Abstract

Here, we synthesized metal-free organic dye (CCPICPB) with two carbazole donor groups and two anchoring groups that exhibit a panchromatic absorption in the near-infrared range of up to 750 nm. To study the photophysical properties of synthesized CCPICPB dye, the UV–Vis and cyclic voltammetric experiments were studied and the obtained results were validated with theoretical simulation studies. After that, the solvothermal approach is used to synthesize pristine anatase and calcium (Ca)-doped TiO2 microspheres with a smooth morphology. These microstructures are examined in depth using XRD, electron microscopy and electrochemical analysis methods. On TiO2 and Ca-doped TiO2 photoanode materials, we first evaluated the performance of CCPICPB dye. Upon our optimized experimental condition, the 3% Ca-TiO2 photoanode-based device exhibits an efficiency of 4.04%, which is greater than that of the pristine TiO2 photoanode-based device (2.93%). Because of the quicker electron transport in the Ca-TiO2 film, the short-circuit current density and efficiency of DSSCs were improved. Moreover, when the CCPICPB dye was used as a co-sensitizer with the common Ru(II) dye (Z907), interestingly it showed the highest efficiency (6.11%) when compared with Z907 alone (5.12%). This improved efficiency of the co-sensitized device resulted from greater VOC conjugated with improved JSC. The JSC was improved because CCPICB dye could compensate for the photocurrent loss caused by redox electrolyte while the VOC was improved because electron recombination was inhibited under the co-sensitization conditions.

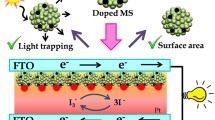

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

For a long time, a continual search for alternate energy sources has been undertaken to address the energy crisis. Compared to the other renewable energy sources, solar energy has the most potential for growth, making it a strong contender for sustainable and renewable energy [1]. Different types of photovoltaic devices were came into existence to convert solar energy into electrical energy [2,3,4,5,6,7,8,9,10,11,12,13,14]. Because of its cheap manufacturing cost and environmental compatibility, dye-sensitized solar cells (DSSCs) have piqued the interest of researchers as a next-generation solar cell technology [15,16,17,18,19,20,21]. Various types of efficient DSSCs have been created since the first report in 1991 [22].

The wide band gap semiconductor photoanode is known as the heart of the DSSC, which has a high surface area for the adsorption of sensitizer. Over the last two decades, advances in nanotechnology have produced a variety of metal oxide semiconductor nanostructures that have considerably improved the performance of solar cell devices on commercial modules [23]. Because of its matching band structure compatibility, outstanding physical properties and high electrical mobility, different metal oxides, including SnO2, ZnO and TiO2, were extensively explored as photoanodes in DSSCs. TiO2-based photoanodes are widely employed among them because of its stability, non-toxic nature and high bulk electron mobility [24]. A photoanode with a good dye loading capacity, large surface area, strong light-scattering effect for enhanced light absorption and quick electron transport is required as an essential component of DSSC. As a result, improving the photoanode morphology is required to enhance its performance on device. To synthesize different structured TiO2, various techniques have been developed to date [25,26,27,28,29,30,31,32]. DSSCs using TiO2 microspheres as photoanode have showed improved efficiency because of their well-connected nanocrystallinity, strong scattering ability and large special surface area [33, 34]. Further, doping of TiO2 with non-metallic or metallic ions has received a lot of interest in recent decades because of the enormous variety of surface states in nanocrystalline TiO2, which makes it simple to modify features like electron density, band gap or Fermi level [35, 36]. In recent years, cation-doped TiO2, namely Cu- [37], Cr- [38], Ca- [39], Ni- [40] and Mn-doped TiO2 [41], has been investigated for use as DSSC photoanodes. Furthermore, the majority of the doping effort has been concentrated on the nanoparticle structure, which has several barriers, resulting in a significant recombination possibility. Recently, Zafar Arshad et al. have reported that non-metal like Ca doped in TiO2 with different Ca compositions for improving the electron transport of perovskite solar cells [42]. In this work, we have taken an effort to synthesis Ca ion-doped microstructured TiO2 for the first time to use as a photoanode material which showed better device performance than the pristine microstructured TiO2.

The performance of photovoltaic devices is directly determined by the photosensitizer, which is a crucial component of DSSCs [43]. To improve the power conversion efficiency (PCE) of devices, a photosensitizer synthesis method is important to broadening of the absorption spectra and raises the molar extinction coefficient in order to collect more photons from solar energy. Many kinds of photosensitizers have been studied so far, including ruthenium complexes [44], porphyrin dyes [45, 46] and metal-free organic dyes [47, 48]. Metal-free organic sensitizers have increased the interest of many researchers because of their unique properties like ease of synthesis, low purifying cost, customizable absorption spectra, high molar extinction coefficient and customizing energy levels [43, 49]. Metal-free sensitizers are usually made up of donor (D), spacer (π) and acceptor (A). On this basis, dyes with different architectures (D–π–A, 2D–π–2A, D–D–π–A and so on) have also been developed to attain higher power efficiency [50,51,52]. A number of donors have been established as the molecular structure's core, including, carbazole [53], triphenylamine [54], indoline [55], fluorine [56] and phenothiazine [57, 58]. Carbazole is a popular donor because of its electron-rich characteristics, high hole transport capabilities, and chemical and thermal stability [59]. Furthermore, using several anchoring units within the one molecule enhances the photovoltaic efficacy of the generated dye [60,61,62,63,64]. However, the co-sensitization strategy incorporates the combining of different types of dyes in the DSSCs which showed further boosting the overall DSSC device's performance [65,66,67,68].

In the present work, anatase type TiO2 and different concentrations of Ca-doped TiO2 (Ca-TiO2) with microsphere shape were synthesized using solvothermal method. These microstructures have been thoroughly analysed using XRD, electron microscopy and electrochemical methods. Further, the DSSC performance of photoanodes made with these microspheres is examined. The high efficiency was obtained for 3% Ca-TiO2-based device compared to that of bare TiO2-based device. The design and synthesis of a new metal-free organic sensitizer with a 2(D–π–A) structure is reported here (CCPICPB). It utilizes acid as the anchoring group and N-etyl-carbazole as the electron donor. Additionally, their optical, electrochemical and photovoltaic properties were thoroughly studied and investigated their co-sensitization with ruthenium complexes like Z907. Compared to the device with Z907 (5.12%) alone, the CCPICPB co-sensitized DSSC demonstrated higher photovoltaic performance (6.11%), which is mainly attributed to their increased short-circuit current density (JSC) and boosted open-circuit voltage (VOC).

