Abstract

Impregnation modifications improve the decay resistance of wood, but the mechanisms behind improved resistance are not yet fully understood. In this study, Scots pine sapwood samples were impregnation modified to investigate the relationship between moisture properties, decay resistance and chemical changes caused by decay. The samples were modified with phenol formaldehyde (PF) and sorbitol-citric acid (SCA) at different solids contents to study the effects of two different types of resins. The anti-swelling efficiency (ASE) and moisture exclusion efficiency (MEE) of the samples were measured, after which they were exposed to the brown rot fungi Coniophora puteana and Rhodonia placenta to determine their mass losses, moisture contents and chemical changes due to decay. The results showed that both modifications were able to increase ASE, MEE and decay resistance, and that neither modification was appreciably degraded by the fungi. However, no uniform relationship was found between mass loss and ASE or MEE for the two modifications, and there was a clear increase in the moisture contents of the decayed samples and sterile controls under decay test conditions with increasing modification degree. Overall, the results showed that modification with PF and SCA increases decay resistance, but the relationship between resistance and moisture properties requires further investigation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wood is a natural composite material with many advantageous properties. However, the presence of abundant hydroxyl groups on the wood cell wall polymers renders the material hygroscopic. The wood cell walls absorb moisture when they are in contact with liquid water and from water vapour in the surrounding atmosphere, which results in swelling at the cell wall and bulk level and therefore dimensional instability. Furthermore, if the moisture content is high enough, the wood material becomes susceptible to degradation by wood decaying fungi [1]. Susceptible wood is traditionally protected using preservative treatments, but improved decay resistance as well as dimensional stability can also be achieved by the use of wood modification. Wood modification is a term given to a range of treatments that improves the properties of wood through a non-toxic mode of action [2].

A large number of wood modification methods have been developed to date [2,3,4], and although the different modification processes affect the wood material in different ways, most of them improve the decay resistance of wood. The primary reason for the improved decay resistance is thought to be a reduction in the moisture content of the modified wood cell walls [5,6,7]. One theory is that modification reduces the rate of diffusion in the wood cell wall, interfering with the transport of fungal degradative agents [5, 7]. However, the exact mechanisms remain poorly understood and may in fact vary between different modification methods [5].

The extent of decay resistance improvement afforded by modification is linked to the extent of moisture content reduction. For most types of modifications, the decay resistance generally improves with increasing modification degree, but the relationship between decay resistance and moisture reduction varies depending on the type of modification and the method used to assess the moisture reduction. Thybring [8] analysed data from a number of studies on the decay resistance of modified wood and found that moisture exclusion efficiency (MEE, decrease in equilibrium moisture content) provided a good prediction of resistance across different types of modifications, while the relationship between anti-swelling efficiency (ASE, decrease in swelling at water saturation) and resistance was inconsistent. However, only a limited number of modifications were considered in the analysis, and it was recognised that the relationships may differ between modifications. In addition to the extent of moisture reduction, decay resistance is also influenced by the distribution of the modification agent in the wood and also likely by the stability of the modification itself. Given the non-toxic nature of wood modification, wood decaying fungi can grow in modified woods [9, 10] and degrade them over time [11,12,13]. The modification itself may be degradable as exemplified by the deacetylation of acetylated wood [11, 13].

One group of modifications where the origins of decay resistance warrant further investigation is impregnation modification, which involves the impregnation of wood with small molecular weight chemicals that are then polymerised to fix them within the wood structure. Impregnation modifications introduce material into wood that may itself absorb moisture [14,15,16], changing the relationship between decay resistance and moisture reduction. Impregnation-modified woods may even absorb more moisture than unmodified wood under some conditions [15,16,17,18,19,20]. It has also been suggested that the modification agents introduced by impregnation modification may be more resistant to degradation by fungi than modifications relying on reaction with wood hydroxyl groups, such as acetylation [13]. To investigate the decay resistance of impregnation-modified wood, wood samples were modified using different concentrations of phenol formaldehyde (PF) and sorbitol-citric acid (SCA). Both modifications are known to increase decay resistance [17, 21,22,23], but the chemistries of the impregnation resins are different. Furthermore, PF modification is known to reduce moisture uptake [22, 24,25,26], while SCA modification may have the opposite effect under some conditions [14, 17]. The anti-swelling and moisture exclusion efficiencies of the PF and SCA-modified samples were determined, after which the samples were subjected to degradation by brown rot fungi. Their mass losses, moisture contents and chemical composition were then measured to better understand the relationships between moisture reduction, decay resistance and modification agent degradation in impregnation-modified wood.

