Abstract

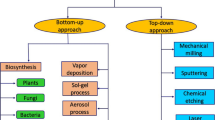

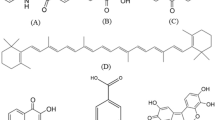

The self-cleaning mechanism attribute of organic surfaces is grabbing much attention in most of the commercially available commodities. Among organic surfaces, investigations on hydrophobic surfaces are much insightful and intriguing. The self-cleaning phenomena of hydrophobic surfaces are also known as the lotus effect. The effect uses the right combination of roughness and surface chemistry, which makes high contact angle of water droplets on a surface, making the quick roll-off of the water droplet from the surface, also picking up the dirt on its way. Thus, the plant leaves surface wetness has many ecological and physiological consequences, and its extent and duration can be affected by the leaf surface containing morphological structure, which contributes to the ecosystem interception rates. In this review, we have described the causes and behaviour of phyto-based hydrophobic surfaces. Furthermore, the applications of various phyto-based hydrophobic surfaces, either by implementing directly or by mimicking micro-/nanostructures of the surfaces, have been illustrated. Lastly, the methods for fabricating the artificial super-hydrophobic surface by mimicking the phyto-based natural hydrophobic surfaces, precisely by following the top-down, bottom-up, and hybrid approaches, have been explained. This article could benefit scientists and researchers currently working on phyto-based super-hydrophobicity fields.

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Bhushan B, Jung YC (2006) Micro- and nanoscale characterization of hydrophobic and hydrophilic leaf surfaces. Nanotechnology 17:2758–2772. https://doi.org/10.1088/0957-4484/17/11/008

Feng L, Zhang Y, Xi J et al (2008) Petal effect: a superhydrophobic state with high adhesive force. Langmuir 24:4114–4119

Poynor A, Hong L, Robinson IK et al (2006) How water meets a hydrophobic surface. Phys Rev Lett 97:1–4. https://doi.org/10.1103/PhysRevLett.97.266101

Wimalasiri VK, Weerathunga HU, Kottegoda N, Karunaratne V (2017) Silica Based Superhydrophobic Nanocoatings for Natural Rubber Surfaces. J Nanomater 2017:1–14. https://doi.org/10.1155/2017/2102467

Manoharan K, Bhattacharya S (2019) Superhydrophobic surfaces review: functional application, fabrication techniques and limitations. J Micromanufacturing 2:59–78. https://doi.org/10.1177/2516598419836345

Parvate S, Dixit P, Chattopadhyay S (2020) Superhydrophobic surfaces: insights from theory and experiment. J Phys Chem B 124:1323–1360. https://doi.org/10.1021/acs.jpcb.9b08567

Park S, Kim J, Park CH (2015) Superhydrophobic textiles: review of theoretical definitions, fabrication and functional evaluation. J Eng Fiber Fabr 10:1–18. https://doi.org/10.1177/155892501501000401

Jiaqiang E, Jin Y, Deng Y et al (2018) Wetting models and working mechanisms of typical surfaces existing in nature and their application on superhydrophobic surfaces: a review. Adv Mater Interfaces 5:1–39. https://doi.org/10.1002/admi.201701052

Sedai BR, Khatiwada BK, Mortazavian H, Blum FD (2016) Development of superhydrophobicity in silane treated diatomaceous earth and coatings. Appl Surf Sci 386:178–186

Yoshimitsu Z, Nakajima A, Watanabe T, Hashimoto K (2002) Effects of surface structure on the hydrophobicity and sliding behavior of water droplets. Langmuir 18:5818–5822. https://doi.org/10.1021/la020088p

Kijlstra J, Reihs K, Klamt A (2002) Roughness and topology of ultra-hydrophobic surfaces. Coll Surf A Physicochem Eng Asp 206:521–529. https://doi.org/10.1016/S0927-7757(02)00089-4

Latthe SS, Terashima C, Nakata K, Fujishima A (2014) Superhydrophobic surfaces developed by mimicking hierarchical surface morphology of lotus leaf. Molecules 19:4256–4283. https://doi.org/10.3390/molecules19044256

Blossey R (2003) Self-cleaning surfaces - virtual realities. Nat Mater 2:301–306. https://doi.org/10.1038/nmat856

Chen MH, Hsu TH, Chuang YJ, Tseng FG (2009) Dual hierarchical biomimic superhydrophobic surface with three energy states. Appl Phys Lett 95:1–4. https://doi.org/10.1063/1.3180114

Feng L, Song Y, Zhai J et al (2003) Creation of a superhydrophobic surface from an amphiphilic polymer. Angew Chemie 115:824–826. https://doi.org/10.1002/ange.200390181

Kim H, Kim MH, Kim J (2009) Wettability of dual-scaled surfaces fabricated by the combination of a conventional silicon wet-etching and a ZnO solution method. J Micromech Microeng 19:1–7. https://doi.org/10.1088/0960-1317/19/9/095002

Kwon Y, Patankar N, Choi J, Lee J (2009) Design of surface hierarchy for extreme hydrophobicity. Langmuir 25:6129–6136. https://doi.org/10.1021/la803249t