Experimental

Materials and methods

Chemicals were used as received (from TCI and Merck) without further purification. An FTIR spectrum of synthesized dye was recorded in a Shimadzu-8400S spectrometer in the range 400–4000 cm−1. Further its 1H-NMR and 13C-NMR recorded with TMS as an internal reference in Bruker (400 MHz and 100 MHz, respectively) spectrometers. The crystallographic phases of the bare and Ca-TiO2 microspheres were analysed using X-ray diffraction (XRD) using Bruker Miniflex 600 model. The electrochemical measurements like cyclic voltammetry, electrochemical impedance spectroscopy and Tafel graph were analysed using BioLogic SP-150. The fabricated DSSC was analysed using Keithly 2450 source meter.

Synthesis of 4-(2-((5-(4-carboxyphenyl)-3-(9-ethyl-9H-carbazol-3-yl)-1H-pyrrol-2-yl)imino)-3-(9-ethyl-9H-carbazol-3-yl)-2H-pyrrol-5-yl)benzoic acid (CCPICPB)

-

Step 1Synthesis of 4-(3-(9-ethyl-9H-carbazol-3-yl)acryloyl)benzoic acid

Ethyl-9H-carbazole-3-carbaldehyde (2 mmol), 4-acetylbenzoic acid (2 mmol) and NaOH were dissolved in ethanol and agitated at room temperature for 24 h. After the completion of the reaction, the obtained mixture was poured to water and acidified with hydrochloric acid. The obtained precipitate was filtered, washed with water, dried and recrystallized with methanol. Yield 75%.

-

Step 2Synthesis of 4-(3-(9-ethyl-9H-carbazol-3-yl)-4-nitrobutanoyl)benzoic acid

4-(3-(9-Ethyl-9H-carbazol-3-yl)acryloyl)benzoic acid (4 mmol) was dissolved in anhydrous ethanol, followed by nitromethane (20 mmol) and diethylamine (20 mmol). Then the mixture was kept at 80 °C for 24 h. After the completion of the reaction, the obtained mixture was poured to water and acidified with 1 M hydrochloric acid. Further, the obtained precipitate was filtered and recrystallized from methanol. Yield 82%.

-

Step 3Synthesis of CCPICPB

4-(3-(9-Ethyl-9H-carbazol-3-yl)-4-nitrobutanoyl)benzoic acid (2 mmol) and ammonium acetate (70 mmol) were dissolved in ethanol, and the reaction mixture was refluxed for 48 h. The product was precipitated from the reaction mixture as the reaction progressed. After the completion of the reaction, the product CCPICPB was obtained by filtering and washing with cold ethanol. The CCPICPB obtained as dark blue solid with 44% yield (Scheme 1).

FTIR (cm−1): 1482.1 (C=C), 1724.1 (–C=O), 2916.3 (CH), 3306.5 (OH); 1H NMR (DMSO) δ (ppm): 1.25 (t, J = 7.1 Hz, 3H), 4.32 (q, J = 7.1 Hz, 2H), 7.03 (t, J = 7.4 Hz, 1H), 7.43 (t, J = 9.1 Hz, 2H), 7.58 (d, J = 8.2 Hz, 1H), 7.70 (s, 1H), 7.90 (d, J = 7.7 Hz, 1H), 8.13 (s, 4H), 8.34–8.27 (m, 1H), 8.83 (d, J = 1.7 Hz, 1H), 12.81 (s, 1H); 13C NMR (DMSO) δ (ppm): 14.11, 37.41, 109.22, 109.58, 115.27, 119.15, 120.82, 121.27, 122.90, 124.91, 126.18, 126.66, 127.58, 130.49, 132.36, 135.34, 139.80, 140.32, 143.81, 150.29, 154.19, 167.42.

Synthesis of TiO2 and Ca-TiO2 microspheres

One-pot solvothermal technique was used to create the TiO2 microspheres. The synthesis procedure is as follows: 20 mL of ethanol and 2 mL of acetic acid were mixed, and the mixture was agitated for 15 min at room temperature. 7.4 mL of titanium tetraisopropoxide (TTIP) was gradually added to this solution. The translucent, colourless liquid was sealed in a Teflon-lined autoclave after agitating at room temperature for 15 min. For 2 h, the autoclave was kept at 200 °C. After cooling of Teflon-lined autoclave to ambient temperature, the obtained precipitate was centrifuged and repeatedly washed with ethanol and water, and to obtain crystalline anatase TiO2 microspheres, it was calcinated at 450 °C for 4 h. Following the same procedure as above, the appropriate amount of calcium chloride (1, 2 and 3 mol%) was added to the mixture after addition of TTIP in order to make Ca-TiO2 microspheres.

Fabrication of DSSCs

The synthesized pristine and Ca-TiO2 microsphere films and platinum (Pt) counter electrodes (CE) were fabricated as reported elsewhere [69]. Further, fabricated TiO2, 1% Ca-TiO2, 2% Ca-TiO2 and 3% Ca-TiO2 photoanodes were soaked in CCPICPB dye (0.5 mM) in ethanol/THF (1:1) solutions for 24 h, as well as TiO2 and 3% Ca-TiO2-based photoanodes in Z907 (0.5 mM) in ethanol/THF (1:1) solutions. For the co-sensitization device, photoanode dipped in Z907 dye was then dipped in CCPICPB solution for 24 h. The sensitized and co-sensitized photoanode materials were washed with ethanol to take out unattached sensitizers. The dye anchored photoanodes were then assembled with a Pt CE and polymer electrolyte (PE) made of poly(vinylidene fluoride), polyethylene glycol, potassium iodide, 1-n-hexyl-3-methylimidazolium iodide and iodine [70].

Results and discussion

Optical properties of CCPICPB

Figure 1a shows the UV–Vis absorption spectra of the CCPICPB dye in THF solution, and Table 1 lists the relevant outcomes. Two notable bands were seen in the UV–Vis spectra of solution: one at around 300 nm and the other at 634 nm. The former is explained by the π–π* transitions resulting from the conjugation of the multiple aromatic rings. The intramolecular charge transfer (ICT) transition from the carbazole donor groups to the azadipyrro cores linked to the acid acceptor unit may be responsible for the absorption band at 634 nm. The absorption spectra of the dye anchored on TiO2 film was also examined in order to observe the spectral response upon sensitization. Its absorption curves broaden significantly in contrast to the absorption spectra of CCPICPB in THF (Fig. 1b). CCPICPB's spectral response increased till 850 nm. Additionally, compared to those in the solution state, their absorption peaks were red-shifted; CCPICPB had a significant absorption peak at 648 nm, which should be due to the J-aggregation effect. The red-shift of absorption maxima around 14 nm is also attributed to the deprotonation of the acid group and the charge transfer transitions [71,72,73].