Materials and methods

Sample preparation

Wood samples with dimensions approx. 8 mm × 8 mm × 12 mm (T × L × R) were prepared from kiln-dried boards of Scots pine sapwood. The samples were first dried at 105 °C for 24 h to record their initial dry mass (mdry0) and cross-sectional (T × R) area (Adry0). Modifications with PF were performed using a low molecular weight phenol formaldehyde resin obtained from Prefere (Prefere Resins Finland Oy). The solids content of the supplied resin stock solution was determined, after which resin solutions for modification were prepared by diluting the stock solution with deionised water to solids contents of 2.5, 5, 10, 20 and 30% (w w−1), followed by the addition of 3% of NaOH per g of solid resin. Wood samples were impregnated with the resin solutions under vacuum at 100 mbar for 1 h, followed by soaking in the solution at atmospheric pressure for 2 h. The impregnated samples were allowed to dry overnight in a fume hood and then cured at 105 °C for 24 h. Modifications with SCA were performed using solutions with total solid contents of 5, 10, 20, 30 and 40% (w w−1). All solutions contained citric acid and sorbitol at a molar ratio of 3:1 in deionised water. Wood samples were impregnated with the solutions using the same process as used for PF. The impregnated samples were allowed to dry overnight in a fume hood and then cured at 140 °C for 24 h. The modified dry mass (mdry1) and cross-sectional area (Adry1) of the PF- and SCA-modified samples were recorded after resin curing. With both modifications, the number of replicate samples prepared at each solids content was 25.

The samples and the flow of subsequent tests are summarised in Fig. 1.

The prepared samples were leached and conditioned to determine modification efficiency and then subjected to brown rot decay or used as sterile controls to determine mass loss and moisture content. After decay, modified samples with representative mass loss were selected for fluorescence microscopy and composition analysis to analyse changes in resin distribution and sample composition due to decay.

Leaching and conditioning

The modified samples as well as untreated references previously dried, weighed and measured were vacuum impregnated with deionised water and leached for 1 week with daily water changes. The dimensions of the samples were measured on the last day of leaching to record their water saturated cross-sectional area (Awet), after which the samples were dried overnight in a fume hood and then at 105 °C for 24 h to record their leached dry mass (mdry2) and cross-sectional area (Adry2). Finally, the samples were conditioned in a climate chamber at 85% RH at 20 °C for 4 weeks and weighed to determine their conditioned mass (mRH85).

Modification efficiency

Weight percent gain (WPG) before and after leaching, swelling (S), corrected swelling (S*), equilibrium moisture content (EMC) and corrected EMC (EMC*) at 85% RH were calculated as follows:

where mx is mdry1 or mdry2 to give values before and after leaching, respectively.

Anti-swelling efficiency (ASE), corrected ASE (ASE*), moisture exclusion efficiency (MEE), and corrected MEE (MEE*) were then calculated as follows:

where the subscripts unmod and mod stand for unmodified and modified, respectively.

Decay test

After conditioning at 85% RH, the modified samples and untreated references were wrapped in aluminium foil and sterilised in an autoclave (2 × 30 min at 121 °C). The decay test was conducted in 112-cm-diameter plastic dishes containing 70 ml of 2% malt extract agar. A 2-cm hole was drilled into the screw-top lid of every dish and plugged with cotton to allow gas exchange. Each dish was inoculated with one plug of Coniophora puteana (strain BAM Ebw. 15) or Rhodonia placenta (strain BAM 113) mycelium excised from the growing edges of stock cultures maintained on 2% malt extract agar. After 16 days of growth, the sterilised wood samples were added to the inoculated dishes, with each dish receiving 8 differently treated samples. The samples were placed on plastic mesh supports to avoid direct contact with the agar medium. A total of 10 samples from every treatment group as well as the untreated references were exposed to each fungus. An additional five samples from every treatment group were also added to uninoculated agar medium dishes on supports to act as sterile controls. The dishes were incubated at 85% RH at room temperature for 6.5 weeks, after which the samples were removed from the dishes and cleaned of adhering mycelium. The samples were weighed immediately after they were removed from the dishes and cleaned to determine their wet decaying mass (mwet) and then dried overnight in a fume hood and then at 105 °C for 24 h to determine their decayed dry mass (mdry3). Their moisture content (MC), corrected moisture content (MC*), mass loss due to decay (ML) and corrected ML (MLc) were calculated as follows:

where MLdecayed is the mass loss of the decayed samples and MLcontrol the mass loss of the sterile controls.

Fluorescence microscopy

After the decay test, one decayed sample and sterile control from every sample group were selected for microscopy. Samples from every group were selected so that their mass losses were as close as possible to the average of the sample group. Radial sections approx. 25 µm in thickness were cut from every sample using a rotary microtome, embedded in water on objective slides, covered with coverslips and sealed with nail polish to prevent evaporation. Fluorescence images were collected using an Olympus BX53 microscope equipped with a 4x (NA 0.13) air objective, and a QImaging Micropublisher RTV 3.3 camera. Images from PF-modified wood were collected using both UV excitation (330–385 nm excitation, 420-nm emission) and green excitation (545–580 nm excitation, 610-nm emission), while images from SCA-modified wood were collected using UV excitation only. For PF-modified samples, composite images combining the UV and green excitation images were generated in ImageJ.

