Abstract

There is an ever-increasing demand for polymer-based electrical leads patterned on polymer substrates of any shape to connect two electrical components. Much, however, still remains challenging about electrical leads made of polymer nanocomposites that have high affinity to polymer substrates and outstanding applicability to curved surfaces, unlike metals. This leads to the need for the development of photopatternable and electrically conductive polymer nanocomposites and, by extension, comprehensive understanding of the constituent and processes involved in their development. Here, a set of polymer nanocomposites incorporating exfoliated graphite nanoplatelet (xGnP) into SU-8, xGnP/SU-8 nanocomposites, are developed as photopatternable and electrically conductive nanocomposites for electrical lead micropatterning. The inclusion of xGnP, carbon-based conductive nanofiller, is intended to provide electrical conductivity, and the use of SU-8, photocurable host polymer, is designed to achieve both patternability and strong adhesion to polymer surfaces. First, the dependence of patterning characteristics (i.e., patterning thickness and patterning error) on xGnP content and UV exposure dose are extensively explored. The patterning thickness varies from 7.4 to 199.6 μm, and the patterning error changes from 12.1 to 32.7 μm with variations in xGnP content of 0.00–9.65 vol% and UV exposure dose of 500–5000 mJ/cm2. Next, an evolution in the electrical conductivity of xGnP/SU-8 nanocomposites with variation of xGnP content is explored to understand their electrical behavior. The electrical conductivity increases from 0.8 µS/m to 866.7 S/m with an increase in xGnP content of 0.00–9.65 vol%. Finally yet importantly, the applicability of xGnP/SU-8 nanocomposites to electrical lead micropatterning is demonstrated by photopatterning an electrical circuit for light-emitting diode chips using the xGnP/SU-8 nanocomposites on polydimethylsiloxane (PDMS) substrate. The findings of this study will contribute to a significant growth of polymer-based electrical leads and better understanding of photopatternable and electrically conductive nanocomposites.

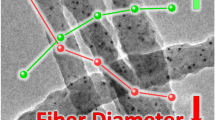

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Jose JP, Joseph K (2012) Advances in polymer composites: macro- and microcomposites—state of the art, new challenges, and opportunities. In: Thomas S, Kuruvilla J, Malhotra SK, Goda K, Sadasivan SM (eds) Polymer composites. Wiley-VCH, Weinheim, pp 1–16

Park S, Nam G, Choi Y, Woo S, Uhm W, Park S, Yoon S-H (2018) Mechanoelectrical properties of a GnF/PDMS composite controlled by the aspect ratio and concentration of GnF. Compos Sci Technol 159:77–86. https://doi.org/10.1016/j.compscitech.2018.02.032

Ha S, Choi Y, Lee W, Kim Y, Yoon S-H (2021) Prediction of mechanical properties of graphite nanoflake/polydimethylsiloxane nanocomposites as affected by processing method. Compos Part B Eng 224:109186. https://doi.org/10.1016/j.compositesb.2021.109186

Bae M, Woo S, Lee JM, Lee W, Yoon S-H (2022) A prediction model for photopatternable thickness of photocurable polymer nanocomposites containing carbon-based high-aspect-ratio fillers. Compos Sci Technol 218:109207. https://doi.org/10.1016/j.compscitech.2021.109207

Chang J-H, Park KM (2001) Polyimide nanocomposites: comparison of their properties with precursor polymer nanocomposites. Polym Eng Sci 41:2226–2230. https://doi.org/10.1002/pen.10918

Kim H, Miura Y, Macosko CW (2010) Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem Mater 22:3441–3450. https://doi.org/10.1021/cm100477v

Paran SMR, Naderi G, Javadi F, Shemshadi R, Saeb MR (2020) Experimental and theoretical analyses on mechanical properties and stiffness of hybrid graphene/graphene oxide reinforced EPDM/NBR nanocomposites. Mater Today Commun 22:100763. https://doi.org/10.1016/j.mtcomm.2019.100763

Chartier T, Hinczewski C, Corbel S (1999) UV curable systems for tape casting. J Eur Ceram Soc 19:67–74. https://doi.org/10.1016/S0955-2219(98)00177-0