Electrochemical properties of CCPICPB

Level matching is a crucial need before beginning to construct the dye molecular structure. For devices to operate at high VOC and JSC, better regeneration efficiency and high electron injection efficiency are necessary. The ground-state oxidation potential (Eox) of CCPICPB was examined using cyclic voltammetry (CV) to monitor the ability of excited state electron injection and dye regeneration. This will allow us to assess the dye's regenerative capacity as well as its ability to electron injection [74]. We examined the CV characteristics of the CCPICPB dye at a scan rate of 20 mV s−1 in 0.1 M tetraethylammonium tetrafluoroborate (TEABF4) in acetonitrile using glassy carbon as working electrode, Pt as CE and an Ag/AgCl non-aqueous electrode as reference electrode. Additionally, these data were converted to a normal hydrogen electrode (NHE) after being calibrated with Fc/Fc+ as an internal reference (by adding 0.407 V). The obtained CV is depicted in Fig. 2. It is noticeable that the CCPICPB's Eox is 0.91 V from the CV curve (versus NHE). They have a substantially higher positive redox potential than the I−/I3− couple's redox potential of 0.4 V, allowing for efficient recycling of the oxidized dyes [75]. Additionally, the intersection of absorption spectra can be utilized to calculate the zero–zero excitation energy (E0-0), and the value of CCPICPB is 1.61 eV. As a result, the LUMO of CCPICPB is − 0.7 V, which is more negative compared to the TiO2’s conduction band ( − 0.5 V vs NHE). This suggests that the excited dye's electrons may effectively inject into the TiO2 conduction band [76].

Theoretical calculation

The Schrodinger material suite software was used in theoretical investigations to examine the origin of the molecular features of the dye. Calculations using energy minimization and density functional theory (DFT) at the B3LYP-D3 functional and 6-31G** basis set led to the optimized geometries of the CCPICPB dye. Figure 3 shows the HOMO and LUMO frontier molecular orbital of the CCPICPB dye. The electron is delocalized in the donor moiety and π-bridge at the HOMO energy level, whereas the LUMO orbitals are mostly delocalized over the anchoring moiety (benzoic acid). The ICT process from the donor to acceptor is efficiently induced, as seen by the overlapping HOMO and LUMO orbitals on the π-bridge, indicating the favourable charge separation and electron injection into conduction band of TiO2. The CCPICPB dye molecule has HOMO energy level of − 5.00 eV and LUMO energy level of − 2.90 eV, and an energy band gap of 2.1 eV.

Crystalline structure of TiO2 and Ca-TiO2 microspheres

Figure 4 shows the XRD patterns of the Ca-TiO2 and undoped TiO2 microspheres. The anatase phase of TiO2 may be identified by the strong crystalline peak at 2θ = 25.4°. Further, from the graph the anatase phase of the undoped TiO2 is clearly noticeable. No phase transition from the anatase to the rutile or brookite phases was seen. Also it can be observed that the Ca-TiO2 microspheres' noticeable peaks were matching with the undoped TiO2 peaks. The average crystallite size in TiO2, 1%, 2% and 3% doped TiO2, according to the Scherrer equation, is 12.5, 9.2, 9.1 and 8.4 nm, respectively. Ca2+ ions have an ionic radius of 0.112 nm, while Ti4+ ions have an ionic radius of 0.061 nm [77, 78]. The lattice structure of TiO2 is impacted by doping, which is influenced by the ionic radius of the dopant. However, Ca-TiO2 microspheres showed a minor left shift that may have been caused by the introduction of larger Ca2+ into the Ti4+ network expanding the lattice. The absence of a Ca2+ peak in the pattern indicates that the Ca2+ ions have been completely integrated into the TiO2 crystal lattice [79,80,81].

Morphology and structures of TiO2 and 3% Ca-TiO2

Figure 5a–d shows the scanning electron microscopy (SEM) images of prepared TiO2 and 3% Ca-TiO2 microspheres synthesized one-pot solvothermal technique. Figure 5a and b shows that the TiO2 microspheres are well dispersed with a smooth surface. SEM images of 3% Ca-TiO2 show that microspheres are well dispersed with a smooth surface and are connected to each other by broad strong neck (Fig. 5c and d). Same morphologies were also being seen in the field emission scanning electron microscopy (FESEM) images of TiO2 and 3% Ca-TiO2 (Fig. 6a–d). Figure 6a and b shows that TiO2 smooth spherical particles have an average size ~ 5 μm. 3% Ca-TiO2 displayed a typical micrograph that clearly demonstrates polydispersed, well-connected microspheres with expanded necks. These smooth, spherical, polydispersed particles have a size with diameter of ~ 3 μm (Fig. 6c and d). It is clearly visible that 3% Ca-TiO2 microsphere has little rough surface than the bare TiO2 microsphere in inset Fig. 8b and d.

The microsphere structure of doped and bare TiO2 is further confirmed in the high-resolution transmission electron microscopy (HRTEM) images (Fig. 7a and e). The high-magnification picture in Fig. 7b and f reveals that these microspheres are in fact composed of nanoparticles. Figure 7c shows that bare TiO2 displayed (101) plane of TiO2 with interplanar spacing of d = 0.35 nm [82,83,84]. However, 3% Ca-TiO2 particles also showed (101) plane corresponding to anatase TiO2 (Fig. 7g). This demonstrates that bare TiO2 and 3% Ca-TiO2 particles have anatase phase. The high-magnification picture in Fig. 7c and g reveals that these microspheres are in fact comprised of nanoparticles. The associated selected area electron diffraction (SAED) patterns shown in Fig. 7d and h further support the anatase TiO2 (101) plane. The presence of titanium, oxygen and Ca elements in the synthesized photoanode materials is confirmed through EDAX spectrum (Fig. S4), and their contents are presented in Table S1. The EDAX result reveals that the TiO2, 1% Ca-TiO2, 2% Ca-TiO2 and 3% Ca-TiO2 have a Ca content of 0, 0.9, 1.1 and 2.3 wt%, respectively. These results demonstrated that doping has been accomplished on average, despite the fact that EDAX results are semiquantitative and not always accurate. Additionally, the 3% Ca-doped TiO2's EDAX mapping (Fig. 8) shows that Ca was effectively doped into the TiO2.

Electrochemical performance of TiO2and 3% Ca-TiO2 microspheres

The electrochemical behaviour of TiO2 and Ca-TiO2 was examined using CV (Fig. 9a). CV was measured using TiO2 and 3% Ca-TiO2-coated FTO as working electrodes and Ag/AgCl as a reference in 0.5 M KOH solution containing Pt CE. It was obvious that Ca doping had boosted the capacitance current passing response. This is in good agreement with all prior research, showing that doping Ca into TiO2 increased its electrical conductivity. It might be a result of their high photocatalytic activity. The changes in capacitance current shows how doping has changed the dynamic properties [85,86,87,88].