Chemical composition of wood

After decay, 3–6 decayed and control samples from every sample group were pooled and ground to a fine powder in a laboratory mill. Samples from every group were selected so that their mass losses were as close as possible to the average of the sample group. To remove solvent extractable material from the samples, approx. 1 g of each wood powder was extracted with 95:5 acetone:water in an accelerated solvent extractor (Dionex ASE 350) using 3 × 5 min extraction cycles at 90 °C. After extraction, the powders were acid hydrolysed according to NREL/TP-510-42618 [27] to determine their lignin content and carbohydrate monomer composition. Briefly, 0.3 g of each powder was pre-hydrolysed with 72% (w w−1) sulphuric acid for 60 min at 30 °C, followed by dilution to 4% (w w−1) acid content and hydrolysis in an autoclave at 121 °C for 60 min. The hydrolysates were filtered and the solid residues dried at 105 °C and weighed to determine Klason lignin content. To quantify carbohydrate monomers, the filtered hydrolysates were diluted and then analysed by High Performance Anion Exchange Chromatography with Pulsed Amperometric Detection (Thermo Scientific Dionex ICS-5000 +) using a CarboPac PA20 column and water as eluent at 0.37 ml min−1. The concentrations of glucose, mannose, xylose, galactose, arabinose, and rhamnose were determined against external calibration standards. Acid-soluble lignin content was analysed by spectrophotometry (Shimadzu UV-2550) using a wavelength of 205 nm and an absorptivity constant of 110 g l−1 cm−1. Chemical composition analyses were performed in duplicate.

Chemical composition of droplets

At the end of the decay test, droplets of fluid were often observed on, under or around the modified samples exposed to C. puteana and R. placenta (see Fig. S1). Droplets substantial enough in size were collected using a pipette and pooled according to sample type. To analyse their chemical composition, 100 μl (PF-modified samples) or 50 μl (SCA-modified samples) of each type of fluid was combined with 1 ml of internal standard solution (30 μg ml−1 heptadecanoic acid in methanol) and evaporated to dryness under N2 flow. The samples were trimethylsilylated using 100 μl of N,O-Bis(trimethylsilyl)trifluoroacetamide, 50 μl of chlorotrimethylsilane and 20 μl of pyridine at 70 °C for 20 min and then analysed by GC–MS (HP 6890/HP 5973) using a HP-5 column (30 m; 0.25 inner diameter, 0.25 μm film thickness). Helium was used as the carrier gas at 1.5 ml min−1, and the oven temperature programme was 7 °C min−1 from 75 to 310 °C, followed by 10 min at 310 °C. Mass spectra (30–700 m/z) were recorded at 70 eV. No replicate analyses were performed.

Results

Modification efficiency

Scots pine sapwood samples were modified with different concentrations of PF and SCA to achieve a range of modification intensities. The effects of modification on sample properties are summarised in Fig. 2. The unleached WPGs (Fig. 2a) of the PF-modified samples increased from 4.8 to 43.8% when the solids content of the treatment solution was increased from 2.5 to 30%, while the WPGs of the SCA-modified samples increased from 4.7 to 52.9% when the solids content increased from 5 to 40%. Both the PF- and SCA-modified samples lost mass on leaching, and the maximum WPGs decreased to 39.5 and 50.0% for PF and SCA, respectively. However, most of the added mass remained fixated in the samples. The incorporation of the modification agent into the samples increased their dry dimensions (Fig. 2b), which shows that the modification agents successfully penetrated the wood cell wall and caused bulking. PF modification at the highest solids content increased the dry dimensions after leaching by 5.8%. SCA had a stronger effect on the dry dimensions than PF, with a 12.5% increase in post-leaching dry dimensions at 40% solids content. PF modification had little effect on the water-swollen dimensions of the samples (Fig. 2b), which resulted in a decrease in the quantity of water in the cell wall and an increase in the anti-swelling efficiency with treatment intensity (Fig. 2c). However, due to the modest cell wall bulking caused by the treatments, the recorded ASE/ASE* values were also modest, with the highest treatment intensity samples reaching an ASE of 32.3% and an ASE* of 28.3%. SCA on the other hand caused an increase in the water-swollen dimensions in addition to an increase in the dry dimensions (Fig. 2b). ASE and ASE* reached values of 40.7 and 34.1%, respectively, at a solids content of 30%, then decreased at 40% solids content (Fig. 2c). In addition to the incorporation of modification agent into the cell walls as demonstrated by the increase in dimensions, fluorescence microscopy showed that deposits of resin were also present in the cell lumens in both PF- and SCA-modified wood (see Figs. S2 and S3).