Patankar NA (2003) On the modeling of hydrophobic contact angles on rough surfaces. Langmuir 19:1249–1253. https://doi.org/10.1021/la026612+

Quére D, Lafuma A, Bico J (2003) Slippy and sticky microtextured solids. Nanotechnology 14:1109–1112. https://doi.org/10.1088/0957-4484/14/10/307

Roach P, Shirtcliffe NJ, Newton MI (2008) Progess in superhydrophobic surface development. Soft Matter 4:224–240. https://doi.org/10.1039/b712575p

Basu BJ, Hariprakash V, Aruna ST et al (2010) Effect of microstructure and surface roughness on the wettability of superhydrophobic Sol-gel nanocomposite coatings. J Sol-Gel Sci Technol 56:278–286. https://doi.org/10.1007/s10971-010-2304-8

Kumikov VK, Khokonov KB (1983) On the measurement of surface free energy and surface tension of solid metals. J Appl Phys 54:1346–1350. https://doi.org/10.1063/1.332209

Orowan E (1970) Surface energy and surface tension in solids and liquids. Proc R Soc London A Math Phys Sci 316:473–491. https://doi.org/10.1098/rspa.1970.0091

Chibowski E (2011) Apparent surface free energy of superhydrophobic surfaces. J Adhes Sci Technol 25:1323–1336. https://doi.org/10.1163/016942411X555890

Skalna I (2013) Algorithm for min-range multiplication of affine forms. Numer Algorithms 63:601–614. https://doi.org/10.1007/s11075-012-9644-0

Shirtcliffe NJ, McHale G, Atherton S, Newton MI (2010) An introduction to superhydrophobicity. Adv Coll Interface Sci 161:124–138. https://doi.org/10.1016/j.cis.2009.11.001

Wang J, Chen H, Sui T et al (2009) Investigation on hydrophobicity of lotus leaf: experiment and theory. Plant Sci 176:687–695. https://doi.org/10.1016/j.plantsci.2009.02.013

Chen W, Fadeev AY, Hsieh MC et al (1999) Ultrahydrophobic and ultralyophobic surfaces: some comments and examples. Langmuir 15:3395–3399. https://doi.org/10.1021/la990074s

Zhang K, Li Z, Maxey M et al (2019) Self-cleaning of hydrophobic rough surfaces by coalescence-induced wetting transition. Langmuir 35:2431–2442. https://doi.org/10.1021/acs.langmuir.8b03664

Li J, Tian J, Gao Y et al (2021) All-natural superhydrophobic coating for packaging and blood-repelling materials. Chem Eng J 410:128347. https://doi.org/10.1016/j.cej.2020.128347

Mock U, Förster R, Menz W, Rühe J (2005) Towards ultrahydrophobic surfaces: a biomimetic approach. J Phys Condens Matter 17:639–648. https://doi.org/10.1088/0953-8984/17/9/021

Hassan HA, Ghazali MJ, Azhari CH, Meric C (2017) Microstructural effects of banana leaf on adhesion and self cleaning behaviour. MATEC Web Conf 87:02026. https://doi.org/10.1051/matecconf/20178702026

Gobalakrishnan M, Anubama S, Aravindan S, Bharath V (2020) Superhydrophobic nature of some plant leaves. Int J Eng Appl Sci Technol 5:222–227

Balani K, Batista RG, Lahiri D, Agarwal A (2009) The hydrophobicity of a lotus leaf: a nanomechanical and computational approach. Nanotechnology 20:1. https://doi.org/10.1088/0957-4484/20/30/305707

Gao A, Wu Q, Wang D et al (2015) A superhydrophobic surface templated by protein self-assembly and emerging application toward protein crystallization. Adv Mater 28:579–587. https://doi.org/10.1002/adma.201504769

Puliyalil H, Filipič G, Cvelbar U (2015) Recent advances in the methods for designing superhydrophobic surfaces. Surf Energy. https://doi.org/10.5772/60852

Zhou SS, Guan ZS, Pang Y (2012) Fabrication of polypropylene super-hydrophobic surface using PTFE-coated-sieves template via templating and splitting process. Polym - Plast Technol Eng 51:845–848. https://doi.org/10.1080/03602559.2012.671417

Razavi SMR, Oh J, Sett S et al (2017) Superhydrophobic surfaces made from naturally derived hydrophobic materials. ACS Sustain Chem Eng 5:11362–11370. https://doi.org/10.1021/acssuschemeng.7b02424

Shiu JY, Kuo CW, Chen P, Mou CY (2004) Fabrication of tunable superhydrophobic surfaces by nanosphere lithography. Chem Mater 16:561–564. https://doi.org/10.1021/cm034696h

Yanagida T, Shimizu N, Kimura T (2003) Properties of wax extracted from banana leaves. 2003 ASAE Annu Meet 0300:1. https://doi.org/10.13031/2013.14121

Ghazali MJ, Hassan HA, Azhari CH, Mamat FA (2016) The bio-adhesion behaviour of banana leaves as soil remover at elevated temperatures. Tribol Online 11:264–271. https://doi.org/10.2474/trol.11.264

Hassan HA, Ghazali MJ, Meric C, Azhari CH (2019) Wettability effect of the surface morphologies of Musa acuminata leaves. BioResources 14:8331–8344

