Abstract

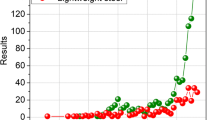

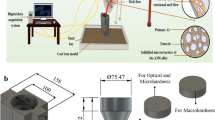

Accurate and consistent constitutive model is required to characterize the material behavior in a variety of thermo-mechanical problems. Herein, widely used Johnson–Cook (J–C) model parameters are evaluated for Fe–30Mn–9Al–0.8C low-density steel to predict the flow stress in various forming applications. For this low-density steel prepared in our laboratory, the material compositions are optimally chosen to yield the best ductility (> 70%) with good tensile strength. Tensile tests have been performed at strain rates varying from 10–4 to 10–1 s−1 and at various temperatures such as 150 °C, 300 °C and 450 °C to determine the J–C parameters. Thereafter, genetic algorithm (GA) technique has been used to obtain optimum values of J–C parameters that best fit the experimental stress–strain data. The improved values of the J–C parameter are implemented in ABAQUS explicit software to replicate the experimentally observed tensile test data. It has been observed that the developed constitutive model can produce a fairly accurate and precise estimation of flow stress with a good correlation to experimental data under various strain rates and temperature conditions.

Similar content being viewed by others

Data and code availability

Not applicable.

References

Tisza M (2020) Development of lightweight steels for automotive applications. Eng. Steels High Entropy-Alloys, 1–22

Zuazo I, Hallstedt B, Lindahl B, Selleby M, Soler M, Etienne A, Perlade A, Hasenpouth D, Massardier-Jourdan V, Cazottes S, Kleber X (2014) Low-density steels: complex metallurgy for automotive applications. JOM 66:1747–1758. https://doi.org/10.1007/s11837-014-1084-y

Chen S, Rana R, Haldar A, Ray RK (2017) Current state of Fe–Mn–Al–C low density steels. Prog Mater Sci 89:345–391. https://doi.org/10.1016/j.pmatsci.2017.05.002

Mohamadizadeh A, Zarei-Hanzaki A, Abedi HR (2016) Modified constitutive analysis and activation energy evolution of a low-density steel considering the effect of deformation parameters. Mech Mater 95:60–70. https://doi.org/10.1016/j.mechmat.2016.01.001

Song YLR, Yang EWF (2016) Hot deformation and dynamic recrystallization behavior of austenite-based low-density Fe–Mn–Al–C steel. Acta Metall Sin 29:441–449. https://doi.org/10.1007/s40195-016-0406-1

Wang Y, Hu F, Wang Z, Fu K, Li W, Wang J, Guo J (2022) Microstructure and constitutive equation of hot compressive Fe–15Mn–15Al–5Ni–1C low-density steel. Materials 15:1–18. https://doi.org/10.3390/ma15082721

Wan P, Yu H, Li F, Gao P, Zhang L, Zhao Z (2022) Hot deformation behaviors and process parameters optimization of low-density high-strength Fe–Mn–Al–C alloy steel. Met Mater Int 28:2498–2512. https://doi.org/10.1007/s12540-021-01144-x

Wang CH, Sun CY, Qian LY, Cai W, Jiang J, Xiao Y (2021) Dynamic mechanical behaviour induced by adiabatic temperature rise of Fe–Mn–Al–C steel. Mat Sci Tech 37:280–291. https://doi.org/10.1080/02670836.2021.1885580

Wang YY, Sun X, Wang YD, Zbib HM (2015) Effects of Mn content on the deformation behavior of Fe–Mn–Al–C TWIP steels: a computational study. J Eng Mater Technol Trans 137:021001. https://doi.org/10.1115/1.4029041

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21:31–48. https://doi.org/10.1016/0013-7944(85)90052-9

Galan-Lopez J, Verleysen P (2018) Simulation of the plastic response of Ti–6Al–4V thin sheet under different loading conditions using the viscoplastic self- consistent model. Mater Sci Eng A 712:1–11. https://doi.org/10.1016/j.msea.2017.11.070