Properties of samples modified with phenol formaldehyde (PF) and sorbitol-citric acid (SCA) at different resin solids contents. Weight percent gain (WPG) before and after leaching (a), relative dimensions in the dry condition before and after leaching and at water saturation (b), anti-swelling efficiency without (ASE) and with (ASE*) correction for dimensional changes caused by modification (c), and moisture exclusion efficiency at 85% RH without (MEE) and with (MEE*) correction for weight gain due to modification (d).

The incorporation of the modification agents into the cell wall also reduced the EMC at 85% RH (see Fig. S4) and therefore increased MEE/MEE* (Fig. 2d). However, the obtained improvements were modest at best. The highest MEE and MEE* values reached by PF-modified wood were 32.0% (at 30% solids content) and 12.3% (at 10% solids content), respectively, while SCA-modified wood reached a MEE value of 30.6% at 30% solids content and a MEE* value of 15.0% at 10% solids content. With both modifications, the MEE* values showed an initial increase with increasing treatment intensity, followed by a decrease with further increases in intensity. The decrease in MEE* values indicates that the addition of further modification agent increased the absolute amount of water in the wood material. The decrease was particularly strong in the case of SCA, and the MEE* values became negative at 40% solids content, which means that the modified samples contained more water relative to their initial weight than the unmodified references.

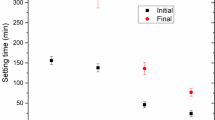

Degradation by brown rot fungi

The modified wood samples as well as unmodified references were exposed to C. puteana and R. placenta for 6.5 weeks. Additional modified sterile control samples were exposed under the same conditions in the absence of fungi. The mass losses of the decayed and control samples are shown in Fig. 3a, while their moisture contents (corrected for WPG and mass loss) are presented in Fig. 3b. As expected, the highest mass losses were seen in the unmodified reference samples. PF modification proved highly effective at reducing mass loss by both fungi even at low modification intensities, with mass losses by C. puteana decreasing to 17.4% and 5.3% at 2.5% and 5% solids content, respectively, and by R. placenta to 21.5% and 7.6%, respectively. No mass loss was recorded in samples treated with higher concentrations of PF resin. SCA modification also reduced mass loss due to brown rot fungi, but the effect was less pronounced than with PF, particularly in the case of R. placenta. Modification using a 30% solids content solution reduced the average mass loss due to R. placenta to 8.7%, while treatment with 40% solids content reduced the mass loss to 7.7%. Mass loss due to C. puteana decreased more rapidly with increasing modification intensity, reaching 5.7% at 20% solids content with no further decrease with increasing modification intensity. The PF-modified control samples lost less than 1% of their mass when incubated in the absence of fungi, while the mass losses of the SCA-modified controls increased with modification intensity, reaching 5.1% at 40% solids content.

Mass losses (ML) (a) and corrected moisture contents (MC*) (b) of samples modified with phenol formaldehyde (PF) and sorbitol-citric acid (SCA) at different resin solids contents after exposure to R. placenta and C. puteana or use as sterile controls. Moisture contents (MC*) were corrected for WPG due to modification and mass loss due to decay.

When corrected for WPG and mass loss due to decay, it was found that the moisture contents of the decayed and sterile control samples increased with modification intensity. In PF-modified wood, the moisture contents of the sterile controls increased at high modification degrees, reaching 93.0% at 30% solids content. The moisture contents of the decayed samples were higher than those of the sterile controls, with exposure to C. puteana producing higher values than exposure to R. placenta. In SCA-modified wood, the moisture contents of the sterile controls increased rapidly with increasing modification intensity, reaching a final value of 130.3% at 40% solids content. The moisture contents of the decayed samples were generally similar to those of the controls, with no consistent differences observable between the two fungi.

