Abstract

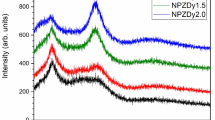

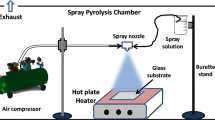

Cerium activated yttrium aluminium garnet (Y3Al5O12; YAG) powder was synthesized by co-precipitation method using aluminium nitrate, yttrium nitrate and cerium nitrate as starting materials and ammonium carbonate as precipitant. The concentration of cerium (Ce) was varied from 0.02 to 0.1 mol. The precursor of Ce doped YAG was calcined at 1250 °C for 1–12 h for achieving different morphology of particles. X-ray diffraction analysis was carried out to confirm the formation of YAG phase. Electrophoretic deposition was used for uniform coating of synthesized YAG:Ce powder on glass substrate. The deposition time was varied from 1 to 9 min for achieving different thickness of coating. Photoluminescence property of coating was investigated as a function of dopant concentration, particle morphology and coating thickness. The excitation wavelength used in this investigation was 430 nm. YAG:Ce showed peak emission at ~530 nm. The maximum emission intensity was achieved at Ce content of 0.04 mol in YAG with spherical morphology of particles having 300 nm particle size and 11 μm coating thickness.

Similar content being viewed by others

References

W.-H. Chao, R.-J. Wu, T.-B. Wu, J. Alloys Compd. 506, 98 (2010)

S.-H. Yang, C.-Y. Lu, J. Electrochem. Soc. 154, J397 (2007)

Y. Zorenko, T. Voznyak, V.V. Gorbenko, A. Doroshenko, A. Tolmachev, R. Yavetskiy, I. Petrusha, V. Turkevich, Opt. Mater. 35, 2049 (2013)

I. Kandarakis, D. Cavouras, I. Sianoudis, D. Nikolopoulos, A. Episkopakis, D. Linardatos, D. Margetis, E. Nirgianaki, M. Roussou, P. Melissaropoulos, N. Kalivas, I. Kalatzis, K. Kourkoutas, N. Dimitropoulos, A. Louizi, C. Nomicos, G. Panayiotakis, Nucl. Instrum. Methods Phys. Res. A 538, 615 (2005)

K. Renuka, F. Becker, W. Ensinger, P. Forck, R. Haseitl, B. Walasek-Höhne, IEEE Trans. Nucl. Sci. 59, 2301 (2012)

L. Pidol, B. Viana, A. Kahn-Harari, A. Galtayries, A. Bessière, P. Dorenbos, J. Appl. Phys. 95, 7731 (2004)

B. Walasek-Höhne, C. Andre, P. Forck, E. Gütlich, G. Kube, P. Lecoq, A. Reiter, IEEE Trans. Nucl. Sci. 59, 2307 (2012)

L.T. Su, A.I.Y. Tok, F.Y.C. Boey, X.H. Zhang, J.L. Woodhead, C.J. Summers, J. Appl. Phys. 102, 083541 (2007)

Y. Matsui, H. Horikawa, M. Iwasaki, W. Park, J. Ceram. Process. Res. 12, 348 (2011)

Z. Shusheng, Z. Weidong, H. Tao, L. Yauanhong, L. Ronghui, G. Wengui, H. Yaunsheng, L. Zhen, J. Rare Earths 28, 713 (2010)

Y. Zhour, J. Lin, M. Yu, S. Wang, H. Zhang, Mater. Lett. 56, 628 (2002)

Y. Pan, M. Wu, Q. Su, Mater. Sci. Eng. B 106, 251 (2004)

L. Wang, F. Zhao, J. Zhuang, C. Pan, H. Huang, Mater. Lett. 120, 163 (2014)

C.C. Chiang, M.S. Tsai, C.S. Hsiao, M.H. Hon, J. Alloys Compd. 416, 265 (2006)

M. Zeng, Y. Ma, Y. Wang, C. Pei, Ceram. Int. 38, 6951 (2012)

K. Zhang, He-Z Liu, Ya-T Wu, Wen-B Hu, J. Alloys Compd. 453, 265 (2008)

H. Yucai, L.Ü. Yimin, Y.U. Xuehua, Z. Li, Y. Junsheng, J. Rare Earths 28, 303 (2010)

F. Yuan, H. Ryu, Mater. Sci. Eng. B 107, 14 (2004)

Y. Li, M. Rui, Almeida Opt. Mater. 34, 1148 (2012)

Jun-H Yum, Seok-S Kim, Yung-E Sung, Colloids Surf. A Physicochem. Eng. Asp. 251, 203 (2004)

Jun-h Yum, Soo-Y Seo, S. Lee, Yung-E Sung, J. Electrochem. Soc. 150, H47 (2003)

I. Corni, M.P. Ryan, A.R. Boccaccini, J. Eur. Ceram. Soc. 28, 1353 (2008)

J.I. Choi, M. Anc, M. Anc, A. Piquette, M.E. Hannah, K.C. Mishra, J. Mc Kittrick, J.B. Talbot, J. Solid State Sci. Technol. 2, R153 (2013)

B.E. Russ, J.B. Talbot, J. Electrochem. Soc. 145, 1245 (1998)

Wen-R Chen, Jau-A Bai, Chien-J Huang, Teen-H Meen, Ferroelectrics 420, 95 (2011)

Ho-J Byun, Woo-S Song, Yong-S Kim, H. Yang, J. Phys. D Appl. Phys. 43, 195401 (2010)

J.A. Mares, M. Nikl, A. Beitlerova, C. D´Ambrosio, F. de Notaristefani, K. Blazek, P. Maly, K. Nejezchleb, Opt. Mater. 24, 281 (2003)

Acknowledgments

The authors are grateful to Dr. Maqsood Ahmad (LINAC) for the financial support for this R & D work. The authors acknowledge with thanks the help provided by Mr. Liaqat (O-Labs) for photoluminescence spectrometry and Dr. Ahmad Nawaz Khan (SCME, NUST) for profilometric measurement. Last but not the least, thanks are due to the staff of Powder Processing Group for their efforts and cooperation in carrying out this work.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asghar, Z., Zahid, G.H., Ahmad, E. et al. Effect of particle morphology and coating thickness on fluorescent behavior of Ce doped yttrium aluminium garnet phosphor screens. J Mater Sci: Mater Electron 26, 6744–6749 (2015). https://doi.org/10.1007/s10854-015-3279-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3279-6