To investigate the electron transport process, electrochemical impedance spectroscopy (EIS) was used. To characterize two electron-transporting materials (TiO2 and 3% Ca-TiO2), experiment was conducted using symmetric cells. Symmetric cells were fabricated by sandwiching two identical electrodes (TiO2 or 3% Ca-TiO2) using polymer electrolyte. The EIS was analysed within 100 mHz–1 MHz frequency range and amplitude of 10 mV. Figure 9b depicts the Nyquist plot for both TiO2 and 3% Ca-TiO2. Both showed the one semicircle in the Nyquist plot. The semicircle's diameter referred to the charge transfer resistance. As shown in Fig. 9b, the charge transfer resistance for 3% Ca-TiO2 is decreased when compared with pristine TiO2 and confirmed that the enormous increase in TiO2 conductivity brought on by Ca doping. The Ca ion doping of the TiO2 matrix boosts the material's mobility, improves the charge carrier and confirms the doped samples' fastest interfacial electron transfer and lowest recombination rate [89, 90].

In order to investigate the electrocatalytic activity, Tafel polarization was also carried out utilizing the symmetric cells (Fig. 9c). The variance in curve behaviour is mainly due to various charge transfer processes at the interface of photoanode. When a photoanode gets a negative bias, the charge will initially fill the vacant surface states under the conduction band edge before concentrating in the space charge layer [91]. Contrary to TiO2, the 3% Ca-TiO2 polarization curve demonstrated a negative shift, indicating that the flat band potential of TiO2 after Ca doping had changed negatively. Electrode flat band potential and electrolyte redox potential can be used to assess VOC, with the electrode flat band potential change indicating a device's VOC fluctuation. A decrease in redox potential and an increase in VOC are both caused by a negative electrode flat band potential shift [92, 93].

Photovoltaic performance

The photovoltaic characteristics of devices made with Ca-TiO2 and TiO2 microspheres as photoanodes are investigated. The current density (J) versus potential (V) graphs of these DSSCs are displayed in Fig. 10. Table 2 presents a list of the key characteristic parameters of DSSCs. TiO2 microsphere-based photoanode films having CCPICPB were found to have 2.93% efficiency. Device having Z907-sensitized TiO2 microsphere-based photoanode displayed efficiency of 4.42%. The best option for enhancing material performance is a microsphere structure since it may benefit from both nanoscale components and micron- or submicron-scale assemblies. But the micron-sized spherical particle-based DSSC's effectiveness is constrained by the presence of spaces between the two bigger particles, which results in a low packing fraction and constricts the dye adsorption. We fabricated Ca-TiO2 microsphere photoanodes to improve the performance of DSSC. Different concentrations of Ca were doped to TiO2 microsphere and evaluated its DSSC performance. When compared to photoanode formed of bare TiO2, the efficiency of DSSC cells made with doped films (1%, 2% and 3% Ca-TiO2) is much higher. Doped TiO2 film efficiency is found to be between 3.18 and 6.11% (Table 2). 3% Ca-TiO2 microsphere-based device showed more than 4% efficiency. With an increase in the Ca ratio in the doped film, the DSSC's photovoltaic efficiency rises. This increment is may be because increasing the packing fraction by evenly connecting the microsphere and the neck (the connection between two particles) has been strengthened. The JSC achieved is lower when using bare TiO2 as the photoanode in a solar cell device. We explain this by the low JSC caused by the weak connection between the microsphere particles. When compared to bare microsphere photoanodes, it is observed that the JSC is higher for photoanodes formed with doped microspheres. The rise in JSC that has been seen can be attributed to the doping of Ca into microspheres, which improves the connection between microsphere particles.

Furthermore, using a 3% Ca-doped TiO2 microsphere photoanode, Z907 dye demonstrated greater efficiency (5.12%) than CCPICPB dye (4.04%). The intermolecular stacking aggregations, the self-quenching process of CCPICPB and the recombination mechanism were the key causes of the CCPICPB dye's low efficiency. DSSCs were fabricated using Z907 dye and CCPICPB dye to assess the effects of the co-sensitization (having 3% Ca-doped TiO2 anode material). The J–V characteristic of a co-sensitized DSSC is shown in Fig. 10. Z907 alone showed an efficiency of 5.12%, but co-sensitized device showed 6.11% efficiency. The maximum JSC and VOC values of the co-sensitized device as compared to the Z907 dye-based device explain its superior performance. The co-sensitized device's increased VOC value (0.72 V) may be the result of the bulky Z907 dye leaving empty areas on the TiO2 surface for the relatively tiny organic dye CCPICPB to adsorb in. The co-sensitization process therefore raises the VOC value.

EIS analysis

Electrochemical impedance spectroscopy (EIS) experiments on the DSSC devices were conducted in the frequency range 100 mHz–1 MHz and amplitude of 10 mV to better understand the impact of doping on the photoanode on the ionic and electronic conduction process in comparison with bare TiO2 microsphere photoanode. Figure 11 shows the EIS spectra of the devices generated from doped photoanodes (1%, 2% and 3% Ca-TiO2) and bare photoanodes (TiO2) with equivalent circuit inset. The same figure also includes the Nyquist plots of DSSC devices with Z907 dye and CCPICPB + Z907 dyes. Nyquist plots with three semicircles are typically seen on DSSCs at various frequency ranges. The charge transfer activities taking place at the Pt/electrolyte interface can be linked to the first semicircle that arises in the high-frequency band. The second semicircle, which is visible at intermediate frequencies, is caused by electron recombination and diffusion in the TiO2 layer at the interphase of TiO2/dye/electrolyte. The diffusion of I3− in the electrolyte corresponds to the third semicircle that arises at low frequencies [94, 95]. In the process of our examination, we only discovered one semicircle. The interface resistance of the photoanode is correlated with the semicircle's diameter. Lower VOC results from quicker charge recombination at low interface resistance [96]. As indicated in Table 2, the Rct values of devices can be calculated by fitting curves using ZView software. These values are on the order of 3% Ca-T/Z907 + CCPICPB > 3% Ca-T/Z907 > T/Z907 > 3% Ca-T/CCPICPB > 2% Ca-T /CCPICPB > 1% Ca-T/CCPICPB > T/CCPICPB, which is in agreement with the value of the experimental VOC. The Rct value for the CCPICPB-based device (3% Ca-TiO2) was estimated to be about 396.3 Ω. This low Rct means that there is a lot of charge loss, charge recombination and dark current at the interface of the photoanode and electrolyte. It is important to note that the Rct of co-sensitization DSSCs is higher than that of Z907, showing that co-sensitization slowed down electron recombination between the injected electrons and the electrolyte.

