Abstract

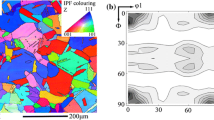

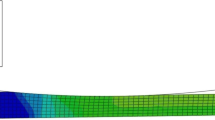

Cold angular rolling process (CARP) has emerged as a potential continuous severe plastic deformation technique enabling the processing of bulk metal sheets with improved mechanical properties. The CARP technique involves a combination of cold rolling of a sheet by a single rotation roller followed by equal-channel angular pressing of the sheet passing through a bent channel. The present work uses finite element method (FEM) to model CARP by considering processing conditions, including different friction values and processing velocities for different copper and stainless steel alloys. The simulations reveal the influence of these processing parameters on distributions of strain, strain rate, stress (in both the metal sheet and the CARP tool), temperature, and torque requirements through one pass of CARP on the metal sheets. The modeling results are validated by the experimental characterization of the hardness distribution and microstructure after CARP on a copper sheet. The results from FEM are used to estimate the energy incorporated into different metal alloys at various processing conditions. Finally, this study discusses the feasibility of scaling up the CARP technique.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding authors on reasonable request.

References

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58:33–39. https://doi.org/10.1007/s11837-006-0213-7

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2016) Producing bulk ultrafine-grained materials by severe plastic deformation: Ten years later. JOM 68:1216–1226. https://doi.org/10.1007/s11837-016-1820-6

Edalati K, Bachmaier A, Beloshenko VA, Beygelzimer Y, Blank VD, Botta WJ, Bryla K, Cizek J, Divinski S, Enikeev NA, Estrin Y, Faraji G, Figueiredo RB, Fuji M, Furuta T, Grosdidier T, Gubicza J, Hohenwarter A, Horita Z, Huot J, Ikoma Y, Janecek M, Kawasaki M, Kral P, Kuramoto S, Langdon TG, Leiva DR, Levitas VI, Mazilkin A, Mito M, Miyamoto H, Nishizaki T, Pippan R, Popov VV, Popova EN, Purcek G, Renk O, Revesz A, Sauvage X, Sklenicka V, Skrotzki W, Straumal BB, Suwas S, Toth LS, Tsuji N, Valiev RZ, Wilde G, Zehetbauer MJ, Zhu XK (2022) Nanomaterials by severe plastic deformation: review of historical developments and recent advances. Mater Res Lett 10:163–256. https://doi.org/10.1080/21663831.2022.2029779

Figueiredo RB, Langdon TG (2021) Deformation mechanisms in ultrafine-grained metals with an emphasis on the Hall-Petch relationship and strain rate sensitivity. J Mater Res Technol 14:137–159. https://doi.org/10.1016/j.jmrt.2021.06.016

Kawasaki M, Langdon TG (2015) Review: achieving superplastic properties in ultrafine-grained materials at high temperatures. J Mater Sci 51:19–32. https://doi.org/10.1007/s10853-015-9176-9

V Segal (1977) Materials preparation for following processing, Invention Certificate of USSR. No.575892 Sverdlovsk, Russia,

VI Kopylov, VM Segal (1977) A device for continuous pressing of metals, Invention Certificate of USSR. No.575151 Sverdlovsk, Russia, .

Raab GJ, Valiev RZ, Lowe TC, Zhu YT (2004) Continuous processing of ultrafine grained Al by ECAP-conform. Mater Sci Eng A 382:30–34. https://doi.org/10.1016/j.msea.2004.04.021

Xu C, Schroeder S, Berbon PB, Langdon TG (2010) Principles of ECAP-Conform as a continuous process for achieving grain refinement: application to an aluminum alloy. Acta Mater 58:1379–1386. https://doi.org/10.1016/j.actamat.2009.10.044

Raab GI, Valiev R, Gunderov D, Lowe TC, Misra A (2008) YT Zhu Long-length ultrafine-grained titanium rods produced by ECAP-conform. Mater Sci Forum 584–586:80–85. https://doi.org/10.4028/www.scientific.net/MSF.584-586.80

Lowe TC, Valiev RZ, Li XC, Ewing BR (2021) Commercialization of bulk nanostructured metals and alloys. MRS Bull 46:265–272. https://doi.org/10.1557/s43577-021-00060-0

