Abstract

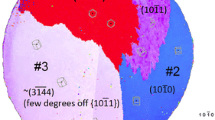

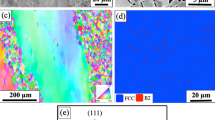

Shock compression and spallation damage of a dual-phase polycrystalline cobalt material is investigated via plate impact experiments along with free-surface velocity measurements. The as-received and postmortem samples are characterized with X-ray diffraction measurement and electron back-scatter diffraction. Free-surface velocity histories, the Hugoniot equation of state and spall strength at different peak shock stress are determined. Multiple deformation mechanisms are found. Except for the dislocation slip in both phase, \(\{10{\bar{1}}2\}\) and \(\{11{\bar{2}}1\}\) deformation twinning in the hexagonal close-packed (HCP) phase, and the face-center cubic (FCC) to HCP phase transition are also observed. The \(\{10{\bar{1}}2\}\) twin density at the impact surface increases with increasing shock stress, but is less than twin density at the spall plane for the same shot. Ductile fracture is the main damage mode, and voids are nucleated preferentially within the HCP phase because of the strain localization. The Johnson–Cook constitutive model can describe the dynamic responses of the dual-phase Co. With this model, finite element modeling is consistent with the shock compression part of experimental observations well.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Weißensteiner I, Petersmann M, Erdely P, Stark A, Antretter T, Clemens H, Maier-Kiener V (2019) Deformation-induced phase transformation in a Co-Cr-W-Mo alloy studied by high-energy X-ray diffraction during in-situ compression tests. Acta Mater 164:272–282

Wang B, An X, Huang Z, Song M, Ni S, Liu S (2019) Nitrogen doped Co-Cr-Mo-W based alloys fabricated by selective laser melting with enhanced strength and good ductility. J Alloy Compd 785:305–311

Barreca D, Massignan C, Daolio S, Fabrizio M, Piccirillo C, Armelao L, Tondello E (2001) Composition and microstructure of cobalt oxide thin films obtained from a novel cobalt (II) precursor by chemical vapor deposition. Chem Mater 13(2):588–593

Srivastava M, Selvi VE, Grips VW, Rajam K (2006) Corrosion resistance and microstructure of electrodeposited nickel-cobalt alloy coatings. Surf Coat Technol 201(6):3051–3060

Sing SL, Huang S, Yeong WY (2020) Effect of solution heat treatment on microstructure and mechanical properties of laser powder bed fusion produced cobalt-28chromium-6molybdenum. Mater Sci Eng A 769:138511

Benson M, Reetz B, Liaw P, Reimers W, Choo H, Brown D, Saleh T, Klarstrom D (2011) Phase-transformation and subgrain-deformation characteristics in a cobalt-based superalloy. Mater Sci Eng A 528(4–5):1987–1993

Tolédano P, Krexner G, Prem M, Weber H-P, Dmitriev V (2001) Theory of the martensitic transformation in cobalt. Phys Rev B 64(14):144104

Jiang M, Oikawa K, Ikeshoji T (2005) Molecular-dynamic simulations of martensitic transformation of cobalt. Metall Mater Trans A 36:2307–2314

Lee SB, Kim D-I, Kim Y, Yoo SJ, Byun JY, Han HN, Lee DN (2015) Effects of film stress and geometry on texture evolution before and after the martensitic transformation in a nanocrystalline Co thin film. Metall Mater Trans A 46:1888–1899

Hu Q-M, Yang R (2013) Basal-plane stacking fault energy of hexagonal close-packed metals based on the Ising model. Acta Mater 61(4):1136–1145

An X, Li Y, Ni S, Wang Z, Song M (2020) Grain refinement process in a cold-rolled polycrystalline cobalt. Mater Charact 164:110360

Zheng G (2010) Molecular dynamics and first-principles studies on the deformation mechanisms of nanostructured cobalt. J Alloy Compd 504:S467–S471

Qi Y, Luo Z, Li X, Lu K (2022) Transition of deformation mechanisms from twinning to dislocation slip in nanograined pure cobalt. J Mater Sci Technol 121:124–129

