Abstract

Sintering conditions govern the optimized functional properties of ceramics. However, solid-state processing of Bi1/2K1/2TiO3 (BKT), an important end member for lead-free piezoelectric solid solutions suitable for higher temperature (≤ 300 °C) transducer applications, is challenging due to the low melting temperature (≈1070 °C). In this work, the sintering temperature (1030 °C, 1050 °C, and 1060 °C) and dwell time (10 h, 20 h, and 40 h)-dependent functional properties of solid-state processed BKT were investigated, where the sintering condition-dependent dielectric and electromechanical properties were correlated with the variations in crystal structure and microstructure. Although X-ray diffraction data revealed a single-phase tetragonal structure of BKT at room temperature for all sintering conditions, significant changes in both the tetragonal distortion and spontaneous relaxor-ferroelectric transition were observed, which were directly related to the optimized functional properties. In addition, Rayleigh behavior of the piezoelectric coefficient was characterized between −150 °C and 400 °C, demonstrating that the electromechanical response is dominated by the intrinsic contribution, which can be explained by large tetragonal distortion and associated suppression of non-180° domain wall motion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Piezoelectric materials enable numerous applications, including inkjet printheads, angular sensors, ultrasonic cleaners, and energy harvesting systems [1]. In order to reduce the use of lead, which currently makes up more than 60 wt% of most commercially used material system lead zirconate titanate (Pb(Zr,Ti)O3, PZT)[2], various lead-free compositions have been developed [3]. Among the currently reported lead-free piezoelectric ceramic compositions, Bi1/2K1/2TiO3 (BKT) is interesting for its simple chemical composition with a large remanent polarization (≈22 μC/cm2) [4], a large tetragonal distortion (\(c/a\) ratio ~ 1.02) [5], and high ferroelectric-to-paraelectric phase transition temperature, i.e., \({T}_{c}\) = 380 °C [6]. In particular, BKT has been widely used as an end member in lead-free ferroelectric solid solutions [7,8,9,10]. The material demonstrates apparent high Curie temperature; however, Ivanova et al. [11] reported that the BKT undergoes a structural transition from tetragonal to pseudocubic at ~ 260 °C, followed by a transition to cubic at ~ 380 °C. Although the exact structure of the pseudocubic phase is not well understood, it is considered to consist of tetragonal nano-sized polar domains embedded in a cubic matrix, resulting in a relaxor-type intermediate state [11, 12].

Although BKT displays promising electromechanical properties and considerable temperature stability, difficulties in densification are observed related to the high volatility of the A-site cations Bi3+ and K+ as well as the low melting point of the perovskite phase, hindering further enhancement of dielectric properties through, e.g., a reduction in conductivity [4]. Despite the simple chemical composition, the ferroelectric and relaxor nature as well as the corresponding structure–property relationships at room temperature are not well understood [13, 14]. Bi-based titanates, such as BKT [7, 15], display complex local structure [15] that can be influenced by a number of factors, such as externally applied fields [16,17,18], microstructure [12, 19, 20], and annealing conditions [21,22,23]. For example, a change in grain size originated from prolonged sintering (~ 100 h) was found to trigger ferroelectric domains in relaxor BKT, which was attributed to the variation in internal residual stress, i.e., the spontaneous relaxor-to-ferroelectric transition is suppressed by the larger internal stresses (associated with the volume change during the temperature-dependent phase transition) generated in finer grained BKT [12]. In addition, the role of A-site cation is critical to the structure and stability of Bi-based titanates [18, 24]. For example, Bi1/2Na1/2TiO3 (BNT) exhibits significantly different structure and functional responses than those of BKT. In contrast to the spontaneous relaxor (RE)-to-ferroelectric (FE) transition, “RE–FE”, observed in the dielectric response of BKT upon cooling, BNT exhibits a frequency dispersion in the temperature-dependent dielectric permittivity data without a sharp TF-R [18, 25]. This difference is possibly associated with the crystal structure and Bi-K+ or Na+ chemistry, whereby the larger relative difference in ionic radii of A-site cations, i.e., Bi3+ (1.36 Å) with K+ (1.65 Å) compared to Bi3+ with Na+ (1.39 Å), can influence the correlation length of cation ordering [13, 14, 26,27,28]. Nevertheless, these previous investigations clearly demonstrate that in addition to the chemical tuning, thermal treatment, including the sintering condition, is critical in controlling the relaxor and ferroelectric nature of Bi-based titanates, such as BKT.

Due to the challenge in fabricating phase-pure and dense BKT with the conventional solid-state route [29], numerous synthesis methods, such as sol–gel synthesis, hydrothermal, polymerized complex, or hot pressing, have been utilized to enhance the functional properties [30, 31]. However, there is no consistent report of the functional properties of BKT produced by the solid-state process due to sintering issues [32, 33]. It should be noted that to optimize the sinterability of the BKT, the focus has been on fabricating BKT nanoparticles using chemical processes [34, 35], although these processes are generally not suitable for large-scale production. Moreover, the incomplete or improper chemical reaction often hinders the fabrication of phase-pure and dense BKT. For example, the hydrothermally prepared BKT powder contains a significant number of hydroxyl groups as a lattice defect [36, 37], as such, a large volume expansion, i.e., removal of –OH group as H2O vapor [38], of the samples during sintering with higher dwell time makes them challenging to sinter as bulk ceramic samples. As such, a comprehensive investigation of solid-state processing of BKT and the structure/microstructure property relationship is critical.

Sintering dense functional ceramics typically requires elevated temperatures, which can lead to point defects, such as vacancies, induced by the volatility of constituent elements, preventing the final composition from achieving optimum and consistent crystal structure, microstructure, and functional properties. For example, Zhang et al. [39] reported improved functional properties in BNT-based materials resulting from optimized sintered microstructure, i.e., densification and grain growth. Similarly, a grain size increase and an enhancement in dielectric properties are found in BKT ceramics after prolonged sintering [12]. Moreover, density and dielectric properties are reduced for ceramics sintered below and above the optimum sintering temperature as reported in BKT and 0.8(Bi0.5Na0.5TiO3)-0.2(Bi0.5K0.5TiO3) (BNKT) solid solution, both synthesized by the combustion technique [19, 40]. It is worth mentioning that the maximum temperature used here is higher than the reported optimum sintering temperatures for BKT ceramics processed by combustion technique and solid-state reaction [19, 41]. For example, differential thermal analyses and heating-microscope analyses have indicated a sintering window below 1040 °C for the solid-state processed BKT powder [29]. However, it should be noted that a minor variation in stoichiometry during the powder fabrication process can create low-melting Bi-rich and K-rich secondary phases during the high-temperature reaction. Here, Tabuchi et al. [42] has been successfully able to fabricate solid-state processed BKT using ≈100 nm TiO2 powder as a starting material.

However, little effort has been devoted to studying the sintering of solid-state processed BKT by varying both the sintering temperature and sintering dwell time. Moreover, the influence of sintering conditions on the structure and temperature-dependent electromechanical responses in solid-state processed BKT is not well known. Based on these considerations, this work reports the influence of the sintering parameters (temperature and dwell time) on the phase transition, structure, microstructure, and piezoelectric properties of the conventional solid-state processed lead-free ferroelectric BKT.

Experimental methodology

Bi1/2K1/2TiO3 (BKT) ceramic powder was prepared by the solid-state route using the following starting materials: K2CO3 (99.0% purity, Alfa Aesar, Germany), Bi2O3 (99.0% purity, Alfa Aesar, Germany), and TiO2 (99.6% purity, Alfa Aesar, Germany). The starting materials were dried overnight in an oven at 120 °C to remove moisture content, especially for hygroscopic K2CO3 and subsequently weighed and combined to the required stoichiometric ratio inside a glove box containing dry silica gel to maintain a relative humidity level lower than 10% during weighing. The mixture was then homogenized for 24 h in a polyethylene bottle by using 5-mm zirconia milling balls as the milling media and absolute ethanol. The milled dispersion was dried using a rotary evaporator and then calcined using a double-step calcination profile 750 °C for 5 h and then 900 °C for 3 h. The two-step calcination was used to ensure the formation of phase-pure BKT ceramic powder [4, 31]. Following this, the calcinated BKT powder was cold isostatically pressed into pellets with a diameter of 10.2 mm. The green bodies were sintered in a closed alumina crucible at 1030 °C, 1050 °C, and 1060 °C with dwell times of 10 h, 20 h, and 40 h. During the sintering, to minimize the evaporation of the constituent elements, the BKT ceramic samples were embedded in the powder bed of calcinated BKT powder (sacrificial powder). Sintered samples were ground to 0.5 mm (± 0.01 mm) thick using a surface grinder. An annealing step at 600 °C for 1 h, with heating and cooling rate of 5 K/min, was used to relieve residual stresses induced by machining.