Hassan HA, Ghazali J, Zainuddin M et al (2018) Kesan Lilin ke Atas Sifat Hidrofobik Permukaan Daun Pisang (Wax Effect on Hydrophobic Properties of Banana Leaves). J Kejuruter 29:1–7

Burton Z, Bhushan B (2006) Surface characterization and adhesion and friction properties of hydrophobic leaf surfaces. Ultramicroscopy 106:709–719. https://doi.org/10.1016/j.ultramic.2005.10.007

Ma J, Sun Y, Gleichauf K et al (2011) Nanostructure on taro leaves resists fouling by colloids and bacteria under submerged conditions. Langmuir 27:10035–10040. https://doi.org/10.1021/la2010024

Kumar M, Bhardwaj R (2020) Wetting characteristics of Colocasia esculenta (Taro) leaf and a bioinspired surface thereof. Sci Rep 10:1–15

Negara KMT, Wardana ING, Widhiyanuriyawan D, Hamidi N (2019) The role of the slope on taro leaf surface to produce electrical energy. IOP Conf Ser Mater Sci Eng 494:1–9. https://doi.org/10.1088/1757-899X/494/1/012084

Kurokawa Y, Nagai K, Huan PD et al (2018) Rice leaf hydrophobicity and gas films are conferred by a wax synthesis gene (LGF1) and contribute to flood tolerance. New Phytol 218:1558–1569. https://doi.org/10.1111/nph.15070

Zhu Y, Gao Y, Zhang C et al (2018) Static and dynamic wetting behavior of TX-100 solution on super-hydrophobic rice (Oryza sativa.) leaf surfaces. Coll Surf A Physicochem Eng Asp 547:148–156. https://doi.org/10.1016/j.colsurfa.2018.03.008

Oriol RA, Roger CA, Escobar AM, Núria LI (2018) Superhydrophobic coating bioinspired on rice leaf: a first attempt to enhance erosion resistance properties at environmental conditions with ceramic particles. Mater Sci Forum 941:1874–1879. https://doi.org/10.4028/www.scientific.net/MSF.941.1874

Yao J, Wang JN, Yu YH et al (2012) Biomimetic fabrication and characterization of an artificial rice leaf surface with anisotropic wetting. Chin Sci Bull 57:2631–2634. https://doi.org/10.1007/s11434-012-5220-1

Yang XH, Xiao JH, Ou JF (2013) Special wetting behaviors on canna leaf and its dependence with microstructures. Adv Mater Res 779:64–67. https://doi.org/10.4028/www.scientific.net/AMR.779-780.64

Liu C, Bu W, Wang T (2017) Numerical investigation on effects of thermophysical properties on fluid flow in hydraulic retarder. Int J Heat Mass Transf 114:1146–1158. https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.124

Yang Y, Shen H, Qiu J (2020) Fabrication of biomimetic robust self-cleaning superhydrophobic wood with canna-leaf-like micro/nanostructure through morph-genetic method improved water-, UV-, and corrosion resistance properties. J Mol Struct 1219:128616. https://doi.org/10.1016/j.molstruc.2020.128616

Mattaparthi S, Sharma CS (2014) Biomimicked high-aspect-ratio hierarchical superhydrophobic polymer surfaces. Bioinspired Biomim Nanobiomater 3:4–9. https://doi.org/10.1680/bbn.13.00015

Mohamad N, Abdul Hamid NN, Abdul Aziz NA et al (2015) Potential of epoxidized natural rubber (ENR) as hydrophobicity contributor in chitosan-urea fertilizer. Appl Mech Mater 761:536–541. https://doi.org/10.4028/www.scientific.net/amm.761.536

Do Nascimento RM, Ramos SMM, Bechtold IH, Hernandes AC (2018) Wettability study on natural rubber surfaces for applications as biomembranes. ACS Biomater Sci Eng 4:2784–2793. https://doi.org/10.1021/acsbiomaterials.8b00723

Kato A, Kokubo Y, Tsushi R, Ikeda Y (2014) Hydrophobic and hydrophilic silica-filled cross-linked natural rubber (NR): structure and properties

Samyn P, Driessen F, Stanssens D (2020) Natural rubber composites for paper coating applications. Mater Proc 2:29. https://doi.org/10.3390/ciwc2020-06832

Ju J, Bai H, Zheng Y et al (2012) A multi-structural and multi-functional integrated fog collection system in cactus. Nat Commun 3:1246–1247. https://doi.org/10.1038/ncomms2253

Kim K, Kim H, Park SH, Lee SJ (2017) Hydraulic strategy of cactus trichome for absorption and storage of water under arid environment. Front Plant Sci 8:1–8. https://doi.org/10.3389/fpls.2017.01777

Lee SJ, Ha N, Kim H (2019) Superhydrophilic-superhydrophobic water harvester inspired by wetting property of cactus stem. ACS Sustain Chem Eng 7:10561–10569. https://doi.org/10.1021/acssuschemeng.9b01113

Zhu Y, Sun F, Qian H et al (2018) A biomimetic spherical cactus superhydrophobic coating with durable and multiple anti-corrosion effects. Chem Eng J 338:670–679. https://doi.org/10.1016/j.cej.2018.01.082

