Abstract

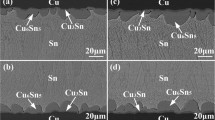

The present paper investigates the influence of electric currents on the formation of Sn/Cu intermetallic compounds. Solidification experiments of Sn droplets on Cu substrate were performed under the impact of direct csurrents (DC) and pulsed electric currents (ECP), respectively. The results show that the precipitation of Cu6Sn5 from the Sn/Cu interfacial reaction is significantly enhanced by both DC and ECP. DC promotes the formation of Cu6Sn5 at the interface, whereas ECP triggers the detachment of Cu6Sn5 at the interface and favors the growth of freely floated Cu6Sn5 particles in the bulk Sn melt. Numerical simulations were conducted to calculate the distribution of electric current, induced magnetic field, Lorentz force and forced flow inside the Sn melt. The numerical results show that a strong downwards Lorentz force is generated adjacent electrode bottom owing to the interaction between electric current and induced magnetic field. As a result, a global forced flow is caused inside the Sn melt. It is possible that the forced flow induces the elements transport to promote the precipitation of intermetallic compounds. Moreover, a strong Lorentz force difference between Sn melt and Cu6Sn5 is generated under the application of ECP compared with that of DC, thereby increasing the potential to initiate the detachment of Cu6Sn5.

Similar content being viewed by others

References

Hu XW, Li YL, Min ZX (2013) Interfacial reaction and growth behavior of IMCs layer between Sn–58Bi solders and a Cu substrate. J Mater Sci—Mater Electron 24(6):2027–2034. https://doi.org/10.1007/s10854-012-1052-7

Wang Q, Chen H, Wang F (2019) Effect of trace Zn addition on interfacial evolution in Sn-10Bi/Cu solder joints during aging condition. Materials (Basel) 12(24):4240. https://doi.org/10.3390/ma12244240

Yang WG, Felton LE, Messler RW (1995) The effect of soldering process variables on the microstructure and mechanical properties of eutectic Sn–Ag/Cu solder joints. J Electron Mater 24(10):1465–1472. https://doi.org/10.1007/BF02655465

Zhao D, Zhang KK, Ma N, Li SJ, Yin CX, Huo FP (2020) Dynamic observation of interfacial IMC evolution and fracture mechanism of Sn2.5Ag0.7Cu0.1RE/Cu lead-free solder joints during isothermal sging. Materials (Basel) 13(4):831. https://doi.org/10.3390/ma13040831

Zhang KK, Zhang XJ, Qiu RF, Shi HX, Liu YJ (2014) The combined effects of ultrasonic wave and electric field on the microstructure and properties of Sn2.5Ag0.7Cu0.1RE/Cu soldered joints. J Mater Sci—Mater Electron 25(4):1681–1686. https://doi.org/10.1007/s10854-014-1783-8

Choi S, Lucas JP, Subramanian KN (2000) Formation and growth of interfacial intermetallic layers in eutectic Sn–Ag solder and its composite solder joints. J Mater Sci—Mater Electron 11(6):497–502. https://doi.org/10.1023/A:1008968518512

Tan FL, Tso CP (2004) Cooling of mobile electronic devices using phase change materials. Appl Therm Eng 24(2–3):159–169. https://doi.org/10.1016/j.applthermaleng.2003.09.005

Zeng KJ, Stierman R, Chiu TC, Edwards D, Ano K, Tu KN (2005) Kirkendall void formation in eutectic SnPb solder joints on bare Cu and its effect on joint reliability. J Appl Phys 97(2):024508. https://doi.org/10.1063/1.1839637

Wang TM, Zhou P, Cao F, Kang HJ, Chen ZN, Fu YA, Xiao TQ, Huang WX, Yuan QX (2015) Growth behavior of Cu6Sn5 in Sn–6.5 Cu solders under DC considering trace Al: in situ observation. Intermetallics 58:84–90. https://doi.org/10.1016/j.intermet.2014.11.010

Huang JR, Tsai CM, Lin YW, Kao CR (2011) Pronounced electromigration of Cu in molten Sn-based solders. J Mater Res 23(1):250–257. https://doi.org/10.1557/jmr.2008.0024

Chen D, Ho CE, Kuo JC (2011) Current stressing-induced growth of Cu3Sn in Cu/Sn/Cu solder joints. Mater Lett 65(9):1276–1279. https://doi.org/10.1016/j.matlet.2011.01.048