Jiguet S, Bertsch A, Hofmann H, Renaud P (2005) Conductive SU8 photoresist for microfabrication. Adv Funct Mater 15:1511–1516. https://doi.org/10.1002/adfm.200400575

Damean N, Parviz BA, Lee JN, Odom T, Whitesides GM (2005) Composite ferromagnetic photoresist for the fabrication of microelectromechanical systems. J Micromech Microeng 15:29–34. https://doi.org/10.1088/0960-1317/15/1/005

Chen G, Wu D, Weng W, Wu C (2003) Exfoliation of graphite flake and its nanocomposites. Carbon 41:619–621. https://doi.org/10.1016/S0008-6223(02)00409-8

Grimaldi C, Mionić M, Gaal R, Forró L, Magrez A (2013) Electrical conductivity of multi-walled carbon nanotubes-SU8 epoxy composites. Appl Phys Lett 102:223114. https://doi.org/10.1063/1.4809923

Wardle BL, Saito DS, García EJ, Hart AJ, de Villoria RG, Verploegen EA (2008) Fabrication and characterization of ultrahigh-volume-fraction aligned carbon nanotube–polymer composites. Adv Mater 20:2707–2714. https://doi.org/10.1002/adma.200800295

Wang Z, Li X, Wang L et al (2020) Flexible multi-walled carbon nanotubes/polydimethylsiloxane membranous composites toward high-permittivity performance. Adv Compos Hybrid Mater 3:1–7. https://doi.org/10.1007/s42114-020-00144-6

Choi DY, Kang HW, Sung HJ, Kim SS (2013) Annealing-free, flexible silver nanowire–polymer composite electrodes via a continuous two-step spray-coating method. Nanoscale 5:977–983. https://doi.org/10.1039/C2NR32221H

Stankovich S, Dikin DA, Dommett GHB et al (2006) Graphene-based composite materials. Nature 442:282–286. https://doi.org/10.1038/nature04969

Majidian M, Grimaldi C, Pisoni A, Forró L, Magrez A (2014) Electrical conduction of photo-patternable SU8–graphene composites. Carbon 80:364–372. https://doi.org/10.1016/j.carbon.2014.08.075

Luo X, Yang G, Schubert DW (2022) Electrically conductive polymer composite containing hybrid graphene nanoplatelets and carbon nanotubes: synergistic effect and tunable conductivity anisotropy. Adv Compos Hybrid Mater 5:250–262. https://doi.org/10.1007/s42114-021-00332-y

Lu H, Li X, Lei Q (2021) Conjugated conductive polymer materials and its applications: a mini-review. Front Chem. https://doi.org/10.3389/fchem.2021.732132

Ha JS, Lee SW, Lee HJ et al (2008) The fabrication of vertical light-emitting diodes using chemical lift-off process. IEEE Photonics Technol Lett 20:175–177. https://doi.org/10.1109/LPT.2007.912491

Liu H, Li Q, Zhang S et al (2018) Electrically conductive polymer composites for smart flexible strain sensors: a critical review. J Mater Chem C 6:12121–12141. https://doi.org/10.1039/C8TC04079F

Wang T, Zhang Y, Liu Q et al (2018) A self-healable, highly stretchable, and solution processable conductive polymer composite for ultrasensitive strain and pressure sensing. Adv Func Mater 28:1705551. https://doi.org/10.1002/adfm.201705551

Gao J, Wang L, Guo Z et al (2020) Flexible, superhydrophobic, and electrically conductive polymer nanofiber composite for multifunctional sensing applications. Chem Eng J 381:122778. https://doi.org/10.1016/j.cej.2019.122778

Chen J, Zhu Y, Guo Z, Nasibulin AG (2020) Recent progress on thermo-electrical properties of conductive polymer composites and their application in temperature sensors. Eng Sci 12:13–22. https://doi.org/10.30919/es8d1129

Zhao W, Chen L, Hu S, Shi Z, Gao X, Silberschmidt VV (2020) Printed hydrogel nanocomposites: fine-tuning nanostructure for anisotropic mechanical and conductive properties. Adv Compos Hybrid Mater 3:315–324. https://doi.org/10.1007/s42114-020-00161-5

