Abstract

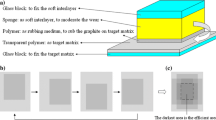

In this research, we developed a simple direct friction method to fabricate transparent conductive films. It is a highly efficient technology as the progress consumes only several minutes from raw materials to final products and the adhesion between matrix and functional layer is strong. Flexible transparent conductive films (TCFs) based on graphite and polyethylene terephthalate substrates exhibited satisfied properties with surface resistivity from 5.07 to 83.6 KΩ sq−1, optical transparency from 70 to 85% at 550 nm wavelength, and surface stability strong enough to protect them from aging under destructive surface treatments and bending. The main mechanisms are based on three key factors: (1) The lubrication property of two dimensional layered graphite, (2) Suitable wear properties of target transparent polymer matrix and rubbing medium, (3) A soft interlayer between glass block and rubbing medium. Furthermore, the samples show some potential applications such as flexible transparent heaters, flexible transparent humidity sensors and flexible transparent strain sensors. This technology has great potential to meet the requirements of transparent conductive electrodes for future optoelectronics: lightweight, flexible, economic, and especially compatible with large-scale manufacture. This method and the TCFs have some economical, environmental and energy saving advantages.

Similar content being viewed by others

References

M. Ruoho, T. Juntunen, T. Alasaarela, M. Pudas, I. Tittonen, Adv. Mater. Technol. 1, 1600204 (2016)

Y. Zhou, M. Layani, F.Y.C. Boey, I. Sokolov, S. Magdassi, Y. Long, Adv. Mater. Technol. 1, 1600069 (2016)

O.S. Elsherif, G.E.A. Muftah, O. Abubaker, I.M. Dharmadasa, J. Mater. Sci. 27, 12280 (2016)

F. Bella, A. Lamberti, S. Bianco, E. Tresso, C. Gerbaldi, C. F. Pirri, Adv. Mater. Technol. 1, 1600002 (2016)

S. Bykkam, K.V. Rao, R.N. Kumar, C.S. Chakra, T. Dayakar, J. Mater. Sci. 27, 12574 (2016)

S. Yang, E. Ng, N. Lu, Extreme Mech. Lett. 2, 37 (2015)

S. Jun, B. Ju, J. Kim, Adv. Mater. Technol. 1, 1600062 (2016)

C. Bianchi, J. Loureiro, P. Duarte, J. Marques, J. Figueira, I. Ropio, I. Ferreira, Adv. Mater. Technol. 1, 1600077 (2016)

Q. Nian, M. Saei, Y. Hu, B. Deng, S. Jin, G.J. Cheng, Extreme Mech. Lett. 9, 531 (2016)

J. Young, M. Yang, Adv. Mater. Technol. 1, 1600029 (2016)

D.V.R. Kumar, K. Woo, J. Moon, Nanoscale 7, 17195 (2015)

K. Ellmer, Nat. Photon. 6, 809 (2012)

P. Paletti, R. Pawar, G. Ulisse, F. Brunetti, G. Iannaccone, G. Fiori, 2D Mater. 2, 045006 (2015)

M. Itkis, A. Peller, X. Tian, E. Bekyarova, R. Haddon, Acc. Chem. Res. 48, 2270 (2015)

J. Du, S. Pei, L. Ma, H. Cheng, Adv. Mater. 26, 1958 (2014)

Y. Zhang, Z. Li, H. Li, J. Gao, J. Zhang, Y. Zeng, J. Mater. Sci. 25, 2692 (2014)

Y. Zhong, Z. Tian, G.P. Simon, D. Li, Mater. Today 18, 73 (2015)

J.N. Coleman, Acc. Chem. Res. 46, 14 (2013)

Q. Zheng, Z. Li, J. Yang, J. Kim, Prog. Mater. Sci. 64, 200 (2014)

S. Bae, S. Kim, D. Shin, J. Ahn, B. Hong, Phys. Scr. T146, 014024 (2012)

T.H. Bointon, G.F. Jones, A. De Sanctis, R. Hill-Pearce, M.F. Craciun, S. Russo, Sci. Rep. 5, 16464 (2015)