Thermogravimetric analysis (TGA) (STA 449 F3, Netzsch, Germany) was performed on non-calcined BKT powder to determine the reaction temperatures for the formation of BKT. For that purpose, a small amount (16.5 mg) of non-calcined BKT powder was placed in a ZrO2 crucible and heated using the above-mentioned instrument in air atmosphere at 5 K/min from 18 °C to 1080 °C. After 10 min holding at 1080 °C, the whole assembly was subsequently cooled down to 18 °C at the same rate. X-ray diffraction method was used to investigate the crystal structure of the calcinated powder and sintered samples. An X-ray diffractometer (Bruker D8 ADVANCE Eco, Bruker AXS, Germany) in Bragg–Brentano geometry with a source operating at 40 kV and 25 mA and fixed divergence slit width of 0.2° and Soller slit of 2.5° was used. Data were collected at room temperature within the range 2\(\theta\) = 20–80° with a step size of 0.02° and 1 s per step. A Ni-filter was used to remove the Cu \({K}_{\beta }\) contribution from the diffraction patterns.

Archimedes’ method was used to determine the density of the sintered samples. The weighing was performed on three samples of each condition. A scanning electron microscope (SEM) (Helios NanoLab 600i FIB Workstation, FEI Company, OR, USA) was used to analyze the change in microstructure for the different sintering conditions. For microstructure analysis, an 18-µm grinding disk was used to ensure flatness. Subsequent polishing steps of 9 µm, 6 µm, 3 µm and 1 µm were performed using respective polishing pads and diamond suspension, with a final polishing step with OPS (silica oxide polishing suspension). Mirror-polished samples were thermally etched at 1000 °C for 1 h to allow grain size observation. The average grain size of sintered BKT ceramic was calculated using the ImageJ software, where the grain area was characterized and the equivalent grain diameter was determined [43]. For this purpose, a total of three images of respective samples, where at least 100 grains were measured has been considered.

The two parallel cylindrical surfaces were sputtered with Pt electrodes with an approximate thickness of 20 nm for the electromechanical measurements. Temperature-dependent dielectric permittivity measurements were performed from room temperature to 600 °C (2 K/min heating and cooling rate) over a frequency range from 1 kHz to 1 MHz, using an oven (Nabertherm, LE 4/11/3216, Germany) equipped with a custom-built sample holder and an LCR meter (Keysight 4980 AL, USA) controlled by a LabView program. The polarization- and strain-electric field loops were measured from room temperature to 125 °C using a commercially available piezoelectric testing system (aixACCT TFAnalyzer 2000, aixACCT Systems GmbH, Germany). A triangular, bipolar electric field of 6 kV/mm generated by a high voltage amplifier (20/20C, Trek Inc., USA) was applied on 0.5-mm-thick samples with a frequency of 1 Hz. For small-signal piezoelectric measurements, BKT samples were poled at 90 °C for 15 min in an oil bath and field cooled to room temperature. 24 h after the poling procedure, the direct piezoelectric coefficient, \({d}_{33}\), was measured at room temperature with a Berlincourt meter (PiezoMeter System PM300; Piezotest Ltd., UK), by which a mechanical force of 10.2 N was applied on the sample with a frequency of 110 Hz. Following this, temperature-dependent \({d}_{33}\) and permittivity measurements were conducted from − 150 °C to 400 °C over a frequency range from 0.5–140 Hz to 1–1000 kHz, respectively, using a custom-built setup consisting of a modified screw-type load frame (5967, Instron, USA) and a thermal chamber that uses liquid nitrogen for cooling [16]. Samples with a height of 6 mm and a diameter of 5.8 mm were placed on polished tungsten carbide bearing enabling electrical contact, inside of the chamber and a piezoelectric stack actuator (P-025.80, PI Ceramics GmbH, Germany) applied a constant stress amplitude of ± 0.5 MPa at varying frequencies between 0.5 and 140 Hz. In addition to this, measurements were also performed under a pre-stress of −15 MPa at varying stress amplitude between 0.5 and 5 MPa for 10 Hz frequency across the same temperature range, which provided a stress-amplitude-dependent Rayleigh-type analysis that enabled the evaluation of the intrinsic and extrinsic contributions to the piezoelectric properties. Details of the measurement setup can be found in our previous work [16].

Results and discussion

Formation of BKT ceramic powder

Thermogravimetric analysis is critical in identifying the reaction temperature range for final product formation from different constituent elements. As such, TGA was conducted up to 1080 °C in an air atmosphere with a heating rate of 5 K/min to characterize the reaction temperatures of the constituent oxides (Bi2O3, TiO2) and carbonate (K2CO3) for the formation of perovskite oxide BKT ceramic, as shown in Fig. 1a.

The calculated theoretical weight loss for BKT is approximately 5%; meanwhile, the total weight loss observed on the TGA curve of BKT is approximately 9%. The excess weight loss is possibly related to the presence of humidity and/or absolute ethanol content used during the fabrication of the BKT powder as seen in the first three weight loss anomalies, and the rest is due to solid-state reaction which fits perfectly with the theoretical value.

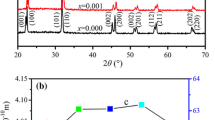

The TGA data revealed noticeable weight losses between ranges of 52 °C–92 °C, 276 °C–309 °C, 440 °C–545 °C, 550 °C–700 °C, and finally above approximately 1070 °C. The loss of moisture is likely responsible for the first three weight loss anomalies, namely moisture content evaporation at 100 °C in the first temperature range, evaporation of the remaining hygroscopic water content between 276 °C and 309 °C, and finally the decomposition of absorbed water between 440 °C and 545 °C [44]. Subsequently, within the range of 545 °C to 700 °C, the weight loss is understood to be due to the solid-state reaction forming the perovskite BKT powder, where a stabilization is observed above approximately 700 °C, indicating the end of the reaction. Although the TGA data show no significant weight loss above 700 °C, XRD data (see Fig SI) of 750 °C calcinated powder showed traces of a secondary phase. In addition, a double-step calcination at 800 °C and 950 °C was used in BKT ceramics produced by solid-state reaction; however, except for hot-pressed samples for which minor peaks were found above 1080 °C, impurities peaks were found for pellet-sintered above 1030 °C in the case of conventional sintering [4, 31]. Therefore, a double-step calcination temperature at 750 °C and 900 °C was used in this work to ensure the formation of phase-pure BKT ceramic powder, as seen from the XRD data presented in Fig. 1b. The diffraction patterns of the calcined BKT powder revealed a single-phase perovskite-type reflection, corresponding to a tetragonal structure with a space group P4 mm. Finally, the gradual decrease in weight continues above 1070 °C, which is considered the melting point of BKT [29, 45].

Interestingly, previous research on solid-state processed BKT powder revealed that 1030 °C is the optimum sintering temperature, with thermal decomposition occurring at 1040 °C during sintering [41]. It should be mentioned here that the presence of a minor extent of low-melting secondary phase could deteriorate the sintering process. However, in our work, the two-step calcinated phase-pure BKT powder was possible to sinter at higher temperatures up to 1060 °C without any significant formation of secondary phases within the resolution limit of the XRD instrument used.

