Abstract

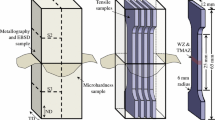

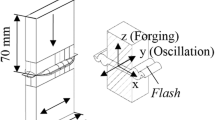

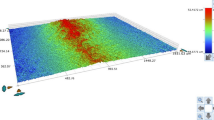

Linear friction welding of equiaxed Ti17 titanium alloy with great strength–plasticity matching was carried out in this study and the microstructure evolution, tensile property and impact toughness of this joint were investigated in detail. Results show that α dissolution (α → metastable β transformation) takes place in both thermo-mechanically affected zone (TMAZ) and weld zone (WZ). The metastable β in TMAZ near base metal (BM) is affected by stress during welding, resulting in concentrated orientation and high dislocation density. Dynamic recrystallizations of α and metastable β phases occur in TMAZ near WZ, leading to fine recrystallized α grains and equiaxed recrystallized β grains. Complete α dissolution and total dynamic recrystallization appear in WZ owing to the effect of strong thermomechanical coupling. Above microstructure evolution causes significant work hardening and fine grain strengthening effects, counteracting the weakening effect induced by α dissolution, and resulting in the tensile strength (1250.0 MPa), elongation (12.2%) and impact toughness (28.8 J/cm2) of the joint are higher than those of the BM. In addition, the tensile strength and elongation of the equiaxed Ti17 joint are increased compared to those of bimodal as well as basketweave Ti17 joints.

Similar content being viewed by others

Data availability

The processed data required to reproduce these findings cannot be shared at this time as data belong to a greater ongoing study.

References

Cam G, Ipekoglu G, Bohm KH, Kocak M (2006) Investigation into the microstructure and mechanical properties of diffusion bonded TiAl alloys. J Mater Sci 41:5273–5282. https://doi.org/10.1007/s10853-006-0292-4

McAndrew AR, Colegrove PA, Addison AC, Flipo BCD, Russell MJ (2015) Modelling the influence of the process inputs on the removal of surface contaminants from Ti-6Al-4V linear friction welds. Mater Des 66:183–195. https://doi.org/10.1016/j.matdes.2014.10.058

Guo ZG, Ma TJ, Yang XW, Chen X, Tao J, Li J, Li WY, Vairis A (2022) Linear friction welding of Ti60 near- α titanium alloy: Investigating phase transformations and dynamic recrystallization mechanisms. Mater Charact 194:112424. https://doi.org/10.1016/j.matchar.2022.112424

Shtrikman MM (2010) Linear friction welding Weld Int 24:563–569. https://doi.org/10.1080/09507110903569149

Vairis A (2022) Linear friction welded titanium alloy joints: a brief review of microstructure evolution and mechanical properties. Weld Int 36:647–654. https://doi.org/10.1080/09507116.2022.2149366

Zhao PK, Wei C, Li Y, Tao TJ, Zhang CC, Xiao XD, Zhang M (2021) Effect of heat treatment on the microstructure, microhardness and impact toughness of TC11 and TC17 linear friction welded joint. Mater Sci Eng A 803:140496. https://doi.org/10.1016/j.msea.2020.140496

Zhao PK, Wei C, Xiao XD, Chu QL, Niu JP, Guo ML, Zhang CC, Li SJ, Zhang M (2021) Thermal deformation mechanism of TC11/TC17 linear friction welded joint during isothermal compression. Mater Charact 178:111319. https://doi.org/10.1016/j.matchar.2021.111319

Li HM, Li MQ, Luo J, Wang K (2015) Microstructure and mechanical properties of heat-treated Ti-5Al-2Sn-2Zr-4Mo-4Cr. Trans Nonferrous Met Soc China 25:2893–2900. https://doi.org/10.1016/S1003-6326(15)63915-2

Zhao PK, Fu L (2015) Strain hardening behavior of linear friction welded joints between TC11 and TC17 dissimilar titanium alloys. Mater Sci Eng A 621:149–156. https://doi.org/10.1016/j.msea.2014.10.044

Pang HY, Luo J, Zhang ZG, Han WC, Xu KF, Li MQ (2022) Quantitative analysis of globularization and modeling of TC17 alloy with basketweave microstructure. Trans Nonferrous Met Soc China 32:850–867. https://doi.org/10.1016/S1003-6326(22)65838-2

Zhang CC, Zhang TC, Ji YJ, Huang JH (2013) Effects of heat treatment on microstructure and microhardness of linear friction welded dissimilar Ti alloys. Trans Nonferrous Met Soc China 23:3540–3544. https://doi.org/10.1016/S1003-6326(13)62898-8