Conclusion

One of the biggest challenges in developing new hybrid materials with useful functionality is finding new materials for DSSCs and comprehending how they interact. In the current study, a new CCPICPB dye containing di-donating and anchoring groups was synthesized and used in DSSC. The findings demonstrated that the PCE of CCPICPB-based device is about 2.93% and further enhanced to 4.04% using a 3% Ca-TiO2 photoanode. Furthermore, dye CCPICPB co-sensitized with Z907 in DSSC demonstrated PCE of 6.11%, which is greater than the DSSC based on single Z907 dye (5.12%) under the same conditions.

In addition, TiO2 and Ca-TiO2 microspheres have been successfully synthesized using a one-step solvothermal process. Impact of Ca doping into TiO2 microsphere was examined and described. All of the samples had anatase phase, according to XRD analysis. Images obtained using FESEM showed that doping significantly altered by increasing the strength of neck, which helps in increasing the packing fraction by evenly connecting the microspheres. The fabrication of 3% Ca-TiO2-based DSSC demonstrated an effective PCE of 4.04% as opposed to undoped DSSC, which displayed an efficiency of 2.93% using CCPICPB dye. As a result, a photoanode film composed of well-connected microspheres doped with a dopant can be utilized as a preferable photoanode for DSSCs to obtain a higher efficiency than a photoanode built of individual microspheres.

Abbreviations

- Ca:

-

Calcium

- TiO2 :

-

Titanium dioxide

- DSSC:

-

Dye-sensitized solar cell

- PCE:

-

Power conversion efficiency

References

Cai K, Wu H, Hua T et al (2022) Molecular engineering of the fused azacycle donors in the D-A-π-A metal-free organic dyes for efficient dye-sensitized solar cells. Dye Pigment 197:109922. https://doi.org/10.1016/j.dyepig.2021.109922

Liu M, Johnston MB, Snaith HJ (2013) Efficient planar heterojunction perovskite solar cells by vapour deposition. Nature 501:395–398. https://doi.org/10.1038/nature12509

Zhang W, Eperon GE, Snaith HJ (2016) Metal halide perovskites for energy applications. Nat Energy. https://doi.org/10.1038/nenergy.2016.48

Tzounis L, Stergiopoulos T, Zachariadis A et al (2017) Perovskite solar cells from small scale spin coating process towards roll-to-roll printing: optical and morphological studies. Mater Today Proc 4:5082–5089. https://doi.org/10.1016/j.matpr.2017.04.117

Miles RW, Zoppi G, Forbes I (2007) Inorganic photovoltaic cells The inorganic semiconductor materials used to make photovoltaic cells. Mater Today 10:20–27. https://doi.org/10.1016/S1369-7021(07)70275-4

McCandless BE, Sites JR (2011) Cadmium telluride solar cells. In: Handbook of photovoltaic science and engineering. John Wiley & Sons, Ltd, Chichester, UK, pp 600–641

Meng L, Zhang Y, Wan X, Li C, Zhang X, Wang Y, Ke X, Xiao Z, Ding L, Xia R, Yip H-L, Cao Y, Chen Y (2018) Organic and solution-processed tandem solar cells with 17.3% efficiency. Science 361(6407):1094–1098. https://doi.org/10.1126/science.aat2612

Riede M, Uhrich C, Widmer J et al (2011) Efficient organic tandem solar cells based on small molecules. Adv Funct Mater 21:3019–3028. https://doi.org/10.1002/adfm.201002760

Ameri T, Li N, Brabec CJ (2013) Highly efficient organic tandem solar cells: a follow up review. Energy Environ Sci 6:2390–2413. https://doi.org/10.1039/c3ee40388b

Tvrdy K, Kamat PV (2011) Quantum dot solar cells. Compr Nanosci Technol 1–5:257–275. https://doi.org/10.1016/B978-0-12-374396-1.00129-X

Ning Z, Gong X, Comin R et al (2015) Quantum-dot-in-perovskite solids. Nature 523:324–328. https://doi.org/10.1038/nature14563

Pan Z, Rao H, Mora-Seró I et al (2018) Quantum dot-sensitized solar cells. Chem Soc Rev 47:7659–7702. https://doi.org/10.1039/c8cs00431e

Devadiga D, Selvakumar M, Shetty P, Santosh MS (2022) The integration of flexible dye-sensitized solar cells and storage devices towards wearable self-charging power systems: a review. Renew Sustain Energy Rev 159:112252. https://doi.org/10.1016/j.rser.2022.112252

Devadiga D, Selvakumar M, Shetty P, Santosh MS (2021) Recent progress in dye sensitized solar cell materials and photo-supercapacitors: a review. J Power Sources 493:229698. https://doi.org/10.1016/j.jpowsour.2021.229698

Kavan L (2017) Electrochemistry and dye-sensitized solar cells. Curr Opin Electrochem 2:88–96. https://doi.org/10.1016/j.coelec.2017.03.008

Feldt SM, Gibson EA, Gabrielsson E et al (2010) Design of organic dyes and cobalt polypyridine redox mediators for high-efficiency dye-sensitized solar cells. J Am Chem Soc 132:16714–16724. https://doi.org/10.1021/ja1088869

Dette C, Pérez-Osorio MA, Kley CS et al (2014) TiO2 anatase with a bandgap in the visible region. Nano Lett 14:6533–6538. https://doi.org/10.1021/nl503131s

Woronowicz K, Ahmed S, Biradar AA et al (2012) Near-IR absorbing solar cell sensitized with bacterial photosynthetic membranes. Photochem Photobiol 88:1467–1472. https://doi.org/10.1111/j.1751-1097.2012.01190.x

Tan B, Toman E, Li Y, Wu Y (2007) Zinc stannate (Zn2SnO4) dye-sensitized solar cells. J Am Chem Soc 129:4162–4163. https://doi.org/10.1021/ja070804f

Kumar D, Wong KT (2017) Organic dianchor dyes for dye-sensitized solar cells. Mater Today Energy 5:243–279. https://doi.org/10.1016/j.mtener.2017.05.007

Devadiga D, Selvakumar M, Shetty P, Santosh MS (2021) Dye-sensitized solar cell for indoor applications: a mini-review. J Electron Mater 50:3187–3206. https://doi.org/10.1007/s11664-021-08854-3

Regan BO, Gratzelt M (1991) A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353:737–740. https://doi.org/10.1038/353737a0

Ilaiyaraja P, Kumar Das T, Mocherla PSV, Sudakar C (2017) Well-connected microsphere-nanoparticulate TiO2 composites as high performance photoanode for dye sensitized solar cell. Sol Energy Mater Sol Cells 169:86–97. https://doi.org/10.1016/j.solmat.2017.05.001