Sintering condition-dependent microstructure and crystal structure

The surface microstructure of thermally etched samples is shown in Fig. 2, revealing an apparent increase in the grain size for both sintering temperature and dwell time as well as a decrease in porosity. Qualitative observation reveals samples sintered at 1030 °C and 10 h dwell time exhibit a greater extent of pores than those sintered at higher temperatures and longer dwell times. Importantly, the black spots exceeding 500 nm in length observed at 1060 °C/10 h (Fig. 2g) are attributed to image contrast and do not represent porosity. In addition, domains appear more visible for samples sintered for 40 h irrespective of the maximum sintering temperature since the formation of domains is more favorable due to increased grain size [20]. As reported in the case of BaTiO3 ceramics, domains are not found below a critical grain size of ≈300 nm because of the increased net surface energy of the domain wall [12, 20, 46].

The relative density of the sintered samples estimated as the percentage of theoretical density is displayed in Fig. 3a as a function of the sintering conditions. The highest relative density (≈97.9%) could be obtained for a dwell time of 40 h regardless of the maximum sintering temperature. The samples sintered at 1030 °C show a gradual increase in density with increasing dwell time, whereas the 1050 °C and 1060 °C sintered samples show a decrease in density for 20 h dwell time and then an increase at 40 h dwell time. The decrease in density observed at 20 h remains unclear; the volatilization of constituent elements cannot explain this behavior since the ceramics sintered at higher temperatures are dense. It is important to note that the relative density was estimated as the percentage of theoretical density, which was calculated from XRD data. As such, the presence of a minor secondary phase could influence the estimated theoretical density and consequently the relative density. Nevertheless, samples sintered for 40 h show the highest density, highlighting the advantage of prolonged sintering of BKT ceramics, which is consistent with the previous report by König et al. [41].

Moreover, the average grain size as a function of sintering conditions was determined in Fig. 3b, showing an increase in grain size with both increasing sintering time and temperature. In particular, the sintering data clearly indicate that temperatures above 1030 °C as well as longer sintering times significantly increase grain size in BKT (Fig. 3b). This is consistent with previous studies, for example, on hydrothermally processed BKT ceramics sintered at 1050 °C that revealed a grain growth from 0.18 to 1 µm by varying the sintering holding time from 5 to 100 h [12, 20]. Importantly, BKT has demonstrated significant changes in the functional properties with varying grain size. A decreasing grain size was found to decrease the observed piezoelectric and dielectric response, which is suggested to be due to a low permittivity grain boundary or to the influence of enhanced internal stress in smaller grains suppressing the RE–FE transition [12]. For example, grain size less than 1 μm has been found to affect the phase transition behavior as well as the dielectric permittivity in BKT ceramic [21]. Moreover, the grain size effect on ferroelectric properties was shown in BKT, where samples with larger gain size, i.e., ≥ 1.01 μm, exhibited saturated polarization–electric field behavior [20]. In addition, it has also been shown that the room temperature piezoelectric coefficient of BKT is influenced by the grain size, where a decrease in \({d}_{33}\) was observed for grain sizes below 0.4 μm [20].

The sintering data revealed that the largest grain size of 0.49 μm was observed for BKT sintered at 1060 °C/40 h, larger than that found for 1050 °C and even significantly larger than the one found at 1030 °C at 40 h of 0.42 µm and 0.3 µm, respectively. This indicates that an increase in temperature at longer sintering times increases coarsening mechanisms, leading to larger grains, but does not significantly improve densification. Although smaller grains are typically desired for mechanical properties [47,48,49,50,51,52], larger grains have been shown to improve the piezoelectric [4, 20, 53, 54], ferroelectric [4, 20, 32, 55], and ferroelastic [56] properties of electroceramics, in addition to improving the fracture toughening during crack growth [57] and shifting the Curie point [54]. As such, the optimization of dwell time can be beneficial to achieve enhanced functional properties of BKT.

In addition to the density and grain size, the sintering conditions were found to affect the crystal structure, shown in Fig. 4a. These data reveal a perovskite phase BKT ceramic for all sintering conditions. Although diffraction patterns correspond well to a tetragonal P4mm space group, a minor secondary phase was observed, as indicated by the small peak on the left of 110 reflection, at \(\approx\) 30.36° for the lower sintering temperatures (1030 °C and 1050 °C) and prolonged dwell time (> 10 h). Interestingly, the trace of the secondary phase tends to decrease for sintering conditions of 1060 °C/40 h below the resolution limit of our XRD instrument. The origin of increased traces of secondary phases for the intermediate condition is unknown. Further investigation with in situ high-temperature diffractions measurement could highlight the origin of this. Nevertheless, despite the variation in sintering temperature and dwell time, single 111 and split 200 reflections are observed for all samples (Fig. 4b and c), where the splitting of the 002/200 reflection becomes more prominent with increasing sintering dwell time and temperature, indicating the change in tetragonal distortion. This result is in good agreement with previous reports on crystal structure of BKT sintered ceramics. Hagiwara et al. [20], for example, showed larger splitting of 002 and 200 peaks with increasing the sintering time from 5 to 100 h for samples sintered at 1050 °C.

The tetragonality was determined as a function of sintering conditions (Fig. 5), revealing an increase with both sintering temperature and time, corresponding well to the observed grain size. Similar observations have been made for other perovskite ferroelectrics, which was attributed to reduced internal stress [12, 20]. Previous reports on BaTiO3 also showed that larger grain size results in higher tetragonality [58]. Hence, sintering affected the unit cell and samples sintered at 1060 °C/40 h exhibited a more distorted lattice, i.e., \(c/a\) = 1.0209, highlighting the influence of prolonged dwell time on the crystal structure of solid-state processed BKT ceramics. Moreover, the unit cell volume was smallest for lower sintering temperatures and shortest dwell times, which is due to higher internal stress (quasi-hydrostatic) fields associated with the smaller grain size [56, 59]. Such variation in internal residual stresses can also influence the phase transition temperature [56, 60,61,62,63,64].

Sintering condition-dependent dielectric and electromechanical properties

Higher sintering temperature and dwell time are expected to improve the electromechanical properties of BKT due to an increased relative density and grain size. As such, sintering condition-dependent dielectric and electromechanical properties of BKT were investigated to understand the crystal structure– and microstructure–property relationships. In Fig. 6, the temperature dependence of the relative permittivity (\({\varepsilon }_{r}\)) of BKT ceramics measured from room temperature to 600 °C during heating and cooling over a frequency range of 1 kHz to 1 MHz is reported, where an increase in permittivity and decrease in dielectric loss with increasing sintering temperature and time are apparent. The dielectric permittivity at \({T}_{max}\), corresponding to the maximum relative permittivity (\({\varepsilon }_{m}\)) at 1 kHz during the heating cycle, was 4200, 5200, and 6100 for samples sintered at 1030, 1050, and 1060 °C for the same dwell time of 40 h, respectively. Such an increase in dielectric permittivity can be explained by the change in grain size, where previous reports suggested an influence of the low-\({\varepsilon }_{r}\) grain boundary layers in smaller grains [20, 33]. In addition, other perovskite ferroelectrics, such as BaTiO3 [65], display a well-known grain size-dependent permittivity with a maximum at approximately 1 µm. Below this critical grain size, the permittivity is found to decrease with decreasing grain size, which is suggested to be due to changing domain size and internal stresses and is directly correlated with a change in crystal structure, corresponding well with the observations here. The influence of porosity observed in the microstructure of 1030 °C/10 h ceramics is well confirmed on the dielectric response (Fig. 6a) by increased values of loss tangent at a lower temperature. This effect is not visible at higher sintering temperatures and times. In addition, this behavior is also possibly related to hygroscopic K2O-rich phase only present in BKT samples sintered for a shorter time [41].

Despite an increase in the maximum permittivity with increased sintering time and temperature, all of the temperature-dependent dielectric responses have similar features, namely a nonlinear increase in the relative permittivity during heating as well as a shift of the maximum permittivity peak toward higher temperature with increasing frequency, which is a characteristic of relaxor behavior. The temperature-dependent change in permittivity during heating and cooling results in the formation of thermal hysteresis between approximately 291 °C and 318 °C, which was described by previous reports as the signature of spontaneous first-order phase transition for BKT sintered ceramics [12]. This, along with the observed domain structure in Fig. 2, indicates that BKT ceramics exhibit a spontaneous RE–FE phase transition, in contrast to Na1/2Bi1/2TiO3 that displays a relaxor-like response over the same temperature range [15, 66, 67].