McAndrew AR, Colegrove PA, Bühr C, Flipo BCD, Vairis A (2018) A literature review of Ti-6Al-4V linear friction welding. Prog Mater Sci 92:225–257. https://doi.org/10.1016/j.pmatsci.2017.10.003

Li WY, Ma TJ, Yang SQ (2010) Microstructure Evolution and Mechanical Properties of Linear Friction Welded Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti17) Titanium Alloy Joints. Adv Eng Mater 12:35–43. https://doi.org/10.1002/adem.200900185

Ma TJ, Li WY, Zhong B, Zhang Y, Li JL (2012) Effect of post-weld heat treatment on microstructure and property of linear friction welded Ti17 titanium alloy joint. Sci Technol Weld Join 17:180–185. https://doi.org/10.1179/1362171811Y.0000000079

Ballat-Durand D, Bouvier S, Risbet M, Pantleon W (2018) Multi-scale and multi-technic microstructure analysis of a linear friction weld of the metastable-β titanium alloy Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti17) towards a new Post-Weld Heat Treatment. Mater Charact 144:661–670. https://doi.org/10.1016/j.matchar.2018.08.013

Ballat-Durand D, Bouvier S, Risbet M (2019) Contributions of an innovative post-weld heat treatment to the micro-tensile behavior of two mono-material linear friction welded joints using: The β-metastable Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti17) and the near-α Ti-6Al-2Sn-4Zr-2Mo (Ti6242) Ti-alloys. Mater Sci Eng A 766:138334. https://doi.org/10.1016/j.msea.2019.138334

García JM, Gaslain F, Morgeneyer TF (2020) On the effect of a thermal treatment on the tensile and fatigue properties of weak zones of similar Ti17 linear friction welded joints and parent material. Mater Charact 169:110570. https://doi.org/10.1016/j.matchar.2020.110570

Li XH, He JC, Ji YJ, Zhang TC, Zhang YH (2019) Study of the Microstructure and fracture toughness of TC17 titanium alloy linear friction welding joint. Metals 9:430. https://doi.org/10.3390/met9040430

Ji YP, Chai ZZ, Zhao DL, Wu SJ (2014) Linear friction welding of Ti-5Al-2Sn-2Zr-4Mo-4Cr alloy with dissimilar microstructure. J Mater Process Technol 214:979–987. https://doi.org/10.1016/j.jmatprotec.2013.11.006

Guo ZG, Ma TJ, Yang XW, Tao J, Li J, Li WY, Vairis A (2023) In-situ investigation on dislocation slip concentrated fracture mechanism of linear friction welded dissimilar Ti17(α+β)/Ti17(β) titanium alloy joint. Mater Sci Eng A 872:144991. https://doi.org/10.1016/j.msea.2023.144991

Xie P, Zhao H, Liu Y (2016) Measuring residual stresses in linear friction welded joints composed by dissimilar titanium. Sci Technol Weld Join 21:351–357. https://doi.org/10.1080/13621718.2015.1115158

Choi J, Aoki Y, Ushioda K, Fujii H (2021) Linear friction welding of Ti-6Al-4V alloy fabricated below β-phase transformation temperature. Scripta Mater 191:12–16. https://doi.org/10.1016/j.scriptamat.2020.09.013

Choi J, Aoki Y, Ushioda K, Fujii H (2022) Effect of the welding parameters on microstructure and mechanical properties of linear friction welded Ti-6Al-4V alloy. J Manuf Process 75:651–663. https://doi.org/10.1016/j.jmapro.2022.01.033

Ma TJ, Chen T, Li WY, Wang SW, Yang SQ (2011) Formation mechanism of linear friction welded Ti-6Al-4V alloy joint based on microstructure observation. Mater Charact 62:130–135. https://doi.org/10.1016/j.matchar.2010.11.009

Wang XY, Li WY, Ma TJ, Vairis A, Tao J (2020) Microstructural heredity and its effect on mechanical properties of linear friction welded Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy joints. Mater Charact 168:110540. https://doi.org/10.1016/j.matchar.2020.110540

Wang XY, Li WY, Ma TJ, Yang XW, Vairis A (2019) Effect of welding parameters on the microstructure and mechanical properties of linear friction welded Ti-6.5Al-3.5Mo-1.5Zr-0.3Si joints. J Manuf Process 46:100–108. https://doi.org/10.1016/j.jmapro.2019.08.031