Korkmaz ME (2019) Determination and verification of Johnson–Cook parameters for 430 ferritic steels via different gage lengths. Trans Indian Inst Met 72:2663–2672. https://doi.org/10.1007/s12666-019-01734-9

Teker E, Danish M, Gupta MK, Kuntoglu M, Korkmaz ME (2022) Hot deformation behavior and strain rate sensitivity of 33Mn CrB5 boron steel using material constitutive equations. Trans Indian Int Met 75:1–10. https://doi.org/10.1007/s12666-021-02474-5

Buchely MF, Ganguly S, Van Aken DC, O’Malley R, Lekakh S, Chandrashekhara K (2020) Experimental development of johnson-cook strength model for different carbon steel grades and application for single-pass hot rolling. Steel Res Int 91:1900670. https://doi.org/10.1002/srin.201900670

Murugesan M, Jung DW (2019) Johnson cook material and failure model parameters estimation of AISI-1045 medium carbon steel for metal forming applications. Materials (Basel). https://doi.org/10.3390/ma12040609

Prawoto Y, Fanone M, Shahedi S, Ismail MS, Wan Nik WB (2012) Computational approach using Johnson–Cook model on dual phase steel. Comput Mater Sci 54:48–55. https://doi.org/10.1016/j.commatsci.2011.10.021

Hui L, Rui F (2022) Dynamic deformation behavior and corresponding constitutive model of ultra-high strength DP1000 steel. J Constr Steel Res 191:107188. https://doi.org/10.1016/j.jcsr.2022.107188

Bal B, Karaveli KK, Cetin B, Gumus B (2019) the precise determination of the Johnson–Cook material and damage model parameters and mechanical properties of an aluminum 7068–T651 alloy. J Eng Mater Technol Trans 141:1–10. https://doi.org/10.1115/1.4042870

Akturk M, Boy M, Gupta MK, Waqar S, Krolczyk GM, Korkmaz ME (2021) Numerical and experimental investigations of built orientation dependent Johnson–Cook model for selective laser melting manufactured AlSi10Mg. J Mater Res Technol 15:6244–6259. https://doi.org/10.1016/j.jmrt.2021.11.062

Korkmaz ME, Gunay M, Verleysen P (2019) Investigation of tensile Johnson–Cook model parameters for Nimonic 80A superalloy. J Alloys Compd 801:542–549. https://doi.org/10.1016/j.jallcom.2019.06.153

Korkmaz ME, Verleysen P, Gunay M (2018) Identification of constitutive model parameters for nimonic 80A superalloy. Trans Indian Inst Met 71:2945–2952. https://doi.org/10.1007/s12666-018-1394-9

Hasan MS, Pellegrin DD, Clegg R, Yan C (2022) Johnson-Cook model parameters determination for 11% and 14% Mn-Steel. Mater Sci Eng B 283:115788. https://doi.org/10.1016/j.mseb.2022.115788

Wang W, Ma Y, Yang M, Jiang P, Yuan F, Wu X (2017) Strain rate effect on tensile behavior for a high specific strength steel: from quasi-static to intermediate strain rates. Metals (Basel) 8:11. https://doi.org/10.3390/met8010011

Buchely MF, Wang X, Van Aken DC, O’Malley RJ, Lekakh S, Chandrashekhara K (2019) The use of genetic algorithms to calibrate Johnson–cook strength and failure parameters of AISI/SAE 1018 Steel. J Eng Mater Technol Trans ASME 141:1–12. https://doi.org/10.1115/1.4042382

Aghdami AM, Davoodi B (2020) An inverse analysis to identify the Johnson-Cook constitutive model parameters for cold wire drawing process. Mech Ind 21:527. https://doi.org/10.1051/meca/2020070

Sagar CK, Chilukuri A, Priyadrashini A (2018) Determination of johnson cook material model constants for 93% WHA and optimization using genetic algorithm. Mater Today Proc 5:18911–18919. https://doi.org/10.1016/j.matpr.2018.06.240