Interestingly, the extent of thermal hysteresis significantly varies with the sintering conditions, where the sharpest dielectric anomaly is observed for 1060 °C/40 h and gradually diminishing with decreasing sintering conditions and completely vanishing at 1030 °C/10 h, where a relaxor-like dielectric response is observed. To directly investigate this, the integrated area of this thermal hysteresis between 200 and 400 °C for the 1 kHz data presented in Fig. 6 was determined (see Table SI). Therefore, at higher sintering temperatures and dwell times, samples undergo sharper RE–FE transition during cooling in comparison to samples sintered at lower sintering temperatures and dwell times for which the existence of dominant relaxor characteristic at the room temperature is expected.

Previous studies have correlated such a RE–FE transition phenomenon with the decrease in grain size, where it is argued that samples with fine grains lack the spontaneous RE–FE transition [12]. As such, sintering temperature or dwell time can be utilized to control the room temperature RE/FE state in BKT. The noticeable reduction in \({\varepsilon }_{m}\) and a broad peak at the temperature of maximum permittivity, \({T}_{\mathrm{max}}\), observed with decreasing grain size are similar to observation made in the dielectric response of BaTiO3 (BT) when the grain size decreases from 1.8 to 0.28 μm [68]. The broad peak was assigned to relaxor behavior, and the decrease in \({\varepsilon }_{m}\) was linked to structural change from tetragonal to pseudocubic phase caused by the suppression of 90° domain walls occurring in fine grain ~0.7 μm [68]. Therefore, it seems for grain size < 0.35 µm in BKT the pseudocubic relaxor-to-tetragonal transition becomes more difficult, which is also confirmed by a vanishing thermal hysteresis as shown in Fig. 6. Importantly, the phase transition observed in BKT is shifted toward higher temperature with decreasing grain size, corresponding well with investigations on BT, where a \({T}_{c}\) was found to increase in fine grains due to internal stresses and related change in 90° domain wall density [69].

Interestingly, the spontaneous RE–FE transition observed in BKT is not similar to that observed in BNT. The latter does not show such pronounced thermal hysteresis during the heating–cooling cycle of temperature-dependent permittivity measurements, which can be related to the crystal structure, i.e., tetragonal in BKT and rhombohedral in BNT. Hagiwara et al. [18] associated the development of the spontaneous FE order in BKT with the tetragonal crystal structure of the PNRs. Based on the model developed by Pirc and Blinc [27], it was suggested that PNRs with a narrow statistical distribution or strong interaction among each other develop into ferroelectric macroscopic domains. PNRs in BKT should have a narrower interaction due to their tetragonal symmetry with six allowed polar directions than those in rhombohedral BNT with eight allowable polar directions [18]. In addition, the cooling rate can influence the interaction between PNRs in BKT ceramics. Recently, Hagiwara et al. [21] reported that a slow cooling process in BKT possibly induced a more homogeneous distribution of the A-sites cations (Bi3+ and K+), leading to smaller PNRs. Therefore, a reduced interaction between PNRs was observed in slow cooled BKT and could be the reason for the observed inhibition of phase transition into ferroelectric order. In contrast to an as-sintered BKT ceramic in which the A-sites cations are found more heterogeneously distributed, their PNRs are consequently expected to be larger, which was confirmed by their enhanced permittivity on the relaxor side in contrast to the slow cooled BKT sample. Thus, larger PNRs can result in a stronger interaction, leading to the development of a macroscopic domain, i.e., long-range order inducing the RE–FE transition [21].

These observed effects, including the grain size as well as the formation of a long-range ferroelectric order with variations in domain size, are expected to influence the large signal ferroelectric response. As such, the polarization- and strain-electric field behavior was characterized for samples sintered at 1050 °C/40 h and 1060 °C/40 h from 25 to 125 °C with a frequency of 1 Hz (Fig. 7); samples sintered at 1030 °C displayed significant conductivity and were, therefore, not able to be measured. At 25 °C, both samples display unsaturated polarization and strain hysteresis curves with an applied electric field of 6 kV/mm. Such room temperature unsaturated polarization–electric field loops have been previously reported in BKT ceramic [20, 23], which has been attributed to the small grain size that hinders domain switching. Moreover, X-ray photo-electronic spectroscopy data reported by Guo et al. [23] suggested the possibility of oxygen vacancies or defects in the structure of BKT ceramic causing by the A-site (Bi3+, K+) deficiency occurring after a post-annealing. Consequently, such samples will display distorted unit cells and, therefore, require higher electric fields to reorient polarization.

However, with increasing temperature, the saturation region was observed in the large-field polarization response, particularly in the sample sintered at 1060 °C, resulting in an increase in the remanent polarization and maximum strain. These observations correspond well to other reports on BKT [23]. Interestingly, however, the coercive field values were not found to monotonically decrease, as has been observed in other ferroelectrics [70, 71]. In contrast, the 1050 °C sample displayed an increase, while the 1060 °C sample was found to increase and subsequently decrease at the highest investigated temperatures. This behavior was linked to diminished effect of domain wall pinning by oxygen vacancies or defects at elevated temperature, resulting to higher motion or switching of domains producing an enhanced remnant polarization, \({P}_{r}\) [23]. At lower temperatures, pinning centers limit the reorientation, and therefore the saturation, of the polarization response, resulting in slimmer P-E hysteresis loops with a lower effective slope when the maximum and minimum polarization values are connected. With increasing temperature and enhance extrinsic contributions through, e.g., improved domain wall mobility, the initial increase in \({E}_{c}\) can then decrease.

As shown in Fig. 7, an increase in the sintering temperature resulted in an increase in the temperature-dependent maximum strain and remnant polarization, likely related to the larger observed grain size. This effect was also observed for all the tested temperatures. Samples sintered at 1060 °C show enhanced properties, with the highest remanent polarization, \({P}_{r}\) = 14 µC/cm2, and maximum strain, \({S}_{\mathrm{max}}\) = 0.12%, found at 125 °C. This observation indicates that the BKT ceramics need to be poled at a moderately high temperature (~ 100 °C) to obtain a better small-signal piezoelectric response.

The temperature-dependent small-signal piezoelectric coefficient, \({d}_{33}\), and dielectric permittivity were measured simultaneously during heating from − 150 to 400 °C for 1050 °C/40 h and 1060 °C/40 h sintered samples to evaluate the temperature stability and the phase transition temperatures (Fig. 8). During heating from − 150 °C, there is an initial linear increase in \({d}_{33}\), similar to previous observations in PZT [72], where it was suggested to be due to a thermally induced increase in domain wall mobility. In both samples, a peak in the piezoelectric response is found at approximately 90 °C, which is not associated with any apparent phase transition temperature of BKT. Here, for example, there is no apparent anomaly in the dielectric response in that temperature range, indicating that this increase is not due to a structural phase transition. Interestingly, this also approximately corresponds with the temperature where saturation was observed in large signal ferroelectrics measurements (Fig. 7). With further increasing temperature, the piezoelectric response of samples sintered at 1050 °C were found to decrease whereas for those sintered at 1060 °C increased with a subsequent higher temperature peak observed at approximately 220 °C. Although an anomaly is observed in the same range for the 1060 °C sample, this is likely related to measurement artifacts. Above this temperature, both samples displayed a sharp decrease, consistent with depolarization and a thermally induced loss of the poled domain state. The depolarization temperatures of 1050 °C and 1060 °C, determined from the inflection point of the sharp decrease in \({d}_{33}\), was found to be 308 °C and 286 °C, respectively, corresponding well to previous investigations [21, 73].