Fan K, Yu J, Ho W (2017) Improving photoanodes to obtain highly efficient dye-sensitized solar cells: a brief review. Mater Horizons 4:319–344. https://doi.org/10.1039/c6mh00511j

Rajkumar S, Venkatraman MR, Suguna K et al (2022) Synthesis of Ag-incorporated TiO2 nanoparticles by simple green approach as working electrode for dye-sensitized solar cells. J Mater Sci Mater Electron 33:4965–4973. https://doi.org/10.1007/s10854-021-07685-6

Singh S, Maurya IC, Tiwari A et al (2022) Green synthesis of TiO2 nanoparticles using Citrus limon juice extract as a bio-capping agent for enhanced performance of dye-sensitized solar cells. Surf Interf 28:101652. https://doi.org/10.1016/j.surfin.2021.101652

Albu DF, Lungu J, Popescu-Pelin G et al (2022) Thin film fabrication by pulsed laser deposition from TiO2 Targets in O2, N2, He, or Ar for dye-sensitized solar cells. Coatings 12:293. https://doi.org/10.3390/coatings12030293

Xu Y, Li X, Xiao M, Xiong X (2018) Growth of hierarchical TiO2 flower-like microspheres/oriented nanosheet arrays on a titanium mesh for flexible dye-sensitized solar cells. CrystEngComm 20:6280–6290. https://doi.org/10.1039/c8ce01028e

Mo LE, Li ZQ, Ding YC et al (2019) Facile synthesis of TiO2 microspheres via solvothermal alcoholysis method for high performance dye-sensitized solar cells. Sol Energy 177:448–454. https://doi.org/10.1016/j.solener.2018.10.013

Li ZQ, Ding Y, Mo LE et al (2015) Fine tuning of nanocrystal and pore sizes of TiO2 submicrospheres toward high performance dye-sensitized solar cells. ACS Appl Mater Interf 7:22277–22283. https://doi.org/10.1021/acsami.5b06556

Li ZQ, Chen WC, Guo FL et al (2015) Mesoporous TiO2 yolk-shell microspheres for dye-sensitized solar cells with a high efficiency exceeding 11%. Sci Rep 5:1–8. https://doi.org/10.1038/srep14178

Li ZQ, Que YP, Mo LE et al (2015) One-pot synthesis of mesoporous TiO2 micropheres and its application for high-efficiency dye-sensitized solar cells. ACS Appl Mater Interf 7:10928–10934. https://doi.org/10.1021/acsami.5b02195

Wang K, Niu L, Tao L et al (2021) Fabrication of TiO2 microspheres with continuously distributed sizes from nanometer to micronmeter: the increasing light scattering ability and the enhanced photovoltaic performance. Sol Energy 230:935–942. https://doi.org/10.1016/j.solener.2021.11.010

Gowthambabu V, Deshpande M, Govindaraj R et al (2021) Synthesis of anatase TiO2 microspheres and their efficient performance in dye-sensitized solar cell. J Mater Sci Mater Electron 32:26306–26317. https://doi.org/10.1007/s10854-021-06923-1

Dong YX, Wang XL, Jin EM et al (2019) One-step hydrothermal synthesis of Ag decorated TiO2 nanoparticles for dye-sensitized solar cell application. Renew Energy 135:1207–1212. https://doi.org/10.1016/j.renene.2018.12.062

Li W, Yang J, Zhang J et al (2014) Improve photovoltaic performance of titanium dioxide nanorods based dye-sensitized solar cells by Ca-doping. Mater Res Bull 57:177–183. https://doi.org/10.1016/j.materresbull.2014.05.034

Dahlan D, Md Saad SK, Berli AU et al (2017) Synthesis of two-dimensional nanowall of Cu-Doped TiO2 and its application as photoanode in DSSCs. Phys E Low-Dimensional Syst Nanostruct 91:185–189. https://doi.org/10.1016/j.physe.2017.05.003

Gayathri V, John Peter I, Rajamanickam N, Ramachandran K (2019) Improved performance of dye-sensitized solar cells by Cr doped TiO2 nanoparticles. Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.05.381

Prabavathy N, Balasundaraprabhu R, Balaji G et al (2019) Investigations on the photo catalytic activity of calcium doped TiO2 photo electrode for enhanced efficiency of anthocyanins based dye sensitized solar cells. J Photochem Photobiol A Chem 377:43–57. https://doi.org/10.1016/j.jphotochem.2019.03.038

Nguyen DT, Kurokawa Y, Taguchi K (2020) Enhancing DSSC photoanode performance by using Ni-Doped TiO2 to fabricate scattering layers. J Electron Mater. https://doi.org/10.1007/s11664-020-07965-7

Ünlü B, Özacar M (2020) Effect of Cu and Mn amounts doped to TiO2 on the performance of DSSCs. Sol Energy 196:448–456. https://doi.org/10.1016/j.solener.2019.12.043

Arshad Z, Shakir S, Khoja AH et al (2022) Performance analysis of calcium-doped titania (TiO2) as an effective electron transport layer (ETL) for perovskite solar cells. Energies 15:1408. https://doi.org/10.3390/en15041408

Ji JM, Zhou H, Kim HK (2018) Rational design criteria for D-π-A structured organic and porphyrin sensitizers for highly efficient dye-sensitized solar cells. J Mater Chem A 6:14518–14545. https://doi.org/10.1039/c8ta02281j

Han L, Islam A, Chen H et al (2012) High-efficiency dye-sensitized solar cell with a novel co-adsorbent. Energy Environ Sci 5:6057–6060. https://doi.org/10.1039/c2ee03418b

Kang SH, Jeong MJ, Eom YK et al (2017) Porphyrin sensitizers with donor structural engineering for superior performance dye-sensitized solar cells and tandem solar cells for water splitting applications. Adv Energy Mater 7:1–10. https://doi.org/10.1002/aenm.201602117

Humphry-Baker R, Rothlisberger U, Nazeeruddin MK et al (2014) Dye-sensitized solar cells with 13% efficiency achieved through the molecular engineering of porphyrin sensitizers. Nat Chem 6:242–247. https://doi.org/10.1038/nchem.1861

Eom YK, Kang SH, Choi IT et al (2017) Significant light absorption enhancement by a single heterocyclic unit change in the π-bridge moiety from thieno[3,2-b]benzothiophene to thieno[3,2-b]indole for high performance dye-sensitized and tandem solar cells. J Mater Chem A 5:2297–2308. https://doi.org/10.1039/c6ta09836c

Kakiage K, Aoyama Y, Yano T et al (2015) Highly-efficient dye-sensitized solar cells with collaborative sensitization by silyl-anchor and carboxy-anchor dyes. Chem Commun 51:15894–15897. https://doi.org/10.1039/c5cc06759f