Ke JH, Chuang HY, Shih WL, Kao CR (2012) Mechanism for serrated cathode dissolution in Cu/Sn/Cu interconnect under electron current stressing. Acta Mater 60(5):2082–2090. https://doi.org/10.1016/j.actamat.2011.12.021

Gu Y, Shen P, Yang NN, Cao KZ (2014) Effects of direct current on the wetting behavior and interfacial morphology between molten Sn and Cu substrate. J Alloys Compd 586:80–86. https://doi.org/10.1016/j.jallcom.2013.10.021

Zhang HT, Nagaumi H, Cui JZ (2007) Coupled modeling of electromagnetic field, fluid flow, heat transfer and solidification during low frequency electromagnetic casting of 7XXX aluminum alloys. Mater Sci Eng A 448(1–2):177–188. https://doi.org/10.1016/j.msea.2006.10.063

Jia YH, Wang H, Le QC (2019) Transient coupling simulation of multi-physical field during pulse electromagnetic direct-chill casting of AZ80 magnesium alloy. Int J Heat Mass Transfer 143:118524. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118524

Chen Q, Shen H (2018) Numerical study on solidification characteristics under pulsed magnetic field. Int J Heat Mass Transfer 120:997–1008. https://doi.org/10.1016/j.ijheatmasstransfer.2017.12.125

Wang FJ, Yu ZS, Qi K (2007) Intermetallic compound formation at Sn–3.0Ag–0.5Cu–1.0Zn lead-free solder alloy/Cu interface during as-soldered and as-aged conditions. J Alloys Compd 438(1–2):110–115. https://doi.org/10.1016/j.jallcom.2006.08.012

Yang M, Li MY, Wang L, Fu YG, Kim J, Weng LQ (2011) Growth behavior of Cu6Sn5 grains formed at an Sn3.5Ag/Cu interface. Mater Lett 65(10):1506–1509. https://doi.org/10.1016/j.matlet.2011.02.056

Wu WH, Chung HL, Chen CN, Ho CE (2009) The influence of current direction on the Cu–Ni cross-interaction in Cu/Sn/Ni diffusion couples. J Electron Mater 38(12):2563–2572. https://doi.org/10.1007/s11664-009-0876-2

Wang CH, Kuo CY, Chen HH, Chen SW (2011) Effects of current density and temperature on Sn/Ni interfacial reactions under current stressing. Intermetallics 19(1):75–80. https://doi.org/10.1016/j.intermet.2010.09.010

Chen CM, Chen SW (2002) Electromigration effect upon the Sn/Ag and Sn/Ni interfacial reactions at various temperatures. Acta Mater 50:2461–2469. https://doi.org/10.1016/S1359-6454(02)00076-9

Wu L, Graves JE, Cobley AJ (2018) Mechanism for the development of Sn–Cu alloy coatings produced by pulsed current electrodeposition. Mater Lett 217:120–123. https://doi.org/10.1016/j.matlet.2018.01.094

Chao B, Chae SH, Zhang XF, Lu KH, Ding M, Im J, Ho PS (2006) Electromigration enhanced intermetallic growth and void formation in Pb-free solder joints. J Appl Phys 100(8):084909. https://doi.org/10.1063/1.2359135

Chiu WL, Liu CM, Haung YS, Chen C (2016) Formation of plate-like channels in Cu 6 Sn 5 and Cu 3 Sn intermetallic compounds during transient liquid reaction of Cu/Sn/Cu structures. Mater Lett 164:5–8. https://doi.org/10.1016/j.matlet.2015.10.056

Zu FQ, Shen RR, Xi Y, Li XF, Ding GH, Liu HM (2006) Electrical resistivity of liquid Sn–Sb alloy. J Phys Condens Matter 18(10):2817–2823. https://doi.org/10.1088/0953-8984/18/10/007

Wei CC, Chen CF, Liu PC, Chen C (2009) Electromigration in Sn–Cu intermetallic compounds. J Appl Phys 105(2):023715. https://doi.org/10.1063/1.3072662

Acknowledgements

The authors acknowledge the financial supports from National Natural Science Foundation of China (Grant Nos. U1760204, 51974183, 51904182).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, Y., Zhu, R., Zheng, T. et al. Intermetallic compounds formed in Sn droplet on Cu substrate under the impact of electric currents. J Mater Sci 56, 11953–11969 (2021). https://doi.org/10.1007/s10853-021-06048-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06048-0