Variation in temperature-dependent \({\mathrm{d}}_{33}\) with varying stress amplitude (\({\upsigma }_{\mathrm{A}}\)) for a 1050 °C and b 1060 °C sintered BKT measured under pre-stress of \(-\) 15 MPa. Temperature-dependent variation in c, d \({\mathrm{d}}_{\mathrm{init}}\), e, f Rayleigh coefficient, \(\mathrm{\alpha }\), and g, h estimated extrinsic contribution. The insets a, b show linear relation of \({\mathrm{d}}_{33}\) with \({\upsigma }_{\mathrm{A}}\) at different constant measurement temperatures

Grain size, internal stresses and defects are known to affect the phase transition temperature of piezoceramics. Importantly, the 1050 °C shows a higher depolarization temperature,\({T}_{d}\) than the 1060 °C which is related to their smaller grain size as well as their expected higher amount of defects compare to 1060 °C. Moreover, it has been reported a two-step phase transition in BKT [73], where the ferroelectric-to-relaxor transition temperature, \({T}_{F-R}\), is preceded by the depolarization temperature, \({T}_{d}\). Therefore, the sample at 1050 °C is expected to have a higher \({T}_{F-R}\), as well as a higher \({T}_{d}\) compared to the sample sintered at 1060 °C.

Similar temperature-dependent peaks in piezoelectric response at temperatures in the vicinity of the depolarization temperature have also been found in other ferroelectric perovskites, such as PZT [72, 74, 75], BT [76], BNT [77], and BNT-BT [78, 79], which is due to the simultaneous increase in permittivity at the Curie point and the related loss of the polar order [75, 80, 81].

The sharp increase in permittivity, which corresponds to the polar tetragonal to non-polar relaxor state [12], was found to occur at 314 °C and 294 °C at 1 kHz for the 1050 °C and 1060 °C sintered samples, respectively. Those temperatures are often referred to as ferroelectric-to-relaxor transition temperature, \({T}_{F-R}\) in BKT [12, 18, 20, 73]. Previous reports on BKT sintered ceramic manufactured by the solid-state route and hydrothermal process revealed a \({T}_{F-R}\) of 296 °C [73] and 314 °C [12] during heating. Interestingly, the \({T}_{F-R}\) of 1050 °C is 20 °C higher than 1060 °C sample, which is understood to be related to internal stress or defects in the sample. Defects, such as oxygen vacancies, and internal stresses have been reported to influence the transition temperature in BaTiO3 by a shift toward higher temperature [63, 82]. Similarly, Picht et al. reported a shift in \({T}_{C}\) to higher temperature with decreasing grain size in donor-doped PbZrxTi1−xO3 (PZT), which agrees well with our observations and suggesting that the effect of both defect chemistry and internal stresses induced by smaller grains can lead to a shift of the phase transition temperature in BKT [56].

Throughout the investigated temperature range, limited frequency dispersion in the piezoelectric response was observed, particularly at elevated temperatures in the vicinity of the depolarization temperature where larger frequency dispersion is observed in the relative permittivity. In contrast, hard PZT ceramic displays a significant increase of frequency dependence with increasing temperature caused by a thermally enhanced defect mobility [75]. Other compositions with lower defect concentrations, such as soft PZT, display similar results to that observed here in BKT with lower variation in the frequency dispersion of the piezoelectric properties [75]. Importantly in these studies, however, the focus was on defect associates that can act as a dipole and, thereby, be influenced by the applied electric field. This indicates that the defects either require additional thermal energy to increase mobility or that they are not sufficiently influenced by the external electric field. In addition, an increase in \({d}_{33}\) with decreasing frequency has been observed in various piezoelectrics, such as BaTiO3 [76], 0.94(Bi1/2Na1/2)TiO3-0.06BaTiO3 [16], and BNT [77] due to the frequency dependence of the extrinsic contributions [76, 83], such as polarization rotation or domain wall motion [72]. Extrinsic contributions can be influenced by internal stresses developed on the sample [84] as well as grain boundaries trapping domain wall impeding their motion [75].

The Rayleigh model, originally developed to analyze the nonlinear extrinsic response of ferromagnetic materials, has been used extensively in explaining the intrinsic and extrinsic contributions of piezoelectric materials [83]. This model can describe the dependence of the piezoelectric coefficient on the applied electric or mechanical field amplitude, thereby enabling one to determine the contributions of the intrinsic and extrinsic effects to the overall response. The Rayleigh model for variable applied stress amplitude (\({\sigma }_{A}\)) is expressed as \({d}_{33}={d}_{\mathrm{init}}+\alpha {\sigma }_{A}\), where \({d}_{33}\) is the total piezoelectric coefficient, \({d}_{\mathrm{init}}\) is the initial reversible piezoelectric response at zero applied field, and \(\alpha\) is the piezoelectric Rayleigh coefficient that describes the change in \({d}_{33}\) as a function of applied stress amplitude due to the activation of irreversible extrinsic contributions. A higher value α would indicate a greater extent of irreversible contributions to the macroscopic piezoelectric coefficient. Although various extrinsic contributions, such as phase boundaries and defects [72], are possible and can contribute to the observed behavior, the nucleation and motion of domain walls is the primary mechanism in ferroelectric materials [75, 85].

For the Rayleigh analysis, the applied field amplitude should be in the sub-coercive field range, i.e., the applied field magnitude should not change the domain wall density and structure significantly [83]. In our measurements, the maximum applied stress of − 20 MPa was significantly lower than the reported coercive stress value of − 250 MPa for BKT [18]. A pre-stress of − 15 MPa was applied to the sample to avoid contact loss during the temperature-dependent measurements and maintaining continuous electrical contact. The temperature-dependent \({d}_{33}\) value with varying stress amplitude between ± 0.5 and ± 5 MPa was conducted at 10 Hz measurement frequency for 1050 °C and 1060 °C sintered BKT from –150 °C to 400 °C (Fig. 9). The temperature-dependent \({d}_{33}\) data show a similar response to the frequency-dependent measurement conducted with − 5 MPa pre-stress (Fig. 8), confirming that the difference in pre-stress did not significantly influence the nonlinear contributions to the piezoelectric response. The inset of Fig. 9a and b shows the plot of stress amplitude-dependent direct \({d}_{33}\) for selected temperatures.

The \(\alpha\) and \({d}_{\mathrm{init}}\) components of the Rayleigh model can be extracted by using linear fitting of data plotted as \({d}_{33}\) as a function of \({\sigma }_{A}\). Considering the evaluated \({d}_{\mathrm{init}}\), \(\alpha\), and percent extrinsic contributions \(=\alpha {\sigma }_{A}/({d}_{\mathrm{init}}+\alpha {\sigma }_{A})\), it is evident that for the BKT (irrespective of the sintering condition), the piezoelectric coefficient is dominated by the intrinsic contributions, e.g., extrinsic contributions to the piezoelectric coefficient at 23 °C (ambient temperature) accounts for only approximately 2–6% of the overall response. A similar analysis of commercially available soft PZT (PIC151) showed an extrinsic contribution of approximately 26% at the same temperature (see Fig SII), a significantly higher value than that determined for the BKT. It should be noted that the relatively higher scattering in calculated extrinsic contributions above 300 °C is due to the small absolute \({d}_{33}\) value (relatively higher difference in calculated contributions).

During the electrical poling of polycrystalline piezoceramics, lattice distortion, domain switching events, and intergranular constraints play a crucial role in the observed macroscopic piezoelectric properties [86, 87]. The crystal structure influences the domain wall mobility of the non-180° domains [88]. Importantly, the strain mismatch at the domain wall can be influenced by the extent of change in lattice distortion without requiring crystallographic phase change. For example, piezoelectric compositions with higher tetragonal distortion exhibit significantly suppressed electric field-induced non-180° domain switching due to the internal stress associated with the non-180° domain switching events and intergranular constraints [89]. As such, it can be argued that the BKT, a tetragonal composition with a \(c/a\) ≥ 1.021, is significantly higher than the reported distortion of PIC151 (\(c/a\approx 1.012\)) [90], exhibits higher suppression of non-180° domain switching due to internal stress.