Chiang WY, Chan SC (1991) Preparation and properties of UV-autocurable BTDA-based epoxy-multiacrylate resins. Effects of the degree of polymerization and the epoxy type. J Appl Polym Sci 43:1827–1836. https://doi.org/10.1002/app.1991.070431006

Qin Y, Yu Q, Yin X et al (2019) Photo-polymerized trifunctional acrylate resin/magnesium hydroxide fluids/cotton fabric composites with enhancing mechanical and moisture barrier properties. Adv Compos Hybrid Mater 2:320–329. https://doi.org/10.1007/s42114-019-00088-6

Sangermano M, Marchi S, Valentini L, Bon SB, Fabbri P (2011) Transparent and conductive graphene oxide/poly(ethylene glycol) diacrylate coatings obtained by photopolymerization. Macromol Mater Eng 296:401–407. https://doi.org/10.1002/mame.201000372

Li F, Chen S, Wei Y, Liu K, Lin Y, Liu L (2016) Facile, low-cost, UV-curing approach to prepare highly conductive composites for flexible electronics applications. J Electron Mater 45:3603–3611. https://doi.org/10.1007/s11664-016-4525-2

Ando M, Goto T, Tsuchiya M, Uryu T (1988) Microporous polyurethane-acrylamide film cured by electron beam irradiation. Polymer 29:2136–2140. https://doi.org/10.1016/0032-3861(88)90103-6

Abgrall P, Conedera V, Camon H, Gue A-M, Nguyen N-T (2007) SU-8 as a structural material for labs-on-chips and microelectromechanical systems. Electrophoresis 28:4539–4551. https://doi.org/10.1002/elps.200700333

Majidian M, Grimaldi C, Forró L, Magrez A (2017) Role of the particle size polydispersity in the electrical conductivity of carbon nanotube-epoxy composites. Sci Rep 7:12553. https://doi.org/10.1038/s41598-017-12857-8

Mamunya YP, Davydenko VV, Pissis P, Lebedev EV (2002) Electrical and thermal conductivity of polymers filled with metal powders. Eur Polymer J 38:1887–1897. https://doi.org/10.1016/S0014-3057(02)00064-2

Park S, Kim J, Jeon K-J, Yoon S-H (2016) Characterization on the expanding nature of graphite in microwave-irradiated exfoliation. J Nanosci Nanotechnol 16:4450–4455. https://doi.org/10.1166/jnn.2016.10980

Martinez-Duarte R, Madou M (2011) SU-8 photolithography and its impact on microfluidics. In: Mitra SK, Chakraborty S (eds) Microfluidics and nanofluidics handbook. CRC Press, Boca Raton, pp 231–268

Lim H, Ha S, Bae M, Yoon S-H (2021) A highly robust approach to fabricate the mass-customizable mold of sharp-tipped biodegradable polymer microneedles for drug delivery. Int J Pharm 600:120475. https://doi.org/10.1016/j.ijpharm.2021.120475

Vijayarangamuthu K, Ahn S, Seo H, Yoon S-H, Park C-M, Jeon K-J (2016) Temporospatial control of graphene wettability. Adv Mater 28:661–667. https://doi.org/10.1002/adma.201503444

Poli AL, Batista T, Schmitt CC, Gessner F, Neumann MG (2008) Effect of sonication on the particle size of montmorillonite clays. J Colloid Interface Sci 325:386–390. https://doi.org/10.1016/j.jcis.2008.06.016

Becnel C, Desta Y, Kelly K (2005) Ultra-deep x-ray lithography of densely packed SU-8 features: II. Process performance as a function of dose, feature height and post exposure bake temperature. J Micromech Microeng 15:1249–1259. https://doi.org/10.1088/0960-1317/15/6/016

Campo Ad, Greiner C (2007) SU-8: a photoresist for high-aspect-ratio and 3D submicron lithography. J Micromech Microeng 17:R81–R95. https://doi.org/10.1088/0960-1317/17/6/r01

Gaudet M, Camart J-C, Buchaillot L, Arscott S (2006) Variation of absorption coefficient and determination of critical dose of SU-8 at 365 nm. Appl Phys Lett 88:024107. https://doi.org/10.1063/1.2164390

