Abstract

TiAl alloys are potential candidates for replacing conventional Ti-alloys in gas turbine applications in the relatively lower temperature sections, owing to their low density and excellent high temperature properties. However, their intolerable ambient temperature brittleness hinders their use in such applications. Recently, TiAl alloys with some room temperature ductility were developed through alloy development programmes using special production routes such as powder metallurgy. However, the room temperature brittleness of these alloys could not be overcome.

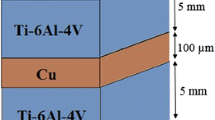

Sound joining of these alloys is a fundamental prerequisite for their successful integration into high temperature aerospace applications. It has been well demonstrated that diffusion bonding, a commonly used joining technology in conventional Ti-alloys, can successfully be used in joining of TiAl alloys both in as-cast or special-rolled conditions. In this study, diffusion bondability of a recently developed C containing TiAl alloy with a duplex microstructure using bonding parameters in the range of commercially available equipments was studied. Microstructural investigations in the joint area of the bonds were conducted to observe the presence of any weld defect. Additionally, the mechanical behaviour of the bonds was determined by shear testing to find out the optimum bonding parameters. Furthermore, the effect of post-bond heat treatment on the mechanical properties was investigated.

Similar content being viewed by others

References

Kim Y-W (1989) JOM 41:24

Kim Y-W, Dimiduk DM (1991) JOM 43:40

Kim Y-W. (1994) JOM 46:30

Yamaguchi M, Umakoshi Y (1990) Prog Mater Sci 34:1

Appel F, Wagner R (1998) Mater Sci Eng R 22:187

Appel F, Brossmann U, Christoph U, Eggert S, Janschek P, Lorenz U, Müllauer J, Oehring M, Paul JDH (2000) Adv Eng Mater 2(11):699

Patterson RA, Martin PL, Damkroger BK, Christodoulou L (1990) Weld J 69:39s

Threadgill PL (1995) Mater Sci Eng A192–193:640

Yan P, Wallach RE (1993) Intermetallics 1:83

Çam G., Bohm K-H, Müllauer J, Koçak M (1996) JOM 48(11):66

Çam G, Müllauer J, Koçak M (1997) Sci Technol Weld Join 2(5):213

Bohm K-H, Ventzke V, Çam G, Koçak M (1997) Schweiβen und Schneiden 49(9):660

Glatz W, Clemens H (1997) Intermetallics 5:415

Çam G, Koçak M (1998) Int Mater Rev 43(1):1

Holmquist M, Recina V, Ockborn J, Pettersson B, Zumalde E (1998) Scripta Mater 39:1101

Çam G, Clemens H, Gerling R, Koçak M (1999) Intermetallics 7(9):1025

Çam G, Clemens H, Gerling R, Koçak M (1999) Z Metallkd 90 (4):284

Çam G, Bohm K-H, Koçak M (1999) Schweiβn und Schneiden 51(8):470

Çam G, Koçak M (1999) J Mater Sci 34:3345

Lee SJ, Wu SK (1999) Intermetallics 7(1):11

Masahashi N, Hanada S, Mizuhara Y (2001) Mater Trans 42(6):1028

Buque C, Appel F (2002) Z Metallkd 93 (8) 784

Gremand M, Garrard M, Kurz W (1990) Acta Metall 38:2587

Lin JG, Yu GS, Wu GQ, Huang Z (2001) J Mater Sci Lett 20:1671

Acknowledgements

This work was carried out within the German–Turkish joint project entitled “Solid State Joining of Advanced Light Weight High Temperature Materials for Aerospace and Automobile Applications’’ financed by KFA-Jülich Reseacrh Center, Germany and Tübitak, Ankara, Turkey. The authors would like to thank both organisations for their financial support. The authors also thank Dr. F. Appel for supplying the new generation C-containing TiAl alloy, Mr. V. Ventzke for his help with SEM and Mrs. P.-M. Fischer for her help with optical microscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çam, G., İpekoğlu, G., Bohm, K.H. et al. Investigation into the microstructure and mechanical properties of diffusion bonded TiAl alloys. J Mater Sci 41, 5273–5282 (2006). https://doi.org/10.1007/s10853-006-0292-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0292-4