Y. Yu, S. Jiang, W. Zhou, X. Miao, Y. Zeng, G. Zhang, J. He, J. Yi, W. Liu, Appl. Phys. Lett. 103, 011601 (2013)

Y. Yu, S. Jiang, W. Zhou, X. Miao, Y. Zeng, G. Zhang, S. Liu, Sci. Rep. 3, 2697 (2013)

S. Jiang, Y. Zeng, W. Zhou, X. Miao, Y. Yu, Sci. Rep. 6, 19313 (2016)

L. Li, T. Zhang, Y. Liu, C. Zhu, J. Mater. Sci. 27, 3193 (2016)

Z. Li, H. Xie, D. Jun, Y. Wang, X. Wang, J. Li, J. Mater. Sci. 26, 6532 (2015)

W. Kim, S. Lee, D. Lee, I. Park, J. Bae, T. Lee, J. Kim, J. Park, Y. Cho, C. Cho, Sci. Rep. 5, 10715 (2015)

M.M. Menamparambath, A.C. Muhammed, K.K. Hee, Y. Daejin, R. Jongwook, P.H. Cheol, K. Chan, C. Jae-Young, B. Seunghyun, Sci. Rep. 5, 16371 (2015)

L. Jiang, X. Lu, X. Zheng, J. Mater. Sci. 25, 174 (2014)

M. Mohl, A. Dombovari, R. Vajtai, P. Ajayan, K. Kordas, Sci. Rep. 5, 13710 (2015)

D. Kim, H. Kim, K. Seo, K. Kim, T. Kim, H. Kim, Sci. Rep. 5, 16838 (2015)

S. Bae, H. Kim, Y. Lee, X. Xu, J. Park, Y. Zheng, J. Balakrishnan, T. Lei, H. Kim, Y. Song, Y. Kim, K. Kim, B. Ozyilmaz, J. Ahn, B. Hong, S. Iijima, Nat. Nanotechnol. 5, 579 (2010)

J.K. Wassei, R.B. Kaner, Mater. Today 13, 52 (2010)

Y. Yu, S. Jiang, G. Zhang, W. Zhou, X. Miao, Y. Zeng, J. Wang, J. He, L. Zhang, Appl. Phys. Lett. 101, 073113 (2012)

Y. Yu, S. Jiang, W. Zhou, X. Miao, Y. Zeng, G. Zhang, Y. Zhang, Q. Zhang, H. Zhao, Appl. Phys. Lett. 101, 023119 (2012)

M. Segev-Bar, N. Bachar, Y. Wolf, B. Ukrainsky, L. Sarraf, H. Haick, Adv. Mater. Technol. 1, 1600206 (2016)

A.S. Pawbake, R.G. Waykar, D.J. Late, S.R. Jadkar, ACS Appl. Mater. Interfaces 8, 3359 (2016)

J.M. Nassar, M.D. Cordero, A.T. Kutbee, M.A. Karimi, G.A.T. Sevilla, A.M. Hussain, A. Shamim, M.M. Hussain, Adv. Mater. Technol. 1, 1600004 (2016)

Y. Yu, L. Ye, Y. Song, Y. Guan, J. Zang, Extreme Mech. Lett. 11, 128 (2017)

Y. Wang, C. Shen, W. Lou, F. Shentu, C. Zhong, X. Dong, L. Tong, Appl. Phys. Lett. 109, 031107 (2016)

Acknowledgements

We acknowledge Analytical and Testing Center of Wuhan University of Technology, for testing our samples.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yu, Q., Li, W. Highly efficient direct friction method for flexible transparent electronic devices based on graphite films featured with economical, environmental and energy saving advantages. J Mater Sci: Mater Electron 28, 10758–10764 (2017). https://doi.org/10.1007/s10854-017-6852-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6852-3