Pan Z, Cheng F, Zhao B (2017) Bio-Inspired polymeric structures with special wettability and their applications: an overview. Polymers (Basel) 9:32–39. https://doi.org/10.3390/polym9120725

Ebert D, Bhushan B (2012) Wear-resistant rose petal-effect surfaces with superhydrophobicity and high droplet adhesion using hydrophobic and hydrophilic nanoparticles. J Coll Interface Sci 384:182–188. https://doi.org/10.1016/j.jcis.2012.06.070

Lin J, Cai Y, Wang X et al (2011) Fabrication of biomimetic superhydrophobic surfaces inspired by lotus leaf and silver ragwort leaf. Nanoscale 3:1258–1262. https://doi.org/10.1039/c0nr00812e

Nuraje N, Khan WS, Lei Y et al (2013) Superhydrophobic electrospun nanofibers. J Mater Chem A 1:1929–1946. https://doi.org/10.1039/c2ta00189f

Wang T, Chang L, Hatton B et al (2014) Preparation and hydrophobicity of biomorphic ZnO/carbon based on a lotus-leaf template. Mater Sci Eng C 43:310–316. https://doi.org/10.1016/j.msec.2014.07.022

Hao L, Yu S, Han X, Zhang S (2015) Design of submicron structures with superhydrophobic and oleophobic properties on zinc substrate. Mater Des 85:653–660. https://doi.org/10.1016/j.matdes.2015.07.057

Zhao W, Wang L, Xue Q (2010) Fabrication of low and high adhesion hydrophobic au surfaces with micro/nano-biomimetic structures. J Phys Chem C 114:11509–11514. https://doi.org/10.1021/jp102052e

Zhang X, Shi F, Niu J et al (2008) Superhydrophobic surfaces: From structural control to functional application. J Mater Chem 18:621–633. https://doi.org/10.1039/b711226b

Yun X, Xiong Z, He Y, Wang X (2020) Superhydrophobic lotus-leaf-like surface made from reduced graphene oxide through soft-lithographic duplication. RSC Adv 10:5478–5486. https://doi.org/10.1039/c9ra10373b

Liang YH, Peng J, Li XJ et al (2016) From natural to biomimetic: the superhydrophobicity and the contact time. Microsc Res Tech 79:712–720. https://doi.org/10.1002/jemt.22689

Yuan Z, Chen H, Tang J et al (2007) Facile method to fabricate stable superhydrophobic polystyrene surface by adding ethanol. Surf Coat Technol 201:7138–7142. https://doi.org/10.1016/j.surfcoat.2007.01.021

Li XM, Reinhoudt D, Crego-Calama M (2007) What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem Soc Rev 36:1350–1368. https://doi.org/10.1039/b602486f

Yu Z, Cheng H (2018) Tunable adhesion for bio-integrated devices. Micromachines 9:1–19. https://doi.org/10.3390/mi9100529

Brock L, Sheng J (2020) Robust fabrication of polymeric nanowire with anodic aluminum oxide templates. Micromachines 11:11–30. https://doi.org/10.3390/mi11010046

Tripathy AR, Choudhury A, Dash A et al (2021) Polymer matrix composite engineering for PDMS based capacitive sensors to achieve high-performance and broad-range pressure sensing. Appl Surf Sci Adv 3:100062

Manna U, Broderick AH, Lynn DM (2012) Chemical patterning and physical refinement of reactive superhydrophobic surfaces. Adv Mater 24:4291–4295. https://doi.org/10.1002/adma.201200903

Jafari R, Asadollahi S, Farzaneh M (2013) Applications of plasma technology in development of superhydrophobic surfaces. Plasma Chem Plasma Process 33:177–200. https://doi.org/10.1007/s11090-012-9413-9

Tsougeni K, Papageorgiou D, Tserepi A, Gogolides E (2010) “Smart” polymeric microfluidics fabricated by plasma processing: controlled wetting, capillary filling and hydrophobic valving. Lab Chip 10:462–469. https://doi.org/10.1039/b916566e

Cerrina F (2000) X-ray imaging: applications to patterning and lithography. IOP Sci 33:103–116

Kim SH, Lee S, Ahn D, Park JY (2019) PDMS double casting method enabled by plasma treatment and alcohol passivation. Sens Actuators B Chem 293:115–121. https://doi.org/10.1016/j.snb.2019.04.145

Twardowski A, Makowski P, Małachowski A et al (2012) Plasma treatment of thermoactive membrane textiles for superhydrophobicity. Medziagotyra 18:163–166. https://doi.org/10.5755/j01.ms.18.2.1920

Il YY, Moon HS, Lyoo WS et al (2009) Superhydrophobicity of cellulose triacetate fibrous mats produced by electrospinning and plasma treatment. Carbohydr Polym 75:246–250. https://doi.org/10.1016/j.carbpol.2008.07.015

Zhou Y, Song X, Munan YU et al (2006) Superhydrophobic surfaces prepared by plasma fluorination of lotus-leaf-like amorphous carbon films. Surf Rev Lett 13:117–122. https://doi.org/10.1142/S0218625X06007895

