Abstract

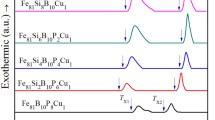

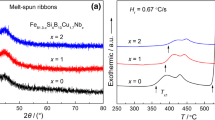

The effect of conventional annealing and rapid annealing on the magnetic properties and microstructure of Fe78+2xSi7.2-xB13-xCu0.8Nb1 (x = 0, 1, 2) alloys is discussed systematically. The study was found that the existence of a large number of pre-existing nuclei in the amorphous phase of Fe82Si5.2B11Cu0.8Nb1 alloy can produce tiny nanocrystals and thus result in excellent soft magnetic properties. When the average nanocrystal size is 16 nm using rapid annealing, the best soft magnetic performance can be obtained, in which Bs reaches 1.80 T, Hc is 5 A/m, and μ is 20,000 at 1 kHz. The crystallization kinetics shows that as the Fe content increases, the incubation time of nucleation of the alloys decreases, and the nucleation is faster and easier. In addition, a large number of pre-existing crystal nuclei not only greatly reduces the nucleation activation energy of the alloy but also achieves grain refinement and excellent magnetic properties through grain competition growth.

Similar content being viewed by others

References

Gutfleisch O, Willard MA, Brück E, Christina H, Chen SG, Sankar LPJ (2011) Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv Mater 23:821–842. https://doi.org/10.1016/S0921-5093(96)10693-6

Herzer G (2013) Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater 61:718–734. https://doi.org/10.1016/j.actamat.2012.10.040

Zhao CL, Wang AD, He AN, Yue SQ, Chang CT, Wang XM, Li RW (2016) Correlation between soft-magnetic properties and Tx1-Tc in high Bs FeCoSiBPC amorphous alloys. J Alloy Compd 659:193–197. https://doi.org/10.1016/j.jallcom.2015.11.044

Azuma D, Hasegawa R (2008) Audible noise from amorphous metal and silicon steel-based transformer core. IEEE Trans Magn 44:4104–4106. https://doi.org/10.1109/TMAG.2008.2003174

Wang AD, Zhao CL, Men H, He AN, Chang CT, Wang XM, Li RW (2015) Fe-based amorphous alloys for wide ribbon production with high Bs and outstanding amorphous forming ability. J Alloy Compd 630:209–213. https://doi.org/10.1016/j.jallcom.2015.01.056

Yoshizawa Y, Oguma S, Yamauchi K (1988) New Fe-based soft magnetic alloys composed of ultrafine grain structure. J Appl Phys 64:6044–6046. https://doi.org/10.1063/1.342149

Makino A, Men H, Kubota T, Yubuta K, Inoue A (2009) New excellent soft magnetic FeSiBPCu nanocrystallized alloys with high Bs of 1.9 T from nanohetero-amorphous phase. IEEE Trans Magn 45:4302–4305. https://doi.org/10.1109/TMAG.2009.2023862

Makino A, Men A, Kubota T, Yubuta K, Inoue A (2009) New Fe-metalloids based nanocrystalline alloys with high Bs of 1.9 T and excellent magnetic softness. J Appl Phys 105:218–221. https://doi.org/10.1063/1.3058624

Liu T, Wang AD, Zhao CL, Yue SQ, Wang XM, Liu CT (2019) Compositional design and crystallization mechanism of High Bs nanocrystalline alloys. Mater Res Bull 112:323–330. https://doi.org/10.1016/j.materresbull.2019.01.007

Ren XC, Li YH, Jia XJ, Qiu ZY, Xie GY, Zhang W (2018) Microstructure and magnetic properties of Fe81.3Si4B13Cu1.7 nanocrystalline alloys with minor Nb addition. J Iron Steel Res Int 25:614–618. https://doi.org/10.1007/s42243-018-0087-2

Motoki O, Yoshihito Y (2009) Effect of heating rate on soft magnetic properties in nanocrystalline Fe80.5Cu1.5Si4B14 and Fe82Cu1Nb1Si4B12 alloys. Appl Phys Express 023005. https://doi.org/10.1143/APEX.2.023005

Li YH, Jia XJ, Zhang W, Zhang Y, Xie GY, Qiu ZY, Luan JH, Jiao ZB (2021) Formation and crystallization behavior of Fe-based amorphous precursors with pre-existing α-Fe nanoparticles—Structure and magnetic properties of high-Cu-content Fe-Si-B-Cu-Nb nanocrystalline alloys. J Mater Sci Technol 65:171–181. https://doi.org/10.1016/j.jmst.2020.05.049

Motoki O, Yoshihito Y (2008) Cu addition effect on soft magnetic properties in FeSiB alloy system. J Appl Phys 103:07E722. https://doi.org/10.1063/1.2829240

Zang B, Parsons R, Onodera K, Kishimoto H, Kato A, Liu ACY, Suzuki K (2017) Effect of heating rate during primary crystallization on soft magnetic properties of melt-spun FeB alloys. Scripta Mater 132:68–72. https://doi.org/10.1016/j.scriptamat.2017.01.030

Suzuki K, Parsons R, Zang BW, Onodera K, Kishimoto H, Kato A (2017) Copper-free nanocrystalline soft magnetic materials with high saturation magnetization comparable to that of Si steel. Appl Phys Lett 110:012407–012414. https://doi.org/10.1063/1.4973772