To analyse the chemical changes behind mass loss caused by C. puteana and R. placenta, decayed samples and sterile controls were pooled, ground to powder and acid hydrolysed according to NREL/TP-510-42618 [27] to determine their chemical composition (Fig. 4, see Table S1 for full composition information from duplicate measurements). Both fungi were found to cause compositional changes typical of brown rot in both types of modified wood: both cellulose and hemicelluloses were consumed while the gravimetric lignin content remained largely unchanged (with the exception of SCA at 5% and 10% solids content, both of which showed a loss of lignin). The analysis indicated that neither fungus caused substantial removal of either modification agent from the samples. In the case of PF modification, the undecayed samples showed that the modification agent was not acid hydrolysable and remained in the solid residue, causing an increase in the measured Klason lignin content. The samples exposed to C. puteana and R. placenta showed no decrease in lignin content, which suggests that the fungi were unable to remove the resin from the wood material. In the case of SCA, the modification agent was mostly acid hydrolysable and dissolved into the liquid fraction, remaining undetected in both the lignin and sugar analyses. Substantial amounts of material could also be recovered from the undecayed samples by solvent extraction. Fungal exposure did not cause notable changes in the amount of undetected material, which points towards a lack of resin removal from the wood. Fluorescence imaging showed no changes in the abundance of resin deposits in the cell lumens in PF- or SCA-modified wood (see Figs. S2 and S3), providing further evidence supporting the lack of resin removal. However, at the end of the decay test droplets of fluid were found around the modified samples (see Fig. S1), particularly those modified using 20 and 30% solids content PF and 30 and 40% solids content SCA. GC–MS analysis of the exuded fluids showed that the droplets around PF-modified samples consisted mostly of oxalic acid, sugars and sugar alcohols (Fig. S5); no potential PF-derived degradation products were detected by GC–MS. The droplets around the SCA-modified samples on the other hand contained a large number of different compounds, including free sorbitol and very large amounts of free citric acid (Figs. S6 and S7). The droplets also contained several compounds whose mass spectra shared many features in common with citric acid (Figs. S8 and S9), suggesting that the compounds may be citric acid-derived.

Chemical composition of samples modified with phenol formaldehyde (a) and sorbitol-citric acid (b) at different resin solids contents after decay. C = sterile control, Cp = decayed by C. puteana, Rp = decayed by R. placenta. Lignin = gravimetrically determined Klason lignin + acid soluble lignin, Glu = glucose, Non-glu = sugars other than glucose, Other = difference between 100% and sum total of all measured components in SCA-modified wood, Extractable = components soluble in 95:5 acetone:water, Mass loss = mass loss due to decay. Chemical composition was determined using pooled replicate samples.

Relationship between moisture properties and decay resistance

To investigate the relationship between mass loss and moisture properties in PF- and SCA-modified wood, the mass losses (corrected by subtracting the mass losses of the sterile controls) due to C. puteana and R. placenta were plotted against ASE* and MEE* (Fig. 5). No uniform relationship was found between mass loss by the two fungi and ASE* for the two modifications. Mass loss due to both fungi decreased with increasing ASE/ASE* at seemingly similar rates for both modifications, but zero mass loss under the current experimental conditions was reached at much lower ASE* values by PF-modified wood than SCA-modified wood. In the case of MEE*, no consistent relationship was seen with mass loss due to the decrease in MEE* at higher modification intensities. In addition to mass loss, the corrected moisture contents of the decayed and control samples were also plotted against ASE* and MEE* to study the relationship between the measured moisture properties and moisture performance during decay (Fig. 6). The results showed that the moisture contents of all samples increased with increasing ASE*, while no consistent trend was found with MEE* due to the decrease in MEE* at higher modification intensities. The relationships between moisture content and ASE* and moisture content and MEE* were similar for both modifications and for the decayed and control samples.

Corrected mass losses (MLc) of samples modified with phenol formaldehyde (PF) and sorbitol-citric acid (SCA) due to R. placenta (Rp) and C. puteana (Cp) as a function of anti-swelling efficiency with correction for dimensional changes caused by modification (ASE*) (a) and moisture exclusion efficiency with correction for weight gain due to modification (MEE*) (b).

Corrected moisture contents (MC*) of samples modified with phenol formaldehyde (PF) and sorbitol-citric acid (SCA) at different resin solids contents after exposure to R. placenta (Rp) and C. puteana (Cp) (a, b) or use as sterile controls (C) (c, d) as a function of anti-swelling efficiency with correction for dimensional changes caused by modification (ASE*) (a, c) and moisture exclusion efficiency with correction for weight gain due to modification (MEE*) (b, d).

Discussion

Modification of Scots pine sapwood samples with PF and SCA resulted in the uptake of resin, as evidenced by the increase in sample mass (Fig. 2a) and the appearance of resin deposits in cell lumens (Figs. S2 and S3). PF modification increased the dry dimensions of the samples but had little effect on the wet dimensions (Fig. 1b), which resulted in increased ASE/ASE* (Fig. 2c). However, the increases were modest at best and lower than the improvements obtained by previous researchers at comparable WPGs [21, 22, 24, 26, 28]. SCA modification on the other hand increased both the dry and wet dimensions of the samples (Fig. 2b); ASE/ASE* increased until a solids content of 30% and then decreased at 40% solids content (Fig. 2c). Increasing water-swollen dimensions and decreasing ASE values have been previously recorded for SCA treated wood [14, 17, 23]. The increased swelling is thought to be caused by the high acidity of the treatment solution, which causes degradation of cell wall carbohydrates and increased swelling [14, 17]. The samples are then cured in this condition, which allows them to swell excessively upon saturation.