Byun D, Lee Y, Tran SBQ et al (2008) Electrospray on superhydrophobic nozzles treated with argon and oxygen plasma. Appl Phys Lett 92:093507. https://doi.org/10.1063/1.2840725

Ryu J, Kim K, Park JY et al (2017) Nearly perfect durable superhydrophobic surfaces fabricated by a simple one-step plasma treatment. Sci Rep 7:1–8. https://doi.org/10.1038/s41598-017-02108-1

Lee SJ, Paik BG, Kim GB, Jang YG (2006) Self-cleaning features of plasma-treated surfaces with self-assembled monolayer coating. Japanese J Appl Phys, Part 1 Regul Pap Short Notes Rev Pap 45:912–918

Hwang SJ, Oh DJ, Jung PG et al (2009) Dry etching of polydimethylsiloxane using microwave plasma. J Micromech Microeng. https://doi.org/10.1088/0960-1317/19/9/095010

Han ZJ, Tay BK, Shakerzadeh M, Ostrikov K (2009) Superhydrophobic amorphous carbon/carbon nanotube nanocomposites. Appl Phys Lett 94:223106. https://doi.org/10.1063/1.3148667

Ji YY, Kim SS, Kwon OP, Lee SH (2009) Easy fabrication of large-size superhydrophobic surfaces by atmospheric pressure plasma polymerization with non-polar aromatic hydrocarbon in an in-line process. Appl Surf Sci 255:4575–4578. https://doi.org/10.1016/j.apsusc.2008.12.002

Berendsen CWJ, Škereň M, Najdek D, Černý F (2009) Superhydrophobic surface structures in thermoplastic polymers by interference lithography and thermal imprinting. Appl Surf Sci 255:9305–9310. https://doi.org/10.1016/j.apsusc.2009.07.001

Sun Y, Ouyang B, Rawat RS, Chen Z (2020) Rapid and stable plasma transformation of polyester fabrics for highly efficient oil-water separation. Glob Challenges 4:1900095. https://doi.org/10.1002/gch2.201900095

Li Y, Zhang J, Zhu S et al (2010) Bioinspired silica surfaces with near-infrared improved transmittance and superhydrophobicity by colloidal lithography. Langmuir 26:9842–9847. https://doi.org/10.1021/la100183y

Zhang G, Wang D, Gu Z, Mo H (2005) Fabrication of superhydrophobic surfaces from binary colloidal assembly. Langmuir 21:9143–9148

Michels AF, Soave PA, Nardi J et al (2016) Adjustable, (super)hydrophobicity by e-beam deposition of nanostructured PTFE on textured silicon surfaces. J Mater Sci 51:1316–1323. https://doi.org/10.1007/s10853-015-9449-3

Milionis A, S. I, Fragouli D, et al (2013) Combination of lithography and coating methods for surface wetting control. Updat Adv Lithogr. https://doi.org/10.5772/56173

Sreenivasan SV (2017) Nanoimprint lithography steppers for volume fabrication of leading-edge semiconductor integrated circuits. Microsyst Nanoeng 3:1–19. https://doi.org/10.1038/micronano.2017.75

Pozzato A, Zilio SD, Fois G et al (2006) Superhydrophobic surfaces fabricated by nanoimprint lithography. Microelectron Eng 83:884–888. https://doi.org/10.1016/j.mee.2006.01.012

Yang Y, He H, Li Y, Qiu J (2019) Using nanoimprint lithography to create robust, buoyant, superhydrophobic PVB/SiO2 coatings on wood surfaces inspired by red roses petal. Sci Rep 9:1–9. https://doi.org/10.1038/s41598-019-46337-y

Choi HJ, Choo S, Shin JH et al (2013) Fabrication of superhydrophobic and oleophobic surfaces with overhang structure by reverse nanoimprint lithography. J Phys Chem C 117:24354–24359. https://doi.org/10.1021/jp4070399

Roy T, Sabharwal TP, Kumar M et al (2020) Mathematical modelling of superhydrophobic surfaces for determining the correlation between water contact angle and geometrical parameters. Precis Eng 61:55–64. https://doi.org/10.1016/j.precisioneng.2019.10.005

Wang F, Wang L, Wu H et al (2017) A lotus-leaf-like SiO2 superhydrophobic bamboo surface based on soft lithography. Coll Surf A Physicochem Eng Asp 520:834–840. https://doi.org/10.1016/j.colsurfa.2017.02.043

Li G, Li Z, Lu L et al (2012) Fabrication and wettable investigation of superhydrophobic surface by soft lithography. J Wuhan Univ Technol Mater Sci Ed 27:138–141. https://doi.org/10.1007/s11595-012-0424-4

Zhang D, Li H, Chen X et al (2014) Effect of surface microstructures on hydrophobicity and barrier property of anticorrosive coatings prepared by soft lithography. Adv Mater Sci Eng 2014:1. https://doi.org/10.1155/2014/342184

Long CJ, Schumacher JF, Brennan AB (2009) Potential for tunable static and dynamic contact angle anisotropy on gradient microscale patterned topographies. Langmuir 25:12982–12989. https://doi.org/10.1021/la901836w