Mishra A, Fischer MKR, Büuerle P (2009) Metal-free organic dyes for dye-sensitized solar cells: from structure: property relationships to design rules. Angew Chemie - Int Ed 48:2474–2499. https://doi.org/10.1002/anie.200804709

Han L, Liu J, Liu Y, Cui Y (2019) Novel D-A-π-A type benzocarbazole sensitizers for dye sensitized solar cells. J Mol Struct 1180:651–658. https://doi.org/10.1016/j.molstruc.2018.12.052

Jiang H, Ren Y, Zhang W et al (2020) Phenanthrene-fused-quinoxaline as a key building block for highly efficient and stable sensitizers in copper-electrolyte-based dye-sensitized solar cells. Angew Chemie Int Ed 59:9324–9329. https://doi.org/10.1002/anie.202000892

Wu Y, Zhu WH, Zakeeruddin SM, Grätzel M (2015) Insight into D-A-π-A structured sensitizers: a promising route to highly efficient and stable dye-sensitized solar cells. ACS Appl Mater Interfaces 7:9307–9318. https://doi.org/10.1021/acsami.5b02475

Naik P, Elmorsy MR, Su R et al (2017) New carbazole based metal-free organic dyes with D-Π-A-Π-A architecture for DSSCs: synthesis, theoretical and cell performance studies. Sol Energy 153:600–610. https://doi.org/10.1016/j.solener.2017.05.088

Chiykowski VA, Lam B, Du C, Berlinguette CP (2017) Comparative analysis of triarylamine and phenothiazine sensitizer donor units in dye-sensitized solar cells. Chem Commun 53:2367–2370. https://doi.org/10.1039/c6cc09178d

Ohta N, Awasthi K, Okoshi K et al (2016) Stark spectroscopy of absorption and emission of indoline sensitizers: a correlation with the performance of photovoltaic cells. J Phys Chem C 120:26206–26216. https://doi.org/10.1021/acs.jpcc.6b08531

Kumar D, Justin Thomas KR, Lee CP, Ho KC (2014) Organic dyes containing fluorene decorated with imidazole units for dye-sensitized solar cells. J Org Chem 79:3159–3172. https://doi.org/10.1021/jo500330r

Han ML, Zhu YZ, Liu S et al (2018) The improved photovoltaic performance of phenothiazine-dithienopyrrole based dyes with auxiliary acceptors. J Power Sources 387:117–125. https://doi.org/10.1016/j.jpowsour.2018.03.059

Devadiga D, Selvakumar M, Shetty P et al (2021) Recent developments in metal-free organic sensitizers derived from carbazole, triphenylamine, and phenothiazine for dye-sensitized solar cells. Int J Energy Res 45:6584–6643. https://doi.org/10.1002/er.6348

Naik P, Su R, Elmorsy MR et al (2018) New carbazole based dyes as effective co-sensitizers for DSSCs sensitized with ruthenium (II) complex (NCSU-10). J Energy Chem 27:351–360. https://doi.org/10.1016/j.jechem.2017.12.013

Elsherbiny D, Yildirim E, El-Essawy F et al (2017) Structure-property relationships: Influence of number of anchoring groups in triphenylamine-carbazole motifs on light harvesting and photovoltaic performance for dye-sensitized solar cells. Dye Pigment 147:491–504. https://doi.org/10.1016/j.dyepig.2017.08.022

Zhang K, Zhang W, Huang J et al (2017) Metal-free photosensitizers based on benzodithienothiophene as π-conjugated spacer for dye-sensitized solar cells. Org Electron 42:275–283. https://doi.org/10.1016/j.orgel.2016.12.044

Ramasamy S (2020) Organic photosensitizers containing fused indole-imidazole ancillary acceptor with triphenylamine donor moieties for efficient dye-sensitized solar cells. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2020.10.248

Liao X, Zhang H, Huang J et al (2018) (D−π−A)3−Type metal-free organic dye for dye-sensitized solar cells application. Dye Pigment 158:240–248. https://doi.org/10.1016/j.dyepig.2018.03.075

Zhang W, Dai X, Liao X et al (2020) Phenothiazine (or phenoxazine) based (D–π–A)-L2-(A–π–D–π–A)2-type organic dyes with five anchors for efficient dye-sensitized solar cells. Sol Energy 212:220–230. https://doi.org/10.1016/j.solener.2020.11.008

Badawy SA, Su R, Fadda AA et al (2022) Highly efficient (N-benzothiazolyl)-cyanoacetamide based co-sensitizers for high efficiency dye-sensitized solar cells. Optik (Stuttg) 249:168274. https://doi.org/10.1016/j.ijleo.2021.168274

Koteshwar D, Prasanthkumar S, Singh SP et al (2022) Effects of methoxy group(s) on D-π-A porphyrin based DSSCs: efficiency enhanced by co-sensitization. Mater Chem Front 6:580–592. https://doi.org/10.1039/d1qm01450a

Watson J, Rodrigues RR, Delcamp JH (2022) Near-infrared unsymmetrical squaraine core-based sensitizers for co-sensitized high-photocurrent dye-sensitized solar cells. Cell Reports Phys Sci 3:100701. https://doi.org/10.1016/j.xcrp.2021.100701

Eltoukhi M, Fadda AA, Abdel-Latif E, Elmorsy MR (2022) Low cost carbazole-based organic dyes bearing the acrylamide and 2-pyridone moieties for efficient dye-sensitized solar cells. J Photochem Photobiol A Chem 426:113760. https://doi.org/10.1016/j.jphotochem.2021.113760

Devadiga D, Selvakumar M, Shetty P et al (2021) Novel photosensitizer for dye-sensitized solar cell based on ionic liquid–doped blend polymer electrolyte. J Solid State Electrochem 25:1461–1478. https://doi.org/10.1007/s10008-021-04920-2

Devadiga D, Selvakumar M, Devadiga D et al (2022) Synthesis and characterization of a new phenothiazine-based sensitizer/co-sensitizer for efficient dye-sensitized solar cell performance using a gel polymer electrolyte and Ni–TiO2 as a photoanode. New J Chem 46:21373–21385. https://doi.org/10.1039/D2NJ03589H

Wang Z, Sugihara H (2006) N3-sensitized TiO2 films. In situ proton exchange toward open-circuit photovoltage enhancement. Langmuir 22:9718–9722. https://doi.org/10.1021/la061315g

Wielopolski M, Marszalek M, Brunetti FG et al (2016) Synthesis and optoelectronic properties of chemically modified bi-fluorenylidenes. J Mater Chem C 4:3798–3808. https://doi.org/10.1039/C5TC03501E