Azimi A, Tutunchilar S, Faraji G, Givi MKB (2012) Mechanical properties and microstructural evolution during multi-pass ECAR of Al 1100-O alloy. Mater Design 42:388–394. https://doi.org/10.1016/j.matdes.2012.06.035

Chung YH, Park JW, Lee KH (2006) An analysis of accumulated deformation in the equal channel angular rolling (ECAR) process. Met Mater Int 12:289–292. https://doi.org/10.1007/Bf03027545

Honarpisheh M, Entezami SS, Akhavan S (2019) Effect of equal channel angular rolling process on the fracture mechanisms of Al-7057 and Al-5052 alloys. Metallogr Microstruct Anal 8:336–348. https://doi.org/10.1007/s13632-019-00540-5

Cheng YQ, Chen ZH, Xia WJ (2007) Drawability of AZ31 magnesium alloy sheet produced by equal channel angular rolling at room temperature. Mater Charact 58:617–622. https://doi.org/10.1016/j.matchar.2006.07.007

Habibi A, Ketabchi M, Eskandarzadeh M (2011) Nano-grained pure copper with high-strength and high-conductivity produced by equal channel angular rolling process. J Mater Process Tech 211:1085–1090. https://doi.org/10.1016/j.jmatprotec.2011.01.009

Huang Y, Prangnell PB (2007) Continuous frictional angular extrusion and its application in the production of ultrafine-grained sheet metals. Scripta Mater 56:333–336. https://doi.org/10.1016/j.scriptamat.2006.11.011

Lee HH, Yoon JI, Kim HS (2018) Single-roll angular-rolling: A new continuous severe plastic deformation process for metal sheets. Scripta Mater 146:204–207. https://doi.org/10.1016/j.scriptamat.2017.11.043

Lee HH, Yoon JI, Park HK, Kim HS (2019) Unique microstructure and simultaneous enhancements of strength and ductility in gradient-microstructured Cu sheet produced by single-roll angular-rolling. Acta Mater 166:638–649. https://doi.org/10.1016/j.actamat.2019.01.021

Lee HH, Park HK, Jung J, Hwang KJ, Kim HS (2019) Microstructural tailoring in reverse gradient-structured copper sheet using single-roll angular-rolling and subsequent annealing. Mater Sci Eng A 764:138258. https://doi.org/10.1016/j.msea.2019.138258

Lee HH, Hwang KJ, Park HK, Kim HS (2020) Effect of processing route on microstructure and mechanical properties in single-roll angular-rolling. Materials 13:2471. https://doi.org/10.3390/ma13112471

Lee HH, Park HK, Jung J, Amanov A, Kim HS (2020) Multi-layered gradient structure manufactured by single-roll angular-rolling and ultrasonic nanocrystalline surface modification. Scripta Mater 186:52–56. https://doi.org/10.1016/j.scriptamat.2020.03.051

Pereira PHR, Figueiredo RB (2019) Finite element modelling of high-pressure torsion: an overview. Mater Trans 60:1139–1150. https://doi.org/10.2320/matertrans.MF201906

Hu JM, Kulagin R, Ivanisenko Y, Baretzky B, Zhang H (2020) Finite element modeling of Conform-HPTE process for a continuous severe plastic deformation path. J Manuf Process 55:373–380. https://doi.org/10.1016/j.jmapro.2020.04.052

Kocich R, Kuncicka L, Mihola M, Skotnicova K (2013) Numerical and experimental analysis of twist channel angular pressing (TCAP) as a SPD process. Mater Sci Eng A 563:86–94. https://doi.org/10.1016/j.msea.2012.11.047

Prangnell PB, Harris C, Roberts SM (1997) Finite element modelling of equal channel angular extrusion. Scripta Mater 37:983–989. https://doi.org/10.1016/S1359-6462(97)00192-9

Bowen JR, Gholinia A, Roberts SM, Prangnell PB (2000) Analysis of the billet deformation behaviour in equal channel angular extrusion. Mater Sci Eng A 287:87–99. https://doi.org/10.1016/S0921-5093(00)00834-0

Kim HS, Seo MH, Hong SI (2000) On the die corner gap formation in equal channel angular pressing. Mater Sci Eng A 291:86–90. https://doi.org/10.1016/S0921-5093(00)00970-9