Wu W, Guijt RM, Silina YE et al (2016) Plant leaves as templates for soft lithography. RSC Adv 6:22469–22475

Ahmed MMM, Chi YT, Hung YH et al (2022) UV-cured electroactive polyurethane acrylate coatings with superhydrophobic surface structure of biomimetic peacock feather for anticorrosion application. Prog Org Coat 165:106679. https://doi.org/10.1016/J.PORGCOAT.2021.106679

Lee SM, Kwon TH (2007) Effects of intrinsic hydrophobicity on wettability of polymer replicas of a superhydrophobic lotus leaf. J Micromech Microeng 17:687–692. https://doi.org/10.1088/0960-1317/17/4/003

Lee SM, Kwon TH (2006) Mass-producible replication of highly hydrophobic surfaces from plant leaves. Nanotechnology 17:3189–3196. https://doi.org/10.1088/0957-4484/17/13/019

Marmur A (2004) The lotus effect: superhydrophobicity and metastability. Langmuir 20:3517–3519. https://doi.org/10.1021/la036369u

Mertaniemi H, Laukkanen A, Teirfolk JE et al (2012) Functionalized porous microparticles of nanofibrillated cellulose for biomimetic hierarchically structured superhydrophobic surfaces. RSC Adv 2:2882–2886. https://doi.org/10.1039/c2ra00020b

Jung YC, Bhushan B (2009) Mechanically durable carbon nanotube− composite hierarchical structures with superhydrophobicity, self-cleaning, and low-drag. ACS Nano 3:4155–4163

Chen W, McCarthy TJ (1997) Layer-by-layer deposition: a tool for polymer surface modification. Macromolecules 30:78–86. https://doi.org/10.1021/ma961096d

Moon CH, Yasmeen S, Park K et al (2022) Icephobic coating through a self-formed superhydrophobic surface using a polymer and microsized particles. ACS Appl Mater Interfaces 14:3334–3343. https://doi.org/10.1021/ACSAMI.1C22404/SUPPL_FILE/AM1C22404_SI_002.MP4

Chunder A, Etcheverry K, Londe G et al (2009) Conformal switchable superhydrophobic/hydrophilic surfaces for microscale flow control. Coll Surf A Physicochem Eng Asp 333:187–193

Jindasuwan S, Nimittrakoolchai O, Sujaridworakun P et al (2009) Surface characteristics of water-repellent polyelectrolyte multilayer films containing various silica contents. Thin Solid Films 517:5001–5005

Sun C, Ge LQ, Gu ZZ (2007) Fabrication of super-hydrophobic film with dual-size roughness by silica sphere assembly. Thin Solid Films 515:4686–4690. https://doi.org/10.1016/j.tsf.2006.11.027

Zhao Y, Li M, Lu Q, Shi Z (2008) Superhydrophobic polyimide films with a hierarchical topography: combined replica molding and layer-by-layer assembly. Langmuir 24:12651–12657. https://doi.org/10.1021/la8024364

Zhu Y, Li J, Wan M, Jiang L (2008) Superhydrophobic 3D microstructures assembled from 1D nanofibers of polyaniline. Macromol Rapid Commun 29:239–243

Xue C-H, Jia S-T, Zhang J, Tian L-Q (2009) Superhydrophobic surfaces on cotton textiles by complex coating of silica nanoparticles and hydrophobization. Thin Solid Films 517:4593–4598

Manca M, Cannavale A, De Marco L et al (2009) Durable superhydrophobic and antireflective surfaces by trimethylsilanized silica nanoparticles-based sol-gel processing. Langmuir 25:6357–6362. https://doi.org/10.1021/la804166t

Hikita M, Tanaka K, Nakamura T et al (2005) Super-liquid-repellent surfaces prepared by colloidal silica nanoparticles covered with fluoroalkyl groups. Langmuir 21:7299–7302. https://doi.org/10.1021/la050901r

Zheng J, He A, Li J et al (2006) Studies on the controlled morphology and wettability of polystyrene surfaces by electrospinning or electrospraying. Polymer (Guildf) 47:7095–7102. https://doi.org/10.1016/j.polymer.2006.08.019

Mahltig B, Böttcher H (2003) Modified silica sol coatings for water-repellent textiles. J Sol-Gel Sci Technol 27:43–52

Zhu M, Zuo W, Yu H et al (2006) Superhydrophobic surface directly created by electrospinning based on hydrophilic material. J Mater Sci 41:3793–3797. https://doi.org/10.1007/s10853-005-5910-z

Gleason KK, Rutledge GC, Gupta M et al (2005) Superhydrophobic fibers produced by electrospinning and chemical vapor deposition. Macromolecules 38:9742–9748

Burkarter E, Saul CK, Thomazi F et al (2007) Electrosprayed superhydrophobic PTFE: a non-contaminating surface. J Phys D Appl Phys 40:7778

Yang Z, Peng H, Wang W, Liu T (2010) Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci 116:2658–2667. https://doi.org/10.1002/app

Hattori A, Kawahara T, Uemoto T et al (2000) Ultrathin SiO(x) film coating effect on the wettability change of TiO2 surfaces in the presence and absence of UV light illumination. J Coll Interface Sci 232:410–413. https://doi.org/10.1006/jcis.2000.7166