Polyanskiy MN (2008) Refractive index database. https://refractiveindex.info. Accessed 15 May 2022

Swinehart DF (1962) The Beer–Lambert law. J Chem Educ 39:333. https://doi.org/10.1021/ed039p333

Yu PY, Cardona M (1996) Electrical transport. In: Yu PY, Cardona M (eds) Fundamentals of semiconductors: physics and materials properties. Springer, Berlin, pp 203–241

Mutiso RM, Winey KI (2012) Electrical conductivity of polymer nanocomposites. In: Matyjaszewski K, Möller M (eds) Polymer science: a comprehensive reference. Elsevier, Amsterdam, pp 327–344

Ponnamma D, Ninan N, Thomas S (2018) Carbon nanotube tube filled polymer nanocomposites and their applications in tissue engineering. In: Mohan Bhagyaraj S, Oluwafemi OS, Kalarikkal N, Thomas S (eds) Applications of nanomaterials. Woodhead Publishing, pp 391–414

Mansor MR, Fadzullah SHSM, Masripan NAB, Omar G, Akop MZ (2019) Comparison between functionalized graphene and carbon nanotubes: effect of morphology and surface group on mechanical, electrical, and thermal properties of nanocomposites. In: Jawaid M, Bouhfid R, Kacem Qaiss AE (eds) Functionalized graphene nanocomposites and their derivatives. Elsevier, pp 177–204

Mohd Radzuan NA, Sulong AB, Sahari J (2017) A review of electrical conductivity models for conductive polymer composite. Int J Hydrogen Energy 42:9262–9273. https://doi.org/10.1016/j.ijhydene.2016.03.045

Kwon OS, Park SJ, Hong J-Y et al (2012) Flexible FET-type VEGF Aptasensor based on nitrogen-doped graphene converted from conducting polymer. ACS Nano 6:1486–1493. https://doi.org/10.1021/nn204395n

Williams G, Seger B, Kamat PV (2008) TiO2-graphene nanocomposites. UV-assisted photocatalytic reduction of graphene oxide. ACS Nano 2:1487–1491. https://doi.org/10.1021/nn800251f

Kalita G, Wakita K, Takahashi M, Umeno M (2011) Iodine doping in solid precursor-based CVD growth graphene film. J Mater Chem 21:15209–15213. https://doi.org/10.1039/C1JM13268G

Zhang X, Hsu A, Wang H, Song Y, Kong J, Dresselhaus MS, Palacios T (2013) Impact of chlorine functionalization on high-mobility chemical vapor deposition grown graphene. ACS Nano 7:7262–7270. https://doi.org/10.1021/nn4026756

Ceyssens F, Puers R (2012) SU-8 photoresist. In: Bhushan B (ed) Encyclopedia of nanotechnology. Springer, Netherlands, pp 2530–2543

Lee SY, Park K-I, Huh C et al (2012) Water-resistant flexible GaN LED on a liquid crystal polymer substrate for implantable biomedical applications. Nano Energy 1:145–151. https://doi.org/10.1016/j.nanoen.2011.07.001

Peng Y, Que M, Lee HE et al (2019) Achieving high-resolution pressure mapping via flexible GaN/ ZnO nanowire LEDs array by piezo-phototronic effect. Nano Energy 58:633–640. https://doi.org/10.1016/j.nanoen.2019.01.076

Pantelopoulos A, Bourbakis NG (2010) Prognosis—a wearable health-monitoring system for people at risk: methodology and modeling. IEEE Trans Inf Technol Biomed 14:613–621. https://doi.org/10.1109/TITB.2010.2040085

Acknowledgements

This work was supported by the Agency for Defense Development Grant funded by the Korean Government (UG210017GD and UE211160SD).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Handling Editor: Handling Editor: Kevin Jones.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, Y., Song, S., Lee, W. et al. Exfoliated graphite nanoplatelet-reinforced SU-8 for microelectrical contacts. J Mater Sci 58, 7380–7397 (2023). https://doi.org/10.1007/s10853-023-08492-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08492-6