PF and SCA modification also affected the EMC at 85% RH (Fig. S4) and therefore the MEE/MEE* (Fig. 2d). However, with both modifications the obtained improvements were modest at best. In the case of PF, the reductions in EMC were lower than in previous reports [24, 25], while in the case of SCA the results were in line with previous findings [14]. With both modifications, the highest MEE* values were reached at relative low modification intensities, with further increases in modification resulting in a decrease in MEE*. The effect was particularly strong in the case of SCA, where negative MEE* values were found at 40% solids content. The decreasing MEE* values are likely related to the absorption of water by the modification resin, which was present not only in the cell walls but also in the cell lumens (Figs. S2 and S3). Pure polymerised SCA is highly hygroscopic [14], and while PF is likely to be less hygroscopic, the polymer contains free OH groups which can be expected to participate in sorption. Increased water absorption in the hygroscopic range has also been documented for other resin impregnated woods under certain conditions [15, 16, 19, 20].

The decay resistance of the PF- and SCA-modified samples was tested against the brown rot fungi C. puteana and R. placenta. PF modification was highly effective against both fungi, and the mass losses (Fig. 3a) became negative at 10% resin solids content. The effectiveness of PF modification is consistent with previous findings, which revealed strong reductions in mass loss due to brown rot fungi at low resin loadings [21, 22]. SCA-modification also reduced mass loss due to both fungi (Fig. 3a), but the effect was stronger against C. puteana than R. placenta. The mass losses of the SCA modified samples were not reduced to 0 even at the highest resin solids contents, where substantial mass losses were seen also in the sterile controls. Substantial mass losses in sterile controls were also reported by Beck [17] for Scots pine modified using a similar procedure as in this experiment. This suggests that the modification may not be entirely stable under high moisture conditions. Good decay resistance (< 5% mass loss due to decay) has been previously obtained by SCA modification at around 30–50% WPG [17, 23].

The results from the chemical composition analysis (Fig. 4) indicated that fungal degradation did not cause substantial removal of the modification resin in PF- or SCA-modified wood. Recent studies on the decay of modified wood have shown that R. placenta can deacetylate acetylated wood [11, 13] but was found incapable of removing the resin polymer introduced by furfurylation [13], which led Thygesen et al. [13] to propose that impregnation modifications may be less degradable than modifications relying on reaction with wood hydroxyl groups. The lack of resin removal is in agreement with this hypothesis, although the composition of the droplets found around the SCA-modified samples (Fig. S6-S9) suggests that some degradation of the resin polymer may still take place. It is not clear whether the presence of SCA fragments in the droplets is due to fungal degradation of the resin or to hydrolysis of the resin under high moisture load. The formation of droplets around SCA-modified samples exposed to R. placenta has been previously observed by Beck [17] for Scots pine modified using a similar procedure as in this experiment.

Since the results gave no indication of substantial resin degradation in PF- or SCA-modified wood, their decay resistance can be assumed to be a function of a reduction in moisture content [5,6,7,8]. When mass losses due to C. puteana and R. placenta were plotted against ASE* and MEE* (Fig. 5), no uniform relationship was found between mass loss and ASE*, which is in agreement with previous results [8]. However, in contrast to previous results [8], no consistent relationship was seen between mass loss and MEE* either. When the moisture contents of the decayed and control samples were plotted against ASE* and MEE* (Fig. 6), the moisture contents of all samples increased with increasing ASE* and showed no consistent trend with MEE* due to the decrease in MEE* at higher modification intensities (Fig. 2).

The lack of consistent relationships between mass loss and moisture properties (ASE*, MEE*, MC*) is likely to be due to their inability to represent qualities that are relevant for moisture performance during decay. ASE* is beneficial because it is measured at saturation and because it measures changes in volume, which should represent the amount of water in the cell wall. However, the changes in external dimensions may not be representative of changes in actual cell wall volume, as has been found for acetylated wood [29, 30]. Changes in cell shape and thickness have also been detected in furfurylated wood [31]. MEE* and MC* on the other hand measure changes in bulk mass, which means that they respond to moisture uptake both in and outside the cell walls. Deposits of resin were found in the cell lumens in both PF- and SCA-modified wood (Figs. S2 and S3); these deposits may absorb moisture, increasing the moisture content of the bulk sample even if the cell walls themselves absorb no further moisture. It is clear from the moisture content data (Fig. 6) that moisture absorption and bulk swelling are not directly connected in resin impregnated wood, and that the moisture contents measured under hygroscopic conditions do not accurately reflect moisture uptake under decay conditions. Although moisture absorption under decay conditions increases in both PF- and SCA-modified wood with increasing modification intensity, it is not clear from the data how much of the water is absorbed into the wood cell walls and how much is found in the cell lumens. An increase in moisture uptake under overhygroscopic conditions has been recorded in furfurylated wood, where it was attributed to capillary condensation in cracks and microvoids caused by the modification [18]. Similar effects may be active in PF- and SCA-modified wood, which would allow for an increase in bulk moisture content without an increase in cell wall moisture content.