Martinez M, Fleurier G, Chmelík F, Knapek M, Viguier B, Hug E (2017) Tem analysis of the deformation microstructure of polycrystalline cobalt plastically strained in tension. Mater Charact 134:76–83

Liu W, An X, Jiang W, Ni S, Song M (2021) Microstructural evolution of a polycrystalline cobalt during tensile deformation. Mater Sci Eng A 826:141970

Kappacher J, Tkadletz M, Clemens H, Maier-Kiener V (2021) High temperature nanoindentation as a tool to investigate plasticity upon phase transformations demonstrated on cobalt. Materialia 16:101084

Martinez M, Hug E (2019) Characterization of deformation twinning in polycrystalline cobalt: a quantitative analysis. Materialia 7:100420

Martinez Celis M, Minárik P, Hug E, Dorenlor J, Chmelík F, Knapek M, Dobroň P (2021) Analysis of the twin variant selection in polycrystalline cobalt. J Mater Sci 56:7740–7752. https://doi.org/10.1007/s10853-020-05718-9

Liu W, An X, Jiang W, Ni S, Song M (2023) The effects of strain rate and strain on the deformation-induced grain refinement process and hardness evolution of a polycrystalline cobalt. J Alloy Compd 944:169193

Zhang X, Zhu Y, Liu Q (2010) Deformation twinning in polycrystalline Co during room temperature dynamic plastic deformation. Scripta Mater 63(4):387–390

Betteridge W (1980) The properties of metallic cobalt. Prog Mater Sci 24:51–142

Dubos P-A, Fajoui J, Girault B, Gloaguen D (2023) Influence of plastic anisotropy and strain path on strain-induced phase transformation of cobalt. Met Mater Int 1–12

Knapek M, Minárik P, Dobroň P, Šmilauerová J, Celis MM, Hug E, Chmelík F (2020) The effect of different thermal treatment on the allotropic FCC-HCP transformation and compression behavior of polycrystalline cobalt. Materials 13(24):5775

Iskounen N, Dubos P-A, Fajoui J, Coret M, Moya M-J, Girault B, Barrier N, Bruzy N, Hug E, Gloaguen D (2021) Experimental investigation of allotropic transformation of cobalt: influence of temperature cycle, mechanical loading and starting microstructure. Metall Mater Trans A 52:1477–1491

Song K, Li Z, Fang M, Xiao Z, Zhu Y, Lei Q (2022) Recrystallization behavior and phase transformation in a hot-rolled pure cobalt during annealing at the elevated temperature. Mater Sci Eng A 845:143178

Wang W, Yuan F, Jiang P, Wu X (2017) Size effects of lamellar twins on the strength and deformation mechanisms of nanocrystalline hcp cobalt. Sci Rep 7(1):9550

Wang W, Jiang P, Yuan F, Wu X (2018) Size effects of nano-spaced basal stacking faults on the strength and deformation mechanisms of nanocrystalline pure hcp metals. Phil Mag 98(13):1186–1203

Zhu Y, Li Z, Xiao Z, Qiu W, Fang M, Chen Z (2020) Effect of accumulative roll-bonding process on phase transformation and magnetic properties of polycrystalline cobalt. Mater Charact 163:110290

Marsh SP (1980) LASL shock Hugoniot data, vol 5. Univ of California Press, Berkeley

Zaretsky E (2010) Impact response of cobalt over the 300–1400 K temperature range. J Appl Phys 108(8):083525

Baumung K, Bluhm H, Kanel GI, Müller G, Razorenov SV, Singer J, Utkin AV (2001) Tensile strength of five metals and alloys in the nanosecond load duration range at normal and elevated temperatures. Int J Impact Eng 25(7):631–639

Razorenov S, Kanel’ G, Kramshonkov E, Baumung K (2002) Shock compression and spalling of cobalt at normal and elevated temperatures. Combust Explos Shock 38:598–601

Brown JM, McQueen RG (1986) Phase transitions, Grüneisen parameter, and elasticity for shocked iron between 77 GPa and 400 GPa. J Geophys Res-Solid Earth 91(B7):7485–7494