Machida M, Norimoto K, Watanabe T (1999) The effect of SiO2 addition in super-hydrophilic property of TiO2 photocatalyst. J Mater Sci 34:2569–2574

Nakajima A, Koizumi SI, Watanabe T, Hashimoto K (2000) Photoinduced amphiphilic surface on polycrystalline anatase TiO2 thin films. Langmuir 16:7048–7050. https://doi.org/10.1021/la0004348

Wang R, Hashimoto K, Fujishima A et al (1998) Photogeneration of highly amphiphilic TiO2 surfaces. Adv Mater 10:135–138. https://doi.org/10.1002/(SICI)1521-4095(199801)10:2%3c135::AID-ADMA135%3e3.0.CO;2-M

Wang R, Hashimoto K, Fujishima A et al (1997) Light-induced amphiphilic surfaces. Nature 388:431–432. https://doi.org/10.1038/41233

Fujishima A, Zhang X (2006) Titanium dioxide photocatalysis: present situation and future approaches. Comptes Rendus Chim 9:750–760. https://doi.org/10.1016/j.crci.2005.02.055

Fujishima A, Zhang X, Tryk DA (2008) TiO2 photocatalysis and related surface phenomena. Surf Sci Rep 63:515–582. https://doi.org/10.1016/j.surfrep.2008.10.001

Liu H, Feng L, Zhai J et al (2004) Reversible wettability of a chemical vapor deposition prepared ZnO film between superhydrophobicity and superhydrophilicity. Langmuir 20:5659–5661. https://doi.org/10.1021/la036280o

De SR, Nakajima A, Fujishima A et al (2001) Photoinduced surface wettability conversion of ZnO and TiO2 thin films. J Phys Chem B 105:1984–1990. https://doi.org/10.1021/jp002525j

Lai Y, Lin Z, Huang J et al (2010) Controllable construction of ZnO/TiO2 patterning nanostructures by superhydrophilic/superhydrophobic templates. New J Chem 34:44–51. https://doi.org/10.1039/b9nj00325h

Sun R-D, Nakajima A, Fujishima A et al (2001) Photoinduced surface wettability conversion of ZnO and TiO2 thin films. J Phys Chem B 105:1984–1990

Gao H, Wang X, Yao H et al (2005) Mechanics of hierarchical adhesion structures of geckos. Mech Mater 37:275–285. https://doi.org/10.1016/j.mechmat.2004.03.008

Li X, Chen G, Ma Y et al (2006) Preparation of a super-hydrophobic poly(vinyl chloride) surface via solvent-nonsolvent coating. Polymer (Guildf) 47:506–509. https://doi.org/10.1016/j.polymer.2005.08.097

Song W, Veiga DD, Custódio CA, Mano JF (2009) Bioinspired degradable substrates with extreme wettability properties. Adv Mater 21:1830–1834. https://doi.org/10.1002/adma.200803680

Hu Z, Xia X (2004) Hydrogel nanoparticle dispersions with inverse thermoreversible gelation. Adv Mater 16:305–309. https://doi.org/10.1002/adma.200305560

Li X, Chen G, Ma Y et al (2006) Preparation of a super-hydrophobic poly (vinyl chloride) surface via solvent–nonsolvent coating. Polymer (Guildf) 47:506–509

Teisala H, Tuominen M, Kuusipalo J (2011) Adhesion mechanism of water droplets on hierarchically rough superhydrophobic rose petal surface. J Nanomater 2011:1–6. https://doi.org/10.1155/2011/818707

Chakraborty M, Weibel JA, Schaber JA, Garimella SV (2019) Petal effect: the wetting state of water on a rose petal. Adv Mater Interfaces 6:1900652–19006527

Cheng G, Huang H, Zhou L et al (2019) Chemical composition and water permeability of the cuticular wax barrier in rose leaf and petal: a comparative investigation. Plant Physiol Biochem 135:404–410

Aideo SN, Mohanta D (2018) Surface-wettability and structural colouration property of certain Rosaceae cultivars with off-to-dark pink appearances. J Bionic Eng 15:1012–1024

Ji WF, Li CW, Yu SK et al (2017) Biomimetic electroactive polyimide with rose petal-like surface structure for anticorrosive coating application. Expr Polym Lett 11:635–644

Yuan C, Huang M, Yu X et al (2016) A simple approach to fabricate the rose petal-like hierarchical surfaces for droplet transportation. Appl Surf Sci 385:562–568

Franzen FDL, Silvia M, De OR et al (2019) Chemical composition of rose, sunflower and calendula flower petals for human food use Composición química de pétalos de flores de rosa, girasol y. Cienc y Tecnol Agropecu 20:159–168

Han Y, Han Y, Huang Y et al (2022) Laser-induced graphene superhydrophobic surface transition from pinning to rolling for multiple applications. Small Methods. https://doi.org/10.1002/SMTD.202200096

Nasri NS, Ahmed MM, Mohd Noor N et al (2014) Hydrophobicity characterization of bio-wax derived from taro leaf for surface coating applications. In: Advanced Materials Research. Trans Tech Publ, pp 184–188