The lack of consistent relationships between mass loss and moisture properties may also be due to the involvement of factors other than simple moisture content reduction in decay resistance. The increased moisture uptake in the impregnation-modified samples may be due to moisture uptake and condensation outside the cell walls as discussed above, but previous research has indicated that the cell wall moisture content of SCA-modified wood at saturation may in fact increase, most likely due to the super swelling of the cell walls caused by the acidic treatment solution [17]. Therefore, to understand the decay resistance of impregnation-modified wood, it is important to determine the actual amount of cell wall water under decay-relevant conditions. The samples studied in this experiment and by Beck [17] still have improved decay resistance, which means that if cell wall moisture content actually increases, then factors other than moisture reduction are likely to be involved in decay resistance.

Conclusions

To understand the decay resistance of impregnation-modified wood, pine sapwood samples were treated with PF and SCA at different solids contents to create a range of modification intensities using two different types of resin. Both modifications provided improved decay resistance, but no consistent relationships were seen amongst mass loss, ASE*, MEE* and MC* that would explain the improvement in resistance. Neither resin appeared to be degraded by the wood decaying fungi to a substantial extent, which shows that the modifications are resistant to fungal degradation and that the improvements in resistance are related to stable changes in wood properties. However, it is clear from the results that the origins of decay resistance in resin-modified wood require further investigation. To study the link between moisture performance and decay resistance, the uptake of moisture by the wood cell walls should be determined under decay-relevant conditions.

Supplementary Information

Supplementary information is available in Supplementary Material.pdf.

Data availability

The datasets presented in this study can be found in online repositories at: https://doi.org/10.5281/zenodo.7980308.

References

Brischke C, Alfredsen G (2020) Wood-water relationships and their role for wood susceptibility to fungal decay. Appl Microbiol Biotechnol 104:3781–3795. https://doi.org/10.1007/s00253-020-10479-1

Hill CAS (2006) Wood modification: chemical, thermal and other processes. John Wiley

Sandberg D, Kutnar A, Mantanis G (2017) Wood modification technologies—a review. iForest 10:895. https://doi.org/10.3832/ifor2380-010

Zelinka SL, Altgen M, Emmerich L et al (2022) Review of wood modification and wood functionalization technologies. Forests 13:1004. https://doi.org/10.3390/f13071004

Ringman R, Beck G, Pilgård A (2019) The importance of moisture for brown rot degradation of modified wood: a critical discussion. Forests 10:522. https://doi.org/10.3390/f10060522

Ringman R, Pilgård A, Brischke C, Richter K (2014) Mode of action of brown rot decay resistance in modified wood: a review. Holzforschung 68:239–246. https://doi.org/10.1515/hf-2013-0057

Zelinka SL, Ringman R, Pilgård A et al (2016) The role of chemical transport in the brown-rot decay resistance of modified wood. Int Wood Prod J 7:66–70. https://doi.org/10.1080/20426445.2016.1161867

Thybring EE (2013) The decay resistance of modified wood influenced by moisture exclusion and swelling reduction. Int Biodeter Biodegrad 82:87–95. https://doi.org/10.1016/j.ibiod.2013.02.004

Emmerich L, Bleckmann M, Strohbusch S et al (2021) Growth behavior of wood-destroying fungi in chemically modified wood: wood degradation and translocation of nitrogen compounds. Holzforschung. https://doi.org/10.1515/hf-2020-0252

Meyer L, Brischke C, Treu A, Larsson-Brelid P (2016) Critical moisture conditions for fungal decay of modified wood by basidiomycetes as detected by pile tests. Holzforschung 70:331–339. https://doi.org/10.1515/hf-2015-0046

Beck G, Thybring EE, Thygesen LG (2018) Brown-rot fungal degradation and de-acetylation of acetylated wood. Int Biodeter Biodegrad 135:62–70. https://doi.org/10.1016/j.ibiod.2018.09.009

Ringman R, Pilgård A, Kölle M et al (2016) Effects of thermal modification on Postia placenta wood degradation dynamics: measurements of mass loss, structural integrity and gene expression. Wood Sci Technol 50:385–397. https://doi.org/10.1007/s00226-015-0791-z

Thygesen LG, Beck G, Nagy NE, Alfredsen G (2021) Cell wall changes during brown rot degradation of furfurylated and acetylated wood. Int Biodeter Biodegrad 162:105257. https://doi.org/10.1016/j.ibiod.2021.105257

Kurkowiak K, Emmerich L, Militz H (2021) Sorption behavior and swelling of citric acid and sorbitol (SorCA) treated wood. Holzforschung 75:1136–1149. https://doi.org/10.1515/hf-2021-0068