Chen G, Ren C, Yu W, Yang X, Zhang L (2012) Application of genetic algorithms for optimizing the Johnson–Cook constitutive model parameters when simulating the titanium alloy Ti–6Al–4V machining process. Proc Inst Mech Eng Part B J Eng Manuf 226:1287–1297. https://doi.org/10.1177/0954405412447735

Loschner P, Jarosz K, Niesłony P (2019) Optimization of Johnson–Cook constitutive model parameters. Eng Mech Eng Manuf 19:66–73. https://doi.org/10.5604/01.3001.0013.4082

Kim H, Suh DW, Kim NJ (2013) Fe–Al–Mn–C lightweight structural alloys: a review on the microstructures and mechanical properties. Sci Technol Adv Mater. 14:014205. https://doi.org/10.1088/1468-6996/14/1/014205

Howell RA, Gerth R (2017) Fe–Mn–Al–C alloy steels–a new armor class. SAE Tech Paper. https://doi.org/10.4271/2017-01-1703

Hu S, Zheng Z, Yang W, Yang H (2022) Fe–Mn–C–Al low-density steel for structural materials: a review of alloying, heat treatment, microstructure, and mechanical properties. Steel Res Int 93:2200191. https://doi.org/10.1002/srin.202200191

Ivoditov VA, Perkas MM, Shelest AE, Yusupov VS (2008) Materials science in automobile design. Steel Transl 38:876–880. https://doi.org/10.3103/S0967091208100197

Grassel O, Kruger L, Frommeyer G, Meyer LW (2000) High strength Fe–Mn–(Al, Si) TRIP/TWIP steels development—properties—application. Int J Plasticity 16:1391–1409. https://doi.org/10.1016/S0749-6419(00)00015-2

Tjong SC, Zhu SM (1997) Tensile deformation behavior and work hardening mechanism of Fe–28Mn–9Al–0.4 C and Fe–28Mn–9Al–1C alloys. Mater Trans JIM 38:112–118. https://doi.org/10.2320/matertrans1989.38.112

Chen Z, Liu MX, Zhang JK, Yang L, Zhang YH, Song CJ, Zhai QJ (2021) Effect of annealing treatment on microstructures and properties of austenite-based Fe–28Mn–9Al–0.8 C lightweight steel with addition of Cu. China Foundry 18:207–216. https://doi.org/10.1007/s41230-021-1026-6

Xing J, Hou L, Du H, Liu B, Wei Y (2019) A new explanation for the effect of dynamic strain aging on negative strain rate sensitivity in Fe–30Mn–9Al–1C steel. Materials (Basel) 12:1–15. https://doi.org/10.3390/ma12203426

Du J, Chen P, Guan X, Cai J, Peng Q, Lin C, Li X (2022) The effect of strain rate on the deformation behavior of Fe–30Mn–8Al–1.0C austenitic low-density steel. Metals (Basel) 120:1374. https://doi.org/10.3390/met12081374

Yoo JD, Park KT (2008) Microband-induced plasticity in a high Mn–Al–C light steel. Mater Sci Eng A 496:417–424. https://doi.org/10.1016/j.msea.2008.05.042

Yoo JD, Hwang SW, Park KT (2009) Factors influencing the tensile behavior of a Fe–28Mn–9Al–0.8C steel. Mater Sci Eng A 508:234–240. https://doi.org/10.1016/j.msea.2008.12.055

Acknowledgements

The authors are most grateful to the reviewers of this paper, particularly for some positive comments and constructive criticism, thereby leading to a more improved presentation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors disclose that there are no conflicts of interest related to the present work.

Ethical Approval

Not applicable.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, H., Manna, R. & Khan, D. Evaluation of Johnson–Cook material model parameters for Fe–30Mn–9Al–0.8C low-density steel in metal forming applications. J Mater Sci 58, 8118–8129 (2023). https://doi.org/10.1007/s10853-023-08485-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08485-5