Strand OT, Goosman D, Martinez C, Whitworth T, Kuhlow W (2006) Compact system for high-speed velocimetry using heterodyne techniques. Rev Sci Instrum 77(8):083108

Bourne N, Gray G (2005) Computational design of recovery experiments for ductile metals. Proc R Soc A 461(2062):3297–3312

Vignjevic R, Hughes K, De Vuyst T, Djordjevic N, Campbell JC, Stojkovic M, Gulavani O, Hiermaier S (2015) Lagrangian analysis led design of a shock recovery plate impact experiment. Int J Impact Eng 77:16–29

Zhang NB, Xu J, Feng ZD, Sun Y, Huang JY, Zhao XJ, Yao XH, Chen S, Lu L, Luo SN (2022) Shock compression and spallation damage of high-entropy alloy \({{\text{Al}}_{0.1}}{\text{CoCrFeNi}}\). J Mater Sci Technol 128:1–9

Zhao SP, Feng ZD, Li LX, Zhao XJ, Lu L, Chen S, Zhang NB, Cai Y, Luo SN (2023) Dynamic mechanical properties, deformation and damage mechanisms of eutectic high-entropy alloy \({{\text{Al}}_{0.1}}{\text{CoCrFeNi}}\) under plate impact. J Mater Sci Technol 134:178–188

Yoo C-S, Söderlind P, Cynn H (1998) The phase diagram of cobalt at high pressure and temperature: the stability of-cobalt and new-cobalt. J Phys Condens Mater 10(20):L311

Nishiyama Z (2012) Martensitic transformation. Elsevier, New York

Sinha S, Nene SS, Frank M, Liu K, Agrawal P, Mishra RS (2019) On the evolving nature of c/a ratio in a hexagonal close-packed epsilon martensite phase in transformative high entropy alloys. Sci Rep 9(1):1–14

Zhu Y, Zhang X, Liu Q (2011) Observation of twins in polycrystalline cobalt containing face-center-cubic and hexagonal-close-packed phases. Mater Sci Eng A 528(28):8145–8149

Niu P, Li R, Fan Z, Yuan T, Zhang Z (2021) Additive manufacturing of trip-assisted dual-phases \({\rm Fe_{50}Mn_{30}Co_{10}Cr_{10}}\) high-entropy alloy: Microstructure evolution, mechanical properties and deformation mechanisms. Mater Sci Eng A 814:141264

Zhang NB, Zhang C, Li B, Sun Y, Chen L, Cai Y, Zhao X, Tang Y, Lu L, Luo SN (2023) Impact response of metastable dual-phase high-entropy alloy Cr10Mn30Fe50Co10. J Alloy Compd 965:171341

Tu J, Zhang S, Zhou Z, Tang H (2016) Structural characterization of a special boundary between \(\alpha\) plates after martensitic transformation in cobalt. Mater Charact 112:219–223

Mitchell A, Nellis W (1981) Shock compression of aluminum, copper, and tantalum. J Appl Phys 52(5):3363–3374

Luo S, Cai Y, Xu J, Shock physics: Hugoniot and spall data

Zhang NB, Liu Q, Yang K, Li C, Cai Y, Luo SN, Yao XH, Chen S (2022) Effects of shock-induced phase transition on spallation of a mild carbon steel. Int J Mech Sci 213:106858

Antoun T, Curran DR, Seaman L, Kanel GI, Razorenov SV, Utkin AV (2003) Spall fracture. Springer Science & Business Media, New York

Kanel GI (2010) Spall fracture: methodological aspects, mechanisms and governing factors. Int J Fract 163(1–2):173–191

Stepanov G (1976) Spall fracture of metals by elastic-plastic loading waves. Prob Strength (USSR) 8:66–70

Cai Y, Wu HA, Luo SN (2017) Spall strength of liquid copper and accuracy of the acoustic method. J Appl Phys 121(10):105901

Kanel GI, Utkin AV (1996) Estimation of the spall fracture kinetics from the free-surface velocity profiles. In: AIP Conf Proc vol 370, AIP, Seattle, Washington (USA), pp. 487–490

Badji R, Chauveau T, Bacroix B (2013) Texture, misorientation and mechanical anisotropy in a deformed dual phase stainless steel weld joint. Mater Sci Eng A 575:94–103