Li S, Bourke MAM, Beyerlein IJ, Alexander DJ, Clausen B (2004) Finite element analysis of the plastic deformation zone and working load in equal channel angular extrusion. Mater Sci Eng A 382:217–236. https://doi.org/10.1016/j.msea.2004.04.067

DeLo DP, Semiatin SL (1999) Finite-element modeling of nonisothermal equal-channel angular extrusion. Metall Mater Trans A 30:1391–1402. https://doi.org/10.1007/s11661-999-0287-2

Semiatin SL, Delo DP, Shell EB (2000) The effect of material properties and tooling design on deformation and fracture during equal channel angular extrusion. Acta Mater 48:1841–1851. https://doi.org/10.1016/S1359-6454(00)00019-7

Figueiredo RB, Cetlin PR, Langdon TG (2007) The processing of difficult-to-work alloys by ECAP with an emphasis on magnesium alloys. Acta Mater 55:4769–4779. https://doi.org/10.1016/j.actamat.2007.04.043

Figueiredo RB, Cetlin PR, Langdon TG (2009) The evolution of damage in perfect-plastic and strain hardening materials processed by equal-channel angular pressing. Mater Sci Eng A 518:124–131. https://doi.org/10.1016/j.msea.2009.04.007

Cetlin PR, Aguilar MTP, Figueiredo RB, Langdon TG (2010) Avoiding cracks and inhomogeneities in billets processed by ECAP. J Mater Sci 45:4561–4570. https://doi.org/10.1007/s10853-010-4384-9

Figueiredo RB, Aguilar MTP, Cetlin PR (2006) Finite element modelling of plastic instability during ECAP processing of flow-softening materials. Mater Sci Eng A 430:179–184. https://doi.org/10.1016/j.msea.2006.05.116

Figueiredo RB, Cetlin PR, Langdon TG (2009) Stable and unstable flow in materials processed by equal-channel angular pressing with an emphasis on magnesium alloys. Metall Mater Trans A 41A:778–786. https://doi.org/10.1007/s11661-009-0100-2

Lapovok RYE (2005) The role of back-pressure in equal channel angular extrusion. J Mater Sci 40:341–346. https://doi.org/10.1007/s10853-005-6088-0

Xu SB, Zhao GQ, Ren W, Guan YJ (2008) Numerical investigation of aluminum deformation behavior in three-dimensional continuous confined strip shearing process. Mater Sci Eng A 476:281–289. https://doi.org/10.1016/j.msea.2007.05.003

Wei W, Zhang W, Wei KX, Zhong Y, Cheng G, Hu J (2009) Finite element analysis of deformation behavior in continuous ECAP process. Mater Sci Eng A 516:111–118. https://doi.org/10.1016/j.msea.2009.03.001

Gholami J, Sedighi M, Pourbashiri M (2015) Effect of channel angle and friction in modified ECAP-Conform process of Al-6061: a numerical study. Iran J Mater Sci Eng 12:71–76. https://doi.org/10.22068/ijmse.12.4.71

Nemati Chari R, Mollaei Dariani B, Fallahi Arezodar A (2016) Numerical and experimental studies on deformation behavior of 5083 aluminum alloy strips in equal channel angular rolling. Proc Inst Mech Eng B J Eng Manuf 232:1031–1043. https://doi.org/10.1177/0954405416661005

QForm 10.1.3 [program]. https://www.qform3d.com/

Levanov AN (1997) Improvement of metal forming processes by means of useful effects of plastic friction. J Mater Process Tech 72:314–316. https://doi.org/10.1016/S0924-0136(97)00191-X

Alawadhi MY, Sabbaghianrad S, Huang Y, Langdon TG (2017) Direct influence of recovery behaviour on mechanical properties in oxygen-free copper processed using different SPD techniques: HPT and ECAP. J Mater Res Technol 6:369–377. https://doi.org/10.1016/j.jmrt.2017.05.005

Huang Y, Sabbaghianrad S, Almazrouee AI, Al-Fadhalah KJ, Alhajeri SN, Langdon TG (2016) The significance of self-annealing at room temperature in high purity copper processed by high-pressure torsion. Mater Sci Eng A 656:55–66. https://doi.org/10.1016/j.msea.2016.01.027

