivity on paper via inkjet printing. J. Mater. Chem. C 2(2), 286–294 (2014)

Y. Wang, Y. Wang, J.J. Chen et al., A facile process combined with inkjet printing, surface modification and electroless deposition to fabricate adhesion-enhanced copper patterns on flexible polymer substrates for functional flexible electronics. Electrochim. Acta 218, 24–31 (2016)

Y. Chang, Y. Tao, Q. Zhang, Z.G. Yang, Selective adsorption of catalyst and copper plating for additive fabrication of conductive patterns and through-holes. Electrochim. Acta 158, 7–12 (2015)

D. Chen, Y. Zhang, T. Bessho, Layer by layer electroless deposition: an efficient route for preparing adhesion-enhanced metallic coatings on plastic surfaces. Chem. Eng. J. 303, 100–108 (2016)

J.J. Huang, C.A. Tian, J. Wang et al., Fabrication of selective electroless copper plating on PET sheet: effect of PET surface structure on resolution and adhesion of copper coating. Appl. Surf. Sci. 458, 734–742 (2018)

Z.P. Sun, J.J. Huang, L.B. Wang et al., Method for electroless nickel plating on poly(ethylene terephthalate) substrate modified with primer and self-assembled monolayer. J. Mater. Sci. 26, 10132–10137 (2015)

J.J. Huang, Z.M. Chen, F. Zhou et al., High-adhesive electroless copper plating on polyethylene surface modified with primer. J. Solid State Electrochem. 21, 1559–1566 (2017)

A. Hashemi, A. Bahari, S. Ghasemi, Reduction the leakage current through povidone-SiO2 nano-composite as a promising gate dielectric of FETs. J. Mater. Sci. 28(18), 13313–13319 (2017)

L.X. Yi, J. Heitmann, R. Scholz, M. Zacharias, Si rings, Si clusters, and Si nanocrystals-different states of ultrathin SiOx, layers. Appl. Phys. Lett. 81(22), 4248–4250 (2002)

X. Wang, H. Hu, Y. Shen et al., Stretchable conductors with ultrahigh tensile strain and stable metallic conductance enabled by prestrained polyelectrolyte nanoplatforms. Adv. Mater. 23(27), 3090 (2011)

Z. Chen, X. Xu, C.C. Wong, S. Mhaisalkar, Effect of plating parameters on the intrinsic stress in electroless nickel plating. Surf. Coat Technol. 167(2–3), 170–176 (2003)

Y. Lu, S. Sathasivam, J. Song et al., Robust self-cleaning surfaces that function when exposed to either air or oil. Science 347(6226), 1132–1135 (2015)

M. Baloch, C.M. López, Effect of additives on the pulsed-galvanostatic electrodeposition of iron nanoparticles from formamide media. ChemElectroChem 3(6), 883–886 (2016)

Y.J. Yim, K.Y. Rhee, S.J. Park, Influence of electroless nickel-plating on fracture toughness of pitch-based carbon fibre reinforced composites. Compos. Part B 76, 286–291 (2015)

Acknowledgement

The authors thank the financial supports by the Research Foundation of Hefei University (No: 17ZR03ZDA), the State Key Laboratory of Rare Earth Permanent Magnetic Materials (No: SKLREPM17OF05) and the Opening project of Guangxi Key Laboratory of Calcium Carbonate Resources Comprehensive Utilization (HZXYKFKT201805).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qin, G., Zhang, Y., Yuan, M. et al. A facile method combined with catalyst solution printing and electroless plating to fabricate selective metal coating on inert polymer. J Mater Sci: Mater Electron 30, 9767–9774 (2019). https://doi.org/10.1007/s10854-019-01313-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01313-0