Trichter F, Rabinkin A, Ron M, Sharfstein A (1978) A study of \(\gamma \, \rightarrow \, \varepsilon\) phase transformation in Fe-Mn alloys induced by high pressure and plastic deformation. Scripta Metall 12(5):431–434

Zeng ZH, Li X, Li C, Lu L, Zhang H, Luo SN (2019) Deformation twinning in a mild steel: loading dependence and strengthening. Mater Sci Eng A 751:332–339

Meyers MA (1994) Dynamic behavior of materials. John Wiley & Sons, New York

Chen S, Li YX, Zhang NB et al (2019) Capture deformation twinning in mg during shock compression with ultrafast synchrotron X-ray diffraction. Phys Rev Lett 123(25):255501

Turneaure SJ, Renganathan P, Winey J et al (2018) Twinning and dislocation evolution during shock compression and release of single crystals: real-time x-ray diffraction. Phys Rev Lett 120(26):265503

Czarnota C, Jacques N, Mercier S, Molinari A (2008) Modelling of dynamic ductile fracture and application to the simulation of plate impact tests on tantalum. J Mech Phys Solids 56(4):1624–1650

Krishnan K, Brown A, Wayne L, Vo J, Opie S, Lim H, Peralta P, Luo S-N, Byler D, McClellan KJ et al (2015) Three-dimensional characterization and modeling of microstructural weak links for spall damage in FCC metals. Metall Mater Trans A 46(10):4527–4538

Li C, Huang J, Tang X, Chai H, Xiao X, Feng Z, Luo SN (2017) Effects of structural anisotropy on deformation and damage of a duplex stainless steel under high strain rate loading. Mater Sci Eng A 705:265–272

Fensin SJ, Walker EK, Cerreta EK, Trujillo CP, Martinez D, Gray G III (2015) Dynamic failure in two-phase materials. J Appl Phys 118(23):235305

Yang Y, Wang C, Chen X, Hu H, Chen K, Fu Y (2018) Effects of the phase interface on spallation damage nucleation and evolution in multiphase alloy. J Alloy Compd 740:321–329

Yang Y, Wang C, Chen X, Chen K, Hu H, Fu Y (2018) The void nucleation mechanism within lead phase during spallation of leaded brass. Phil Mag 98(21):1975–1990

Fensin S, Escobedo J, Gray G III, Patterson B, Trujillo C, Cerreta E (2014) Dynamic damage nucleation and evolution in multiphase materials. J Appl Phys 115(20):203516

Fensin SJ, Jones DR, Walker EK, Farrow A, Imhoff SD, Clarke K, Trujillo CP, Martinez DT, Gray GT III, Cerreta EK (2016) The effect of distribution of second phase on dynamic damage. J Appl Phys 120(8):085901

Cheng M, Li C, Tang M, Lu L, Li Z, Luo SN (2018) Intragranular void formation in shock-spalled tantalum: mechanisms and governing factors. Acta Mater 148:38–48

Johnson GR (1983) A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. In: Proc 7th Inf Sympos Ballistics 541–547

Dugdale JS, MacDonald D (1953) The thermal expansion of solids. Phys Rev 89(4):832

Acknowledgements

This work is sponsored in part by Sichuan Science and Technology Program (Grant No. 2023YFG0077) and Natural Science Foundation of China (Grant Nos. 12302489, 12102491 and 11627901).

Author information

Authors and Affiliations

Contributions

YTC contributed to investigation, visualization, data curation, writing—original draft. YC contributed to methodology. LZC and XHL contributed to resources. SPZ contributed to investigation and methodology. JX contributed to data curation and resources. NBZ contributed to validation, supervision, writing—review and editing. LL contributed to validation, supervision, resources. SNL contributed to validation, supervision, writing—review and editing, project administration, funding acquisition, resources.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y.T., Cai, Y., Chen, L.Z. et al. Mechanical response, deformation and damage mechanisms in dual-phase cobalt upon plate impact. J Mater Sci 59, 6537–6550 (2024). https://doi.org/10.1007/s10853-024-09540-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09540-5