Altgen M, Altgen D, Klüppel A, Rautkari L (2020) Effect of curing conditions on the water vapor sorption behavior of melamine formaldehyde resin and resin-modified wood. J Mater Sci 55:11253–11266. https://doi.org/10.1007/s10853-020-04814-0

Emmerich L, Altgen M, Rautkari L, Militz H (2020) Sorption behavior and hydroxyl accessibility of wood treated with different cyclic N-methylol compounds. J Mater Sci 55:16561–16575. https://doi.org/10.1007/s10853-020-05224-y

Beck G (2020) Leachability and decay resistance of wood polyesterified with sorbitol and citric acid. Forests 11:650. https://doi.org/10.3390/f11060650

Thygesen LG, Engelund ET, Hoffmeyer P (2010) Water sorption in wood and modified wood at high values of relative humidity. Part I: results for untreated, acetylated, and furfurylated Norway spruce. Holzforschung 64:315–323. https://doi.org/10.1515/hf.2010.044

Shen X, Guo D, Jiang P et al (2021) Water vapor sorption mechanism of furfurylated wood. J Mater Sci 56:11324–11334. https://doi.org/10.1007/s10853-021-06041-7

Militz H (1993) Treatment of timber with water soluble dimethylol resins to improve their dimensional stability and durability. Wood Sci Technol 27:347–355. https://doi.org/10.1007/BF00192221

Biziks V, Bicke S, Koch G, Militz H (2021) Effect of phenol-formaldehyde (PF) resin oligomer size on the decay resistance of beech wood. Holzforschung 75:574–583. https://doi.org/10.1515/hf-2020-0020

Furuno T, Imamura Y, Kajita H (2004) The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci Technol 37:349–361. https://doi.org/10.1007/s00226-003-0176-6

Mubarok M, Militz H, Dumarçay S, Gérardin P (2020) Beech wood modification based on in situ esterification with sorbitol and citric acid. Wood Sci Technol 54:479–502. https://doi.org/10.1007/s00226-020-01172-7

Deka M, Saikia CN (2000) Chemical modification of wood with thermosetting resin: effect on dimensional stability and strength property. Bioresour Technol 73:179–181. https://doi.org/10.1016/S0960-8524(99)00167-4

Hosseinpourpia R, Adamopoulos S, Mai C (2016) Dynamic vapour sorption of wood and holocellulose modified with thermosetting resins. Wood Sci Technol 50:165–178. https://doi.org/10.1007/s00226-015-0765-1

Wang X, Chen X, Xie X et al (2019) Multi-scale evaluation of the effect of phenol formaldehyde resin impregnation on the dimensional stability and mechanical properties of pinus massoniana lamb. Forests 10:646. https://doi.org/10.3390/f10080646

Sluiter A, Hames B, Ruiz R et al (2012) Determination of structural carbohydrates and lignin in biomass: laboratory analytical procedure (LAP). National Renewable Energy Laboratory, Technical Report NREL/TP-510-42618

Klüppel A, Mai C (2013) The influence of curing conditions on the chemical distribution in wood modified with thermosetting resins. Wood Sci Technol 47:643–658. https://doi.org/10.1007/s00226-013-0530-2

Hill CAS, Ormondroyd GA (2004) Dimensional changes in Corsican pine (Pinus nigra Arnold) modified with acetic anhydride measured using a helium pycnometer. Holzforschung 58:544–547. https://doi.org/10.1515/HF.2004.082

Kwon JH, Hill CAS, Ormondroyd GA, Karim S (2007) Changes in the cell wall volume of a number of wood species due to reaction with acetic anhydride. Holzforschung 61:138–142. https://doi.org/10.1515/HF.2007.025

Moghaddam MS, den Bulcke JV, Wålinder MEP et al (2017) Microstructure of chemically modified wood using X-ray computed tomography in relation to wetting properties. Holzforschung 71:119–128. https://doi.org/10.1515/hf-2015-0227

Acknowledgements

This work received funding from the Academy of Finland (Grant No. 330087).

Funding

Open access funding provided by Natural Resources Institute Finland (LUKE).

Author information

Authors and Affiliations

Contributions

TB: Conceptualization; Funding acquisition; Investigation; Methodology; Resources; Visualization; Writing—original draft; Writing—review & editing. SK: Investigation; Writing—review & editing. ATK: Investigation; Writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Ethical approval

NotApplicable.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Belt, T., Kyyrö, S. & Kilpinen, A.T. Relationship between decay resistance and moisture properties in wood modified with phenol formaldehyde and sorbitol-citric acid. J Mater Sci 58, 13678–13690 (2023). https://doi.org/10.1007/s10853-023-08874-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08874-w