Although the absolute value of the \({d}_{33}\) is different depending on the sintering condition, which is possibly due to the larger grain size and higher structural distortion (Figs. 3, 5), the local maximum of \({d}_{33}\) and \({d}_{\mathrm{init}}\) was found to be approximately 90 °C irrespective of the sintering condition. The difference in \({d}_{33}\) and \({d}_{init}\) above 90 °C for differently sintered samples can be related to the variation in internal stress state, i.e., smaller grain size indicates higher internal stress. The \(\alpha\) coefficient for the 1060 °C sample remains below 0.35 pC m2/N2 × 10−6 up to 90 °C and then increases rapidly above this temperature and reaches the value of 0.98 pC m2/N2 × 10−6 at the depolarization temperature (~ 285 °C). However, for the 1050 °C sintered sample, the \(\alpha\) coefficient varies between 0.15 and 0.45 pC m2/N2 × 10−6 for the entire piezoelectrically active temperature range. “The increase in \(\alpha\) values with increasing temperature indicates the increased domain wall mobility, which is expected to be the origin of the nearly linear increase in \({d}_{33}\) with temperature from −150 °C to approximately 50 °C for both compositions. With further increasing temperature, a peak in the \({d}_{33}\) curve at \(\sim\) 90 °C is observed that doesn’t correspond to any dielectric anomaly that would suggest a phase transition, followed by a subsequent decrease due to the thermally induced changes in the crystal structure and destabilization of the poled domain state.”

It can be argued that the difference in temperature-dependent \({d}_{33}\) for 1050 °C and 1060 °C sintered samples above 90 °C is possibly associated with the relative change in intrinsic (\({d}_{\mathrm{init}}\)) and extrinsic contributions (\(\alpha\)) at higher temperatures. However, to confirm the influence of lattice distortion on the local maximum around 90 °C, in situ temperature-dependent investigations of crystal structure, i.e., change in \(c/a\) ratio with temperature, will be required. Importantly, our analysis of the temperature-dependent change in the intrinsic and extrinsic contribution of BKT highlight that the temperature stability of \({d}_{33}\), even with the same piezoelectrically active crystallographic phase, is influenced by the relative change in intrinsic and extrinsic contributions with temperature variation.

Conclusions

In this study, phase-pure BKT ceramics with a density up to 98% of the theoretical density were fabricated by the conventional solid-state reaction method. Structure and microstructure analysis and dielectric and ferroelectric measurements of differently sintered samples revealed an enhanced functional property for samples sintered at 1060 °C/40 h. The resulting data show a higher remanent polarization, higher remanent strain, and a higher relative permittivity. This is related to the largest grain size obtained for samples sintered at 1060 °C/40 h. Moreover, theses samples also showed better piezoelectric response with \({d}_{33}\) and temperature stability. The Rayleigh analysis highlights a significantly higher extent of intrinsic contributions (> 94%) to the piezoelectric coefficient in BKT, possibly related to their single tetragonal phase with significant distortion, \(c/a\) ≥ 1.02. It was also evident that the temperature stability of \({d}_{33}\) depends on the extent of relative change in intrinsic and extrinsic contributions. This work comprehensively demonstrates the microstructure/structure–piezoelectric property relationships in solid-state processed BKT.

References

Shibata K, Wang R, Tou T, Koruza J (2018) Applications of lead-free piezoelectric materials. MRS Bull. https://doi.org/10.1557/mrs.2018.180

Rödel J, Jo W, Seifert KTP, Anton E-M, Granzow T, Damjanovic D (2009) Perspective on the development of Lead-free Piezoceramics. J Am Ceram Soc. https://doi.org/10.1111/j.1551-2916.2009.03061.x

Webber KG, Vögler M, Khansur NH, Kaeswurm B, Daniels JE, Schader FH (2017) Review of the mechanical and fracture behavior of perovskite lead-free ferroelectrics for actuator applications. Smart Mater Struct. https://doi.org/10.1088/1361-665X/aa590c

Hiruma Y, Aoyagi R, Nagata H, Takenaka T (2005) Ferroelectric and piezoelectric properties of (Bi 1/2 K 1/2)TiO 3 ceramics. Jpn J Appl Phys. https://doi.org/10.1143/JJAP.44.5040

Smolenskii GA, Isupov VA, Agranovskaya AI et al (1961) New ferroelectrics of complex compositions. Soviet Phys Solid State. 2:2651–2654

Razumovskaya ON, Kuleshova TB, Rudkovskaya LM (1983) Reactions of formation of BiFeO3, K05 Bi0.5TiO3, and Na0.5Bi0.5TiO3. Neorganich Mater Inorg Mater 19:113–115

Buhrer CF (1962) Some properties of bismuth perovskites. J Chem Phys. https://doi.org/10.1063/1.1732613

Wada T, Toyoike K, Imanaka Y, Matsuo Y (2001) Dielectric and piezoelectric properties of (A0. 5Bi0. 5) TiO3–ANbO3 (A= Na, K) systems. J J Appl Phys 40(9S):5703

Chen W, Li Y, Xu Q, Zhou J (2005) Electromechanical properties and morphotropic phase boundary of Na0.5Bi0.5TiO3-K0.5Bi0.5TiO3-BaTiO3 lead-free piezoelectric ceramics. J Electroceram 15(3):229–235

Sasaki A, Chiba T, Mamiya Y, Otsuki E (1999) Dielectric and piezoelectric properties of (Bi0.5Na0.5) TiO3–(Bi0.5K0.5) TiO3 systems. Jpn J Appl Phys 38(9S):5564

Otoničar M, Škapin SD, Jančar B, Ubic R, Suvorov D (2010) Analysis of the phase transition and the domain structure in K0.5Bi0.5TiO3 perovskite ceramics by in situ XRD and TEM. J Am Ceram Soc. https://doi.org/10.1111/j.1551-2916.2010.04013.x

Hagiwara M, Fujihara S (2015) Grain-size-dependent spontaneous relaxor-to-ferroelectric phase transition in (Bi 1/2 K 1/2)TiO 3 ceramics. Appl Phys Lett. https://doi.org/10.1063/1.4926496

Levin I, Keeble DS, Cibin G, Playford HY, Eremenko M, Krayzman V, Laws WJ, Reaney IM (2019) Nanoscale polar heterogeneities and branching bi-displacement directions in K0.5 Bi0.5 TiO3. Chem Mater. https://doi.org/10.1021/acs.chemmater.8b05187

Jiang B, Grande T, Selbach SM (2017) Local structure of disordered Bi0.5 K0.5 TiO3 investigated by pair distribution function analysis and first-principles calculations. Chem Mater. https://doi.org/10.1021/acs.chemmater.7b00276

Isupov VA (2005) Ferroelectric Na0.5 Bi0.5 TiO3 and K0.5 Bi0.5 TiO3 perovskites and their solid solutions. Ferroelectrics. https://doi.org/10.1080/001501990910276

Schader FH, Wang Z, Hinterstein M, Daniels JE, Webber KG (2016) Stress-modulated relaxor-to-ferroelectric transition in lead-free (Na1/2Bi1/2)TiO3−BaTiO3 ferroelectrics. Phys Rev B. https://doi.org/10.1103/PhysRevB.93.134111

Ehara Y, Novak N, Ayrikyan A, Geiger PT, Webber KG (2016) Phase transformation induced by electric field and mechanical stress in Mn-doped (Bi 1/2 Na 1/2)TiO 3 -(Bi 1/2 K 1/2)TiO 3 ceramics. J Appl Phys. https://doi.org/10.1063/1.4966614

Hagiwara M, Ehara Y, Novak N, Khansur NH, Ayrikyan A, Webber KG, Fujihara S (2017) Relaxor-ferroelectric crossover in (Bi1/2K1/2)TiO3 Origin of the spontaneous phase transition and the effect of an applied external field. Phys Rev B. https://doi.org/10.1103/PhysRevB.96.014103

Thongtha A, Laowanidwatana A, Bongkarn T (2013) Phase formation, microstructure and dielectric properties of bismuth potassium titanate ceramic fabricated using the combustion technique. Integr Ferroelect. https://doi.org/10.1080/10584587.2013.852921

Hagiwara M, Fujihara S (2015) Grain size effect on phase transition behavior and electrical properties of (Bi 1/2 K 1/2)TiO 3 piezoelectric ceramics. Jpn J Appl Phys. https://doi.org/10.7567/JJAP.54.10ND10

Hagiwara M, Fujihara S (2017) Effect of thermal history on stability of the relaxor state in (Bi 1/2 K 1/2)TiO 3 ceramics. Jpn J Appl Phys. https://doi.org/10.7567/JJAP.56.10PC03