Wang XY, Li WY, Ma TJ, Yang XW, Vairis A (2019) Microstructural evolution and mechanical properties of a linear friction welded two-phase Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy joint. Mater Sci Eng A 743:12–23. https://doi.org/10.1016/j.msea.2018.11.059

Guo ZG, Ma TJ, Li WY, Zhang Y, Zhao ZP, Tao J, Kang WJ (2021) Intergrowth bonding mechanism and mechanical property of linear friction welded dissimilar near-alpha to near-beta titanium alloy joint. Adv Eng Mater 23:2001479. https://doi.org/10.1002/adem.202001479

Bruneseaux F, Aeby-Gautier E, Geandier G, Teixeira JDC, Appolaire B, Weisbecker P, Mauro A (2008) In situ characterizations of phase transformations kinetics in the Ti17 titanium alloy by electrical resistivity and high temperature synchrotron X-ray diffraction. Mater Sci Eng A 476:60–68. https://doi.org/10.1016/j.msea.2007.04.072

Zhang SF, Zeng WD, Zhao QY, Ge LL, Zhang M (2017) In situ SEM study of tensile deformation of a near-β titanium alloy. Mater Sci Eng A 708:574–581. https://doi.org/10.1016/j.msea.2017.10.028

Dalgaard E, Wanjara P, Gholipour J, Cao X, Jonas JJ (2012) Linear friction welding of a near-β titanium alloy. Acta Mater 60:770–780. https://doi.org/10.1016/j.actamat.2011.04.037

García JM, Esin VA, Morgeneyer TF (2021) Strength, fatigue strength and toughness of dissimilar Ti17-Ti64 linear friction welded joints: Effect of soft surface contamination and depletion of α precipitates. Mater Sci Eng A 799:139989. https://doi.org/10.1016/j.msea.2020.139989

Guo ZG, Ma TJ, Chen X, Yang XW, Tao J, Li J, Li WY, Vairis A (2023) Interfacial bonding mechanism of linear friction welded dissimilar Ti2AlNb-Ti60 joint: grain intergrowth induced by combined effects of dynamic recrystallization, phase transformation and elemental diffusion. J Mater Res Technol 24:5660–5668. https://doi.org/10.1016/j.jmrt.2023.04.184

Baczynski J, Jonas JJ (1996) Texture development during the torsion testing of α-iron and two IF steels. Acta Mater 44:4273–4288. https://doi.org/10.1016/1359-6454(96)00114-0

Li SY, Beyerlein IJ, Bourke MAM (2005) Texture formation during equal channel angular extrusion of fcc and bcc materials: comparison with simple shear. Mater Sci Eng A 394:66–77. https://doi.org/10.1016/j.msea.2004.11.032

Fonda RW, Knipling KE (2010) Texture development in near-α Ti friction stir welds. Acta Mater 58:6452–6463. https://doi.org/10.1016/j.actamat.2010.08.007

Robinson JS, Redington W (2015) The influence of alloy composition on residual stresses in heat treated aluminum alloys. Mater Charact 105:47–55. https://doi.org/10.1016/j.matchar.2015.04.017

Zhou J, Liang W, Zhang CB, Wu YQ (2020) Microstructure and mechanical properties of linear friction welding joint of TC17 titanium alloy. Trans China Weld Inst 41:36–41. https://doi.org/10.12073/j.hjxb.20200408002. (in Chinese)

Guo ZG, Ma TJ, Li J, Li WY, Tang LF (2021) Effect of post-weld heat treatment on microstructure and mechanical properties of linear friction welded Ti17 titanium alloy joint. J Netshape Form Eng 13:155–160. https://doi.org/10.3969/j.issn.1674-6457.2021.05.020. (in Chinese)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant no. 52105400) and Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University.

Author information

Authors and Affiliations

Contributions

ZG contributed to conception, experimental design, carrying out measurements and manuscript composition; TM contributed to conception and experimental design; TC contributed to carrying out measurements; JW contributed to carrying out measurements; XC contributed to carrying out measurements and manuscript composition; XY contributed to carrying out measurements and manuscript composition; JT contributed to manuscript composition; JL contributed to manuscript composition; WL contributed to manuscript composition; AV contributed to manuscript composition.

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that there are no conflicts of interest or competing interests to the work reported in this paper.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Z., Ma, T., Chen, T. et al. Linear friction welding of equiaxed Ti17 titanium alloy: Effects of microstructure evolution on tensile and impact properties. J Mater Sci 58, 10189–10200 (2023). https://doi.org/10.1007/s10853-023-08666-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08666-2