Lin H, Huang AS (1993) Chemical composition and some physical properties of a water-soluble gum in taro (Colocasia esculenta). Food Chem 48:403–409. https://doi.org/10.1016/0308-8146(93)90325-A

Yang XH, Xiao JH, Ou JF (2013) Special wetting behaviors on canna leaf and its dependence with microstructures. In: Advanced Materials Research. Trans Tech Publ, pp 64–67

Al-Snafi AE (2015) Bioactive components and pharmacological effects of Canna indica-an overview. Int J Pharmacol Toxicol 5:71–75

Lim TK (2016) Edible medicinal and non-medicinal plants. Edible Med Non-Med Plants 10:1–659. https://doi.org/10.1007/978-94-017-7276-1

Rykaczewski K, Jordan JS, Linder R et al (2016) Microscale mechanism of age dependent wetting properties of prickly pear cacti (Opuntia). Langmuir 32:9335–9341

Ventura-Aguilar RI, Bosquez-Molina E, Bautista-Baños S, Rivera-Cabrera F (2017) Cactus stem (Opuntia ficus-indica Mill): anatomy, physiology and chemical composition with emphasis on its biofunctional properties. J Sci Food Agric 97:5065–5073

de Santiago KM, Dibildox-Alvarado E, Rendòn-Huerta JA et al (2020) Extraction and thermal characterization of epicuticular wax from Opuntia streptacantha at different stages of maturation. J Prof Assoc Cactus Dev 22:62–71

Jimenez-Aguilar D, Mujica-Paz H, Welti-Chanes J (2014) Phytochemical characterization of prickly pear (Opuntia spp.) and of its nutritional and functional properties: a review. Curr Nutr Food Sci 10:57–69. https://doi.org/10.2174/157340131001140328120952

Ensikat HJ, Ditsche-Kuru P, Neinhuis C, Barthlott W (2011) Superhydrophobicity in perfection: the outstanding properties of the lotus leaf. Beilstein J Nanotechnol 2:152–161

Extrand CW, Moon SI (2014) Repellency of the lotus leaf: contact angles, drop retention, and sliding angles. Langmuir 30:8791–8797

Balani K, Batista RG, Lahiri D, Agarwal A (2009) The hydrophobicity of a lotus leaf: a nanomechanical and computational approach. Nanotechnology 20:305707–305712

Nosonovsky M, Bhushan B (2008) Lotus-effect and water-repellent surfaces in nature. multiscale dissipative mech hierarchical surfaces frict superhydrophobicity, Biomimetics 181–197

Lin HY, Kuo YH, Lin YL, Chiang W (2009) Antioxidative effect and active components from leaves of lotus (Nelumbo nucifera). J Agric Food Chem 57:6623–6629. https://doi.org/10.1021/jf900950z

Blake AI, Co ED, Marangoni AG (2014) Structure and physical properties of plant wax crystal networks and their relationship to oil binding capacity. J Am Oil Chem Soc 91:885–903

Charumanee S, Yotsawimonwat S, Sirisa-Ard P, Pholsongkram K (2017) Characterization and chemical composition of epicuticular wax from banana leaves grown in Northern Thailand. Songklanakarin J Sci Technol 39:509–516

Abu Hassan H, Ghazali MJ, Zainuddin NM, Azhari CH (2017) Wax effect on hydrophobic properties of banana leaves. J Kejuruter 29:1–7

Abdullah N, Sulaiman F, Taib RM (2013) Characterization of banana (Musa spp.) plantation wastes as a potential renewable energy source. AIP Conf Proc 1528:325–330. https://doi.org/10.1063/1.4803618

Bianchi G, Lupotto E, Russo S (1979) Composition of epicuticular wax of rice. Oryza sativa Experientia 35:1417

Guan H, Feng X, Zhang J et al (2019) Phragmites communis leaves with anisotropy, superhydrophobicity and self-cleaning effect and biomimetic polydimethylsiloxane (PDMS) replicas. Coatings 9:541

Jawad AH, Mallah SH, Mastuli MS (2018) Adsorption behavior of methylene blue on acid-treated rubber (Hevea brasiliensis) leaf. Desalin Water Treat 124:297–307. https://doi.org/10.5004/dwt.2018.22915

Acknowledgements

Sandipan Mallik and Shrabani Guhathakurata would like to sincerely thank the Department of Science and Technology-Science and Engineering Research Board (DST-SERB) New Delhi, India, for providing research funding [Project no: ECR/2018/002477] under DST-ECR scheme.

Author information

Authors and Affiliations

Contributions

DD: Conceptualization, Writing–original draft, and Data curation. SPS: Conceptualization, Writing–original draft, and Data curation. SM: Writing–original draft and Software. SG: Formal Analysis, Resources. DP: Supervision, Validation, Writing–review & editing. SM: Conceptualization, Supervision, Validation, Writing–review & editing. DD, SPS, and SM contributed equally.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Annela M. Seddon.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deo, D., Singh, S.P., Mohanty, S. et al. Biomimicking of phyto-based super-hydrophobic surfaces towards prospective applications: a review. J Mater Sci 57, 8569–8596 (2022). https://doi.org/10.1007/s10853-022-07172-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07172-1