Guo J, Zhu M, Li L, Zheng M, Hou Y (2017) Relaxor to ferroelectric crossover in KBT ceramics by prolonged annealing. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2017.01.299

Guo J, Zhu M, Li L, Qing T, Wang C, Liu L, Zheng M, Hou Y (2017) Normal-relaxor ferroelectric modulation of a-site complex perovskite ferroelectric (K 1/2 Bi 1/2)TiO 3 by post-annealing. J Appl Phys. https://doi.org/10.1063/1.4973124

Park J-H, Woodward PM, Parise JB, Reeder RJ, Lubomirsky I, Stafsudd O (1999) Synthesis, structure, and dielectric properties of (Bi 1/2 Ag 1/2)TiO 3. Chem Mater. https://doi.org/10.1021/cm9806533

Groszewicz PB, Gröting M, Breitzke H, Jo W, Albe K, Buntkowsky G, Rödel J (2016) Reconciling local structure disorder and the Relaxor state in (Bi1/2Na1/2)TiO3-BaTiO3. Sci Rep. https://doi.org/10.1038/srep31739

Jeong I, Park CY, Kim DJ, Kim S, Moon BK, Kim IW, Ahn CW (2011) Neutron total scattering studies on A-site disorder in lead-free ferroelectric Bi0. 5 (Na1–x K x) 0.5 TiO3. 2196–7105

Aksel E, Forrester JS, Nino JC, Page K, Shoemaker DP, Jones JL (2013) Local atomic structure deviation from average structure of Na0.5 Bi0.5 TiO3: Combined x-ray and neutron total scattering study. Phys. Rev. B 87(10):104113

Gadelmawla A, Riess K, Birkenstock J, Hinterstein M, Webber KG, Khansur NH (2021) Effect of varying Bi content on the temperature-dependent mechanical, dielectric, and structural properties of nominal Na 1/2 Bi 1/2 TiO 3. J Appl Phys. https://doi.org/10.1063/5.0070594

König J, Spreitzer M, Jančar B, Suvorov D, Samardžija Z, Popovič A (2009) The thermal decomposition of K0.5Bi0.5TiO3 ceramics. J Eur Ceram Soc. https://doi.org/10.1016/j.jeurceramsoc.2008.10.002

Hagiwara M, Fujihara S (2015) Fabrication of dense (Bi1/2K1/2)TiO3 ceramics using hydrothermally derived fine powders. J Mater Sci. https://doi.org/10.1007/s10853-015-9144-4

Hiruma Y, Marumo K, Aoyagi R, Nagata H, Takenaka T (2008) Ferroelectric and piezoelectric properties of (Bi1/2K1/2)TiO3 ceramics fabricated by hot-pressing method. J Electroceram. https://doi.org/10.1007/s10832-007-9146-y

Hiruma Y, Nagata H, Takenaka T (2007) Grain-size effect on electrical properties of (Bi 1/2 K 1/2)TiO 3 ceramics. Jpn J Appl Phys. https://doi.org/10.1143/JJAP.46.1081

Hagiwara M, Fujihara S (2015) Appl. Phys. Lett. 107(1):012903

Krad I, Bidault O, Geoffroy N, Maaoui MEL (2016) Preparation and characterization of K0.5Bi0.5TiO3 particles synthesized by a stirring hydrothermal method. Ceram Int. https://doi.org/10.1016/j.ceramint.2015.10.158

Zhu G, Miao H, Tan G, Liu YU, Xia AO (2006) Hydrothermal synthesis of potassium bismuth titanate nanoparticles. Int J Nanosci. https://doi.org/10.1142/S0219581X06004954

Hagiwara M, Ito M, Fujihara S (2017) Defects and microstructure of a hydrothermally derived (Bi 1/2 K 1/2) TiO 3 powder. J Asian Ceram Soc. https://doi.org/10.1016/j.jascer.2016.12.003

Hagiwara M (2021) (Bi1/2K1/2)TiO3 lead-free ferroelectric ceramics: processing, properties, and compositional modifications. J Ceram Soc Japan. https://doi.org/10.2109/jcersj2.21060

Hennings DFK, Metzmacher C, Schreinemacher BS (2001) Defect chemistry and microstructure of hydrothermal barium titanate. J Am Ceram Soc. https://doi.org/10.1111/j.1151-2916.2001.tb00627.x

Zhang Y-R, Li J-F, Zhang B-P (2008) Enhancing electrical properties in NBT-KBT lead-free piezoelectric ceramics by optimizing sintering temperature. J Am Ceram Soc. https://doi.org/10.1111/j.1551-2916.2008.02469.x

Thongtha A, Bongkarn T (2011) Optimum sintering temperature for fabrication of 0.8Bi0.5Na0.5TiO3–0.2Bi0.5K0.5TiO3 lead-free ceramics by combustion technique. KEM. https://doi.org/10.4028/www.scientific.net/KEM.474-476.1754

König J, Suvorov D (2015) Evolution of the electrical properties of K0.5Bi0.5TiO3 as a result of prolonged sintering. J Eur Ceram Soc. https://doi.org/10.1016/j.jeurceramsoc.2015.04.003

Tabuchi K, Inoue Y, Nagata H, Takenaka T (2013) Effects of starting raw materials for fabricating dense (Bi 1/2 K 1/2)TiO3 ceramics. Ferroelectrics. https://doi.org/10.1080/00150193.2013.848767

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods. https://doi.org/10.1038/nmeth.2089

Ng CY, Razak KA (2011) Properties of praseodymium-doped bismuth potassium titanate (Bi0.5K0.5TiO3) synthesised using the soft combustion technique. J Alloys Comp. https://doi.org/10.1016/j.jallcom.2010.09.136

Rao PVB, Ramana EV, Sankaram TB (2009) Electrical properties of K0.5Bi0.5TiO3. J Alloys Comp. https://doi.org/10.1016/j.jallcom.2007.11.089

Zhao Z, Buscaglia V, Viviani M, Buscaglia MT, Mitoseriu L, Testino A, Nygren M, Johnsson M, Nanni P (2004) Grain-size effects on the ferroelectric behavior of dense nanocrystalline BaTiO3 ceramics. Phys Rev B. https://doi.org/10.1103/PhysRevB.70.024107

Yang Z, Du H, Qu S, Hou Y, Ma H, Wang J, Wang J, Wei X, Xu Z (2016) Significantly enhanced recoverable energy storage density in potassium–sodium niobate-based lead free ceramics. J Mater Chem A. https://doi.org/10.1039/C6TA04107H

Shao T, Du H, Ma H, Qu S, Wang J, Wang J, Wei X, Xu Z (2017) Potassium–sodium niobate based lead-free ceramics: novel electrical energy storage materials. J Mater Chem A. https://doi.org/10.1039/C6TA07803F

Neusel C, Schneider GA (2014) Size-dependence of the dielectric breakdown strength from nano- to millimeter scale. J Mech Phys Solids. https://doi.org/10.1016/j.jmps.2013.09.009

Tunkasiri T, Rujijanagul G (1996) Dielectric strength of fine grained barium titanate ceramics. J Mater Sci Lett. https://doi.org/10.1007/BF00275336

Yip S (1998) The strongest size. Nature. https://doi.org/10.1038/35254

Yang Z, Gao F, Du H, Jin L, Yan L, Hu Q, Yu Y, Qu S, Wei X, Xu Z, Wang Y-J (2019) Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties. Nano Energy. https://doi.org/10.1016/j.nanoen.2019.02.003

Yang A, Wang C-A, Guo R, Huang Y, Nan C-W (2010) Effects of sintering behavior on microstructure and piezoelectric properties of porous PZT ceramics. Ceram Int. https://doi.org/10.1016/j.ceramint.2009.09.022

Randall CA, Kim N, Kucera J-P, Cao W, Shrout TR (1998) Intrinsic and extrinsic size effects in fine-grained morphotropic-phase-boundary lead zirconate titanate ceramics. J Am Ceram Soc. https://doi.org/10.1111/j.1151-2916.1998.tb02389.x

Cao W, Randall CA (1996) Grain size and domain size relations in bulk ceramic ferroelectric materials. J Phys Chem Solids. https://doi.org/10.1016/0022-3697(96)00019-4