Han YB, Wang AD, He AN, Chang CT, Li FS, Wang XM (2015) Improvement of magnetic properties, microstructure and magnetic structure of Fe73.5Cu1Nb3Si15.5B7 nanocrystalline alloys by two-step annealing process. J Mater Sci Mater Electron 27:3736–3741. https://doi.org/10.1007/s10854-015-4216-4

Gupta P, Gupta A, Shukla A, Ganguli T, Sinha AK (2011) Structural evolution and the kinetics of Cu clustering in the amorphous phase of Fe-Cu-Nb-Si-B alloy. J Appl Phys 110:033537. https://doi.org/10.1063/1.3622325

Sharma P, Zhang X, Zhang Y, Makinoa A (2015) Competition driven nanocrystallization in high Bs and low coreloss FeSiBPCu soft magnetic alloys. Scripta Mater 95:3–6. https://doi.org/10.1016/j.scriptamat.2014.08.023

Bitoha T, Makinoa A, Inoueb A, Masumoto T (2003) Random Anisotropy Model for nanocrystalline soft magnetic alloys with grain-size distribution. Mater Trans 44:2011–2019. https://doi.org/10.2320/matertrans.44.2011

Bitoha T, Makinoa A, Inoueb A (2004) The effect of grain-size distribution on coercivity in nanocrystalline soft magnetic alloys. J Magn Magn Mater 272:1445–1446. https://doi.org/10.1016/j.jmmm.2003.12.368

Yashpal SV, Kumar BVM (2015) Issues in determining size of nano-crystalline ceramic particles by X-ray diffusion. Mater Today 2:3534–3538. https://doi.org/10.1016/j.matpr.2015.07.330

Parsonsa R, Zang B, Onoderab K, Kishimotob H, Shojib T (2019) Core loss of ultra-rapidly annealed Fe-rich nanocrystalline soft magnetic alloys. J Magn Magn Mater 476:142–148. https://doi.org/10.1016/j.jmmm.2018.12.053

Suzuki K, Ito N, Garitaonandia JS, Cashion JD, Herzer G (2008) Local random magnetocrystalline and macroscopic induced anisotropies in magnetic nanostructures. J Non-Cryst Solids 354:5089–5092. https://doi.org/10.1016/j.jnoncrysol.2008.06.118

Lin WD, Yang YZ, Xu J, Li W (2018) Effect of Nb, Si and Cu on the crystallization process and magnetic properties of FeNbBP alloys. J Alloy Compd 735:1195–1199. https://doi.org/10.1016/j.jallcom.2017.11.256

Ramasamy P, Stoica M, Taghvaei A, Prashanth KG, Kumar R, Eckert J (2016) Kinetic analysis of the non-isothermal crystallization process, magnetic and mechanical properties of FeCoBSiNb and FeCoBSiNbCu bulk metallic glasses. J Appl Phys 119:073908. https://doi.org/10.1063/1.4942179

Jerzy A, Marcin K, Elżbieta J, Jerzy L (2009) Small-angle X-ray scattering from phase-separating amorphous metallic Alloys undergoing nanocrystallization. J Alloy Compd 483:116–119. https://doi.org/10.1016/j.jallcom.2008.08.117

Arun P, Lad KN, Rao TSL, Pinal M (2004) Kinetics of crystallization of amorphous Cu50Ti50 alloy. J Non-Cryst Solids 345:178–181. https://doi.org/10.1016/j.jnoncrysol.2004.08.018

Ashish S, Shravana K, JaN I, Dahotre NB (2013) Nanocrystallization in spark plasma sintered Fe48Cr15Mo14Y2C15B6 bulk amorphous alloy. J Appl Phys 114:054903. https://doi.org/10.1063/1.4817379

Pere B, Rojas PE, Jose I, Daniel C (2009) Phase-field modelling of microstructural evolution in primary crystallization. J Alloy Compd 483:645–649. https://doi.org/10.1016/j.jallcom.2008.07.215

Peng C, Chen ZH, Zhao XY, Zhang AL, Zhang LK, Chen D (2014) Crystallization kinetics of Zr60Cu25Fe5Al10 bulk metallic glass. J Non-Cryst Solids 405:7–11. https://doi.org/10.1016/j.jnoncrysol.2014.08.030

Ouyang YF, Wang LY, Chen HM, Cheng XY (2008) The formation and crystallization of amorphous Al65Fe20Zr15. J Non-Cryst Solids 354:5555–5558. https://doi.org/10.1016/j.jnoncrysol.2007.02.099

Wang Y, Xu K, Li Q (2012) Comparative study of non-isothermal crystallization kinetics between Fe80P13C7 bulk metallic glass and melt-spun glassy ribbon. J Alloy Compd 540:6–15. https://doi.org/10.1016/j.jallcom.2012.06.016

Acknowledgments

This work was supported by the National Key Research and Development Program of China (grant number 2016YFB0300500), the S&T Innovation 2025 Major Special Program (grant number 2018B10084), the National Natural Science Foundation of China (grant number 51801224, 51771161), and the Leading Talents of Tianshan Cedar Program of Xinjiang Uygur Autonomous Region (grant number 2019XS02) and the Tianshan Innovation Team Program of Xinjiang Uygur Autonomous Region (grand number 2020D14038).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bai, F., Dong, Y., Xie, L. et al. Effect of pre-existing nuclei on microstructure and magnetic properties of high Bs FINEMET-like nanocrystalline alloys. J Mater Sci 56, 9254–9262 (2021). https://doi.org/10.1007/s10853-021-05861-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05861-x