Zhang W, Wu Y, Zhu H et al (2015) Rational molecular engineering of indoline-based D-A-π-A organic sensitizers for long-wavelength-responsive dye-sensitized solar cells. ACS Appl Mater Interf 7:26802–26810. https://doi.org/10.1021/acsami.5b08888

Jia HL, Li SS, Gong BQ et al (2019) Efficient cosensitization of new organic dyes containing bipyridine anchors with porphyrins for dye-sensitized solar cells. Sustain Energy Fuels 4:347–353. https://doi.org/10.1039/c9se00810a

Lokhande PKM, Sonigara KK, Jadhav MM et al (2019) Multi-dentate carbazole based schiff base dyes with chlorovinylene group in spacer for dye-sensitized solar cells: a combined theoretical and experimental study. ChemistrySelect 4:4044–4056. https://doi.org/10.1002/slct.201803940

Salimi Beni A, Zarandi M, Hosseinzadeh B, Najafi Chermahini A (2018) Density functional theory study of carbazole dyes: potential application of carbazole dyes in dye-sensitized solar cells. J Mol Struct 1164:155–163. https://doi.org/10.1016/j.molstruc.2018.02.094

Rafieh AI, Ekanayake P, Tan AL, Lim CM (2017) Effects of ionic radii of co-dopants (Mg, Ca, Al and La) in TiO2 on performance of dye-sensitized solar cells. Sol Energy 141:249–255. https://doi.org/10.1016/j.solener.2016.11.052

Li Y, Peng S, Jiang F et al (2007) Effect of doping TiO2 with alkaline-earth metal ions on its photocatalytic activity. J Serbian Chem Soc 72:393–402. https://doi.org/10.2298/JSC0704393L

Santos LM, Machado WA, França MD et al (2015) Structural characterization of Ag-doped TiO2 with enhanced photocatalytic activity. RSC Adv 5:103752–103759. https://doi.org/10.1039/c5ra22647c

Huang J, Guo X, Wang B et al (2015) Synthesis and photocatalytic activity of Mo-doped TiO2 nanoparticles. J Spectrosc 2015:1–8. https://doi.org/10.1155/2015/681850

Devadiga D, Selvakumar M, Shetty P et al (2021) Novel photosensitizer for dye-sensitized solar cell based on ionic liquid–doped blend polymer electrolyte. J Solid State Electrochem. https://doi.org/10.1007/s10008-021-04920-2

Wang F, Zhang S, Li C et al (2014) Catalytic behavior of supported Ru nanoparticles on the (101) and (001) facets of anatase TiO2. RSC Adv 4:10834–10840. https://doi.org/10.1039/c3ra47076h

Ren R, Wen Z, Cui S et al (2015) Controllable synthesis and tunable photocatalytic properties of Ti3+-doped TiO2. Sci Rep 5:1–11. https://doi.org/10.1038/srep10714

Qian X, Han H, Chen Y, Yuan Y (2018) Sol–gel solvothermal route to synthesize anatase/brookite/rutile TiO2 nanocomposites with highly photocatalytic activity. J Sol-Gel Sci Technol 85:394–401. https://doi.org/10.1007/s10971-017-4544-3

Neetu SS, Srivastava P, Bahadur L (2020) Hydrothermal synthesized Nd-doped TiO2 with Anatase and Brookite phases as highly improved photoanode for dye-sensitized solar cell. Sol Energy 208:173–181. https://doi.org/10.1016/j.solener.2020.07.085

Szkoda M, Lisowska-Oleksiak A, Siuzdak K (2016) Optimization of boron-doping process of titania nanotubes via electrochemical method toward enhanced photoactivity. J Solid State Electrochem 20:1765–1774. https://doi.org/10.1007/s10008-016-3185-8

Surendra BS (2018) Green engineered synthesis of Ag-doped CuFe2O4: Characterization, cyclic voltammetry and photocatalytic studies. J Sci Adv Mater Devices 3:44–50. https://doi.org/10.1016/j.jsamd.2018.01.005

Huamán A, Quintana M (2018) Surface modification of TiO2 nanostructured films by inserting Mg 2+ ions applied to dye sensitized solar cells. J Phys Conf Ser 1143:12019. https://doi.org/10.1088/1742-6596/1143/1/012019

Ran H, Fan J, Zhang X et al (2018) Enhanced performances of dye-sensitized solar cells based on Au-TiO2 and Ag-TiO2 plasmonic hybrid nanocomposites. Appl Surf Sci 430:415–423. https://doi.org/10.1016/j.apsusc.2017.07.107

Sakthivel T, Kumar KA, Senthilselvan J, Jagannathan K (2018) Effect of Ni dopant in TiO2 matrix on its interfacial charge transportation and efficiency of DSSCs. J Mater Sci Mater Electron 29:2228–2235. https://doi.org/10.1007/s10854-017-8137-2

Feng X, Shankar K, Paulose M, Grimes CA (2009) Tantalum-doped titanium dioxide nanowire arrays for dye-sensitized solar cells with high open-circuit voltage. Angew Chemie - Int Ed 48:8095–8098. https://doi.org/10.1002/anie.200903114

Shaikh SF, Mane RS, Joo OS (2015) La2O3-encapsulated SnO2 nanocrystallite-based photoanodes for enhanced DSSCs performance. Dalt Trans 44:3075–3081. https://doi.org/10.1039/c4dt03564j

Zhang H, Lv Y, Guo Y et al (2018) Fully-air processed Al-doped TiO2 nanorods perovskite solar cell using commercial available carbon instead of hole transport materials and noble metal electrode. J Mater Sci Mater Electron 29:3759–3766. https://doi.org/10.1007/s10854-017-8310-7

Chiappara C, Figà V, Di Marco G et al (2016) Investigation of recovery mechanisms in dye sensitized solar cells. Sol Energy 127:56–66. https://doi.org/10.1016/j.solener.2016.01.010

Bramhankar TS, Pawar SS, Shaikh JS et al (2020) Effect of nickel-zinc Co-doped TiO2 blocking layer on performance of DSSCs. J Alloys Compd 817:152810. https://doi.org/10.1016/j.jallcom.2019.152810

Ji JM, Zhou H, Eom YK et al (2020) 14.2% efficiency dye-sensitized solar cells by co-sensitizing novel thieno[3,2-b]indole-based organic dyes with a promising porphyrin sensitizer. Adv Energy Mater 10:1–12. https://doi.org/10.1002/aenm.202000124

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We have no conflict of interest to declare.

Additional information

Handling Editor: Christopher Blanford.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Devadiga, D., Selvakumar, M., Devadiga, D. et al. Calcium-doped TiO2 microspheres and near-infrared carbazole-based sensitizer for efficient co-sensitized dye-sensitized solar cell. J Mater Sci 58, 5718–5734 (2023). https://doi.org/10.1007/s10853-023-08376-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08376-9