Picht G, Khansur NH, Webber KG, Kungl H, Hoffmann MJ, Hinterstein M (2020) Grain size effects in donor doped lead zirconate titanate ceramics. J Appl Phys. https://doi.org/10.1063/5.0029659

dos Santos e Lucato SL, Lupascu DC, Rödel J (2004) Effect of poling direction on R-curve behavior in lead zirconate titanate. J Am Ceram Soc 83:424–426

Park Y, Kim YK, Kim HG (1996) The effect of grain size on dielectric behavior of BaTiO3, based X7R materials. Mater Lett 28:101–106

Birch F (1947) Finite elastic strain of cubic crystals. Phys Rev 71:809

Jaffe H, Berlincourt D, McKee JM (1957) Effect of pressure on the Curie temperature of polycrystalline ceramic barium titanate. Phys Rev 105(1):57

Merz WJ (1950) The effect of hydrostatic pressure on the Curie point of barium titanate single crystals. Phys Rev 78(1):52

Schader FH, Aulbach E, Webber KG, Rossetti GA (2013) Influence of uniaxial stress on the ferroelectric-to-paraelectric phase change in barium titanate. J Appl Phys. https://doi.org/10.1063/1.4799581

Forsbergh PW (1954) Effect of a two-dimensional pressure on the curie point of barium titanate. Phys Rev. https://doi.org/10.1103/physrev.93.686

Klimowski J (1962) Effect of high hydrostatic pressure on the dielectric properties of BaTiO3 single crystals. Phys Stat Sol. https://doi.org/10.1002/pssb.19620020410

Arlt G, Hennings D, de With G (1985) Dielectric properties of fine-grained barium titanate ceramics. J Appl Phys. https://doi.org/10.1063/1.336051

Paterson AR, Nagata H, Tan X, Daniels JE, Hinterstein M, Ranjan R, Groszewicz PB, Jo W, Jones JL (2018) Relaxor-ferroelectric transitions: Sodium bismuth titanate derivatives. MRS Bull. https://doi.org/10.1557/mrs.2018.156

Tu S, Schmidt, (1994) Sequence of dielectric anomalies and high-temperature relaxation behavior in Na1/2Bi1/2TiO3. Phys Rev B: Condens Matter. https://doi.org/10.1103/PhysRevB.49.11550

Luan W, Gao L, Guo J (1999) Size effect on dielectric properties of fine-grained BaTiO3 ceramics. Ceram Int. https://doi.org/10.1016/S0272-8842%2899%2900009-7

Zheng P, Zhang JL, Tan YQ, Wang CL (2012) Grain-size effects on dielectric and piezoelectric properties of poled BaTiO3 ceramics. Acta Mater. https://doi.org/10.1016/j.actamat.2012.06.015

von Hippel A, Breckenridge RG, Chesley FG, Tisza L (1946) High dielectric constant ceramics. Ind Eng Chem. https://doi.org/10.1021/ie50443a009

Sapper E, Novak N, Jo W, Granzow T, Rödel J (2014) Electric-field–temperature phase diagram of the ferroelectric relaxor system (1–x )Bi 1/2 Na 1/2 TiO3 − xBaTiO3 doped with manganese. J Appl Phys. https://doi.org/10.1063/1.4876746

Kaeswurm B, Schader FH, Webber KG (2018) Ferroelectric, ferroelastic, piezoelectric, and dielectric properties of lead zirconate titanate from –150 °C to 350 °C. Ceram Int. https://doi.org/10.1016/j.ceramint.2017.10.204

Banerjee K, Asthana S (2019) Resolution of ambiguity between the depolarization and ferroelectric–relaxor transition temperature through dielectric studies in lead-free perovskite K0.5Bi0.5TiO3. Mater Chem Phys. https://doi.org/10.1016/j.matchemphys.2019.04.043

Khansur NH, Biggemann J, Stumpf M, Riess K, Fey T, Webber KG (2020) Temperature- and stress-dependent electromechanical response of porous Pb(Zr, Ti)O3. Adv Eng Mater. https://doi.org/10.1002/adem.202000389

Schader FH, Isaia D, Weber M, Aulbach E, Webber KG (2018) High-temperature stress-dependent piezoelectric and dielectric coefficient of soft Pb(Zr, Ti)O3. J Mater Sci. https://doi.org/10.1007/s10853-017-1817-8

Lorenz M, Martin A, Webber KG, Travitzky N (2020) Electromechanical properties of robocasted barium titanate ceramics. Adv Eng Mater. https://doi.org/10.1002/adem.202000325

Riess K, Khansur NH, Martin A, Benčan A, Uršič H, Webber KG (2021) Stress- and frequency-dependent properties of relaxor-like sodium bismuth titanate. Phys Rev B. https://doi.org/10.1103/PhysRevB.103.094113

Khansur NH, Eckstein U, Ursic H, Sadl M, Brehl M, Martin A, Riess K, de Ligny D, Webber KG (2021) Enhanced electromechanical response and thermal stability of 093(Na 1/2 Bi 1/2)TiO 3–007BaTiO 3 through aerosol deposition of base metal electrodes. Adv Mater Interf. https://doi.org/10.1002/admi.202100309

Anton E-M, Jo W, Damjanovic D, Rödel J (2011) Determination of depolarization temperature of (Bi 1/2 Na 1/2)TiO 3 -based lead-free piezoceramics. J Appl Phys. https://doi.org/10.1063/1.3660253

Goswami AK, Cross LE (1968) Pressure and temperature dependence of the dielectric properties of the perovskite barium titanate. Phys Rev. https://doi.org/10.1103/physrev.171.549

Weaver PM, Cain MG, Stewart M (2010) Temperature dependence of high field electromechanical coupling in ferroelectric ceramics. J Phys D: Appl Phys. https://doi.org/10.1088/0022-3727/43/16/165404

Lee S, Liu Z-K, Kim M-H, Randall CA (2007) Influence of nonstoichiometry on ferroelectric phase transition in BaTiO3. J Appl Phys. https://doi.org/10.1063/1.2710280

Damjanovic D (1997) Stress and frequency dependence of the direct piezoelectric effect in ferroelectric ceramics. J Appl Phys. https://doi.org/10.1063/1.365981

Hall Da, Steuwer A, Cherdhirunkorn B, Withers PJ, Mori T (2005) Micromechanics of residual stress and texture development due to poling in polycrystalline ferroelectric ceramics. J Mech Phys Solids 53(2):249–260

Smith RC, Hom CL (1999) Domain wall theory for ferroelectric hysteresis. J Intell Mater Syst Struct. https://doi.org/10.1177/1045389X9901000302

Pramanick A, Damjanovic D, Daniels JE, Nino JC, Jones JL (2011) Origins of electro-mechanical coupling in polycrystalline ferroelectrics during subcoercive electrical loading. J Am Ceram Soc. https://doi.org/10.1111/j.1551-2916.2010.04240.x

Hall DA (2001). J Mater Sci. https://doi.org/10.1023/A:1017959111402

Schultheiß J, Kungl H, Koruza J (2019) Influence of crystallographic structure on polarization reversal in polycrystalline ferroelectric/ferroelastic materials. J Appl Phys. https://doi.org/10.1063/1.5081086

Birch F (1947) Finite elastic strain of cubic crystals. Phys Rev. https://doi.org/10.1103/PhysRev.71.809

Khansur NH, Kawashima H, Wada S, Hudspeth JM, Daniels J (2015) Enhanced extrinsic domain switching strain in core–shell structured BaTiO 3 –KNbO 3 ceramics. Acta Mater. https://doi.org/10.1016/j.actamat.2015.07.034

Acknowledgements

The authors gratefully acknowledge the financial support for this work from the Deutsche Forschungsgemeinschaft under GRK2495/H. We thank Semanti Banerjee for her help with the grain size analysis.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Till Froemling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Eyoum, G.E., Eckstein, U., Riess, K. et al. Sintering condition-dependent electromechanical behavior of the lead-free piezoelectric Bi1/2K1/2TiO3. J Mater Sci 57, 15843–15861 (2022). https://doi.org/10.1007/s10853-022-07630-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07630-w