Abstract

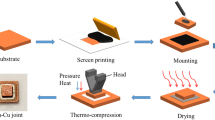

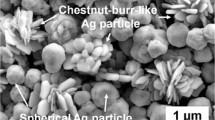

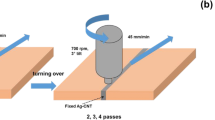

In order to obtain Ag nanoparticles (NPs) sintered Cu–Cu joints with better mechanical properties in a relative short time and under a suitable pressure, a laser sintering process and a novel paste prepared by mixed Ag NPs (19 and 62 nm in diameters) were utilized and studied. The results indicated that joints with low porosities were fabricated within 15 s’ laser irradiation. By increasing laser power and sintering time, shear strength of the joints increased obviously. Shear strength of joints with 30% (mass ratio) 62 nm NPs was the highest and could reach 32 MPa when the samples were sintered at 60 W for 15 s under 5 MPa. The enhanced mechanical properties of the joints could be attributed to small NPs that could fill pores between larger NPs and improve initial packing density of the mixed particles. The results indicated that the mixed pastes had excellent potentials as alternative die-attach materials for high temperature power device applications.

Similar content being viewed by others

References

J.Y. Lee, X. Lu, Q. Lin, Appl. Phys. Lett. 106, 104 (2015)

M. Willander, M. Friesel, Q.U. Wahab, B. Straumal, J. Mater. Sci. Mater. Electron. 17, 1 (2006)

Z. Huang, Y. Zhang, B. Zhao, F. Yang, J. Jiang, G. Deng, B. Li, H. Liang, Y. Chang, J. Song, J. Mater. Sci. Mater. Electron. 27, 1738 (2016)

S. Pareek, M. Sharma, S. Lal, J.K. Quamara, J. Mater. Sci. Mater. Electron. 29, 13043 (2018)

Z. Wang, W. Liu, C. Wang, J. Electron. Mater. 45, 267 (2016)

S. Wang, Y. Tian, C. Wang, C. Hang, J. Electrochem. Soc. 165, D328 (2018)

S. Wang, Y. Tian, C. Hang, C. Wang, Sci. Rep. 8, 5260 (2018)

D.-Y. Shin, Y. Lee, C.H. Kim, Thin Solid Films 517, 6112 (2009)

W. Guo, Z. Zeng, X. Zhang, P. Peng, S. Tang, J. Nanomater. 2015, (2015)

R. Khazaka, L. Mendizabal, D. Henry, J. Electron. Mater. 43, 2459 (2014)

Y. Lee, J.R. Choi, K.J. Lee, N.E. Stott, D. Kim, Nanotechnology 19, (2008)

Y. Zuo, J. Shen, H. Xu, R. Gao, Mater. Lett. 199, 13 (2017)

X. Liu, Z. Zheng, C. Wang, W. Liu, R. An, W. Zhang, J. Mater. Sci. Mater. Electron. 28, 8206 (2017)

X. Liu, C. Wang, W. Liu, Z. Zheng, M. Li, J. Mater. Sci. Mater. Electron. 28, 5446 (2017)

Y. Tian, Z. Jiang, C. Wang, S. Ding, J. Wen, Z. Liu, C. Wang, RSC Adv. 6, 91783 (2016)

S.J. Kim, E.A. Stach, C.A. Handwerker, Appl. Phys. Lett. 96, (2010)

E. Ide, S. Angata, A. Hirose, K.F. Kobayashi, Acta Mater. 53, 2385 (2005). (review 23)

T.G. Lei, J.N. Calata, G. Lu, X. Chen, S. Luo, Integr. Power Syst. 33, 98. (CIPS), 2008 5th International Conference (2010)

M. Knoerr, A. Schletz, 6th International Conference Integrated Power Electronics System (CIPS’2010), March 16–18, 2010, Nurnberg, Ger. 16 (2010)

L.A. Navarro, X. Perpiña, M. Vellvehi, X. Jordà, Ing. Mecãnica Tecnol. y Desarro. 4, 97 (2012)

J. Yan, G. Zou, A.P. Wu, J. Ren, J. Yan, A. Hu, Y. Zhou, Scr. Mater. 66, 582 (2012)

S. Fernandez-Robledo, J. Nekarda, A. Büchler, Sol. Energy Mater. Sol. Cells 161, 397–406 (2017)

N. Yang, S. Li, X. Yuan, C. Liu, X. Ye, G. Liu, H. Li, J. Mater. Sci. Mater. Electron. 29, 8210 (2018)

M. Li, Y. Xiao, Z. Zhang, J. Yu, ACS Appl. Mater. Interfaces 7, 9157 (2015)

N. Nishioka, S. Hamabe, T. Murakami, T. Kitagawa, J. Appl. Polym. Sci. 69, 2133 (1998)

X. Liu, W. Liu, C. Wang, Z. Zheng, J. Mater. Sci. Mater. Electron. 45, 5436 (2016)

X. Chen, R. Li, K. Qi, G.-Q. Lu, J. Electron. Mater. 37, 1574 (2008)

G. Zou, J. Yan, F. Mu, A. Wu, J. Ren, A. Hu, Open Surf. Sci. J. 3, 70 (2010)

Y.Y. Dai, M.Z. Ng, P. Anantha, Y.D. Lin, Z.G. Li, C.L. Gan, C.S. Tan, Appl. Phys. Lett. 108, 263103 (2016)

A. Wonisch, T. Kraft, M. Moseler, H. Riedel, J. Am. Ceram. Soc. 92, 1428 (2009)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51375003 and 51505104).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, W., Wang, Y., Zheng, Z. et al. Laser sintering mechanism and shear performance of Cu–Ag–Cu joints with mixed bimodal size Ag nanoparticles. J Mater Sci: Mater Electron 30, 7787–7793 (2019). https://doi.org/10.1007/s10854-019-01094-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01094-6