Alawadhi MY, Sabbaghianrad S, Huang Y, Langdon TG (2020) The stability of oxygen-free copper processed by high-pressure torsion after room temperature storage for 12 months. Adv Eng Mater 22:1901015. https://doi.org/10.1002/adem.201901015

Iwahashi Y, Wang JT, Horita Z, Nemoto M, Langdon TG (1996) Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scripta Mater 35:143–146. https://doi.org/10.1016/1359-6462(96)00107-8

Alateyah AI, Ahmed MMZ, Zedan Y, Abd El-Hafez H, Alawad MO, El-Garaihy WH (2021) Experimental and numerical investigation of the ECAP processed copper: microstructural evolution crystallographic texture and hardness homogeneity. Metals 11:607. https://doi.org/10.3390/met11040607

Nakashima K, Horita Z, Nemoto M, Langdon TG (2000) Development of a multi-pass facility for equal-channel angular pressing to high total strains. Mater Sci Eng A 281:82–87. https://doi.org/10.1016/S0921-5093(99)00744-3

Atefi S, Parsa MH, Ahmadkhaniha D, Zanella C, Jafarian HR (2022) A study on microstructure development and mechanical properties of pure copper subjected to severe plastic deformation by the ECAP-Conform process. J Mater Res Tech 21:1614–1629. https://doi.org/10.1016/j.jmrt.2022.09.103

Hohenwarter A (2015) Incremental high pressure torsion as a novel severe plastic deformation process: Processing features and application to copper. Mater Sci Eng A 626:80–85. https://doi.org/10.1016/j.msea.2014.12.041

Edalati K, Horita Z (2010) Continuous high-pressure torsion. J Mater Sci 45:4578–4582. https://doi.org/10.1007/s10853-010-4381-z

Edalati K, Lee S, Horita Z (2012) Continuous high-pressure torsion using wires. J Mater Sci 47:473–478. https://doi.org/10.1007/s10853-011-5822-z

Leo P, Cerri E, De Marco PP, Roven HJ (2007) Properties and deformation behaviour of severe plastic deformed aluminium alloys. J Mater Process Tech 182:207–214. https://doi.org/10.1016/j.jmatprotec.2006.07.038

Sordi VL, Mendes Filho AA, Valio GT, Springer P, Rubert JB, Ferrante M (2015) Equal-channel angular pressing: influence of die design on pressure forces, strain homogeneity and corner gap formation. J Mater Sci 51:2380–2393. https://doi.org/10.1007/s10853-015-9547-2

Meyers MA, Xu YB, Xue Q, Perez-Prado MT, McNelley TR (2003) Microstructural evolution in adiabatic shear localization in stainless steel. Acta Mater 51:1307–1325. https://doi.org/10.1016/S1359-6454(02)00526-8

Kubina T, Kövér M, Dlouhý J, Nacházel J (2015) Link between technological parameters and material properties of EN 6082 Processed by ECAP-CONFORM and precipitation hardening. Int J Mater Mech Eng 4:36–43. https://doi.org/10.14355/IJMME.2015.04.006

Allwood JM, Ashby MF, Gutowski TG, Worrell E (2011) Material efficiency: a white paper. Resour Conserv Recy 55:362–381. https://doi.org/10.1016/j.resconrec.2010.11.002

Ahmad N, Enemuoh EU (2020) Energy modeling and eco impact evaluation in direct metal laser sintering hybrid milling. Heliyon 6:e03168. https://doi.org/10.1016/j.heliyon.2020.e03168

Acknowledgements

RBF acknowledges financial support from CNPq (Grant #302445/2018-8) and FAPEMIG (Grant TEC-PPM-00324-17). This study for MK and MKS was supported by the National Science Foundation of the United States under Grant No. CMMI-2051205.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Ethical approval

The authors have adhered to the accepted ethical standards of a genuine research study.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Reis, L.M., Carvalho, A.P., Lee, I. et al. Cold angular rolling process as a continuous severe plastic deformation technique. J Mater Sci 58, 4621–4636 (2023). https://doi.org/10.1007/s10853-023-08295-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08295-9